Chapter 1 Oil Seal Introduction

Diunggah oleh

NCvetarskyDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chapter 1 Oil Seal Introduction

Diunggah oleh

NCvetarskyHak Cipta:

Format Tersedia

Chapter 1 Oil Seal Introduction

1.1 Introduction

Lip seal is one kind of contact type seals. During operation, lip seal is like other transmission elements (e.g. bearing or gear), which needs to establish a thin film to decrease wear and contact friction force between lip and shaft. So that the seal can maintain the sealing function and can have a longer life. In order to have a better understanding on oil seal, we will introduce some basic concepts and characteristics of lip seals below.

1.2 Seal introduction

The main function of a seal is to prevent the fluid (e.g. lubricant or air) to leak from shaft and housing. It can also prevent dust and mud to contaminate the housing. If dust and mud invade the housing, the life of transmission machinery will decrease greatly. The figure below is an illustration of a seal installed in one part of engine. In the early stage, the rotary shaft seal is made of leather. It is found that the rubber material properties for oil seal design is much better than leather. So that after the War , the seal made of rubber is widely used. In these two decades, automotive, aerospace, and other industries require the seals to resist higher temperature, pressure, and speed. This makes engineers have to do more research on material, structure, and function tests to improve the sealing function.

*Illustration of a seal installed in one part of an engine

1.3 Characteristics of rotary shaft lip seal

Characteristics of rotary shaft lip seal: (1) Prevent fluid leaking from shaft and housing, and prevent dust and mud to contaminate the housing. (2) Small torque, good sealing function. (3) Good resistance for high speed and high offset application. (4) Structure is simple and easy to take off from housing. (5) Good adaptation under many applications.

Housing

Seal

Bearing

Shaft

*Illustration of a seal installation

1.4 Applications

Seal is usually used in: tooling machine (e.g. lathe, planer, miller etc.), engineering machine (e.g. excavator, scraper, compacter etc.), transportation (e.g. car, motorcycle etc.), conveyance (e.g. crane etc.), chemical engineering (pump, compressor etc.), agriculture machine (cultivator, reaper etc.), others (tap, washing machine etc.). During machine operation, parts may contact directly. This will generate heat and parts would be worn. The lubricant is usually used to decrease wear and temperature. In order to prevent the lubricant

form leaking that cause reducing machine life, oil seal is necessary in the transportation system.

Rotary lip seals can be used in these areas: 1.Power system

2.Agriculture, mining, and heavy industry

3. National defense industry

4. Chemical engineering, water, electric power industry

5. 3C industry

6. Formula One

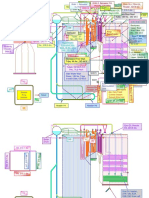

1.5 Seal main parts

Sealing function of rotary shaft lip seal can be divided into static and dynamic sealing. The figure below is the illustration of seal basic parts. Interference between seal outer dimension and housing will generate Press-fit which can prevent fluid from leaking. This is so-called static sealing. After the seal is installed on the rotating shaft, the shaft and seal inner dimension will generate Radial force which can prevent fluid leaking. This is so-called dynamic sealing. Seal is basically composed of three parts: (1) Rubber: A Rubber is usually used to be the seal material. B Lip rubber will contact shaft and form pressure C distribution on shaft. Different geometry seal design will form different pressure distribution. The pressure distribution must be correct so that the seal can have a good sealing function. (2) Case: The case can improve seal stiffness and sealing function. It also helps the seal to be installed correctly. (3) Garter Spring: It offers radial load for sealing lip, and it also can prolong the seal life. We have to consider shaft speed, shaft run-out and anticorrosive factors to select a proper garter spring.

1.6 Seal nomenclature

1

2 3 15

14 13 12 11

4 17 16 5 6 7 8 10 9

1. Seal Width 2. Outer Case 3. Outside Face 4. Dust Lip 5. Heel Section 6. Flex Section 7. Contact Line Height 8. Lip Height 9. Seal Inner Diameter

10. Spring Postion 11. Seal Outer Diameter 12. Spring Groove 13. Inside Face 14. Inner Case 15. Garter Spring 16. Outside Lip Angle 17. Inside Lip Angle

Anda mungkin juga menyukai

- RHH and LTSH links overviewDokumen4 halamanRHH and LTSH links overviewrpshvjuBelum ada peringkat

- New Moment WeightDokumen16 halamanNew Moment WeightRaj KiranBelum ada peringkat

- Thermal Power PlantDokumen13 halamanThermal Power PlantSanat KumarBelum ada peringkat

- 06 P F PlantDokumen161 halaman06 P F Planthirenkumar patelBelum ada peringkat

- Faf OmDokumen41 halamanFaf OmKRSRAMANBelum ada peringkat

- Poor Oil Gun Performance in BoilersDokumen3 halamanPoor Oil Gun Performance in BoilersRAPRATSINBelum ada peringkat

- Dome ValveDokumen6 halamanDome Valvesaisssms9116Belum ada peringkat

- SERIES 22.2: Heavy Duty Gear ReducersDokumen2 halamanSERIES 22.2: Heavy Duty Gear ReducersAmir KhanBelum ada peringkat

- 13 MW Steam Turbine 50 HZ NewDokumen6 halaman13 MW Steam Turbine 50 HZ Newteewee_cuteBelum ada peringkat

- Seal Oil and Hydrogen SystemDokumen34 halamanSeal Oil and Hydrogen Systemashish_ntpcBelum ada peringkat

- Understanding Air Preheater Performance: Storm Technologies, IncDokumen4 halamanUnderstanding Air Preheater Performance: Storm Technologies, IncMahesh MishraBelum ada peringkat

- Aditya Tech Diary PDFDokumen155 halamanAditya Tech Diary PDFSiddhant SatpathyBelum ada peringkat

- Full Pump InductionDokumen94 halamanFull Pump InductionPrathmesh LoharBelum ada peringkat

- Operation and Maintenance Manual of Hogging Vacuum Pump - 2BW5 400Dokumen197 halamanOperation and Maintenance Manual of Hogging Vacuum Pump - 2BW5 400AhmadBelum ada peringkat

- Improving Boiler Efficiency by Using Air PreheaterDokumen14 halamanImproving Boiler Efficiency by Using Air PreheaterBudiharyatno Arif PangestuBelum ada peringkat

- Turbine Part 5Dokumen15 halamanTurbine Part 5Dilip YadavBelum ada peringkat

- Axial Thrust Dummy PistonDokumen12 halamanAxial Thrust Dummy Pistondeevan rajBelum ada peringkat

- Chapter I General Information of Pump UnitDokumen42 halamanChapter I General Information of Pump UnitRahmat Budi HartantoBelum ada peringkat

- Coal Feeding System and Pulveriser OverviewDokumen15 halamanCoal Feeding System and Pulveriser OverviewSanjay GuptaBelum ada peringkat

- Bhel TrainingDokumen41 halamanBhel TrainingArun AroraBelum ada peringkat

- Coal FeederDokumen4 halamanCoal FeederJoydev GangulyBelum ada peringkat

- Boiler Feed PumpDokumen52 halamanBoiler Feed PumpArun Kumar100% (1)

- Steam Turbine 2 Types, Losses and CompundingDokumen9 halamanSteam Turbine 2 Types, Losses and Compundingdoomra50% (2)

- Turbines - New Module Hay PDFDokumen191 halamanTurbines - New Module Hay PDFThái Mai Đình100% (1)

- Jindal Power SOP Load Shedding RelayDokumen4 halamanJindal Power SOP Load Shedding RelayChandramani PatelBelum ada peringkat

- HR 1 - 2008Dokumen1.642 halamanHR 1 - 2008Jay Rameshbhai ParikhBelum ada peringkat

- Superheaters and ReheaterDokumen16 halamanSuperheaters and ReheaterBudi NortonBelum ada peringkat

- Boiler Inspector TRAINING - 2021Dokumen8 halamanBoiler Inspector TRAINING - 2021SUNIL BABURAO GAVADEBelum ada peringkat

- Regenerative Air PreheaterDokumen19 halamanRegenerative Air PreheaterPrakash100% (1)

- Dec 09Dokumen35 halamanDec 09Krishnan SanthanarajBelum ada peringkat

- Bhs PDF en RDVDokumen10 halamanBhs PDF en RDVolgiertBelum ada peringkat

- Hydraulic Turbine Shaft Coupling StandardDokumen21 halamanHydraulic Turbine Shaft Coupling Standardarvi_vinBelum ada peringkat

- Industrial Lubricants Product GuideDokumen29 halamanIndustrial Lubricants Product GuideChandra Kaladhara Rao KuntamukkalaBelum ada peringkat

- GENERator Auxilary System MonitoringDokumen10 halamanGENERator Auxilary System MonitoringdhirendracommonBelum ada peringkat

- IBR Sec 385 PDFDokumen9 halamanIBR Sec 385 PDFgokul_raamBelum ada peringkat

- DVC O&M Manual Axial FanDokumen291 halamanDVC O&M Manual Axial FanAmitava PalBelum ada peringkat

- 03 - Steam Turbines Types PDFDokumen49 halaman03 - Steam Turbines Types PDFVimleshKumarSharma100% (1)

- Coal FeedDokumen8 halamanCoal FeedaakashtrivediBelum ada peringkat

- SLS - APM - Assembly & Partslists Book OCTO 800 3E - Rev6 - 20110525Dokumen42 halamanSLS - APM - Assembly & Partslists Book OCTO 800 3E - Rev6 - 20110525Camilo Torres Fuentes100% (1)

- Losses in Steam TurbineDokumen7 halamanLosses in Steam Turbinemanjeet kumarBelum ada peringkat

- Bhel Block 3 Turbine FileDokumen35 halamanBhel Block 3 Turbine Filerajdeep6panchalBelum ada peringkat

- Seal Oil SystemDokumen38 halamanSeal Oil Systemnaresh977977100% (1)

- Nkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationDokumen7 halamanNkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationAbhishek KumarBelum ada peringkat

- Turbovisory SystemDokumen2 halamanTurbovisory SystemLily Sharma100% (1)

- Bhel Pipe Color Code-Aa10630 1Dokumen7 halamanBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniBelum ada peringkat

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Dokumen74 halamanPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikBelum ada peringkat

- Steam Turbine Description HP Turbine Casing Supports and GuidesDokumen2 halamanSteam Turbine Description HP Turbine Casing Supports and GuidesAmit MukherjeeBelum ada peringkat

- Fire Resistant Fluid Study on Deterioration of Physicochemical PropertiesDokumen34 halamanFire Resistant Fluid Study on Deterioration of Physicochemical Propertiesgolden430Belum ada peringkat

- VHB Presentation (Compatibility Mode) PDFDokumen21 halamanVHB Presentation (Compatibility Mode) PDFhirenkumar patelBelum ada peringkat

- Estudos de Casos - Revamps & Upgrades HOERBIGERDokumen11 halamanEstudos de Casos - Revamps & Upgrades HOERBIGERJoseBelum ada peringkat

- Gear Reference Guide: Types, Applications & Strength CalculationsDokumen15 halamanGear Reference Guide: Types, Applications & Strength CalculationsXuan Phuong HuynhBelum ada peringkat

- Combloc Multi-Fuel BoilerDokumen2 halamanCombloc Multi-Fuel BoilerPRABA KARAN100% (1)

- Final YearDokumen51 halamanFinal YearAnand Kumar0% (1)

- Chapter 1 Oil Seal IntroductionDokumen0 halamanChapter 1 Oil Seal IntroductionZMCONTROLBelum ada peringkat

- maintenancetechnology.com-Selecting the Correct Bearing SealDokumen3 halamanmaintenancetechnology.com-Selecting the Correct Bearing SealamolhwBelum ada peringkat

- Mechanical Seal Principles Manual - Chapter 1Dokumen28 halamanMechanical Seal Principles Manual - Chapter 1avciayBelum ada peringkat

- Dry Gas Seals ReportDokumen19 halamanDry Gas Seals ReportBilal Javed JafraniBelum ada peringkat

- Seal Off Centrifugal Pump ProblemsDokumen6 halamanSeal Off Centrifugal Pump ProblemsArturo Valles TerrazasBelum ada peringkat

- Tribological Problems and How To Reduce ThemDokumen4 halamanTribological Problems and How To Reduce ThemMark Nassef NaguibBelum ada peringkat

- U3l2s Seals - HosesDokumen18 halamanU3l2s Seals - HosespmcisissengueBelum ada peringkat

- FPB Nitrile U-CupsDokumen2 halamanFPB Nitrile U-CupsNCvetarskyBelum ada peringkat

- Coverseals enDokumen6 halamanCoverseals enNCvetarskyBelum ada peringkat

- V RingsDokumen16 halamanV RingsNCvetarskyBelum ada peringkat

- wcp20 enDokumen6 halamanwcp20 enNCvetarskyBelum ada peringkat

- DeclarationDokumen1 halamanDeclarationNCvetarskyBelum ada peringkat

- Case Study Cracked Oil Tanks Investigations Web PDFDokumen2 halamanCase Study Cracked Oil Tanks Investigations Web PDFyamakunBelum ada peringkat

- TMC 421 PDFDokumen82 halamanTMC 421 PDFJamie MooreBelum ada peringkat

- WPD Flotationdrying PDFDokumen19 halamanWPD Flotationdrying PDFVvbjBelum ada peringkat

- Inventory Management PreetDokumen28 halamanInventory Management PreetKawalpreet Singh MakkarBelum ada peringkat

- Equilibrium of A Particle, The Free-Body Diagram & Coplanar Force SystemsDokumen24 halamanEquilibrium of A Particle, The Free-Body Diagram & Coplanar Force SystemsAtef NazBelum ada peringkat

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDokumen7 halamanUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- Boundary Layer Thickness and Heat Transfer CalculationsDokumen9 halamanBoundary Layer Thickness and Heat Transfer Calculationsannie100% (1)

- Catálogo King LaiDokumen144 halamanCatálogo King LaiJason Salas FloresBelum ada peringkat

- MIMO Channel CapacityDokumen9 halamanMIMO Channel CapacityGendyBelum ada peringkat

- CFS50 motor feedback installation instructionsDokumen1 halamanCFS50 motor feedback installation instructionsJavier AlzateBelum ada peringkat

- The Sperry Bombsight: A Pioneering Rival to NordenDokumen6 halamanThe Sperry Bombsight: A Pioneering Rival to NordenPaul DupontBelum ada peringkat

- Huawei EHuawei - Erelay - Solution - OverviewRelay Solution OverviewDokumen31 halamanHuawei EHuawei - Erelay - Solution - OverviewRelay Solution Overviewtariq8283% (6)

- Hino 500S Catalog LR PDFDokumen8 halamanHino 500S Catalog LR PDFZulBelum ada peringkat

- 2014 Solder Joint ReliabilityDokumen18 halaman2014 Solder Joint ReliabilitychoprahariBelum ada peringkat

- Manual Servicio SubaruDokumen5.963 halamanManual Servicio SubaruCristian Mauricio Alarcon RojasBelum ada peringkat

- Rockaway Beach Branch Community Impact StudyDokumen98 halamanRockaway Beach Branch Community Impact StudyHanaRAlbertsBelum ada peringkat

- Munsell Color Charts and GaugesDokumen2 halamanMunsell Color Charts and GaugesMario DalengkadeBelum ada peringkat

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Dokumen3 halamanLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifBelum ada peringkat

- January2016page1to36 Layout 1Dokumen36 halamanJanuary2016page1to36 Layout 1c737Belum ada peringkat

- False Ceiling Construction Details PDFDokumen2 halamanFalse Ceiling Construction Details PDFAlexis17% (6)

- Sinusverteiler Multivalent SolutionsDokumen13 halamanSinusverteiler Multivalent SolutionsIon ZabetBelum ada peringkat

- Pressure Vessel Rivets Welded Joints MDSP PrimeDokumen16 halamanPressure Vessel Rivets Welded Joints MDSP PrimeIvanBelum ada peringkat

- Final ReportDokumen33 halamanFinal ReporttsutsenBelum ada peringkat

- 49 CFR Ch. I (10-1-11 Edition) 173.318Dokumen5 halaman49 CFR Ch. I (10-1-11 Edition) 173.318MauricioBelum ada peringkat

- Racecar Engineering - September 2015Dokumen100 halamanRacecar Engineering - September 2015MrRipleiBelum ada peringkat

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Dokumen227 halamanVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladBelum ada peringkat

- MI MetadataDokumen310 halamanMI MetadataMatthew McCreadyBelum ada peringkat

- Stationary Concrete Pumps en G 16345-0 PDFDokumen20 halamanStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PAROBelum ada peringkat

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeDokumen6 halamanGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanBelum ada peringkat

- Anchors and Fall Arrest System A Guide To Good Practice: PublicationDokumen22 halamanAnchors and Fall Arrest System A Guide To Good Practice: PublicationEdward C100% (1)