MEHB221 Thermofluids Lab 2012

Diunggah oleh

Asyraf Hakim Muhammad AzmiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MEHB221 Thermofluids Lab 2012

Diunggah oleh

Asyraf Hakim Muhammad AzmiHak Cipta:

Format Tersedia

MEHB221

Thermofluids Lab

2012

Experiment No. 2 VENTURI METER

Objectives To measure the discharge and to investigate the characteristic of a Venturi Meter.

Apparatus Solteq Bernoullis Theorem Demonstration Unit, FM 24. TecQuipment Hydraulic Bench, H1.

Figure 1: Arrangement of Venturi meter apparatus.

Summary of Theory Consider the flow of an incompressible fluid through the convergent-divergent pipe shown in Fig.2. The cross-sectional area at the upstream section 1 is a1, at the throat section 2 is a2, and at any other arbitrary section n is an. Piezometer tubes at these sections register h1, h2, and hn as shown.

MEHB221

Thermofluids Lab

2012

Figure 2: Ideal conditions in a Venturi meter. Assuming that there is no loss of energy along the pipe, and that the velocity and piezometric heads are constant across each of the sections considered, then Bernoullis theorem states that u1 2 u22 un 2 + h1 = + h2 = + hn 2g 2g 2g 1 Where u1, u2 and un are the velocities of flow through section 1, 2, and n. The equation of continuity is u1a1 = u2a2 = unan = Q 2 Q denotes the volume flow or discharge rate. Substituting in equation (1) for u1 from equation (2)

u22 a2 u22 + h1 = + h2 2g a 1 2g

2

And solving this equation for u2 leads to

u2 =

2g ( h1 h 2 ) a2 1 a1

2

MEHB221

Thermofluids Lab

2012

So that the discharge rate, from equation becomes:

Q = a2

2g ( h1 h 2 ) a2 1 a1

2

3 In practice, there is some loss of energy between sections 1 and 2, and the velocity is not constant across either of these sections. Consequently, measured values of Q usually fall a little short of those calculated from equation (3) and it is customary to allow for this discrepancy by writing:

Q = Ca 2

2g ( h1 h 2 ) a2 1 a1

2

C is known as the coefficient of the meter, which may be established by experiment. Its value varies slightly from one meter to another and even for a give meter it may vary slightly with the discharge, but usually lies within the range of 0.92 to 0.99. The ideal pressure distribution along the convergent-divergent pipe may be seen from Bernoullis equation 1 to be given by hn h1 = u 1 2 un 2 2g

For the purpose of calculation and of comparison of experimental results with calculation, it is convenient to express (hn h1) as a fraction of the velocity head at the throat of the meter, that is:

hn h 1 a 2 a 2 = u22 a1 an 2g

MEHB221

Thermofluids Lab

2012

Procedures

1. Open fully the flow control valve (on the right side of the hydraulic bench). 2. Open fully the discharge valve. 3. Switch on the hydraulic bench pump by pressing the black button on the right side of the hydraulic bench. 4. Let the water flow through the system for a while. 5. Close the discharge valve. All manometer tubes will show the same water level reading. This is called the total head of the system. 6. Record the total head of the system in the result sheet. 7. Adjust the discharge valve to let the water flow through the venturi meter. Set the water level of manometer tube C at approximately 10mm. 8. Record the water levels of all manometer tubes in the result sheet (Table 2). 9. Place the PVC tubing into the drain hole. Using the stopwatch, measure and record the time it takes for the water to reach 5 litres. The volume of the water could be seen on the left side of the hydraulic bench. Record the time in Table 2. 10. Once it is done, open the drain and let the water flow into the tank. 11. Close the discharge valve slightly to obtain a different flow rate (increase the water level of manometer tube C by approximately 10mm). 12. Record the water level of the piezometer tubes labeled A and C in Table 3. 13. Place the PVC tubing into the drain hole. Using the stopwatch, measure and record the time it takes for the water to reach 5 litres. Record the time in Table 3. 14. Once it is done, open the drain and let the water flow into the sump tank. 15. Repeat steps (11) to (14) to obtain an additional 5 sets of water level reading (A and C) with different flow rates. 16. Switch off the hydraulic bench pump by pressing the red button on the right side of the hydraulic bench. 17. Close the flow control valve and discharge valve.

Data, Observation and Results

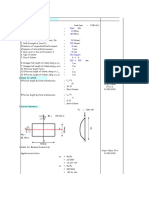

The dimensions of the meter and the position of the piezometer tappings are shown below.

MEHB221

Thermofluids Lab

2012

Complete Table 1 (ideal values). Complete Table 2 (experimental values). Plot the graph of (hn-h1)/(u22/2g) versus the distance (xn) for the ideal and experimental pressure distribution on the same graph (Graph 1). Calculate experimental and ideal (using equation 3) discharge flow rate in Table 3. Calculate the coefficient of Venturi meter using equation 4 in Table 4. Plot the graph of C versus ideal flow rate (Graph 2).

Analysis and Discussion

Describe what happen ideally to the flow as the water flow through the venturi meter. Comment on Graph 1. Define Coefficient of meter, C and state the theoretical value for venturi meter. Comment on Graph 2. List the possible sources of errors and safety precaution.

RESULT SHEET

Table 1: Ideal Pressure Distribution Piezometer tube Dia. of cross Distance from No. (n) section (dn) datum (xn) A (1) 26.0 B 21.6 C (2) 16.0 D 20.0 E 22.0 F 26.0

d2/dn

(a2/a1)2

(a2/a1)2 (a2/an)2

Table 2: Measured Pressure Distribution Q= m3/s Tube No. (u2)2/2g = hn A (1) B C (2) D E F mm hn h1 hn h1 (u2)2/2g

MEHB221

Thermofluids Lab

2012

Table 3: Water level of piezometer tubes A (1) and C (2) Volume (L) 5 5 5 5 5 5 t (sec) h1 (mm) h2 (mm) Qexp (m3/s) (h1-h2) (m) (h1-h2)1/2 (m1/2) Qideal (m3/s)

Table 4: Coefficient of Venturi meter Experimental Q (m3/s) Ideal Q (m3/s) C

Anda mungkin juga menyukai

- Verify Bernoulli's Theorem LabDokumen5 halamanVerify Bernoulli's Theorem LabismailBelum ada peringkat

- Validates Bernoulli's Theorem in Tapered DuctDokumen29 halamanValidates Bernoulli's Theorem in Tapered DuctAnonymous NyvKBWBelum ada peringkat

- Calibrating a Venturi MeterDokumen10 halamanCalibrating a Venturi MeterAgyeman EmmanuelBelum ada peringkat

- Lab7-Phelton Turbine Experiment-UpdatedDokumen7 halamanLab7-Phelton Turbine Experiment-Updatedtomtoms92Belum ada peringkat

- Theory VenturiDokumen7 halamanTheory VenturiMahendranath RamakrishnanBelum ada peringkat

- Lab Report 2Dokumen16 halamanLab Report 2Limmy Yingran0% (1)

- Adiabatic Gas Law Apparatus Instruction ManualDokumen10 halamanAdiabatic Gas Law Apparatus Instruction ManualSyifauliyah AzmiBelum ada peringkat

- Impact of JetDokumen5 halamanImpact of Jetميسرة33% (3)

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Dokumen19 halamanSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaBelum ada peringkat

- Impact of JetDokumen7 halamanImpact of JetHeng Xiu KohBelum ada peringkat

- Impact of A Water JetDokumen5 halamanImpact of A Water JetAnirban SardarBelum ada peringkat

- Bernoulli's TheoremDokumen5 halamanBernoulli's TheoremVrushiket PatilBelum ada peringkat

- How Jet Angles Affect Fluid ForcesDokumen11 halamanHow Jet Angles Affect Fluid Forcesjoshx12Belum ada peringkat

- Orifice and Free Jet Flow: University of NebraskaDokumen8 halamanOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- EXP 6 Study of Impact of Free Water JetDokumen11 halamanEXP 6 Study of Impact of Free Water Jetsiva ramBelum ada peringkat

- Measuring Force Exerted by Fluid Jet Impinging on Flat and Hemispherical SurfacesDokumen17 halamanMeasuring Force Exerted by Fluid Jet Impinging on Flat and Hemispherical SurfacesAnusha AnuBelum ada peringkat

- Fluid Mechanics Lab Experiment 2Dokumen8 halamanFluid Mechanics Lab Experiment 2SSShakeelBelum ada peringkat

- Specific Energy Hydraulic Jumps WeirsDokumen23 halamanSpecific Energy Hydraulic Jumps WeirsHaris jugnooBelum ada peringkat

- Bioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyDokumen18 halamanBioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyAswini Purushothanan0% (1)

- Lab 1 - Fluid Flowmeters (Me) FinalDokumen14 halamanLab 1 - Fluid Flowmeters (Me) Finalizzahyahaya75% (4)

- Hydrostatic forces on immersed plane surfacesDokumen9 halamanHydrostatic forces on immersed plane surfacesEssam Ahmed Abd MeguidBelum ada peringkat

- Exp 2 Friction LossesDokumen15 halamanExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- Calibration of VenturimeterDokumen2 halamanCalibration of VenturimeterAhmedElsayedBelum ada peringkat

- Abstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesDokumen18 halamanAbstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesHariz MiorBelum ada peringkat

- Energy Losses in Pipes: Experiment # 4Dokumen4 halamanEnergy Losses in Pipes: Experiment # 4محمد جوادBelum ada peringkat

- CE 2020 - Fluid Mechanics LaboratoryDokumen67 halamanCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamBelum ada peringkat

- Energy Losses in BendsDokumen10 halamanEnergy Losses in BendsAngelica Joyce BenitoBelum ada peringkat

- Manning's Roughness Coefficient (N)Dokumen11 halamanManning's Roughness Coefficient (N)Khurram MumtazBelum ada peringkat

- Fluid Mechanic Lab ManualDokumen15 halamanFluid Mechanic Lab ManualAltamash NadimallaBelum ada peringkat

- Venturi meter experiment proceduresDokumen2 halamanVenturi meter experiment proceduresAnonymous mRBbdopMKf100% (1)

- Experiment 1Dokumen9 halamanExperiment 1Shaun Loo50% (2)

- Free VortexDokumen3 halamanFree VortexVrushiket Patil67% (3)

- Free and Forced Vortices PDFDokumen6 halamanFree and Forced Vortices PDFdemiseBelum ada peringkat

- Determine Floating Body StabilityDokumen11 halamanDetermine Floating Body StabilityDember Paul100% (1)

- Pitot Tube ExperimentDokumen3 halamanPitot Tube ExperimentinstrutechBelum ada peringkat

- Centre of Hidrostatic PressureDokumen16 halamanCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Lab 2 Mini FLow ChannelDokumen16 halamanLab 2 Mini FLow ChannelIr Fik TBelum ada peringkat

- Venturi MeterDokumen10 halamanVenturi MeterThaerZãghal100% (6)

- Revised LabDokumen18 halamanRevised LabAbu AyemanBelum ada peringkat

- Venturi Meter 1Dokumen13 halamanVenturi Meter 1Da Champ CenaBelum ada peringkat

- EXP 5 - Study of Hydraulic Jump in A Rectangular ChannelDokumen9 halamanEXP 5 - Study of Hydraulic Jump in A Rectangular Channelsiva ramBelum ada peringkat

- 12 Experiment #2: Bernoulli'S Theorem DemonstrationDokumen12 halaman12 Experiment #2: Bernoulli'S Theorem DemonstrationYasir A. Al-ShataifBelum ada peringkat

- 4 Rough Draft2 Impact of A Water JetDokumen14 halaman4 Rough Draft2 Impact of A Water JetBrennan GenusaBelum ada peringkat

- Lab Report 4Dokumen7 halamanLab Report 4api-300265822100% (1)

- LAB REPORT - Discharge Over WeirsDokumen9 halamanLAB REPORT - Discharge Over WeirsLuli LolBelum ada peringkat

- Pelton Wheel TurbineDokumen8 halamanPelton Wheel TurbineSiew LynBelum ada peringkat

- Water Hammer Lab DiscussionDokumen4 halamanWater Hammer Lab DiscussionUmer JavedBelum ada peringkat

- Critical Reynolds Number in Pipe FlowDokumen2 halamanCritical Reynolds Number in Pipe FlowHunterTateBelum ada peringkat

- Table of Content DocDokumen17 halamanTable of Content DocjjBelum ada peringkat

- Impact of Jet Lab ReportDokumen7 halamanImpact of Jet Lab ReportMohamad Hilmy HaririeBelum ada peringkat

- Experimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionDari EverandExperimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionPenilaian: 4 dari 5 bintang4/5 (2)

- Fluids Lab Venturi Meter - 4Dokumen5 halamanFluids Lab Venturi Meter - 4augur886Belum ada peringkat

- Experiment 8 - The Venturi Meter, The Determination of Discharge From A PipeDokumen8 halamanExperiment 8 - The Venturi Meter, The Determination of Discharge From A Pipebkewill6Belum ada peringkat

- Lab # 1 Bernoulli's Theorem: ObjectiveDokumen5 halamanLab # 1 Bernoulli's Theorem: ObjectiveNioBelum ada peringkat

- Bernoullis TheiremDokumen7 halamanBernoullis TheiremAli M. ChehadehBelum ada peringkat

- Exp#3 Venturi Meter - 2016Dokumen6 halamanExp#3 Venturi Meter - 2016ashwindranBelum ada peringkat

- Flow MeasurementDokumen11 halamanFlow MeasurementRaj Ven100% (1)

- Experiment 4 - Flow MeasurementDokumen24 halamanExperiment 4 - Flow MeasurementKhairil Ikram67% (6)

- Pipe FrictionDokumen4 halamanPipe FrictionShubham ChauhanBelum ada peringkat

- Lecture 1Dokumen11 halamanLecture 1Asyraf Hakim Muhammad AzmiBelum ada peringkat

- Assgmnt Fuluid LabDokumen4 halamanAssgmnt Fuluid LabAsyraf Hakim Muhammad AzmiBelum ada peringkat

- English Tongue Twister1Dokumen2 halamanEnglish Tongue Twister1Asyraf Hakim Muhammad AzmiBelum ada peringkat

- Process FlowDokumen6 halamanProcess FlowAsyraf Hakim Muhammad AzmiBelum ada peringkat

- Design of Short Column (Biaxial Bending)Dokumen3 halamanDesign of Short Column (Biaxial Bending)meenu100% (2)

- Anna Bhau Sathe Auditorium, YerwadaDokumen17 halamanAnna Bhau Sathe Auditorium, YerwadaRadhika AgarwalBelum ada peringkat

- Angelina Beams enDokumen38 halamanAngelina Beams enAlem LoajnerBelum ada peringkat

- Ds5 Ds5: / Detail External Horizontal Gutter / Detail - Frieze - Attika / Detail 09Dokumen1 halamanDs5 Ds5: / Detail External Horizontal Gutter / Detail - Frieze - Attika / Detail 09Andreja GjureskiBelum ada peringkat

- Construction of Multi-Purpose Building, Barangay Mahayahay, Iligan CityDokumen8 halamanConstruction of Multi-Purpose Building, Barangay Mahayahay, Iligan CityReymon NepomucenoBelum ada peringkat

- Session-2 - Twin Metro Tunnel in Layered Soil (2D) - Apr - 22Dokumen15 halamanSession-2 - Twin Metro Tunnel in Layered Soil (2D) - Apr - 22Dadi YashwantBelum ada peringkat

- Plumbing Design Lecture - Notes PDFDokumen148 halamanPlumbing Design Lecture - Notes PDFNayeemuddin Meraj Mohammed90% (10)

- Pid ChlorinationDokumen2 halamanPid ChlorinationShanmuganathan ShanBelum ada peringkat

- AndrewDokumen2 halamanAndrewFatima AhmedBelum ada peringkat

- Tentative Renovation Cost EstimatesDokumen6 halamanTentative Renovation Cost EstimatesMainit VOnBelum ada peringkat

- Flow Over WeirsDokumen3 halamanFlow Over WeirsNurshazwani syuhada bt al- badri0% (1)

- Acelerated Precast Bridges PCIDokumen102 halamanAcelerated Precast Bridges PCIaleitaosilva100% (6)

- C I 3304 Detailing CornerDokumen5 halamanC I 3304 Detailing CornerNono_geotecBelum ada peringkat

- FE Exam Review Practice MO S&TDokumen195 halamanFE Exam Review Practice MO S&TAkhdamli ServicesBelum ada peringkat

- PCMC-structural Condition Assessment Inception ReportDokumen4 halamanPCMC-structural Condition Assessment Inception Reportsamirbendre1Belum ada peringkat

- Nfpa 37Dokumen2 halamanNfpa 37Yakdhan YaseenBelum ada peringkat

- Proposed 3BR Bungalow BOMDokumen12 halamanProposed 3BR Bungalow BOMaxl skid santosBelum ada peringkat

- Design of Machine Elements Course OverviewDokumen2 halamanDesign of Machine Elements Course OverviewGitu ShivBelum ada peringkat

- Thick Walled Pressure Vessel - ResearchDokumen31 halamanThick Walled Pressure Vessel - ResearchPeter ManosBelum ada peringkat

- Base Plate External Pipe Rack PK 12bDokumen2 halamanBase Plate External Pipe Rack PK 12bDass DassBelum ada peringkat

- SPC ExampleDokumen3 halamanSPC Exampleeuthan100% (1)

- RFQ On Consultancy Pipeline Project-1Dokumen6 halamanRFQ On Consultancy Pipeline Project-1Atty AttyBelum ada peringkat

- Tower Cranes CommisioningDokumen15 halamanTower Cranes Commisioningpammu18Belum ada peringkat

- Stress-Strain Diagram: Engr. Abdul Rahim KhanDokumen26 halamanStress-Strain Diagram: Engr. Abdul Rahim KhanKashif TaRarBelum ada peringkat

- SDDM February 2015Dokumen535 halamanSDDM February 2015Jeff HedmanBelum ada peringkat

- The Effective Ways of Utilization of Rice-Husk-Ash in Hot Mix AsphaltDokumen6 halamanThe Effective Ways of Utilization of Rice-Husk-Ash in Hot Mix AsphaltDipendra AwasthiBelum ada peringkat

- Auda - 18 & 20-01-2022 - Sarathya West - ResidentialDokumen2 halamanAuda - 18 & 20-01-2022 - Sarathya West - ResidentialJaimin ShahBelum ada peringkat

- Curva Evmu-3-6Dokumen1 halamanCurva Evmu-3-6omaryehudeBelum ada peringkat

- Set 3 - Unit 3Dokumen6 halamanSet 3 - Unit 3Tare Er Kshitij100% (3)

- Characteristic Strength of Machine Made First Class Bricks Found in Different Parts of ManipurDokumen7 halamanCharacteristic Strength of Machine Made First Class Bricks Found in Different Parts of ManipurleGionBelum ada peringkat