Bolts

Diunggah oleh

Juragan IwalDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bolts

Diunggah oleh

Juragan IwalHak Cipta:

Format Tersedia

Table 10 MECHANICAL REQUIREMENTS FOR CARBON STEEL EXTERNALLY-THREADED METRIC FASTENERS Property Nominal Material Class Size of and

Designation Product Treatment Mechanical Requirements Proof Load Stress, MPa Tensile Yield Strength, MPa, Min. 240 Tensile Prod. Hardness, Ultimate Rockwell Strength, Surface, Core MPa, Max. Min. Max. Min. 400 -Property Class Ident. Marking

4.6

M5M100 M1.6M16

low or 225 medium carbon steel low or medium carbon steel, fully or partially annealed low or medium carbon steel, cold worked medium carbon steel, quenched and tempered 310

B67 B95 4.6

4.8

340

420

--

B71 B95 4.8

5.8

M5M24

380

420

520

--

B82 B95 5.8

8.8 A325M Type 1

M16M72 M16M36

600

660

830

30N56

C23 C34 8.8 A325M 8S

8.8 A325M Type 2

M16M36

low carbon 600 boron steel, quenched and tempered atmospheric 600 corrosion resistant steel, quenched and

660

830

30N56

C23 C34 8.8 A325M 8S

A325M Type 3

M16M36

660

830

30N56

C23 C34 A325M 8S3

tempered 9.8 M1.6M16 medium carbon steel, quenched and tempered 650 720 900 30N58 C27 C36 9.8

9.8

M1.6M16

low carbon 650 boron steel, quenched and tempered medium carbon steel, quenched and tempered 830

720

900

30N58

C27 C36 9.8

10.9

M5M20

940

1040

30N59

C33 C39 10.9

10.9 A490M Type 1

M5M100 M12M36

medium 830 carbon alloy steel, quenched and tempered low carbon 830 boron steel, quenched and tempered atmospheric 830 corrosion resistant steel, quenched and tempered alloy steel, quenched and tempered 970

940

1040

30N59

C33 C39 10.9 A490M 10S

10.9 A490M Type 2 A490M Type 3

M5M36 M12M36 M12M36

940

1040

30N59

C33 C39 10.9 A490M 10S

940

1040

30N59

C33 C39 A490M 10S3

12.9

M1.6M100

1100

1220

30N63

C38 C44 12.9

Indicated stresses in Newton/mm2 Strength Designatio 3.6 n Nom. Tensile Strength Min Tensile Strength Lower Yield Stress Stress at Perm. Set 8.8 =< 6.8 16m m 60 0 60 0 800

4.6 4.8

5.6 5.8

8.8 > 16

9.8 10.9

12.9

300

40 0 40 0

400

50 0 50 0

500

800

90 0 90 0

1000

1200

330

420

520

800

830

1000

1200

180/19 24 0 0 -

320/34 30 0 0 -

400/42 48 0 0 -

640

640/66 72 0 0

900/94 1080/10 0 0

In accordance with BS 3692:2001 and BS EN IOS 898-1 : 1999

Tensile Strength Of Metric Nuts Indicated stresses in Newton/mm2

Strength Designation Tensile Strength In accordance with BS 3692:2001

4 400

5 500

6 600

8 800

10 1000

12 1200

The designation system allows the determination of the ultimate and yield/proof strength of the bolt. The designation system is based on two numbers e.g 8.8 . The first number is the tensile strength of the bolt material (N2 )/100. The second number is = 1/100.(the ratio of the Proof (or Yield ) stress and the Tensile strength expressed as a percentage = 100.[Yield (Proof stress) /Tensile strength] /100 The tensile and proof strength of the steel for a 4.6 bolt is therefore calculated as follows Tensile strength (Rm) = 4.100 N/mm2 = 400 N/mm2 .... Proof strength (R0,2) = 0,6*400 * 100 /100 = 240 N/mm2

Tensile and Proof Stress Of Metric Bolts and Screws. (Stainless Steel ) Stainless steels include Austenitic, Martensitic and Ferritic.. Austenitic stainless steels.. Chromium nickel steels which can be cold worked. Non magnetic. Associated grades ( Steel Number according to BS EN 10088 pt 1) = A1 (1.4305) , A2 (1.4301) ,A3 (1.4541) , A4 (1.4401) and A5 (1.4571). Martensitic stainless steels .. Limited corrosion resistance but can be heat treated for superior strength properties. Magnetic Properties. Associated grades ( Steel Number according to BS EN 10088 pt 1) = C1 (1.4006 etc) , C3 (1.4057), C4(1.4104) Ferritic stainless steels .. Plain chromium stainless steels with a chromium content varying between 10.5 and 18% and a low carbon content. They not hardenable by heat treatment. Ferritic alloys have good ductility and formability but a relatively poor high temperature strength compared austenitic grades. Magnetic.. Associated grades = F1 Tensile and Proof Stress Of Metric Bolts and Screws. (Stainless Steel ) Indicated stresses in Newton/mm2 Stainless Steel Steel Grade Strength class Tensile Strength 0,2% proof stress Austenitic A1, A2, A3, A4, A5 50 70 80 100 500 700 800 1000 210 450 600 750 Martensitic C1,C4 50 70 500 700 250 410 Ferritic F1 45 60 450 600 250 410

C1 110 1100 820

C3 80 800 640

Anda mungkin juga menyukai

- Dinner Theater Business PlanDokumen21 halamanDinner Theater Business PlanBhumika KariaBelum ada peringkat

- Ams4945h 2020Dokumen10 halamanAms4945h 2020BauyrzhanBelum ada peringkat

- Applied Welding Engineering: Processes, Codes, and StandardsDari EverandApplied Welding Engineering: Processes, Codes, and StandardsBelum ada peringkat

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- The Essentials of Material Science and Technology for EngineersDari EverandThe Essentials of Material Science and Technology for EngineersPenilaian: 5 dari 5 bintang5/5 (1)

- Tensile and Proof Stress of Metric Bolts and ScrewsDokumen2 halamanTensile and Proof Stress of Metric Bolts and ScrewsMidrenne Millano ManliclicBelum ada peringkat

- Stud Bolt Specification 2Dokumen7 halamanStud Bolt Specification 2santoshblonkarBelum ada peringkat

- Bolts ReferencesDokumen8 halamanBolts ReferencesvinnuzBelum ada peringkat

- Mechanical Properties of Metric FastenersDokumen2 halamanMechanical Properties of Metric FastenersSmilindBelum ada peringkat

- Austenitic Standard GradesDokumen6 halamanAustenitic Standard Gradesfierro44Belum ada peringkat

- Mechanical Properties of Metric Fasteners (Class)Dokumen2 halamanMechanical Properties of Metric Fasteners (Class)Pankaj RaneBelum ada peringkat

- 10 1018Dokumen1 halaman10 1018Uthayan SPBelum ada peringkat

- Carbon Steel and Alloy Steel FastenersDokumen2 halamanCarbon Steel and Alloy Steel FastenersagnisivadasanBelum ada peringkat

- Macsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LDokumen4 halamanMacsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LNirav PatelBelum ada peringkat

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDokumen6 halamanA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98Belum ada peringkat

- Steel Clasification and WeldabilityDokumen32 halamanSteel Clasification and Weldabilitycentaury2013Belum ada peringkat

- BS 970 SteelsDokumen8 halamanBS 970 SteelsTamal Guha100% (2)

- ASTM Equivalents For Metric GradesDokumen1 halamanASTM Equivalents For Metric GradesMarcus ChongBelum ada peringkat

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDokumen12 halaman1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Stud Bolt Specification 3Dokumen7 halamanStud Bolt Specification 3santoshblonkarBelum ada peringkat

- Stainless Steel 304 Material Property Data SheetDokumen2 halamanStainless Steel 304 Material Property Data SheetRahul SrivastavaBelum ada peringkat

- Aisi 200 SeriesDokumen19 halamanAisi 200 Seriessgupta_192494Belum ada peringkat

- Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDokumen20 halamanElectric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingMohamad ShafeyBelum ada peringkat

- Web Page Blocked: Home Matter IndexDokumen5 halamanWeb Page Blocked: Home Matter Index4arunpandeyBelum ada peringkat

- Stainless AISI 3XXDokumen3 halamanStainless AISI 3XXThitaphol HuyananBelum ada peringkat

- WS Hws Hss Asp CPMDokumen12 halamanWS Hws Hss Asp CPMGross Meltiade AlexanderBelum ada peringkat

- Bolts Data Mechanical PropertiesDokumen2 halamanBolts Data Mechanical PropertiesAskarali KoothradanBelum ada peringkat

- Structural SteelsDokumen1 halamanStructural SteelsrjueiBelum ada peringkat

- SS 6mo - 1.4547Dokumen1 halamanSS 6mo - 1.4547f_riseBelum ada peringkat

- P 36 Material 15NiCuMoNb5-6-4Dokumen13 halamanP 36 Material 15NiCuMoNb5-6-4Mudassar Iqbal100% (1)

- Atlas Stainless Steel Data SheetsDokumen57 halamanAtlas Stainless Steel Data Sheetszoksi67% (3)

- FEB09SSIDokumen24 halamanFEB09SSILouHew100% (2)

- The Role Stainless Steel in Industrial Heat ExchangersDokumen46 halamanThe Role Stainless Steel in Industrial Heat ExchangerswholenumberBelum ada peringkat

- Nitronic 30 BrochureDokumen24 halamanNitronic 30 BrochuremkozinBelum ada peringkat

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Dokumen3 halamanFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsBelum ada peringkat

- Principal of DPTDokumen5 halamanPrincipal of DPTJhandu KumarBelum ada peringkat

- 316 316L DataBulletinDokumen7 halaman316 316L DataBulletinAbdurohman RawindaBelum ada peringkat

- SS DataDokumen2 halamanSS Datarobertino00Belum ada peringkat

- Nitronic60 MainDokumen28 halamanNitronic60 MainAnonymous IpqcBBBelum ada peringkat

- A580A580M-15 Standard Specification For Stainless Steel WireDokumen5 halamanA580A580M-15 Standard Specification For Stainless Steel Wiretjt4779Belum ada peringkat

- Pubs 1049240Dokumen12 halamanPubs 1049240cooki77Belum ada peringkat

- 410S Data BulletinDokumen4 halaman410S Data BulletinkatchaniBelum ada peringkat

- Tabela Aço Inox PDFDokumen8 halamanTabela Aço Inox PDFjucalele77Belum ada peringkat

- Cutting Edge BrochureDokumen2 halamanCutting Edge BrochureKen SmithBelum ada peringkat

- Mechanical Properties of Metric FastenersDokumen2 halamanMechanical Properties of Metric Fastenersghostghost123Belum ada peringkat

- 20 TMSS 02 R0Dokumen0 halaman20 TMSS 02 R0renjithas2005Belum ada peringkat

- SX 316 / 316L Technical DataDokumen3 halamanSX 316 / 316L Technical DatavkmsBelum ada peringkat

- 409 Data SheetDokumen2 halaman409 Data SheetMatthieuBelum ada peringkat

- Astm A269Dokumen5 halamanAstm A269Jose M-hBelum ada peringkat

- 31003Dokumen4 halaman31003Elliott RussellBelum ada peringkat

- High Temperature Austenitic Stainless SteelDokumen12 halamanHigh Temperature Austenitic Stainless SteelCarlos Nombela PalaciosBelum ada peringkat

- Stud Bolt SpecificationDokumen8 halamanStud Bolt SpecificationsantoshblonkarBelum ada peringkat

- FsafsaDokumen45 halamanFsafsapvmssonBelum ada peringkat

- BS 970Dokumen5 halamanBS 970aezeadBelum ada peringkat

- Properties Srainless Steel 309LSDokumen3 halamanProperties Srainless Steel 309LSGabriel BozzaBelum ada peringkat

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesDari EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesBelum ada peringkat

- High Temperature Corrosion: Fundamentals and EngineeringDari EverandHigh Temperature Corrosion: Fundamentals and EngineeringBelum ada peringkat

- Civil & Structural Design Basis: Project Name Rev 0 Location Date 13/01/2022 Client by JS HAHA Project Los Angel PT. TepeDokumen1 halamanCivil & Structural Design Basis: Project Name Rev 0 Location Date 13/01/2022 Client by JS HAHA Project Los Angel PT. TepeJuragan IwalBelum ada peringkat

- Braja M Das - Principles-of-Geotechnical-Engineering-5th-Ed - 262Dokumen52 halamanBraja M Das - Principles-of-Geotechnical-Engineering-5th-Ed - 262Juragan IwalBelum ada peringkat

- 2P02 Limestorage DETAIL 1Dokumen3 halaman2P02 Limestorage DETAIL 1Juragan IwalBelum ada peringkat

- STEEL POLE 14M & 16M 350 Dan (Flange Type)Dokumen4 halamanSTEEL POLE 14M & 16M 350 Dan (Flange Type)Juragan IwalBelum ada peringkat

- Pipesupport ps28Dokumen5 halamanPipesupport ps28Juragan IwalBelum ada peringkat

- Company Profile - DTS Engineering V403.10628 RMM - To ABBDokumen15 halamanCompany Profile - DTS Engineering V403.10628 RMM - To ABBJuragan IwalBelum ada peringkat

- Mess Hall YC - GSLAB2-424 - Upd210621 - ReportDokumen92 halamanMess Hall YC - GSLAB2-424 - Upd210621 - ReportJuragan IwalBelum ada peringkat

- Pt. PLN (Persero) Unit Induk Pembangunan Maluku: Pt. Prima Layanan Nasional EnjiniringDokumen5 halamanPt. PLN (Persero) Unit Induk Pembangunan Maluku: Pt. Prima Layanan Nasional EnjiniringJuragan IwalBelum ada peringkat

- Jaw Crusher - Foundation Plan & DetailsDokumen1 halamanJaw Crusher - Foundation Plan & DetailsJuragan IwalBelum ada peringkat

- 2U09STAADDokumen13 halaman2U09STAADJuragan IwalBelum ada peringkat

- Fix WF300Dokumen3 halamanFix WF300Juragan IwalBelum ada peringkat

- Hauling 2 InstallationDokumen1 halamanHauling 2 InstallationJuragan IwalBelum ada peringkat

- Kalsel-1 Coal Fired Power Plant ProjectDokumen1 halamanKalsel-1 Coal Fired Power Plant ProjectJuragan IwalBelum ada peringkat

- Company Profile - DTS Engineering V3.18.09.1 The BreezeDokumen15 halamanCompany Profile - DTS Engineering V3.18.09.1 The BreezeJuragan IwalBelum ada peringkat

- Calculation of Pile Head Center of Gravity: I J K LDokumen1 halamanCalculation of Pile Head Center of Gravity: I J K LJuragan IwalBelum ada peringkat

- Pt. Dunia Teknik Sipil Engineering: Equipment Structure He-5501 Existing Framing Plan EL +5.300 (T.O.S)Dokumen5 halamanPt. Dunia Teknik Sipil Engineering: Equipment Structure He-5501 Existing Framing Plan EL +5.300 (T.O.S)Juragan IwalBelum ada peringkat

- Laporan Perhitungan Struktur - Lampiran 2 - SAP2000 ReportDokumen55 halamanLaporan Perhitungan Struktur - Lampiran 2 - SAP2000 ReportJuragan IwalBelum ada peringkat

- Calculation - Concrete BucketDokumen7 halamanCalculation - Concrete BucketJuragan Iwal100% (1)

- Acco - Accolift2009craneDokumen12 halamanAcco - Accolift2009craneJuragan IwalBelum ada peringkat

- S01 S05 - Foundation - Rev 0Dokumen5 halamanS01 S05 - Foundation - Rev 0Juragan IwalBelum ada peringkat

- Struktur BajaDokumen4 halamanStruktur BajaJuragan IwalBelum ada peringkat

- Water Treatment Container Calculation ReportDokumen15 halamanWater Treatment Container Calculation ReportJuragan IwalBelum ada peringkat

- Jurusan Teknik Sipit: Kementerian Riset, Teknotogi, Dan Pendidikan Tinggi Politeknik Negeri AmbonDokumen1 halamanJurusan Teknik Sipit: Kementerian Riset, Teknotogi, Dan Pendidikan Tinggi Politeknik Negeri AmbonJuragan IwalBelum ada peringkat

- Bollard DeckDokumen1 halamanBollard DeckJuragan IwalBelum ada peringkat

- P0052 Pas 150 Civ DRW 049Dokumen1 halamanP0052 Pas 150 Civ DRW 049Juragan IwalBelum ada peringkat

- Administrative Style Sheet GuideDokumen9 halamanAdministrative Style Sheet GuideTimothy J. RobinsonBelum ada peringkat

- Mezzanine DesignDokumen4 halamanMezzanine DesignJuragan IwalBelum ada peringkat

- Boundary ConditionsDokumen1 halamanBoundary ConditionsJuragan IwalBelum ada peringkat

- Architectural Challenges in Agile PracticeDokumen4 halamanArchitectural Challenges in Agile PracticePranab PyneBelum ada peringkat

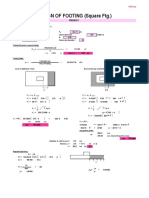

- Design of Footing (Square FTG.) : M Say, L 3.75Dokumen2 halamanDesign of Footing (Square FTG.) : M Say, L 3.75victoriaBelum ada peringkat

- NATIONAL DEVELOPMENT COMPANY v. CADokumen11 halamanNATIONAL DEVELOPMENT COMPANY v. CAAndrei Anne PalomarBelum ada peringkat

- Plasticizers For CPE ElastomersDokumen8 halamanPlasticizers For CPE Elastomersbatur42Belum ada peringkat

- MAC120 PartsDokumen23 halamanMAC120 PartspRAMOD g pATOLEBelum ada peringkat

- BACS2042 Research Methods: Chapter 1 Introduction andDokumen36 halamanBACS2042 Research Methods: Chapter 1 Introduction andblood unityBelum ada peringkat

- 1178-Addendum-Change in Sponsor - HDFC LTD To HDFC Bank - July 1, 2023Dokumen3 halaman1178-Addendum-Change in Sponsor - HDFC LTD To HDFC Bank - July 1, 2023Jai Shree Ambe EnterprisesBelum ada peringkat

- Link Belt Rec Parts LastDokumen15 halamanLink Belt Rec Parts LastBishoo ShenoudaBelum ada peringkat

- Pas 1, Presentation of Financial Statements: Philippine Institute of Certified Public AccountantsDokumen38 halamanPas 1, Presentation of Financial Statements: Philippine Institute of Certified Public AccountantsAie GeraldinoBelum ada peringkat

- Pace 349 ScheduleDokumen3 halamanPace 349 Schedulesaxman011100% (1)

- MockboardexamDokumen13 halamanMockboardexamJayke TanBelum ada peringkat

- Gabuyer Oct13Dokumen72 halamanGabuyer Oct13William Rios0% (1)

- Autonics KRN1000 DatasheetDokumen14 halamanAutonics KRN1000 DatasheetAditia Dwi SaputraBelum ada peringkat

- Transparency in Organizing: A Performative Approach: Oana Brindusa AlbuDokumen272 halamanTransparency in Organizing: A Performative Approach: Oana Brindusa AlbuPhương LêBelum ada peringkat

- Contoh Kuda-Kuda Untuk Pak Henry Truss D&EKK1L KDokumen1 halamanContoh Kuda-Kuda Untuk Pak Henry Truss D&EKK1L KDhany ArsoBelum ada peringkat

- David Sm15 Inppt 06Dokumen57 halamanDavid Sm15 Inppt 06Halima SyedBelum ada peringkat

- Katalog Bonnier BooksDokumen45 halamanKatalog Bonnier BooksghitahirataBelum ada peringkat

- DoctorTecar Brochure MECTRONIC2016 EngDokumen16 halamanDoctorTecar Brochure MECTRONIC2016 EngSergio OlivaBelum ada peringkat

- ANSYS 14.0 Fluid Dynamics Update - Dipankar ChoudhuryDokumen87 halamanANSYS 14.0 Fluid Dynamics Update - Dipankar Choudhuryj_c_garcia_d100% (1)

- BroucherDokumen2 halamanBroucherVishal PoulBelum ada peringkat

- Wind Flow ProfileDokumen5 halamanWind Flow ProfileAhamed HussanBelum ada peringkat

- Reliability EngineerDokumen1 halamanReliability EngineerBesuidenhout Engineering Solutions and ConsultingBelum ada peringkat

- Account Statement From 1 Oct 2018 To 15 Mar 2019: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDokumen8 halamanAccount Statement From 1 Oct 2018 To 15 Mar 2019: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancerohantBelum ada peringkat

- Diagrama Electronico EGED 285Dokumen2 halamanDiagrama Electronico EGED 285Carlos Juarez Chunga100% (1)

- BS Company RecordsDokumen2 halamanBS Company RecordstBelum ada peringkat

- Datascope System 98Dokumen16 halamanDatascope System 98Guillermo ZalazarBelum ada peringkat

- Aquamaster 3 Flow Measurement: Saving Every Drop of Energy and Cost Naturally!Dokumen7 halamanAquamaster 3 Flow Measurement: Saving Every Drop of Energy and Cost Naturally!FIRMANSYAHBelum ada peringkat

- PX4211 2Dokumen3 halamanPX4211 2kalpanaBelum ada peringkat

- Uploading, Sharing, and Image Hosting PlatformsDokumen12 halamanUploading, Sharing, and Image Hosting Platformsmarry janeBelum ada peringkat