Chapter 7. Well Foundations: CE-471: Foundation Engineering

Diunggah oleh

Devesh KumarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chapter 7. Well Foundations: CE-471: Foundation Engineering

Diunggah oleh

Devesh KumarHak Cipta:

Format Tersedia

CE- 471: Foundation Engineering

Chapter 7. Well Foundations

CE- 471: Foundation Engineering

Introduction

Well foundations are being used in India

from very early days. Taj Mahal was

built on such foundations. Wells are

classified as deep foundations. The

main difference between a well and a

pile foundation is that, while a pile is

flexible like a beam under horizontal

loads, the well undergoes rigid body

movement under such loads.

CE- 471: Foundation Engineering

Types of Wells

Wells have different shapes and

accordingly they are named

as

1. Circular Wells

2. Dumb bell

3. Double-D Wells

4. Double Octagonal Wells

5. Single and Double

Rectangular Wells

6. Multiple Dredged Holed

Wells

CE- 471: Foundation Engineering

Components of Well Foundation

The various component of

a well foundations are

1. Cutting Edge

2. Well Curb

3. Bottom Plug

4. Steining

5. Top Plug

6. Well Cap

CE- 471: Foundation Engineering

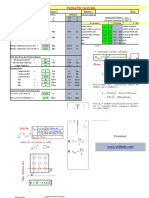

Design of Wells

Design of wells basically involves finding

1. Depth of the well

2. Size of the well and

3. Design of the other components.

CE- 471: Foundation Engineering

Depth of Scour

Well foundations are constructed in river beds, they

should be taken to a safe depth well below the

anticipated scour level. Scour around piers depends on

several factors like flood discharge, the angle of attack

of the flow, flow obstruction etc. The scour depth is

calculated as follows.

(mm) bed river in particle soil of diameter Mean D

D 1.76 factor Silt s

/s) (m discharge Design q

(m) depth Scour D

where

473 . 0

m

m f

3

s

3

1

=

= =

=

=

=

f

s

s

q

D

CE- 471: Foundation Engineering

Values of

Silt Factor

Type of material Mean diameter (mm) s

f

Coarse silt 0.04 0.35

Fine sand 0.08 0.5

Fine sand 0.15 0.68

Medium sand 0.3 0.96

Medium sand

0.5 1.24

Coarse sand

0.7 1.47

Coarse sand

1 1.76

Coarse sand

2 2.49

CE- 471: Foundation Engineering

The foundation should be taken well below the scour level to protect it from

any movement due to the force of the stream and other external forces.

well of length Grip D

.

3

1

=

= s D D

Grip Length for Wells

CE- 471: Foundation Engineering

Size of Wells

The size of dredge hole of a well varies.

In small and shallow wells, the

minimum diameter of the dredge hole

should be 1.8 m. In larger wells, the

minimum size of the dredge hole

should be 3 m. The final size is

decided after satisfying the lateral

stability condition of the wells.

CE- 471: Foundation Engineering

Bearing Capacity of Wells

level scour below foundation well of Depth

well of dimension maller

value SPT Corrected

) (kN/m capacity bearing afe

where

100

)D] N 16(100 B [5.4N

q

failure shear against

safety for value N its on based sands for pressure bearing

allowable for formula following the recommends 3955 IS

2

a

2 2

a

=

=

=

=

+ +

=

D

S B

N

S q

CE- 471: Foundation Engineering

This is subjected to

different types of

stresses. At the

sinking it is subjected

to water and earth

pressure. At dredging

stage, inside surface is

subjected to water

pressure while outside

surface to the earth

pressure. IRC

recommends some

rules of thumb for

fixing the thickness of

steining which are

given below.

Steining

CE- 471: Foundation Engineering

etc. shale kankar, boulders, for 1.20

clay for 1.15

clay soft for 1.1

strata sandy for 1.0

where

) 12 . 0 01 . 0 ( T

wells D - double and r rectangula For 2.

well the of diameter External

well of Height

etc. shale kankar, boulders, clay, hard

including strata hard for 1.25

clay soft and silty sandy, for 1.1

where

) 1 . 0 01 . 0 ( T

wells shaped - dumbbell and circular For 1.

steining concrete Cement

H

=

+ =

=

=

=

+ =

k

D k

D

D

k

D D k

H

e

e H

CE- 471: Foundation Engineering

clay hard for 1.25

clay soft for 1.1

sand for 1.0 k

where

40

D

8

D

k T

Steining Brick

H e

=

(

+ =

CE- 471: Foundation Engineering

The curb of a well transfers all the superimposed loads to the soil through the

cutting edge while sinking. The material used for curbs may be timber or

RCC. The forces acting on well curb are shown in Fig(b). The total horizontal

force on the well curb on both sides is

well the of angle Internal

steining of line centre the along length unit per

curb and well of Weight W

well of diameter Internal D

where

2

D D

Wcot

i e

=

=

=

+

u

u

i

Curb

CE- 471: Foundation Engineering

The cutting edge is provided at the bottom of the well below the curb to cut

through the soil during sinking. It is generally made of steel and welded to an

angle iron to fit the outer dimensions of the well steining. The height of the

cutting edge is given by

concrete of stress e compressiv Safe f

edge cutting of Thickness t

rock of strength Crushing

where

tan f

h

c

c.

.

e

=

=

=

=

u

u

q

t q

u

Cutting Edge

The value of u is usually taken as 30

0

. The choice of this angle has been proved to

be suitable for easy access to the cutting edge.

CE- 471: Foundation Engineering

Bottom Plug

After final grounding of the

well to the required

foundation level, a

concrete plug is provided.

The bottom plug transfer

the entire load to the

ground. The bottom plug

functions as an inverted

dome supported along the

periphery of the steining.

As it is not feasible to

provide reinforcement at

the bottom, it is generally

made thick and a rich

concrete mix (M20) is

used.

CE- 471: Foundation Engineering

Sand Filling

The bottom plug concrete is cured and

after curing, the well is filled with

sand in saturated condition. Sand

filling provides

1. Stability to the bottom of the well.

2. Eliminate the tensile forces at the

base

3. Cancels hoop stresses induced in

steining

CE- 471: Foundation Engineering

Top Plug

The top plug is provided

after the filling is

completed. Top plug

helps in transferring the

load of the pier and

superstructure to the

steining. The thickness

of the top plug is

generally kept greater

than 50 % of the smaller

dimension of the dredge

hole. If sand filling is

used, the top plug is

simply constructed using

PCC of 1:2:4 otherwise

it is reinforced with steel

bars and lean concrete

of 1:3:6 is used.

CE- 471: Foundation Engineering

Well Cap

As the shape of the well pier and cap

are different, the well cap forms an

interim layer to accommodate the

pier. The well cap is so designed that

the base of the pier is provided with

a minimum all round offset. The

centre of the well cap is made to

coincide with that of the pier and not

with that of the well. Such positioning

nullifies the effect of the minor shifts

which might have occurred during

well sinking.

CE- 471: Foundation Engineering

Stability Analysis of Well Foundations

A well foundation supporting a bridge pier is subjected

to vertical and horizontal forces. The various forces

acting on the well are

1. Self weight of the well and its superstructure

2. Live loads

3. Water currents and buoyancy

4. Temperature, wind and earth quake

5. Breaking and tracking forces

6. Resistance of the well walls

7. Base and skin friction

CE- 471: Foundation Engineering

Terzaghi (1943) gave an

approximate solution

based on the analysis

of the free rigid bulk.

Resolve all forces in

vertical direction and

obtain the resultant

P

V

.

Resolve the forces in two

horizontal directions

i.e along and across

the pier and get the

values of P

B

and P

L

CE- 471: Foundation Engineering

The resultant vertical force P

V

and the resultant

horizontal force P

B

are

considered for analysis.

The forces and earth pressure

distribution acting on the

well are shown in the

figure.

Pressure at any depth z below

the scour level is

'

' ) ( p

DK DP z

zK K K z

D

a p

= =

= =

CE- 471: Foundation Engineering

The well is assumed to fail as

soon as the soil reaction at

the bottom is equal to P

D

.

For equilibrium at that

instant

) 3 ( 2 9 3 2D

D for Solving

(2)

3

' 2

2

1

3

'

2

1

) (

E about moment Taking

(1) ) 2 ( '

2

1

) (

' 2

2

1

'

2

1

BCF of area - AEF of area

length unit per pressure total of resultant ) (

1 1

2

1 1

1

1

1

2

1 max

1 max

1

2

max

D H D H H

D

D DK

D

K D H P

D D DK P

or

D DK K D

P

B

B

B

+ =

=

=

=

A A =

=

CE- 471: Foundation Engineering

) (

D

1

tan

as given is well, the of

line centre the of deflection angular then the

nts, displaceme horizontal the are and If

) (P ve conservati

a yields forces frictional these of Omision

wall and base at the friction no is There 3.

ts coefficien pressure earth s Rankine' are K and K 2.

head bulk light a as treated is well The 1.

s assumption

following on based is theory This F. safety of factor

a by P reducing by obtained be can depth safe A

force. horizontal

maximum e sustain th to required length grip the

is D This D. for solving and (1) equation in D Putting

2 1

2 1

max. B

a P

D

1

o

o

=

CE- 471: Foundation Engineering

Stability Analysis of a Heavy Well

In the Terzaghi approximate

analysis, it is assumed that

the bulkhead tends to

rotate about some point O

above the lower edge and

tends to transfer the soil

from elastic to plastic

equilibrium. But in case of

heavy wells embedded in

cohesionless soil, the well is

assumed to rotate about its

base and the assumed

pressure distribution is

given in Fig(a). Taking the

moment about the base,

the value of (P

B

)

max

CE- 471: Foundation Engineering

D H

D D D

K P

D H

D

K K P

B

a P B

+

+

=

+

=

) (

' '

6

1

) (

as given then is force resistance maximum equivlant

The Fig(b). in shown is on distributi pressure

The scour. of depth normal the half to equal be

to assumed be may and assess to difficult very is

D depth surcharge The surcharge. a as acts soil

uncovered the gs, surroundin well the Beyond

place. takes scouring well, the around Normally

) ( '

6

1

) (

2

2

max

2

3

max

CE- 471: Foundation Engineering

base. at the occurs tension no assuming soil the of

capacity bearing safe n the kept withi be should

pressure foundation maximum The

base well the of modulus section z

base well of Area A

friction skin and

buoyancy for allowance making after

base well on the load direct net the is W

where

f

is condition moment g overturnin no for the well

the of base at the f pressure maximum The

2. than less be not should safety of factor The

) (

Pa

as given is

F safety, of factor a allowing after force resisting

total the well, the of length or diameter the is d If

max

=

=

=

=

=

A

W

F

d PB

CE- 471: Foundation Engineering

d K' '

2FP

2F

d y K' '

P

then level,

maximum the below y depth a at zero is force

shear the If zero. is force resultant the where

occurs steining on the moment maximum The

a

2

a

=

=

y

or

CE- 471: Foundation Engineering

IRC and IS Design Recommendations

The IRC and IS 3955 publications recommend

the following procedure for design of well

foundations in sand deposits (for clay the

expressions should be suitably modified)

1 Check the stability of well under working

loads, assuming elastic theory

2. Find the factor of safety of the well against

ultimate failure using ultimate load theory

CE- 471: Foundation Engineering

Causes of Tilts and Shifts

1. Nonuniform bearing capacity

2. Obstruction on one side of the well

3. Sand blowing in wells during sinking. It will cause

sudden sinking of well

4. Method of sinking: Material should be removed from

all sides equally otherwise the well may experience

tilt

5. Sudden sinking due to blasting may also cause tilting

of well

6. Irregular casting of steining will cause less friction on

one side leads to chances of tilting of well.

CE- 471: Foundation Engineering

Rectification of Tilt

1. Eccentric grabbing

2. Eccentric loading

3. Water jetting

4. Arresting the cutting edge

5. Pulling the well

6. Strutting the well

7. Pushing the well by jacks

Anda mungkin juga menyukai

- Chapter 7. Well Foundations: CE-471: Foundation EngineeringDokumen31 halamanChapter 7. Well Foundations: CE-471: Foundation Engineeringmallikarjuna rao bodduBelum ada peringkat

- Slab Culvert Irc 21 Irc 112Dokumen5 halamanSlab Culvert Irc 21 Irc 112Rupendra palBelum ada peringkat

- Well Foundation Irc PaperDokumen6 halamanWell Foundation Irc Paperdumbadumba100% (1)

- Design of Well FoundationDokumen31 halamanDesign of Well FoundationJitender SinghBelum ada peringkat

- GT Report Open Cutting at Ch. 34 KM MizoramDokumen15 halamanGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarBelum ada peringkat

- Construction of High Level Bridge Over Sutlej River Well FoundationDokumen32 halamanConstruction of High Level Bridge Over Sutlej River Well FoundationAvishkar Jain100% (1)

- Retrofitting Well Foundations for Heavy LoadsDokumen32 halamanRetrofitting Well Foundations for Heavy LoadsfaumijkBelum ada peringkat

- Pile Cap Design Calculations With CSI SAFEDokumen6 halamanPile Cap Design Calculations With CSI SAFEroshanBelum ada peringkat

- Well Foundation FinalDokumen21 halamanWell Foundation FinalSwapnil KurheBelum ada peringkat

- Irc 78 2014 PDFDokumen102 halamanIrc 78 2014 PDFSony JsdBelum ada peringkat

- Irc 45 - 1972Dokumen36 halamanIrc 45 - 1972kapinjal_Belum ada peringkat

- Mankhud RE Wall Comments On DesignsDokumen62 halamanMankhud RE Wall Comments On DesignsprathmeshBelum ada peringkat

- Comment - Draft - Comp Girder-26.34-R6Dokumen61 halamanComment - Draft - Comp Girder-26.34-R6Nilay GandhiBelum ada peringkat

- 1 PDFDokumen22 halaman1 PDFNeeraj Sharma0% (1)

- IRC Amendments - January '18Dokumen19 halamanIRC Amendments - January '18Pothineni Sri Ram KumarBelum ada peringkat

- Analysis of Well FoundationDokumen5 halamanAnalysis of Well FoundationSumit Jadhav0% (1)

- SBC Detailed ReportDokumen36 halamanSBC Detailed ReportPraneeth Kumar100% (1)

- PCC Retaining WallDokumen129 halamanPCC Retaining WallSUJEET DUBEY100% (1)

- IRC-6-CNew Clause - 214.5-Approved by B2 in 19th MeetingDokumen3 halamanIRC-6-CNew Clause - 214.5-Approved by B2 in 19th MeetingGobinder Singh VirdeeBelum ada peringkat

- Part 3 Abut - Well Foundation DesignDokumen46 halamanPart 3 Abut - Well Foundation Designshashi rajhansBelum ada peringkat

- IRC 6-2017 - CommentryDokumen368 halamanIRC 6-2017 - CommentryRajan GuptaBelum ada peringkat

- SoilTest ProjectDokumen115 halamanSoilTest ProjectMd Shahimul HaqueBelum ada peringkat

- Well Foundations PDFDokumen45 halamanWell Foundations PDFSANKAR GURUBelum ada peringkat

- Engineering Science and Technology, An International JournalDokumen7 halamanEngineering Science and Technology, An International JournalPoun KumarBelum ada peringkat

- Construction of High Level Bridge EstimateDokumen23 halamanConstruction of High Level Bridge Estimateparas rahangdaleBelum ada peringkat

- Bridge Manual Section 1Dokumen7 halamanBridge Manual Section 1Mohammad NaeemBelum ada peringkat

- IRC-58-2015-for Pakhdeva Kokha MargDokumen9 halamanIRC-58-2015-for Pakhdeva Kokha MargRam Samujh SharmaBelum ada peringkat

- Analysis of Raft Foundation Using Finite Element ApproachDokumen15 halamanAnalysis of Raft Foundation Using Finite Element ApproachShadin Asari ArabaniBelum ada peringkat

- SBC of Well FoundationDokumen9 halamanSBC of Well FoundationPrakash KumarBelum ada peringkat

- White Topping Concrete RoadsDokumen20 halamanWhite Topping Concrete RoadsSohan MeharwadeBelum ada peringkat

- Stability of Well Foundations 2014Dokumen11 halamanStability of Well Foundations 2014Sanjay GargBelum ada peringkat

- JK Prestressing CatalougeDokumen60 halamanJK Prestressing Catalougeravi aroraBelum ada peringkat

- 29+635 - (32 Deg Skew)Dokumen27 halaman29+635 - (32 Deg Skew)Praveen CyssanBelum ada peringkat

- Draft Well PileDokumen42 halamanDraft Well Pilehj_civil081206100% (1)

- Feasibility Report On Design and Construction of Bridge in The State of MeghalayaDokumen7 halamanFeasibility Report On Design and Construction of Bridge in The State of MeghalayaRam KumarBelum ada peringkat

- Directorate General Border Roads Directorate General Border Roads Directorate General Border RoadsDokumen14 halamanDirectorate General Border Roads Directorate General Border Roads Directorate General Border RoadsAaron WilsonBelum ada peringkat

- IRC SP 48-1998 Hill Road Manual - 1 PDFDokumen200 halamanIRC SP 48-1998 Hill Road Manual - 1 PDFsiddharth yadavBelum ada peringkat

- Versova Bandra Sea Link Structural Design StatusDokumen18 halamanVersova Bandra Sea Link Structural Design StatusPravin AwalkondeBelum ada peringkat

- Sub StructureDokumen51 halamanSub StructureamawauceBelum ada peringkat

- Fatigue Provision in IRS Girder Vs InternationalDokumen27 halamanFatigue Provision in IRS Girder Vs Internationalpant_tcBelum ada peringkat

- Dowel Bar-Tie Bar-IRC-58-2015Dokumen3 halamanDowel Bar-Tie Bar-IRC-58-2015SONU SINGHBelum ada peringkat

- Bitcon Pavement Design PDFDokumen18 halamanBitcon Pavement Design PDFVaghasiyaBipinBelum ada peringkat

- Is 14262 Revetment of River EmbankmentDokumen11 halamanIs 14262 Revetment of River EmbankmentAbhisek Roy ChowdhuryBelum ada peringkat

- Is 13365 Part4 DraftDokumen15 halamanIs 13365 Part4 DraftPalak Shivhare0% (1)

- Name of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshDokumen4 halamanName of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshUpadhyayula Subba RaoBelum ada peringkat

- KRIDL Quality Control Instructions for Concrete WorksDokumen36 halamanKRIDL Quality Control Instructions for Concrete WorksvivekBelum ada peringkat

- Well Foundation DesignDokumen31 halamanWell Foundation Designsumit mann100% (1)

- Well Foundation 140321015843 Phpapp01Dokumen31 halamanWell Foundation 140321015843 Phpapp01Manish Kumar SinghBelum ada peringkat

- Design Cantilever Sheetpile WallsDokumen26 halamanDesign Cantilever Sheetpile WallsAlfredo A Lopez100% (1)

- Well FoundationDokumen10 halamanWell FoundationGopal SinghBelum ada peringkat

- CE 402: Part CDokumen26 halamanCE 402: Part CTan ChingBelum ada peringkat

- Structural DesignDokumen52 halamanStructural Designbaig951Belum ada peringkat

- Design Example of Reinforce Concrete BeamsDokumen60 halamanDesign Example of Reinforce Concrete BeamsMario FrankistaBelum ada peringkat

- Lecture of FootingDokumen195 halamanLecture of FootingMonirul IslamBelum ada peringkat

- DSG-SE-02 Tank Found Concrete Ring WallDokumen5 halamanDSG-SE-02 Tank Found Concrete Ring Wallmedhat145100% (1)

- Design of Column Base Plates and Steel Anchorage to ConcreteDokumen31 halamanDesign of Column Base Plates and Steel Anchorage to Concretemonther_alsalkhadiBelum ada peringkat

- Unit 4: Well and Caisson FoundationDokumen93 halamanUnit 4: Well and Caisson FoundationJagadeeswar ReddyBelum ada peringkat

- Chapter 3 Design of Shallow FoundatinDokumen30 halamanChapter 3 Design of Shallow FoundatinYIBELTAL EBABU100% (2)

- Stability of Braced CutsDokumen14 halamanStability of Braced CutsDariush Galebi0% (2)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDari EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionBelum ada peringkat

- ME232 In-Class Finite Element Problem 1) Introduction: Fixed Attachment at Wall. All Six DOF Restricted. Load 100 LBDokumen5 halamanME232 In-Class Finite Element Problem 1) Introduction: Fixed Attachment at Wall. All Six DOF Restricted. Load 100 LBDevesh KumarBelum ada peringkat

- Structural and Machine Design UsingDokumen127 halamanStructural and Machine Design UsingDevesh KumarBelum ada peringkat

- JAS001194Dokumen2 halamanJAS001194Devesh KumarBelum ada peringkat

- Gravity DamDokumen78 halamanGravity DamDevesh Kumar75% (4)

- Planning of Water Storage Structures (Reservoirs) : Instructional ObjectivesDokumen49 halamanPlanning of Water Storage Structures (Reservoirs) : Instructional ObjectivesDevesh KumarBelum ada peringkat

- Carbon Dioxide MsdsDokumen6 halamanCarbon Dioxide MsdsrashaesharpeBelum ada peringkat

- D473 - Sedimetnos Por ExtracciónDokumen6 halamanD473 - Sedimetnos Por ExtracciónCarito LopezBelum ada peringkat

- SyllabusDokumen2 halamanSyllabusDev RanaBelum ada peringkat

- CRD c400Dokumen2 halamanCRD c400Maurizio SiepiBelum ada peringkat

- Cell Membrane Transport: A Guide to Passive and Active ProcessesDokumen2 halamanCell Membrane Transport: A Guide to Passive and Active ProcessesZei-chen LocabenBelum ada peringkat

- 7solutions Datasheet Gaztox enDokumen2 halaman7solutions Datasheet Gaztox enForum PompieriiBelum ada peringkat

- Finals-Fluid Mech PrintDokumen5 halamanFinals-Fluid Mech PrintJune CostalesBelum ada peringkat

- Daftar PustakaDokumen3 halamanDaftar PustakaRoni NovisonBelum ada peringkat

- Relationship Between Polarity and PropertiesDokumen12 halamanRelationship Between Polarity and PropertiesJustine KylaBelum ada peringkat

- Thermodynamic Tables UpdatedDokumen50 halamanThermodynamic Tables Updatedmiraabellaa247Belum ada peringkat

- C 110Dokumen41 halamanC 110Benhur K SamyBelum ada peringkat

- Determining The Rate Law From Experimental DataDokumen45 halamanDetermining The Rate Law From Experimental Datasospeter barasaBelum ada peringkat

- York Yvaa IomDokumen144 halamanYork Yvaa Iomtm_20100% (1)

- Products For QPCR and QRT-PCRDokumen32 halamanProducts For QPCR and QRT-PCRcostajac18882Belum ada peringkat

- Plastic ExtrusionDokumen35 halamanPlastic ExtrusionOff Campus100% (2)

- Is 6396 - 2000 De-CarburisationDokumen10 halamanIs 6396 - 2000 De-CarburisationDheeraj Chavan100% (1)

- S.No Acc No Title of The BookDokumen12 halamanS.No Acc No Title of The BookmechhodBelum ada peringkat

- Guided NotesDokumen4 halamanGuided NotesMahlodi LamolaBelum ada peringkat

- en 10213 2007 Steel Castings For Pressure Purposes PDFDokumen29 halamanen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalBelum ada peringkat

- Thermoforming TroubleshootingDokumen10 halamanThermoforming TroubleshootingdynafloBelum ada peringkat

- Chris DeArmitt PHD ThesisDokumen160 halamanChris DeArmitt PHD Thesisalinbu2007Belum ada peringkat

- M.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Dokumen4 halamanM.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Ƞƛǝǝm KĦáńBelum ada peringkat

- DSSC PresentationDokumen50 halamanDSSC PresentationWisaruth MaethasithBelum ada peringkat

- BdeM Taller No. 2Dokumen2 halamanBdeM Taller No. 2Luisfer PriceBelum ada peringkat

- Thesis Ge TFET Source OnlyDokumen123 halamanThesis Ge TFET Source OnlySumeet KalraBelum ada peringkat

- 6 Warna Water Based Inkjet InkDokumen21 halaman6 Warna Water Based Inkjet InksabunbeningBelum ada peringkat

- GGR240L Use and Care ManualDokumen2 halamanGGR240L Use and Care ManualBobDewilleBelum ada peringkat

- InterpretationDokumen38 halamanInterpretationGM AbeBelum ada peringkat

- Difference Between Nm3 Vs Sm3Dokumen1 halamanDifference Between Nm3 Vs Sm3Arun kumarBelum ada peringkat

- PET Resistance To H2O2Dokumen2 halamanPET Resistance To H2O2JoanBensonBelum ada peringkat