Virtual Cutting Tool Management System For Milling Process

Diunggah oleh

shadowizardDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Virtual Cutting Tool Management System For Milling Process

Diunggah oleh

shadowizardHak Cipta:

Format Tersedia

148

IJCSNS International Journal of Computer Science and Network Security, VOL.10 No.2, February 2010

Virtual Cutting Tool Management System for Milling Process

Haslina Arshad , Rosilah Hassan, Nazlia Omar and Shahnorbanun Sahran, Department of Industrial Computing, Department of Computer Science, Faculty of Information Science and Technology Universiti Kebangsaan Malaysia, Malaysia

catalogues. On the other hand, the manual catalogue provided by the manufacturer is limited to single user only and when more than one user needs to use the catalogue at the same time the problem will surface. This will be a waste of time that could delay the whole cutting process and eventually the lead time of the whole process. Fast and accurate access to information about available manufacturing resources and data is critical to reducing production cost and maximizing machine productivity [1]. Problems also arise when new cutting tools for milling process are introduced to the market. This might take a long time for the manufacturer to amend the information in the old catalogue and produce the new one. Hence, the up-to-date information did not reach the customer or manufacturer at the right time. In this paper, a virtual cutting tool management system is introduced to reduce or eventually solve many of the problems mentioned before. It has the capability of choosing the right cutting tool from a virtual cutting tool catalogue. The cutting tool can be visualized in 3D using Virtual Reality technique. By doing this, we can actually help the user to search for the right cutting tools and also provide them the clear image of the chosen cutter. We also presented the visualization of milling process and how the right cutter is fed into the milling machine for cutting purpose.

Summary

Information of cutting tools is very important for the effectiveness of cutting process. Previously, traditional search methods by referring to the catalogues for the right cutting tool has been a burden to the user. As a result, the probabilities of choosing the wrong cutting tools were high. In this work, a new cutting tools management system for milling process has been developed for training students before they actually perform the milling process. With the specific parameters such as cutter type, part number, dimension and material types and its properties, the user can easily get detail information of the cutting tools such as cutter dimension, insert types and its properties. User can also visualize the chosen cutter and inserts interactively. This web application will help the user to find the best cutting tools. It can also help to educate students or any users in understanding the process of choosing the best cutting tools and the parameters needed for the cutting process.

Key words:

virtual cutting tools, database system, milling process

1. Introduction

Selection process of cutting tools is important and critical in any machining processes. The selection process will require the knowledge of cutting parameters, types of workpiece materials and capability of the machine tools. The wrong choice of cutting tools might lead to a big loss to a company in terms of the time and cost spent in searching for the right tools. This research was done in order to help users of milling machine who have faced problems finding appropriate cutting tools based on the manual catalogue provided by the cutting tools manufacturer. Some of the problems are to find the types of cutting tool material and to specify the right cutting tools for specific workpiece material as they have to go through page by page of the catalogue to find the result. Apart from that, this manual process also might take up a lot of time. The manual process might lead to the wrong choice of the cutting tools due to human error especially when cross-references had to be done between several

2. Related work

Cutting tool management is very important and a lot of research and information system had been developed. Ebrahim and Chao-Liang [2] have highlighted the needs for cutting tool database management in FMS and the requirements for successful cutting tool database. They presented a systematic way to design and develop a relational cutting tool database. The developed cutting tool database is implemented using ORACLE database management system. There are several significant issues which are suitable to successful FMS development. These

Manuscript received February 5, 2010 Manuscript revised February 20, 2010

IJCSNS International Journal of Computer Science and Network Security, VOL.10 No.2, February 2010

149

include the availability of suitable system architecture, reusable software and the use of appropriate system design tools. With the advent of computerized manufacturing systems, Flexible Manufacturing System (FMS), it has become evident that tooling is a major constraint that prevents manufacturing systems from realizing their full flexibility. To increase the efficiency of cutting tool used in an FMS, it is necessary for the cutting tool database to support the information used in the whole tool life cycle and in cutting tool use [3]. Svinjarevic [4] highlighted the benefits of implementing a management system of cutting tools in a company which specializes in metal cutting process. It presents possibilities for improvement of the cutting tool management. Visualization of the whole milling process starting from the selection of the workpiece material and cutting tools up to the milling process can provide users with a clear picture of the whole process. Shop floor operation and process can be visualized through an Interactive VR Training for CNC Machining [5]. A 3D Visualization Technologies for Teleguided Robots showed that the use of 3D stereoscopic visualization could provide users with higher comprehension of remote environments in teleportation when compared to 2D viewing [6]. These had shown the importance of visualization to facilitate understanding and simplify the work flow and learning process. A number of visualization applications exist on the Web in various areas. One of them is a method for simulating basic manufacturing operations such as unload, load, process, move and store in a 3D virtual environment. The virtual environment provides a framework for representing a facility layout in 3D that consists of the static and dynamic behavior of the manufacturing system [7]. Another VR application is a virtual machining laboratory for knowledge learning and skill training in an interactive environment. This virtual lab is specifically designed for helping students to virtually operate a lathe or set machining parameters and input CNC G-code programme to turn the workpiece automatically [8]. An integrated model of the spindle bearing and machine tool system, consisting of a rotating shaft, tool holder, angular contact ball bearings, housing, and the machine tool mounting is developed to allow virtual cutting of a work material with the numerical model of the spindle during the design stage [9].

references were done in the preliminary studies to identify the requirements and needs of the system: 1. Information such as feed rate, cutting speed and cutting tools dimension were obtained from SECO manual cutting tools catalogue [7]. Data on how the users find the best cutting tool based on the standard cutting tools process has been obtained and analyzed. Cutting tools management system from previous works was referred. Based on the research, a clientserver environment was set up and the system let the users to search for the right cutting parameter based on the work piece material, machining process and cutting tools. It also allows the administrator to update the cutting tools data online and also help to distribute the latest data effectively. However, the simulation on how the milling machine works and also the 3D image of cutting tools is not included in the system. XL-MILL machine model from MTAB Engineers (P) LTD company was examined from their website to get its real structure. Each angle of the machine model has been analyzed in order to come out with the best 3D visualization of the milling machine. The information on cutting tools, types of materials and the speed of machine tools were obtained throughout this website. Environment Setup: The system is a web-based clientserver application. Installation of XAMPP-Win321.5.5 (a package for web-based application which includes apache (client-server), mysql_start and PhpMyAdmin 2.9.1.1 for database purpose) is needed and analyzed. For the system interface, Macromedia Dreamweaver 8 software is analyzed. For 3D visualization purpose, AutoCAD 2008 software has been chosen as a good platform to draw a 2D and 3D image with .dwg format of cutting tools and XLMILL machine. Then, 3D Studio Max 8 is the software that will be used to transform the format from .dwg to .wrl and to specify the movement of cutting tools and the milling machine. Lastly, Cortona Client will be used to run the component which has been transformed to .wrl format. From this stage, the visualization can be tested whether it meet the user requirement or still need some adjustment.

2.

3.

4.

2. System Design

To develop the cutting tools management system with the milling machine and cutter visualization, several

This system is designed for two main users, the end user and the administrator. Basically, the end user can retrieve the cutting tools information (dimension, cutter, cutting parameters) based on query criteria like material and part numbers while the administrator also has access to update the cutting tools information in this system. With this structure, the administrator can keep the cutting tools information record up-to-date from time to time. The user can also retrieve all the cutting tools information at a time

150

IJCSNS International Journal of Computer Science and Network Security, VOL.10 No.2, February 2010

by providing the right key for part and material number. A data flow and DFD contact diagram show the relationship between the user and administrator as shown in Figure 1.

Fig. 2 Image of 3D object exported from AutoCAD2008 to 3D Studio Max8 Fig. 1 Data Flow Diagram between user and administrator.

3. Cutting tool management system

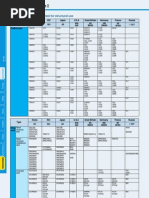

Data dictionary which represent the details about the data storage and also the information about the entity that involves in the system is as in Table 1. In this research the cutter and the milling machines were designed in 3D component by using AutoCAD 2008 software. For visualization, 3D studio Max software has been used to visualize the 3D component created in AutoCAD. Figure 2 shows the 3D object which has been exported from AutoCAD2008 to 3D Studio Max8 presented in 3 views: front, side and perspective view. In order to specify the movement coordinate, rotate command was executed using this application. Then, the time line need to be adjusted for each movement according to the visualization timing requirement. After that, the rendering process begins to provide the real effect to the 3D component. After the rendering process completed, the 3D component is exported to .wrl format. Within this format, it allows the 3D component to run in Cortona browser and viewed at various angles. Now, the 3D milling machine together with the cutter is ready to be integrated into the system. This will show the effectiveness of cutting tools system to help the user to understand the milling process and to find the right cutting tools and cutter for selected materials.

Table 1: Data Structure for Dimension

The cutting tool management system is embedded into a of a virtual workshop prototype. The interface of the virtual workshop is a page that briefly explains the virtual workshop as shown in Figure 3.

Fig. 3 The interface of the simulation application when the Introduction button is clicked

This interface has some functions such as Introduction, Machining Equipment, Virtual Workshop and Simulation which give some description about the CNC milling machine and the milling process. By clicking to the Introduction button, it would link the user to the page which has some explanation about the milling process, types of milling and classification of milling process. The machining equipment menu will describe and displays the cutter and example of CNC milling machine involved in the milling process as shown in Figure 4.

IJCSNS International Journal of Computer Science and Network Security, VOL.10 No.2, February 2010

151

the information of the cutter that is suitable for the cutting process. The part number and material information can be chosen from the drop down menu. The system will display a list of suitable cutting tools. The user will select the required cutting tool and the system will display the information of the selected cutting tools (Figure 6).

Fig. 4 Types of cutters for milling process

In order to do the selection processes for the cutter and cutting tools, the user need choose the machining equipment. Several user interfaces were designed to meet the user requirement such as the first page that requires the user to insert their id and password. This is for security reason. Then the user can start to navigate the system. They can choose to display the information of the cutting tools information by selecting the cutter provided in the system. For this system, two types of cutter available are Quatromill 220.53-12 and Octomill 220.43-07W. The cutters will be displayed in 3D to help the users to visualize the cutter before they make the selection. After selecting the type of cutter, if the information of the part number is known the user can choose to display the information of the cutter such as the diameter, height and cutting depth as shown in Figure 5.

Fig 6 The cutting tools information based-on the selected workpiece material.

Besides getting the cutter information, user also can view the cutter in 3D views as in Figure 7. This also allows the user to interact with the display and see the design of the cutting tool at different angles.

Fig. 7 The cutter in 3D view

Fig. 5 Information of the cutter

The proper cutter diameter should be chosen so that it will not interfere with fixtures, work holding devices and other devices in the setup. If the part number of the cutter and the type of material to be cut are known, the user can get

By clicking the Simulation button (Figure 4), it would link the user to the other page, which has two windows comprising of control panel (user input) and VRML browser for displaying the machining process in a 3D environment. Before the 3D machining process can be displayed, the user has to input the size of the workpiece and choose the type of engagement for the milling process, cutting speed and also the feed rate of worktable. To run the simulation, the user has to input the size of the workpiece and choose the type of engagement for the milling process, cutting speed and also the feed rate of

152

IJCSNS International Journal of Computer Science and Network Security, VOL.10 No.2, February 2010

worktable. When the Start button is clicked, the material removal simulation and the real time graph is generated simultaneously with the virtual machining process as shown in Figure 8.

Fig 10 Virtual End Milling Process with 15% Engagement

4. CONCLUSION

Fig 8 The control panel for user input and simulation of the milling process together with the flank wear graphs

The virtual end milling processes for 100% is shown in Figure 9. It clearly demonstrates that the whole diameter of the cutting tool is used during the machining process. For further verification, the 15% engagement of the cutting tool was used. Figure 10 virtually demonstrates that only 15% of the cutting tool diameter was used during the machining process.

The virtual cutting tool management system and visualization of milling process has been successfully developed. This system provides the virtual selection process for cutting tool and a virtual milling process. After the cutting parameters were selected then visualization of the cutting process in milling machine was displayed. From these two main features, the user not only can have access to the database and search for the cutting tools efficiently; they also can view the 3D visualization of cutter and milling machine. Through this, more than one user can access the database and they can also view the 3D cutter from any angle and learn the milling process better through the visualization of the part and milling process. It is hoped that this system can give benefit to the institution of higher learning and industry to reduce the time consumed in choosing cutting tools and can help in their daily work to become more efficient.

References

[1] [2] R. Wigal, Tool Data Management, Tooling & Production, Vol 64, pp. 1-7, 1998. S. Ebrahim, L. Chao-Liang, Tool Management and Flexible Manufacturing System, Integrated Manufacturing System, Vol 6, pp.26-35, 1995. G. Subrahmanyam, A. Gunasekaran, S. Arunachalam, P. Radhakrishnan, Development of a Tool Database Management System, Advanced Manufacturing Technology, Vol. 15, pp. 562-565, 1999. G. Svinjarevic, A. Stoic, J. Kopac, Implementing of Cutting Tools Management System, Achievement in Materials and Manufacturing Engineering, Vol. 23, pp. 99-101, 2007. X. Wang, P. Zheng, Z. Wei, Y. Sun, B. Luo, L. Yangchun, . Development an Interactive VR Training for CNC Machining, Proceedings, 2004 ACM SIGGRAPH International Conference on Virtual Reality Continuum and its Applications in Industry L. Salvatore, P. Filippo, 3D Visualization Technologies for Teleguided Robots, Proceedings, The ACM Symposium on Virtual Reality Software and Technology.

[3] Fig 9 Virtual End Milling Process with 100% Engagement [4]

[5]

[6]

IJCSNS International Journal of Computer Science and Network Security, VOL.10 No.2, February 2010

153

[7] [8]

[9]

[10]

SECO Tools, SECO Turning, Threading &Grooving product (SECO Tools Press, 1994) R. Chawla, A. Banerjee. 2001. A Virtual Environment For Simulating Manufacturing Operations in 3D. Proceeding of the 2001 Winter Simulation Conference: 991-997. X. D. Fang, S. Luo, N. J. Lee, Jin, F. 1998. Virtual Machining Lab for Knowledge Learning and Skill Training. Computer Applications in Engineering Education, 6(2): 89-97. C. Yuzhong, Altintas, Y. 2007. Modeling of spindle-bearing and machine tool systems for virtual simulation of milling operations, International Journal of Machine Tools and Manufacture, 47(9): 1342-1350.

Haslina Arshad received her BSc in Computer Science from University of Bridgeport, Connecticut, USA in 1986 and MSc in IT for Manufacture from Coventry University, Coventry, UK in 1997. She received her PhD from University Putra Malaysia, Malaysia in Manufacturing System Engineering in 2007.She had been working as an analyst programmer and system analyst before she joined Universiti Kebangsaan Malaysia as a lecturer. She is currently a Senior Lecturer at the Department of Industrial Computing, Faculty of Information Science and Technology, Universiti Kebangsaan Malaysia. Her research interest includes virtual reality, virtual manufacturing and robotics.

Rosilah Hassan received her first degree from Hanyang University, Seoul, Republic of Korea in Electronic Engineering (1996). She worked as an Engineer with Samsung Electronics Malaysia for one year before joining Universiti Kebangsaan Malaysia (UKM) in 1997. She obtained her Master of Electrical Engineering (M.E.E) in Computer and Communication from UKM in 1999. She received her PhD in Mobile Communication from Univesity of Strahclyde in 2007. Her research interest is in mobile communication, networking, 3G, and QoS. Now, she is a senior lecturer at the Department of Computer.Science, Faculty of Information Science and Technology, University Kebangsaan Malaysia.

Nazlia Omar is currently a senior lecturer at the Dep. of Computer Science, Faculty of Information Science and Technology, University Kebangsaan Malaysia. She holds her PhD in Computer Science from the University of Ulster, UK. Her main research interest is in the area of natural language processing and semantic technology.

Shahnorbanun Sahran graduated with BSc in Statistic in 1995 and MSc in Quality and Productivity in 1996 from Universiti Kebangsaan Malaysia, Malaysia. She obtained her Ph.D. in Intelligent Control System from University of Cardiff, Wales, UK in 2007. Shahnorbanun Sahrans major field of study are artificial intelligent, statistic, system modeling and optimisation and quality. She is presently a Senior Lecturer in Industrial Computing Department, Faculty of Information Science and Technology of Universiti Kebangsaan Malaysia.

Anda mungkin juga menyukai

- CNC Programming Systems PDFDokumen22 halamanCNC Programming Systems PDFSurendra SainiBelum ada peringkat

- MODULARDokumen11 halamanMODULARNGỌC MAI BẢOBelum ada peringkat

- Computer Aided ManufacturingDokumen28 halamanComputer Aided ManufacturingSheik AbdullahBelum ada peringkat

- New Tools For The Selection of Technologies Application To Sheet Metal FormingDokumen5 halamanNew Tools For The Selection of Technologies Application To Sheet Metal FormingCarlos ArenasBelum ada peringkat

- Research Paper On CNC Machine PDFDokumen7 halamanResearch Paper On CNC Machine PDFqdvtairif100% (1)

- Intelligent Machinery Product Service BLDokumen16 halamanIntelligent Machinery Product Service BLRachana ParheBelum ada peringkat

- 12 - Application of Fuzzy TOPSIS and Harmonic Mitigation Measurement On Lean Six Sigma A Case Study in Smart FactoryDokumen23 halaman12 - Application of Fuzzy TOPSIS and Harmonic Mitigation Measurement On Lean Six Sigma A Case Study in Smart Factoryleylagale27Belum ada peringkat

- Press Tool ReportDokumen40 halamanPress Tool ReportIshu Bassan100% (2)

- System For Managing Vehicle ServicesDokumen9 halamanSystem For Managing Vehicle ServicesIJRASETPublicationsBelum ada peringkat

- JamesNgondo AssignmentCosting PDFDokumen11 halamanJamesNgondo AssignmentCosting PDFJayO'ConnellBelum ada peringkat

- An Effective Garage Management System Web Applicationfor Customer ServiceDokumen6 halamanAn Effective Garage Management System Web Applicationfor Customer Service3XTR3M3 ᜰ꙰ꦿ NJRBelum ada peringkat

- Minor PublicationsDokumen20 halamanMinor Publications20-311 AkhilBelum ada peringkat

- IJRPR12244Dokumen7 halamanIJRPR12244Sai AnirudhBelum ada peringkat

- Computer Aided Process Planning For Milling Operation: September 2016Dokumen9 halamanComputer Aided Process Planning For Milling Operation: September 2016guptaamitalwBelum ada peringkat

- IJRET20160516038Dokumen4 halamanIJRET20160516038Youssef AliBelum ada peringkat

- Web Based Machine Learning Automated PipelineDokumen6 halamanWeb Based Machine Learning Automated PipelineIJRASETPublications100% (1)

- Ilovepdf Merged 2Dokumen48 halamanIlovepdf Merged 221146387Belum ada peringkat

- Cop Milling 4Dokumen9 halamanCop Milling 4Naseeb Ullah TareenBelum ada peringkat

- Implementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessDokumen8 halamanImplementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessRay SaBelum ada peringkat

- CNC - A Manufacturing ProcessDokumen43 halamanCNC - A Manufacturing Processnaveenkumar_madasett100% (2)

- A Web Based Manufacturing Service System For Rapid Product DevelopmentDokumen31 halamanA Web Based Manufacturing Service System For Rapid Product DevelopmentjosathiBelum ada peringkat

- PLM PDM CPCDokumen8 halamanPLM PDM CPCVijay RichardBelum ada peringkat

- Cam Integrative ProjectDokumen18 halamanCam Integrative ProjectGael SotoBelum ada peringkat

- Data-Driven Manufacturing A Paradigm Shift in The Manufacturing IndustryDokumen5 halamanData-Driven Manufacturing A Paradigm Shift in The Manufacturing IndustryIJRASETPublicationsBelum ada peringkat

- IJCRT2305600Dokumen9 halamanIJCRT2305600JonathanBelum ada peringkat

- IOT - Based Data Capturing System in Machining: Department of Mechanical EngineeringDokumen1 halamanIOT - Based Data Capturing System in Machining: Department of Mechanical EngineeringShankar KBelum ada peringkat

- Applsci 09 00479Dokumen25 halamanApplsci 09 00479Ashu DeshawerBelum ada peringkat

- Predictive Maintenance of Machine Tool Systems Using ArtificiDokumen6 halamanPredictive Maintenance of Machine Tool Systems Using ArtificiNishant SaxenaBelum ada peringkat

- Reverse Engineering Based Methodology For Modelling Cutting ToolsDokumen9 halamanReverse Engineering Based Methodology For Modelling Cutting ToolsbobbyBelum ada peringkat

- Expert System For Rolling Load Prediction in 20 Hi Sendzimir MillDokumen5 halamanExpert System For Rolling Load Prediction in 20 Hi Sendzimir MillIAEME PublicationBelum ada peringkat

- DETC2004-57745: Manufacturing Information Integration in Product Lifecycle Management (PLM)Dokumen7 halamanDETC2004-57745: Manufacturing Information Integration in Product Lifecycle Management (PLM)AVI_ROHINIBelum ada peringkat

- Rancang Bangun Mesin CNC Router Mini Untuk PembelaDokumen7 halamanRancang Bangun Mesin CNC Router Mini Untuk PembelaMuhammad SamuelBelum ada peringkat

- Rancang Bangun Mesin CNC Router Mini Untuk PembelaDokumen7 halamanRancang Bangun Mesin CNC Router Mini Untuk PembelaMuhammad SamuelBelum ada peringkat

- Research Paper On Milling MachineDokumen6 halamanResearch Paper On Milling Machineafnhemzabfueaa100% (1)

- Car Pooling Sytem Final ReportDokumen27 halamanCar Pooling Sytem Final Reportabhishek92nair0% (1)

- Srs RailwaysDokumen23 halamanSrs Railwaysherikow431Belum ada peringkat

- Automatic Automatic Generating CNC-Code For Milling MachineGenerating CNC Code For Milling MachineDokumen7 halamanAutomatic Automatic Generating CNC-Code For Milling MachineGenerating CNC Code For Milling MachineVikas Singh SisodiaBelum ada peringkat

- Chapter 3: Second Deliverable For Object Oriented Approach: Systems SpecificationsDokumen2 halamanChapter 3: Second Deliverable For Object Oriented Approach: Systems SpecificationsSweetsoulUroojMalik100% (1)

- Project Synopsis 2012Dokumen26 halamanProject Synopsis 2012Naveen HoodaBelum ada peringkat

- Ascms BB Final22Dokumen107 halamanAscms BB Final22Tanmaya SahooBelum ada peringkat

- Design & Manufacturing of Components of Modified Bench Vise On Rapid Prototype MachineDokumen13 halamanDesign & Manufacturing of Components of Modified Bench Vise On Rapid Prototype MachineInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Existing System and Need For SystemDokumen41 halamanExisting System and Need For SystemSarlaJaiswalBelum ada peringkat

- Research ProposalDokumen2 halamanResearch Proposalshaim mahamudBelum ada peringkat

- Atde 16 Atde210116Dokumen10 halamanAtde 16 Atde210116Josip StjepandicBelum ada peringkat

- Rancang Bangun Mesin CNC Router Mini Untuk PembelaDokumen7 halamanRancang Bangun Mesin CNC Router Mini Untuk PembelaAkhmad Khoirur RizalBelum ada peringkat

- The Systems Life CycleDokumen28 halamanThe Systems Life CycleNeetikaBelum ada peringkat

- Vehicle Management SystemDokumen27 halamanVehicle Management SystemKaataRanjithkumarBelum ada peringkat

- AI Applications To Metal Stamping Die Design - A Review: Vishal Naranje, Shailendra KumarDokumen7 halamanAI Applications To Metal Stamping Die Design - A Review: Vishal Naranje, Shailendra KumarCandra WahyudiantoBelum ada peringkat

- OptimationDokumen11 halamanOptimationrizkiBelum ada peringkat

- Literature Review On CNC MachineDokumen7 halamanLiterature Review On CNC Machineaflsnbfir100% (1)

- Sustainability 06 08510Dokumen12 halamanSustainability 06 08510starkus92Belum ada peringkat

- Journal of Advanced Mechanical Design, Systems, and ManufacturingDokumen16 halamanJournal of Advanced Mechanical Design, Systems, and ManufacturingAmrik SinghBelum ada peringkat

- Smart Manufacturing - PresentationDokumen33 halamanSmart Manufacturing - Presentation19TUME012 ANTON JOEL.JBelum ada peringkat

- DocumentationDokumen96 halamanDocumentationonly leds (Only LED's)Belum ada peringkat

- Event HubDokumen6 halamanEvent HubIJRASETPublicationsBelum ada peringkat

- Yuanzhi Huang@ucd IeDokumen22 halamanYuanzhi Huang@ucd Iehideki hidekiBelum ada peringkat

- The Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingDokumen24 halamanThe Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingIJRASETPublicationsBelum ada peringkat

- 1 s2.0 S2214785322059521 MainDokumen9 halaman1 s2.0 S2214785322059521 MainfelipeBelum ada peringkat

- Utilizing Deep Learning, Feature Ranking, and Selection Strategies To Classify Diverse Information Technology Ticketing Data EffectivelyDokumen10 halamanUtilizing Deep Learning, Feature Ranking, and Selection Strategies To Classify Diverse Information Technology Ticketing Data EffectivelyIAES IJAIBelum ada peringkat

- Assignment 1 Ridwanul Hamidy (34416)Dokumen2 halamanAssignment 1 Ridwanul Hamidy (34416)shadowizardBelum ada peringkat

- Assignment 1 Ridwanul Hamidy (34416)Dokumen2 halamanAssignment 1 Ridwanul Hamidy (34416)shadowizardBelum ada peringkat

- Twelve Principles of The Network EconomyDokumen1 halamanTwelve Principles of The Network EconomyshadowizardBelum ada peringkat

- Wolfram Alpha Ploty29285x10818xfromx0to9Dokumen1 halamanWolfram Alpha Ploty29285x10818xfromx0to9shadowizardBelum ada peringkat

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- 3.manufacturing Technology IIDokumen6 halaman3.manufacturing Technology IIprasanthprpBelum ada peringkat

- Securing Construction With Nuts BoltsDokumen3 halamanSecuring Construction With Nuts BoltsAnurag GuptaBelum ada peringkat

- Speeds and FeedsDokumen11 halamanSpeeds and Feedszidaaan0% (1)

- Paper Bags Making MachineDokumen59 halamanPaper Bags Making MachinePotluri Vraja Kishore100% (1)

- 500 MW Turbogenerator Stator Winding Assembly: Bharat Heavy Electricals Limited, HardwarDokumen47 halaman500 MW Turbogenerator Stator Winding Assembly: Bharat Heavy Electricals Limited, HardwarAkshita Gupta100% (1)

- Technical BookDokumen37 halamanTechnical BookDariusNeculcia100% (2)

- Sewing Machinr ProjectDokumen65 halamanSewing Machinr ProjectShobhit GoswamiBelum ada peringkat

- Curriculum Vitae (Roy)Dokumen3 halamanCurriculum Vitae (Roy)RoyBelum ada peringkat

- Rulmeca IntrodDokumen34 halamanRulmeca IntrodiranbodBelum ada peringkat

- Citizen M16Dokumen64 halamanCitizen M16Favoreel Patrick100% (1)

- Bauma 2006Dokumen20 halamanBauma 2006James CapplemanBelum ada peringkat

- PKG 5 Customer List in IndiaDokumen5 halamanPKG 5 Customer List in IndiaGiri DharBelum ada peringkat

- Fundamentals of MachiningDokumen39 halamanFundamentals of Machiningpassion481100% (1)

- Tower Manufacturing ProcessDokumen47 halamanTower Manufacturing Processmechajay2002Belum ada peringkat

- Astm B 775Dokumen10 halamanAstm B 775Maram NasraweenBelum ada peringkat

- Die Casting - Wikipedia, The Free EncyclopediaDokumen10 halamanDie Casting - Wikipedia, The Free EncyclopediaSantanu MondalBelum ada peringkat

- Manufacturing ProcessesDokumen4 halamanManufacturing ProcessesVishal BangarBelum ada peringkat

- The IBM BookDokumen55 halamanThe IBM BookPranat Pal Dubey100% (5)

- NEM Manufacturing LeafletDokumen12 halamanNEM Manufacturing LeafletNiels GoedvolkBelum ada peringkat

- Bhoruka Aluminum LTD PDFDokumen12 halamanBhoruka Aluminum LTD PDFGediya RockyBelum ada peringkat

- Proman - IntroductionDokumen9 halamanProman - IntroductionHarshala ChoudharyBelum ada peringkat

- Other Products PDFDokumen41 halamanOther Products PDFnirajBelum ada peringkat

- Zero-Max CD CouplingsDokumen20 halamanZero-Max CD Couplingsataraxia57Belum ada peringkat

- Pgo Trex125&150 Part CatalogeDokumen72 halamanPgo Trex125&150 Part CatalogedanielmakBelum ada peringkat

- Ball Mill TrunnionDokumen2 halamanBall Mill TrunnionBruno67% (3)

- ME 2207 - Manufacturing Technology 1 - Lab ManualDokumen57 halamanME 2207 - Manufacturing Technology 1 - Lab ManualMohan Prasad.M71% (17)

- Iko Combined Needle Roller Bearings PDFDokumen5 halamanIko Combined Needle Roller Bearings PDFSamik MukherjeeBelum ada peringkat

- DOSH Malaysia Notice For Commencement of WorksDokumen2 halamanDOSH Malaysia Notice For Commencement of WorksAyman QasyifulwarithBelum ada peringkat

- Encpo315 350Dokumen34 halamanEncpo315 350ZedtronBelum ada peringkat

- Pipeline Equipment - Ball Valves EtcDokumen43 halamanPipeline Equipment - Ball Valves Etckrish69Belum ada peringkat