Igct

Diunggah oleh

Navaneethaan NathamoorthyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Igct

Diunggah oleh

Navaneethaan NathamoorthyHak Cipta:

Format Tersedia

ABB Industrie AG

IGCT-Technology A Quantum Leap for High-power Converters

IGCT Technology A Quantum Leap for High-power Converters

H. Grning* From the very beginning, the development of power semiconductors was nothing more than the search for the ideal switch. The Lowest on-state commutaion losses, the highest possible commutation frequency and a simple drive circuit were and still are what is needed in practice. From the transistor and Darlington to the IGBT, low voltage applications have benefited all the way along while the medium voltage could only look on. GTOs and more GTOs, nothing else was in sight. Then at last the IGBT grew bigger... Would they make the grade? ABB Switzerland has explored a new avenue of development with the aim of exploiting the advantages of the IGBT for higher powers while retaining the strengths of the GTO as far as possible. Thus the GCT (Gate Commutated Thyristor) grew from the GTO at first with an improved drive and a new gate connection and then with a new housing, new technology wafer, monolithically integrated diodes, hybrid intergrated drive, a much simplified power circuit and much more. We now find the potential of the new device to be so large that we are convinced we have found a worthy successor for the GTO. The secret of the IGCT The Key to success was in the GTO itself. More precisely, the only thing wrong with it was an enormous control problem. A typical turn-off response is shown in Fig.1 Because of the demand for high turn-off amplification, the GTO passes through a region during the transition from the conducting (Thyristor) to the nonconducting (Transistor) states when both anode voltage and cathose current are impressed (red background). As with a mechanical switch, however, a four layer device can only assume one of two stable states on and off. Transition tends to be got through as quickly as possible and be

Anode, Cathode, Gate current [kA] 3 2 1 0 -1

Low losses, small size, reliable, modular and cost-effective uncompromising implementation of IGCT technology creates medium voltage converters with entirely new characteristics.

supported by snubber circuits The basic principle of the GCT resolves these problems, because the device now has what is referred to as a hard drive (Fig.2), i.e. instead of diG/dt @ 50A/s, diG/dt 3000A/s is applied

IA [kA]

4 3

3 IK 2 IA 1 0 -10 IG VG 15 t [s] 20 30 -20

IK [kA]

2 1 0

IG [kA]

-1 -2 -3 5 10

Thyristor

Transistor

Fig.2: Typical turn-off characteristic of a 4,5kV 3kA GTO to the gate. The current is thus switched from the cathode to the gate and the anode can be observed. The conductivity and therefore the low anode voltage remain unchanged for as long as this changes directly from the thyristor to the transistor mode and turns off as stably, fast and without the help of a snubber circuit as an IGBT (Insulated Gate Bipolar Transistor). 1st step towards an IGCT converter a low inductance drive The rate of change of the drive is critical for the operation of the GCT. The anode current has to be turned off in less than 1s otherwise the device moses into the unstable part of the characteristic. This corresponds to

VG [V]

VA [kV]

VA

diG/dt 3000A/s for a 3kA GCT and proportionally more or less for other types. The voltage needed results for a given inductance of the gate circuit, respectively the inductance for a given gate voltage. On the other hand, a simple, reliable and cost effective drive unit is only possible at low voltages. An ideal volta-ge is 20V, because the gate can withstand this voltage after turn-off. The permissible leakage inductance for interrupting 3kA is 6nH or less which is only1/50 of the usual value for a GTO. It was possible to achieve this value by adopting a coaxial configuration of the device connection and a multi layer connection to the power output of the drive. (Fig.3).

Fig. 3: 4.5kV, 3kA, IGCT (Integrated Gate Commutated Thyristor). The GCT and the gate unit form a single part. The PCB (3) conneects the GCT and the drive.

2nd step towards an IGCT converter optimum silicone technology. The so-called hard drive solves the GTOs drive problem. This actually also improves a standard GTO wafer

Interdisciplinary development

Know-how from many disciplines is essential to develop high-power converters. This is where low-power electronics for the control circuit, silicone technologyfor the power semiconductors, metallurgy and ceramics for the hermtically sealed semiconductor housing, power electronics for the main circuit, conductors and cooling and mechanical engineering for the layout and construction all converge. The circuits of GTO converters are complex and a feature of their development is the many interfaces that were necessary.

IA IK

IK >>0 and VA >>0!

3 2 1 0

VA IG

5 10 Thyristor 15 t [s] Unstable Transistor 20 Non Conducting Transistor 25

IGCT megawatt converters of a piece

GCTs have a low-inductance drive circuit and for this reason conduct evenly. Poor compromises are eliminated, development and design become clearer and scalable, the ditches between the disciplines involved are bridged, R&D becomes coordinated a converter of a piece is created.

Fig.1: Typical turn-off characteristic of a 4,5kV 3kA GTO.

Turgi

Seite 1 von 3

1998 Reprint

ABB Industrie AG

IGCT-Technology A Quantum Leap for High-power Converters

and the GCT manufacturer no longer has to compromise when designing the wafer in order to obtain the desired switching characteristic. The GCT wafer can be much thinner than GTO wafer and this smoothes the way to the utilisation of plasma engineering techniques. For this reason, GCTs generate much lower losses than GTOs. (Fig. 4)

Every segment of the wafer, of which a 3 kA unit has more than 2000, knows when it has to switch and excecutes the corresponding command independently of the others: Since all

Fig. 5: GCT (1) and diode (2) on the same wafer. The gate has its contact at the centre (3) on the 51 mm disc (6 kV, 520 A).

Drive circuit

Fig. 7: Reverse conducting GCT with wafer diameters of 38 mm, 51 mm, 68 mm and 91mm and a 91 mm GCT

the segments respond in exactly the same way, optimum parralel operation is achieved and the switching capacity varies in proportion to wafer area. It is therefore relatively simple to develop an approproately graded family of GCT devices (Fig.7). 4th. step towards an IGCT converter reducing circuit complexity. GCTs turn off in the same way as transistors. In contrast to a GTO, a GCT converter does not therefore need snubber condensers, diodes and resistors. It is still necessary, however, to limit the current rise time (dI/dt) when turning a GCT on, because the speed of the high-voltage

Fig. 4: A comparison between GTO 5SGA 40L4501 and GCT 5SGY 35L4502. The commuta-tion losses of both devices are approximately the same.

Cooler GCT

Fig. 6: GCT and drive circuit slide onto the cooler to form a single unit both electrically and mechanically.

main separate. Hybrid integration only achieves a closer blending of GCT and the diode have to remain separate. Hybrid integration achieves a closer blending of GCT, drive unit and cooler (Fig.6). The synergies of the mechanical construction produce advantages with respect to reduced size, greater stability and lower costs. The hard unambiguous drive achieves an overall even, smoother operation.

3rd. step towards an IGCT converter higher converter integration and linear sizing with current IGCT technology applies two levels of integration: monolithic on the wafer and hybrid for the periphery of the GCT. In many cases, the antiparallel diodes can be integrated monolithically (Fig. 5). This eliminates the diode stack and associated heavy current connections. Integration of this kind only becomes impractical at the highest currents and the GCT and the diode have to re-

Series of ratings through modular design

Because of the varying requirements from one application to another and the small quantity needed, there is a con-fusing number of types of high-power converters almost an individual version for every application. A modular system of components is therefore the only sensible solution. IGBT modules have been able to satisfy this demand in the medium power range, i.e. a wide range of currents by connecting chips in parallel in the modules, converters for a wide range of ratings by connecting modules in parallel and a drive system that almost fits into a single IC. The success of the IGBT is assured. Pressure contacts for high powers Because of the stress on the insulation, the gauges of conductors needed and the unhandy size of the converter units, conventional module technology can only handle high voltages and currents with diff culty. It therefore has to be possible to easily dismantle high-power converters into their component parts. IGCT technology employs conventional pressure contacts, but adopts a new approach. Drive unit, power semiconductors and cooler are integrated in a single functional unit and optimised wafers in standard housings have taken the place of the array of chips in expensive parallel configurations. Engineering and manufacture take less time and less money and the units are easier to handle. As a consequence, the range of application can be extended down to 250 kW and by connecting units in series up to 100 MW.

Turgi Seite 2 von 3

Fig.8: Typical circuit of a three phase IGCT converter. A common supervision unit continually checks switch.

silicone diodes is nothing like that of the low-voltage diodes used in IGBT applications. A new heavy current circuit, on the other hand, enables all the phases of an in-verter to be connected to the same DC bus (Fig. 8). This brings the overall cost of an IGCT converter down to about the same level as for a conventional IGBT converter.

1998 Reprint

ABB Industrie AG

IGCT-Technology A Quantum Leap for High-power Converters

by ABB for low-voltage drives in 1995, commutates the IGBTs in the two-point inverter in the ACS600 for limited periods at up to more than 20 kHz. As early as the end of 1997, after a development period of just two years, ABB presented the first of a series of mediumvoltage converters, i.e. the ACS1000 with DTC, three-point IGCT converter and sinusoidal output filter (Fig.11). The most important features of this series Fig. 11: Air-cooled drive converter of the ACS1000 series (4.16 kV, 1.2 MW sinusoidal output) of drives are: A mean commutating frequency of 500 Hz for a three-point Excellent component characteristics converter corresponding to about 2 High rated voltage kHz for a two-point circuit Low turn-on and commutation losses Fig. 9: 100 MW Bremenrailway sys Highly dynamic commutating fre High commutation frequency and tem inter-tie quency intermittently up to 7 kHz absolute peak limit frequency Sinusoidal output with low harmonic Good utilisation of the silicone area content Even current distribution in the sili DTC with all its well-known advancone tages Linear relationship between the ac Small size tive wafer area and currentrating Low number of power semiconduc Relatively easy to model Optimum tors (total of 12 in a three-point concircuit design verter) All three phases suppliedfrom a High reliability (MTBF > 6 years) common DC bus High overall efficiency > 98 % Central dI/dt limiter with integrated Widerange of types from 2.3 kV to clamp 4.16 kV and from 315 kW to 5 kW Uncritical connection of theinterme Simple as the ACS600 to commisdiate circuit sion Absolute safety even underworst Supply for existing, previously uncase conditions regulated motors (retro-fit) Simple drive circuit Fig. 10: Air-cooled three-phase Directly coupled gate signal (on / off) 1.5 MW phase module for a commuSummary and outlook No regulator circuit (dV/dt,dI/dt) In the few years since its incep-tion, Two-wire low-power supply Superior tating frequency of 1050 Hz IGCT technology has been able to performance superior reliability of these devices and establish itself firmly in the medium Only few components: all standard the ease with which they can be convoltage range of applications. Its close Modular mechanical construction nected in series. IGCTs are capable of relationship with the GTO and IGBT Monolithic integration up to the highhigh commutation frequencies at high facilitated a development in finite calest ratings power ratings. They are also ideal for culable steps (Fig. 12). It unifies the Ideally matched power semiconhighly dynamic applications such as advantages of its predecessors and ductors, control system and cooler NBPS (no-break power supplies) (Fig. overcomes their disadvan-tages.The Robust pressure contact technique 10). A dynamic response is also exmain features and advantages of with simple centring pected of traction inverters: the direct IGCT technology Modular design torque control (DTC) system launched Simple to service High overall efficiency e Highest possible reliability eden gen hi Small size and low weight versc endun Anw Well-defined manageable interfaces eitere Plastik-Gehuse w to the intermediate circuit, load and Integrierter Khler control system 80% Modulare GU Highest powers manageable RTh Reduktion Reliable series operation 250A - 4kA GCT Familie Further enhanced reliability due to 6kA / 4,5kV 91mm GCT redundant stages when connected in 40% series 1kA / 6kV rckwrtsleitend With these characteristics and its Dioden ohne Snubber other potential strengths, the IGCT is Transparenter Emitter the ideal successor to the GTO. 3kA / 4,5kV GCT Hart gesteuerter GTO *Horst Grning 0% GCT Converter Development ABB Industrie AG, Switzer 1993 1995 1997 1999 2001 2003

100MVA Bahnnetzkupplung

IGCT converters in operation The first IGCTs were installed in plants built by ABB. The most prominent representative of these is most certainly the 100 MW Bremen railway system intertie (Fig. 9). 288 GCTs have operated without failure in this installation since 1996. It is an example both for the

Fig. 12: The development of IGCT components and their application

Turgi Seite 3 von 3 1998 Reprint

Serieschaltung

U-Modul

ACS 1000 Prototyp ACS 1000 launch 2,5MVA DVR

Anda mungkin juga menyukai

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- IGCT Technology - A Quantum Leap For High-Power ConvertersDokumen5 halamanIGCT Technology - A Quantum Leap For High-Power ConvertersSreenivas_Chim_9626Belum ada peringkat

- IGCTDokumen6 halamanIGCTsuresh5254Belum ada peringkat

- New High Power Semiconductors: High Voltage Igbts and GctsDokumen7 halamanNew High Power Semiconductors: High Voltage Igbts and GctsSinan PravadaliogluBelum ada peringkat

- IGCT Thyristors: High-Power Semiconductor Devices for Voltage ConversionDokumen2 halamanIGCT Thyristors: High-Power Semiconductor Devices for Voltage ConversionS Sivarao JonnalagaddaBelum ada peringkat

- Prospects of IGCT Technology: High Power SemiconductorsDokumen3 halamanProspects of IGCT Technology: High Power SemiconductorspjacqmaeBelum ada peringkat

- Igbt or IgctDokumen6 halamanIgbt or IgctJulian De MarcosBelum ada peringkat

- A New Current-Source Converter Using A Symmetric Gate-Commutated Thyristor (SGCT)Dokumen8 halamanA New Current-Source Converter Using A Symmetric Gate-Commutated Thyristor (SGCT)Nusrat Mary ChowdhuryBelum ada peringkat

- IGCT PresentationDokumen14 halamanIGCT PresentationNinAd Pund100% (2)

- SEMINAR ON IgctDokumen22 halamanSEMINAR ON Igctapi-19757160Belum ada peringkat

- Abb IgctDokumen2 halamanAbb IgctzulryBelum ada peringkat

- Comparison of IGBT and GTO For High Power Inverters PDFDokumen9 halamanComparison of IGBT and GTO For High Power Inverters PDFLuis Eduardo RibeiroBelum ada peringkat

- Insulated Gate Commutated ThyristorDokumen4 halamanInsulated Gate Commutated ThyristorAlejandra TorresBelum ada peringkat

- MOSFET in SMPS High Frequency Application: A New SMPS Non Punch Thru IGBT ReplacesDokumen5 halamanMOSFET in SMPS High Frequency Application: A New SMPS Non Punch Thru IGBT ReplacesAdil ButtBelum ada peringkat

- A New Current Source Converter Using SCGTDokumen7 halamanA New Current Source Converter Using SCGTroggery pieroBelum ada peringkat

- Integrated gate-commutated thyristor device descriptionDokumen3 halamanIntegrated gate-commutated thyristor device descriptionKishore CkBelum ada peringkat

- IGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelDokumen6 halamanIGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelculwavesBelum ada peringkat

- Infineon Coreless Transformer Bodo ART v1.0 enDokumen3 halamanInfineon Coreless Transformer Bodo ART v1.0 enLullaby summerBelum ada peringkat

- Welco ME!: Presented byDokumen18 halamanWelco ME!: Presented byDev KumarBelum ada peringkat

- AND9072/D Effect of Gate-Emitter Voltage On Turn On Losses and Short Circuit CapabilityDokumen5 halamanAND9072/D Effect of Gate-Emitter Voltage On Turn On Losses and Short Circuit CapabilityVíctor Burgos GonzálezBelum ada peringkat

- IgbtDokumen11 halamanIgbtRajeev VaranwalBelum ada peringkat

- IGBT/MOSFET Gate Drive Optocoupler: Optocouplers and Solid-State RelaysDokumen9 halamanIGBT/MOSFET Gate Drive Optocoupler: Optocouplers and Solid-State Relaysme1816Belum ada peringkat

- Abb Discharge SwitchDokumen10 halamanAbb Discharge Switchsantosh_babar_26Belum ada peringkat

- An 9020Dokumen25 halamanAn 9020Reshmi Parikal RaghavanBelum ada peringkat

- Microsemi Power An Unipolar SwitchingDokumen3 halamanMicrosemi Power An Unipolar SwitchingRomitan AlexandraBelum ada peringkat

- A Hybrid Active Gate Drive For Switching Loss Reduction and Voltage Balancing of Series-Connected IGBTsDokumen13 halamanA Hybrid Active Gate Drive For Switching Loss Reduction and Voltage Balancing of Series-Connected IGBTsMahesh KulkarniBelum ada peringkat

- Isolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsDokumen43 halamanIsolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsReneBelum ada peringkat

- Why There Is No Igbt Traction RectifiersDokumen9 halamanWhy There Is No Igbt Traction RectifiersLaurence MichaelBelum ada peringkat

- AN5004Dokumen5 halamanAN5004rdc02271Belum ada peringkat

- Igbt DriverDokumen4 halamanIgbt DriverArmandinho CaveroBelum ada peringkat

- Grid Tie Inverter Schematic and Principals of OperationDokumen6 halamanGrid Tie Inverter Schematic and Principals of Operation31482Belum ada peringkat

- Construction and Applications of Injection Enhanced Gate TransistorsDokumen20 halamanConstruction and Applications of Injection Enhanced Gate TransistorsBurak YanarBelum ada peringkat

- 600/1200V Igbts Set Benchmark Performance in High Switching Speed ApplicationsDokumen4 halaman600/1200V Igbts Set Benchmark Performance in High Switching Speed Applicationsthienvuong90Belum ada peringkat

- Improve Precipitator Efficiency with IGBT Inverter TechnologyDokumen8 halamanImprove Precipitator Efficiency with IGBT Inverter Technologymohammad.zBelum ada peringkat

- IGCTDokumen1 halamanIGCTapi-3753995Belum ada peringkat

- An Experimental Evaluation of Sic Switches in Soft-Switching ConvertersDokumen27 halamanAn Experimental Evaluation of Sic Switches in Soft-Switching Convertersashish88bhardwaj_314Belum ada peringkat

- 06 Design Implementation Highly Efficient PDFDokumen10 halaman06 Design Implementation Highly Efficient PDFEdamEdamBelum ada peringkat

- Mosfet Igbt BJT Difference and ApplicationDokumen5 halamanMosfet Igbt BJT Difference and ApplicationSangammeshwra AbBelum ada peringkat

- Active voltage sharing controls IGBTs in seriesDokumen8 halamanActive voltage sharing controls IGBTs in seriesOsman T.Belum ada peringkat

- IGBT or MOSFET: Choose Wisely: by Carl Blake and Chris Bull, International RectifierDokumen5 halamanIGBT or MOSFET: Choose Wisely: by Carl Blake and Chris Bull, International RectifiergubiliBelum ada peringkat

- A Simple Closed-Loop Active Gate Voltage Driver For Controlling Di - DT and DV - DT in IGBTs PDFDokumen18 halamanA Simple Closed-Loop Active Gate Voltage Driver For Controlling Di - DT and DV - DT in IGBTs PDFzeevko1249Belum ada peringkat

- Guide to Discrete IGBTsDokumen16 halamanGuide to Discrete IGBTsPablo AllosiaBelum ada peringkat

- L6 - Gate Drive and SnubbersDokumen66 halamanL6 - Gate Drive and SnubberssrnankitBelum ada peringkat

- Advancements in P.esDokumen30 halamanAdvancements in P.esSifar TeenBelum ada peringkat

- How To Drive Mosfets and Igbts Into The 21St Century: IXAN0009Dokumen28 halamanHow To Drive Mosfets and Igbts Into The 21St Century: IXAN0009mmBelum ada peringkat

- 1A An-7003 Gate Resistor-Principles and Applications Rev00Dokumen10 halaman1A An-7003 Gate Resistor-Principles and Applications Rev00Barbara EllisBelum ada peringkat

- IGBT TransistorsDokumen16 halamanIGBT TransistorsMiodragBelum ada peringkat

- DC Motor Speed ControlDokumen54 halamanDC Motor Speed ControlAbhishek Gupta100% (3)

- Design Improvements in IGBT Based Variable Frequency Drive MotorsDokumen7 halamanDesign Improvements in IGBT Based Variable Frequency Drive MotorsChris ParkinsonBelum ada peringkat

- Flyer 023Dokumen4 halamanFlyer 023Pankaj Kumar SinghBelum ada peringkat

- Wind PowerDokumen6 halamanWind Powerوليد ابو شاكرBelum ada peringkat

- IGBT Overcurrent and Short Circuit Protection in Industrial Motor Drives PDFDokumen6 halamanIGBT Overcurrent and Short Circuit Protection in Industrial Motor Drives PDFprathap394Belum ada peringkat

- Design For A Gate-Driver CircuitDokumen27 halamanDesign For A Gate-Driver Circuitdhruv100% (1)

- 7 GtoigctDokumen13 halaman7 Gtoigctmohammad2110959Belum ada peringkat

- Recent Developments of High Power Converters For Industry and Traction ApplicationsDokumen16 halamanRecent Developments of High Power Converters For Industry and Traction ApplicationsAris Sid AhmedBelum ada peringkat

- IR2137 IGBT Gate Driver Protects AC MotorsDokumen9 halamanIR2137 IGBT Gate Driver Protects AC MotorsMuMoMaBelum ada peringkat

- Matteini PHD Part3Dokumen28 halamanMatteini PHD Part3Jagabar SathikBelum ada peringkat

- Eee 5 Sem 71Dokumen71 halamanEee 5 Sem 71Navaneethaan NathamoorthyBelum ada peringkat

- Design SnubberDokumen29 halamanDesign Snubberriaancloete100% (2)

- MOSFET TutorialDokumen39 halamanMOSFET Tutorialnoor_dcetBelum ada peringkat

- Mosfet CharacteristicsDokumen12 halamanMosfet CharacteristicsNavaneethaan NathamoorthyBelum ada peringkat

- Malvino PrintDokumen6 halamanMalvino Printmary_nailynBelum ada peringkat

- Switching Regulator Applications: Absolute Maximum RatingsDokumen6 halamanSwitching Regulator Applications: Absolute Maximum RatingsJosé BenavidesBelum ada peringkat

- Procedure For Measuring N-ChannelDokumen20 halamanProcedure For Measuring N-ChannelMirnaBelum ada peringkat

- Tabela SMDDokumen80 halamanTabela SMDUdenir Jeus de moraisBelum ada peringkat

- Embedded System Lecture Notes by Prof. Dr. Surendra Shrestha SirDokumen698 halamanEmbedded System Lecture Notes by Prof. Dr. Surendra Shrestha SirAakura Pyakura50% (2)

- PS9305Dokumen20 halamanPS9305onafetsBelum ada peringkat

- Intelligent Power Device ICDokumen3 halamanIntelligent Power Device ICPedro IsmaelBelum ada peringkat

- SSCMDokumen10 halamanSSCMSachin ChauhanBelum ada peringkat

- Mahadevaswamy U B Analog Electronic Circuits A Simplified APDokumen720 halamanMahadevaswamy U B Analog Electronic Circuits A Simplified APkuttubuddinbaig100% (2)

- Lecture NotesDokumen28 halamanLecture NotesEE22M306 Manvi ChaudharyBelum ada peringkat

- JNTUA B. Tech Syllabus R15 Regulation II Year I Semester 2 1 Electrical Electronics Engineering EEEDokumen16 halamanJNTUA B. Tech Syllabus R15 Regulation II Year I Semester 2 1 Electrical Electronics Engineering EEEThulasi PrasadBelum ada peringkat

- 06163389Dokumen12 halaman06163389sudhirkmnBelum ada peringkat

- SiC MOS UIS Failure Mechanism of SiC Power MOSFETsDokumen5 halamanSiC MOS UIS Failure Mechanism of SiC Power MOSFETsterry chenBelum ada peringkat

- Bq20z45-r1 Liion Batt ManagementDokumen23 halamanBq20z45-r1 Liion Batt ManagementGBelum ada peringkat

- Full Line Condensed Catalog 1993-1994 Baneasa S.a..oDokumen67 halamanFull Line Condensed Catalog 1993-1994 Baneasa S.a..oMos Craciun75% (4)

- TPS51117 Single Synchronous Step-Down Controller: 1 Features 3 DescriptionDokumen33 halamanTPS51117 Single Synchronous Step-Down Controller: 1 Features 3 DescriptionlalukurniawanBelum ada peringkat

- Mosfet GateDokumen16 halamanMosfet GateAnton ChuprynBelum ada peringkat

- Review Questions Transistor and AmplifiersDokumen2 halamanReview Questions Transistor and AmplifiersJohn PHilip MaramagBelum ada peringkat

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Dokumen9 halamanOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezBelum ada peringkat

- Electronic Devices and Circuit TheoryDokumen18 halamanElectronic Devices and Circuit TheoryLuis QuinonesBelum ada peringkat

- LM1823 A High Quality TV Video I F Amplifier and Synchronous DetectorDokumen16 halamanLM1823 A High Quality TV Video I F Amplifier and Synchronous DetectorTitis PrasetyoBelum ada peringkat

- Datasheet 4128Dokumen7 halamanDatasheet 4128عبدالرحمن وعمر وشمس عبداللهBelum ada peringkat

- PHB 55n03lta Logic Level FetDokumen15 halamanPHB 55n03lta Logic Level FetyusufwpBelum ada peringkat

- High-Efficiency MOSFET for Motor Drives and Power ConversionDokumen7 halamanHigh-Efficiency MOSFET for Motor Drives and Power ConversionThongLeBelum ada peringkat

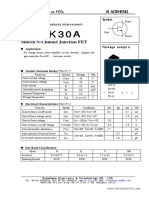

- K30a PDFDokumen1 halamanK30a PDFVictorManuelBernalBlancoBelum ada peringkat

- Digital Electronics Lab Manual: Prepared byDokumen48 halamanDigital Electronics Lab Manual: Prepared bysomesh chandrakarBelum ada peringkat

- HGTG30N60C3D: 63A, 600V, UFS Series N-Channel IGBT With Anti-Parallel Hyperfast Diodes FeaturesDokumen8 halamanHGTG30N60C3D: 63A, 600V, UFS Series N-Channel IGBT With Anti-Parallel Hyperfast Diodes FeaturesMarimuthu RajBelum ada peringkat

- SUD40N03-18P: Vishay SiliconixDokumen4 halamanSUD40N03-18P: Vishay SiliconixAlveant JuniorBelum ada peringkat

- 100V N-Channel Mosfets: General DescriptionDokumen5 halaman100V N-Channel Mosfets: General DescriptionMariusBelum ada peringkat

- MOSFET Lab ExperimentsDokumen19 halamanMOSFET Lab ExperimentsbilluzakBelum ada peringkat