Cad/cam From Cipet

Diunggah oleh

Ap Mani MaranDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cad/cam From Cipet

Diunggah oleh

Ap Mani MaranHak Cipta:

Format Tersedia

CENTRAL INSTITUTE OF PLASTICS ENGINEERING AND TECHNOLOGY (CIPET) (Ministry of Ch emicals and Fertilizers, Govt.

of India) Guindy, Chennai - 600 032 CAD/CAM/CAE Software Training Programmes in CIPET, Chennai 1. CAD PROGRAMMES 1.1 CAD USING UNIGRAPHICS Fee: Rs 10,000/- Duration: 100 hrs Modeling: Introduction, Sketch, Curve, Curve Operations, Form Feature, Feature O peration, Transform. Assembly: Assembly of Components, Exploded Views, Sequencing, Context Control, C loning and Component arrays editing, Top Down Assembly. Drafting: Drawing sheets, Views, Dimensioning, Annotations, Symbols, Tabular not e and Part list. 1.2 CAD USING PRO/E Fee: Rs 10,000/- Duration: 100 hrs Part Modeling: Introduction, Sketch, Base features, datum features, sections in sketch based features, Edit feature, engineering features, construction features , advanced features, tweak feature, UDFs & Group, Relation & family Table, Resol ving feature failures Pro/Assembly: Creating Assemblies, placing, pattering, packaging, freeform Manip ulation of components, Top Down Assemblies, Exploded view. Pro/Detail: Drafting basics, creating a Drawing with Model views, Dimensioning & Detailing, Tables & BOM Balloons 1.3 CAD USING CATIA Fee: Rs 10,000/- Duration: 100 hrs 3 D Part Modeling: Introduction to GUI, Sketcher, Constraints, sketch-based feat ures, Dress up features, Transformation features, Associating bodies with Boolea n Operations, Reference Elements, Modifying Features. Assembly Design: Creating assembly, Manipulating components in assembly, Assembl y constraints, Exploded view, Clash checking, Assembly features, Scene creation, Using Mechanical Standard parts, Top Down Assembly. Drafting: Generative Drafting, Interactive Drafting, Creating Views, Sections, B OM Generation. 1.4 CAD USING I-DEAS Fee: Rs 10,000/- Duration: 100 hrs 3D Modeling: Sketching, Constraining, Catalogs and Parameterized parts, Creating features, Advance features, Feature operations, Construction operations, Surfac e techniques, Bin and Library Management Assembly: Top Down and Bottom Up, Sequencing & animation, Patterning, Exploded V iews, Introduction to Mechanism design. Drafting: Associative and Non-associative Dimensioning, Views and Dimensions, Ut ility Symbols, Bill of Material 2. CAD/CAM PROGRAMMES 2.1 CAD/CAM USING UNIGRAPHICS Fee: Rs 18,000/- Duration: 200 hrs Modeling: Introduction, Sketch, Curve, Curve Operations, Form Feature, Feature O peration, Transform. Assembly: Assembly of Components, Exploded Views, Sequencing, Context Control an d Cloning and Component arrays editing, Top Down Assembly. Drafting: Drawing sheets, Views, Dimensioning, Annotations, Symbols, Tabular not e and Part list. Direct Modeling Free form feature: Sheets from points, Making sheets from variable cross section s, Bridging, Offsetting, Filleting & Trimming sheets Sheet Metal feature: Tab, Flange, Break corner, closed corner, Normal cutout, Jo g, Bend, Dimple, Bead, Unbend, Rebend, Edge rib, flat solid. Manufacturing: Model Creation, Tool Selection, Geometry Definition, Machining Me thods, Planer Milling and Contour milling Operations and Post Processing. 2.2 CAD/CAM USING PRO/E Fee: Rs 18,000/- Duration: 200 hrs

Part Modeling: Introduction, Sketch, Base features, datum features, sections in sketch based features, Edit feature, Engineering features, Construction features , Advanced features, Tweak feature, UDFs & Group, Relation & family Table, Resol ving feature failures Pro/Assembly: Creating Assemblies, placing, patterning, packaging, freeform Mani pulation of components, Top Down Assemblies, Exploded view. Pro/Detail: Drafting basics, creating a Drawing with Model views, Dimensioning & Detailing, Tables & BOM Balloons Pro/Surface: Creating a Surface Feature, Trimming Quilts, Flattening & Bending, Creating Solid Geometry Using Quilt, Freeform Surfaces, Boundary, Conic surface and N-sided patch, style tools Pro/ Sheetmetal: Introduction creates conversion, wall, rip, cut, form, flatten form, notch punch, and bend, unbend, bend back, corner relief, deform, edge bend . Pro/Mold design: Introduction, Reference & work pieces, Mold Parting surfaces, M old volumes, Extracting Mold components, split components. Pro/NC: Manufacturing Process & Parameters, Tooling, NC sequence-Milling & Lathe -turning, CL Data, NC sequence Definition, Creation of CL Data File, NC Post Pro cessing. 2.3 CAD/CAM USING CATIA Fee: Rs 18,000/- Duration: 200 hrs Part Modeling: Introduction to GUI, Sketcher, Constraints, sketch-based features , Dress up features, Transformation features, Associating bodies with Boolean Op erations, Reference Elements, Modifying Features. Assembly Design: Creating assembly, Manipulating components in assembly, Assembl y constraints, Exploded view, Clash checking, Assembly features, Scene creation, Using Mechanical Standard parts, Top Down Assembly. Drafting: Generative Drafting, Interactive Drafting, Creating Views, Sections, B OM Generation. Surface Design: Wire frame geometry creation, Basic surface, Operations on surfa ce, advanced surface, Surface based features in Part design. Sheet metal: Introduction, Sheet Metal Parameters, Creating the Side Walls, Cuto ut, Automatic Bends. Mold Design: Core cavity separation, Basic mold design. Manufacturing: Basic Tasks, Part operations, Programs & Processes, Managing Manu facturing Entities, Verification, Simulation and NC Code generation. 2.4 CAD/CAM USING I-DEAS Fee: Rs 18,000/- Duration: 200 hrs 3D Modeling: Sketching, Constraining, Catalogs and Parameterized parts, Creating features, Advance features, Feature operations, Construction operations, Surfac e techniques, Bin and Library Management Assembly: Top Down and Bottom Up, Sequencing & animation, Patterning, Exploded V iews, Introduction to Mechanism designs. Drafting: Associative and Non-associative Dimensioning, Views and Dimensions, Ut ility Symbols, Bill of Material Simulation: Basics & General Analysis procedure, Free and mapped meshing, Qualit y check, linear, non-linear and variational analysis Manufacturing: Model Creation, Operation and Tool Selection, Generation CL File, Post Processing. 3.CAE PROGRAMMES 3.1 CAE USING HYPERWORKS Fee: Rs 15,000/- Duration: 160 hrs Hypermesh: Basic modeling, Geometry cleanup, Organizing the model with collector s, Extracting mid surfaces & simplifying, Selecting the user Profiles, Project, Numbering, Mask, Normals, Interactive surface meshing, Element density, Algorith ms, Checking element quality. Introduction to solid meshing: Solid panels, Drag, spin, Line drag, element offset, linear solid. Optistruct- Linear Static Analysis, Thermal Analysis, Modal Analysis, Harmonic A nalysis, Inertia Relief Analysis. Optimization- Topology, optimization for solid problems, Optimization for stress

problems. Hypermorph- morph volumes, Morph to geometry, freehand morph, morph options Hypergraph, hyperview, Batch mesher. 3.2 CAE USING ANSYS Fee: Rs 15,000/- Duration: 160 hrs Introduction to FEA & ANSYS: GUI, Basics & general analysis procedure. Modeling: Creating Solid model, Finite element modeling and importing models, Se lect Entities and Component manager. Meshing: Quad and Tetrahedron mesh, Volumes, Areas, Line meshing. Free and mappe d meshing, check mesh. Structural Analysis: Static, Modal, Harmonic, Spectrum, p-method, Nonlinear & Tr ansient analysis. Thermal Analysis: Steady state thermal analysis. ANSYS Workbench: Simulation, CFX Mesh, Engineering Data sheet and FE modeler. Report generation. 3.3 CAE USING LS-DYNA Fees: Rs. 15,000/- Duration: 100 hrs Theory: Introduction to basic concepts of FEA, Contact Analysis, Linear and NonLinear analysis. FEA Terminologies used in LS-Dyna: ALE, SPH. Analysis: Larger Deflection Dynamics, Crash Analysis, Occupant Safety, Impact An alysis and Failure Analysis. Post Processing-using Hyperview. Prerequisite: knowledge of FEA and Hypermesh 8.0. 3.4 CAE USING MOLDFLOW Fees: Rs 15,000/- Duration: 120 hrs Introduction to CAE: Basics of Plastics Product Design, Moldflow Modeling, Mesh Creation, Mesh Checking, Surface repair tools, Creating Feed system and cooling system. Meshing Tools: create Node, curves, regions, move/copy, nodal mesh tools, edge m esh tools & check mesh diagnostics Modules: Mid plane, Fusion and 3D Solid. Analysis: Gate location, Fill, Flow, Cool, Pack, Warp, Shrinkage, molding window , Case Study. Pre-requisite: Plastics & Mold knowledge. 3.5 CAE USING PRO-MECHANICA Fees: Rs 15,000/- Duration: 160 hrs Syllabus of CAD Using Pro/E Plus Pro/Mechanica Basic Mechanica: Static Structural Analysis, Modal Analysis, Buckling and Steady state Thermal. Advanced Mechanica: Vibrational Analysis, Dynamic and Time involving Analysis. Post-Processing Using Pro/E. 4.MOLD PROGRAMMES 4.1UNIGRAPHICS MOLD WIZARD Fees: Rs 10,000/- Duration: 80 hrs Refreshing the part modeling, assembly and drafting. Mold wizard: Loading Product, Family Mould, Shrinkage, Work piece, Layout, Mould Tools, Parting, Mould Base, Standard Parts, Slider lifter, Ejector pin, Runner, Gate, Cooling, Insert, Electrode, Mold trim, Bill of material, Mould Drawing. Prerequisite: Unigraphics & Mold Design Knowledge 4.2 CAD USING UNIGRAPHICS WITH MOLD WIZARD Fees: Rs 15,000/- Duration: 160 hrs Syllabus of CAD Using Unigraphics Mold wizard: Loading Product, Family Mould, Shrinkage, Work piece, Layout, Mould Tools, Parting, Mould Base, Standard Parts, Slider lifter, Ejector pin, Runner, Gate, Cooling, Insert, Electrode, Mold trim, Bill of material, Mould Drawing. Prerequisite: Mold Design Knowledge. 4.3 CAD/CAM USING UNIGRAPHICS WITH MOLD WIZARD Fees: Rs 24,000/- Duration: 260 hrs Syllabus of CAD/CAM Using Unigraphics

Mold wizard: Loading Product, Family Mould, Shrinkage, Work piece, Layout, Mould Tools, Parting, Mould Base, Standard Parts, Slider lifter, Ejector pin, Runner, Gate, Cooling, Insert, Electrode, Mold trim, Bill of material, Mould Drawing. Prerequisite: Mold Design Knowledge. 4.4 PRO/MOLD Fees: Rs 10,000/- Duration: 80 hrs Refreshing the part modeling, assembly and drafting. Pro/Moldesign: Introduction, Mold design sequence, Reference & work pieces, Draf t Checking, Applying Shrinkage, Creation Of Parting Surface, Splitting to Volume , Runner & Waterlines, Molding, Mold Opening Process, Mold Layout, Injection Mol ding Machine, Catalogs. Prerequisite: Pro/E & Mold Design Knowledge. 4.5 CAD USING PRO/E WITH PROMOLD Fees: Rs 15,000/- Duration: 160 hrs Syllabus of CAD Using Pro-E Pro/Mold: Introduction, Mold design sequence, Reference & work pieces, Draft Che cking, Applying Shrinkage, Creation Of Parting Surface, Splitting to Volume, Run ner & Waterlines, Molding, Mold Opening Process, Mold Layout, Injection Molding Machine, Catalogs Prerequisite: Mold Design Knowledge. 4.6 CAD/CAM USING PRO/E WITH PROMOLD Fees: Rs 24,000/- Duration: 260 hrs Syllabus of CAD/CAM Using Pro-E Pro/Mold: Introduction, Mold design sequence, Reference & work pieces, Draft Che cking, Applying Shrinkage, Creation Of Parting Surface, Splitting to Volume, Run ner & Waterlines, Molding, Mold Opening Process, Mold Layout, Injection Molding Machine, Catalogs Prerequisite: Mold Design Knowledge. 5. MULTI software PROGRAMMES - (20% concession) Selection of More than one Programme from Sl. No 1 to 4 6. SPECIAL PROGRAMME 6.1 CAD/CAM USING CATIA WITH REVERSE ENGINEERING Fee: Rs 24000 /- Duration: 260 hrs Part Modeling: Introduction to GUI, Sketcher, Constraints, sketch-based features , Dress up features, Transformation features, Associating bodies with Boolean Op erations, Reference Elements, Modifying Features. Assembly Design: Creating assembly, Manipulating components in assembly, Assembl y constraints, Exploded view, Clash checking, Assembly features, Scene creation, Using Mechanical Standard parts, Top Down Assembly. Drafting: Generative Drafting, Interactive Drafting, Creating Views, Sections, a nd BOM Generation. Surface Design: Wire frame geometry creation, Basic surface, Operations on surfa ce, advanced surface, Surface based features in Part design. Sheet metal: Introduction, Sheet Metal Parameters, Creating the Side Walls, Cuto ut, Automatic Bends. Mold Design: Core cavity separation, Basic mold design. Manufacturing: Basic Tasks, Part operations, Programs & Processes, Managing Manu facturing Entities, Verification, Simulation and NC Code generation. Reverse Engineering: Basics concept, theoretical method of reverse engineering, Training on conventional measuring method, training on CMM, digitized shape edit or, generative shape design, Quick surface reconstruction, free style, and proje ct work. SHIF TIMINGS for all above said courses Timing No. of working hours 06:00 A.M to 10:00 A.M 4 Hours 06:00 A.M to 02:00 A.M 8 Hours 06:00 A.M to 06:00 P.M

12 Hours 06:00 A.M to 10:00 P.M 16 Hours 02:00 P.M to 10:00 P.M 8 Hours 06:00 P.M to 10:00 P.M 4 Hours 06:00 A.M to 06:00 P.M Saturday Batch (12 hours) 06:00 A.M to 06:00 P.M Saturday & Sunday Batch (12 hours) 10:00 P.M to 06:00 A.M 8 hours - Night Batch (Monday to Saturday) Concession in Course Fee# (From Sl. No.1 to 4 &6) SC/ST/BC/MBC/Physically Challenged : 10% Fresh Diploma Holders / Engineers : 10% Women : 15% Students (Colleges/Polytechnics) & Alumni of CIPET : 20% Night Batch (All candidates) -(10:00 PM to 6:00 AM) : 25% CIPET Students/Trainees (LTC) : 50% # conditions apply 7. PLACEMENT ASSISTED PROGRAMMES** (Full time 8 hrs / day (1st or 2nd shift) 7.1 Masters Programme in Product Development with CAD/CAM/CAE (Full time 8 hrs / day) Course code: MPPD-CAD Fee: Rs.75000/- Duration: 4Months Course contents: 4 softwares MODULE- I (ALL software) As per Sl. No.2 [CAD/CAM Programmes (Pro-E, UG & CATIA)] plus As per Sl. No. 4 [ Mold Programmes] MODULE -II (Any ONE software) Ansys/Hyperworks/LS-Dyna /Moldflow MODULE III (Project Work) MODULE -IV (Theory Classes) Plastics Product & Mould Design, Jigs&Fixtures, Sheet Metal, CNC, CBT, Rapid Pro totyping and Reverse Engineering. Course Highlights *Latest Software * Balanced Theory & Practical Classes *Product Development Conc epts * Personality Development Programme * Certificate awarded by CIPET. Eligibility: Diploma / Degree in Mechanical/Production/Polymer/Auto mobile/Aeron autical/Tool engineering/equivalent candidates aspiring to start the career in R &D and product development. 7. 2 Advanced Masters Programme in CAD/CAM/CAE (Full time) Course code: AMP-CAD Fee: Rs. 90,000/- Duration: 4 months + two months in-plant training Stipend: Rs. 5000/- per month during the first 4 months training programme] Date of written test/ interview /admission : Last Monday of Everymonth Course commencement : Subsequent First Monday of Everymonth Written test venue : CIPET, Guindy, Chennai Course contents: 4 softwares MODULE- I (ALL software) As per Sl. No.2 [CAD/CAM Programmes (Pro-E, UG & CATIA)] plus As per Sl. No. 4 [ Mold Programmes] MODULE -II (Any ONE software) Ansys/Hyperworks/LS-Dyna /Moldflow MODULE III (Project Work) MODULE -IV (Theory Classes) Plastics Product & Mould Design, Jigs&Fixtures, Sheet Metal, CNC, CBT, Rapid Pro totyping and Reverse Engineering.

Course Highlights *Latest Software * Balanced Theory & Practical Classes *Product Development Conc epts * Personality Development Programme * Certificate awarded by CIPET. Eligibility: Degree in Mechanical/Production/Polymer/Auto mobile/Aeronautical/To ol engineering/equivalent candidates aspiring to start the career in R&D and pro duct development. Selection: Eligible candidates have to appear in the entrance exam and the short listed candidates will be interviewed for final selection. 7.3 INTEGRATED ENGINEERING SOFTWARE PROGRAMME ON AUTOMOBILE & AEROSPACE PRODUCT DEVELOPMENT WITH CAD/CAM/CAE (Full Time) (Course code: IES - PAAP -CAD) Fee: Rs.1.0 lakh; Duration: 6 months Stipend: Rs. 5000/- p.m during training for 6 months Date of written test/ interview /admission : Last Monday of Everymonth Course commencement : Subsequent First Monday of Everymonth Written test venue: CIPET, Chennai Course contents: 7 softwares MODULE- I (ALL software) As per Sl. No.2 [CAD/CAM Programmes (Pro-E, UG & CATIA)] plus As per Sl. No. 4 [ Mold Programmes] MODULE -II (ALL software) Ansys/Hyperworks/LS-Dyna /Moldflow MODULE III(Project Work) MODULE -IV (Theory Classes) Plastics Product & Mould Design, Jigs&Fixtures, Sheet Metal, CNC, CBT, Rapid Pro totyping and Reverse Engineering. Course Highlights Latest Software Balanced Theory & Practical Classes Product Development Concepts Pe rsonality Development Programme Certificate awarded by CIPET. Eligibility: B.E/B.Tech/M.E/M.Tech in Mech./Prodn/Auto/Aero/Polymer/Plastics/Too l /Die Making or equivalent Written test venue: CIPET, Chennai Selection: Eligible candidates have to appear in the entrance exam and the short listed candidates will be interviewed for final selection. ** Conditions apply. 8. Tailor Made Programmes CORPORATE Personals on CAD/CAM/CAE Softwares* Course Fee, Duration, Period, Syllabus will be decided on mutual discussion For further details / HOW TO APPLY: e-mail/write/send to: cadcamcaecipetchennai@yahoo.com cipetchn@eth.net The Deputy Director, CIPET, Guindy, Chennai 600 032 Ph: 044-22254701 706 (6 lines), Extn: 540, 470, 700; 044-22254709 Fax: 044-22254707, Mobile: 09677123886 www.cipet.gov.in Mode of Payment 1. Cash at Accounts Section , CIPET, Chennai (or) 2. Demand Draft in favour of CIPET, Chennai Alongwith REGISTRATION FORM which is to be obtained in person at CAD/CAM/CAE cen tre. However advance registration can be done for admission in Sl. No. 1 to 6 and 7.1 with requisition letter addressed to: DEPUTY DIRECTOR, CIPET, Guindy, Chennai 600 032

Anda mungkin juga menyukai

- Chap 008Dokumen69 halamanChap 008jjseven22100% (1)

- A Study On Operation Management of Zara, Benetton and H&MDokumen20 halamanA Study On Operation Management of Zara, Benetton and H&MQi Rui100% (3)

- Cadcamcae Course Cipet Chennai - 25!10!2011Dokumen10 halamanCadcamcae Course Cipet Chennai - 25!10!2011ameer8033Belum ada peringkat

- Courses Fees Detail Pamphlet PDFDokumen2 halamanCourses Fees Detail Pamphlet PDFRajkumar ABelum ada peringkat

- Cadcamcae Course Cipet Chennai - 28!10!2015Dokumen15 halamanCadcamcae Course Cipet Chennai - 28!10!2015PraveenKDBelum ada peringkat

- About Cipet: 1. Cad ProgrammesDokumen10 halamanAbout Cipet: 1. Cad ProgrammesGautam TyagiBelum ada peringkat

- Inplant Training Modules & Course ContentsDokumen3 halamanInplant Training Modules & Course ContentsAdi MachhiBelum ada peringkat

- IFS Academy Certified Design Engineer Program: (With 100% Placement Assistance)Dokumen4 halamanIFS Academy Certified Design Engineer Program: (With 100% Placement Assistance)ManjotBelum ada peringkat

- Advanced Diploma in CAD - CAEDokumen2 halamanAdvanced Diploma in CAD - CAETaruun VaiddyaBelum ada peringkat

- Advanced Diploma in CAD/CAM: (With 100% Placement Assistance)Dokumen4 halamanAdvanced Diploma in CAD/CAM: (With 100% Placement Assistance)Harshad Pawar PatilBelum ada peringkat

- MFG1 & MFG2Dokumen4 halamanMFG1 & MFG2Hemant KumawatBelum ada peringkat

- Advanced Diploma in CADDokumen3 halamanAdvanced Diploma in CADSHUBHAM ADEPBelum ada peringkat

- Me - 1 Gtu Cad/cam SyllabusDokumen3 halamanMe - 1 Gtu Cad/cam SyllabusKumar BhattBelum ada peringkat

- Cadcam LabDokumen83 halamanCadcam LabRachit VemulaBelum ada peringkat

- ME Mechanical Engineering - CAD-CAMDokumen29 halamanME Mechanical Engineering - CAD-CAMDilip SutariaBelum ada peringkat

- MODIFIED CAD CAM - 4year 1sem PDFDokumen56 halamanMODIFIED CAD CAM - 4year 1sem PDFSatya AruntejaBelum ada peringkat

- Application of An Integrated CAD/CAE/CAM System For Stamping Dies For AutomobilesDokumen14 halamanApplication of An Integrated CAD/CAE/CAM System For Stamping Dies For AutomobilesSugan Prabhu100% (1)

- CAD For Product DevelopmentDokumen1 halamanCAD For Product DevelopmentHasham ZaidiBelum ada peringkat

- SyllabusDokumen3 halamanSyllabusAnonymous 4h9p1EIQYSBelum ada peringkat

- Oil & Gas CompaniesDokumen5 halamanOil & Gas CompaniesSunilkumar GrBelum ada peringkat

- 15AE308J - Design Lab Manual New 2020Dokumen43 halaman15AE308J - Design Lab Manual New 2020rushan ahmedBelum ada peringkat

- ME170 Syllabus PDFDokumen2 halamanME170 Syllabus PDFjayeshBelum ada peringkat

- School of Engineering & Technology Computer Aided DesignDokumen2 halamanSchool of Engineering & Technology Computer Aided DesignHitesh GahlawatBelum ada peringkat

- Pgdi (Cad Cam Cae) Semester IDokumen7 halamanPgdi (Cad Cam Cae) Semester IPRADEEP NBelum ada peringkat

- Advance Diploma in Computer Aided Engineering (CAE) : (With 100% Placement Assistance)Dokumen4 halamanAdvance Diploma in Computer Aided Engineering (CAE) : (With 100% Placement Assistance)Harshad Pawar PatilBelum ada peringkat

- Cadcamcae Course Cipet Chennai 03-04-2017Dokumen10 halamanCadcamcae Course Cipet Chennai 03-04-2017gayatripackiaBelum ada peringkat

- Stamping CAD-CAE Design General GuidelinesDokumen14 halamanStamping CAD-CAE Design General Guidelinesjcastellon14370Belum ada peringkat

- CAD Exrecise BookDokumen90 halamanCAD Exrecise BookPrashant NarwadeBelum ada peringkat

- Cad Cam Cae Course Cipet Chennai - 04012013Dokumen12 halamanCad Cam Cae Course Cipet Chennai - 04012013Murali KrishnanBelum ada peringkat

- PDMS Course SyllabusDokumen3 halamanPDMS Course SyllabusBalu MuruganBelum ada peringkat

- Computer Aided Design - Computer Aided Manufacturing - CADCAM Course OutlineDokumen2 halamanComputer Aided Design - Computer Aided Manufacturing - CADCAM Course OutlinecjBelum ada peringkat

- Gujarat Technological University: Page 1 of 3Dokumen3 halamanGujarat Technological University: Page 1 of 3jpbhimaniBelum ada peringkat

- CAD CAM AutomationDokumen4 halamanCAD CAM AutomationTiago LopesBelum ada peringkat

- Professional Engineering Training Institute (P.E.T.I) : SR - No Workshop Workshop Contents Duration Fees Per StudentDokumen1 halamanProfessional Engineering Training Institute (P.E.T.I) : SR - No Workshop Workshop Contents Duration Fees Per StudentAmit NirmalBelum ada peringkat

- Question Bank - Cad Cam CaeDokumen12 halamanQuestion Bank - Cad Cam CaePravin DahalkeBelum ada peringkat

- SEP Course Book PDFDokumen36 halamanSEP Course Book PDFfandhiejavanov2009Belum ada peringkat

- Unmesh Vaidya: Curriculum-VitaeDokumen3 halamanUnmesh Vaidya: Curriculum-VitaeUnmesh VaidyaBelum ada peringkat

- Syllabus: ME2309 Cad/Cam Lab LTPC 0 0 3 2 ObjectivesDokumen26 halamanSyllabus: ME2309 Cad/Cam Lab LTPC 0 0 3 2 ObjectivesSenthilkumar SubbiahBelum ada peringkat

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161903Dokumen3 halamanGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161903Bhavesh PatelBelum ada peringkat

- Computer Aided Designing: Course Code: BTM 705 Credit Units: 03 Course ObjectiveDokumen1 halamanComputer Aided Designing: Course Code: BTM 705 Credit Units: 03 Course ObjectiveSanjay GomastaBelum ada peringkat

- Course Name: Catia Mechanical Designer (ADV) Duration: 104 Hrs. SyllabusDokumen2 halamanCourse Name: Catia Mechanical Designer (ADV) Duration: 104 Hrs. SyllabusVinay TungeBelum ada peringkat

- MEC435 Chapter1 v1.1 PDFDokumen47 halamanMEC435 Chapter1 v1.1 PDFSyed AzzizBelum ada peringkat

- SEM VII Syllabus 5Dokumen1 halamanSEM VII Syllabus 5Nishikant KulkarniBelum ada peringkat

- Cad SyllabusDokumen2 halamanCad Syllabusmuru0105Belum ada peringkat

- Boom Bucket2Dokumen6 halamanBoom Bucket2Praveen KumarBelum ada peringkat

- Advanced Diploma in CADDokumen3 halamanAdvanced Diploma in CADAmr AminBelum ada peringkat

- B.Tech. (Mech.) Fourth Year Syllabus (REVISED)Dokumen64 halamanB.Tech. (Mech.) Fourth Year Syllabus (REVISED)bawincipetBelum ada peringkat

- CAD CAM and CAE Course OutlineDokumen3 halamanCAD CAM and CAE Course Outlinedejenem398Belum ada peringkat

- CAD CAM SyllabusDokumen2 halamanCAD CAM SyllabusDeepak AwasthiBelum ada peringkat

- CAD and Its ApplicationsDokumen51 halamanCAD and Its ApplicationsDennis Padec BwochengoBelum ada peringkat

- BE Mechanical-Mumbai UniversityDokumen82 halamanBE Mechanical-Mumbai UniversityJayesh NavareBelum ada peringkat

- Gujarat Technological University: Computer Aided Design SUBJECT CODE: 3710802Dokumen3 halamanGujarat Technological University: Computer Aided Design SUBJECT CODE: 3710802Bamania ChiragBelum ada peringkat

- ME1355-CAD / CAM Laboratory: Lab ManualDokumen42 halamanME1355-CAD / CAM Laboratory: Lab ManualVeeria Chandran S100% (1)

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsDari EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsBelum ada peringkat

- Up and Running with AutoCAD 2012: 2D Drawing and ModelingDari EverandUp and Running with AutoCAD 2012: 2D Drawing and ModelingPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- AutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionDari EverandAutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionBelum ada peringkat

- SolidWorks 2017 Black Book: SolidWorks Black BookDari EverandSolidWorks 2017 Black Book: SolidWorks Black BookPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- AutoCAD 2019: A Problem - Solving Approach, Basic and Intermediate, 25th EditionDari EverandAutoCAD 2019: A Problem - Solving Approach, Basic and Intermediate, 25th EditionBelum ada peringkat

- Up and Running with AutoCAD 2020: 2D Drafting and DesignDari EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignBelum ada peringkat

- Indian Navy English DavpDokumen1 halamanIndian Navy English DavpSushil KumarBelum ada peringkat

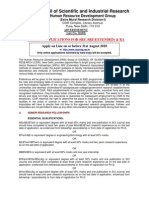

- Council of Scientific and Industrial Research: Inviting Applications For SRF, SRF (Extended) & RaDokumen6 halamanCouncil of Scientific and Industrial Research: Inviting Applications For SRF, SRF (Extended) & Radeepanwitadas14815Belum ada peringkat

- Council of Scientific and Industrial Research: Inviting Applications For SRF, SRF (Extended) & RaDokumen6 halamanCouncil of Scientific and Industrial Research: Inviting Applications For SRF, SRF (Extended) & Radeepanwitadas14815Belum ada peringkat

- Factors Affecting General AviationDokumen9 halamanFactors Affecting General AviationAp Mani MaranBelum ada peringkat

- Mechanical EngineeringDokumen40 halamanMechanical EngineeringRms MaliBelum ada peringkat

- AME SyllabusDokumen36 halamanAME SyllabusAp Mani MaranBelum ada peringkat

- TQM PhilosophyDokumen2 halamanTQM PhilosophyRobert JacksonBelum ada peringkat

- The Prince2 Process Model Diagram: Directing A Project (DP)Dokumen5 halamanThe Prince2 Process Model Diagram: Directing A Project (DP)Antonio RodriguesBelum ada peringkat

- EOQ ProblemsDokumen3 halamanEOQ Problemstomtomtom77750% (4)

- Content: Supply Network Collaboration Planning ProcurementDokumen23 halamanContent: Supply Network Collaboration Planning ProcurementChinky RajBelum ada peringkat

- Mapa ConceptualDokumen1 halamanMapa ConceptualManuel PerezBelum ada peringkat

- Acc Topic 8Dokumen2 halamanAcc Topic 8BM10622P Nur Alyaa Nadhirah Bt Mohd RosliBelum ada peringkat

- Qms 035 SampleDokumen0 halamanQms 035 SamplenikjadhavBelum ada peringkat

- Marginal Costing: Shikha SharmaDokumen13 halamanMarginal Costing: Shikha Sharmadeepakarora201188Belum ada peringkat

- Final Case Study PPT (College)Dokumen24 halamanFinal Case Study PPT (College)dhurjotic9100% (2)

- Lecture11 Limit, Fit & Tolerance BETP2503 Sem1 2015-2016 PDFDokumen46 halamanLecture11 Limit, Fit & Tolerance BETP2503 Sem1 2015-2016 PDFArecap CoolBelum ada peringkat

- CMA - Volume 1Dokumen181 halamanCMA - Volume 1Abdul QaviBelum ada peringkat

- SE362 SoftwareProjectManagementDokumen968 halamanSE362 SoftwareProjectManagementtveldhuiBelum ada peringkat

- 1 - Sejarah Dan Ruang Lingkup Teknik IndustriDokumen10 halaman1 - Sejarah Dan Ruang Lingkup Teknik IndustriValentine PasilaBelum ada peringkat

- Porsche CasestudyDokumen2 halamanPorsche CasestudyAlexandra BotezatuBelum ada peringkat

- 4lean - Catalog Volumen 3Dokumen66 halaman4lean - Catalog Volumen 3Roberto MorattoBelum ada peringkat

- HRM 139 Skill Building Activities Check For Understanding SAS 2Dokumen2 halamanHRM 139 Skill Building Activities Check For Understanding SAS 2James BlueBelum ada peringkat

- UGRD-MGT6147 Strategic Cost Management Prelim ExaminationDokumen13 halamanUGRD-MGT6147 Strategic Cost Management Prelim Examinationjonathan anatBelum ada peringkat

- A Report On Application of Kaizen in Poultry FarmDokumen12 halamanA Report On Application of Kaizen in Poultry FarmMaulik Padh100% (1)

- Chapter 5 The Production Process and CostDokumen29 halamanChapter 5 The Production Process and CostTimothy JordanBelum ada peringkat

- Material CostingDokumen20 halamanMaterial Costingrafiq5002Belum ada peringkat

- Lean Case Study - LeatherDokumen9 halamanLean Case Study - LeatherSk Mosaib AhamedBelum ada peringkat

- Cold and Hot ForgingDokumen6 halamanCold and Hot ForgingAnonymous vvO0nZWflrBelum ada peringkat

- MGMT 027Dokumen10 halamanMGMT 027Muhammad Umer FarooqBelum ada peringkat

- CPIM Part 1 Section C PDFDokumen2 halamanCPIM Part 1 Section C PDFSaurabhBelum ada peringkat

- Joe Van BolderenDokumen2 halamanJoe Van BolderenJoeBelum ada peringkat

- Ashok Leyland 3Dokumen4 halamanAshok Leyland 3Harshith GowdaBelum ada peringkat

- Chapter 12Dokumen61 halamanChapter 12Sandeep PanBelum ada peringkat

- ACCA F5 Study Notes.Dokumen88 halamanACCA F5 Study Notes.Naman. Patel100% (5)