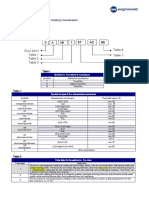

Surface Finish Standard

Diunggah oleh

vinodmysoreDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Surface Finish Standard

Diunggah oleh

vinodmysoreHak Cipta:

Format Tersedia

Maryland Metrics: Standard Platings - Surface Coatings

http://mdmetric.com/tech/267part9.htm

MARYLAND METRICS: Technical Data Chart

STANDARD PLATINGS: SURFACE COATINGS ISO : 4042 (EN ISO 4042) Electroplated coatings DIN : 267 Part 9

Electroplated coatings/Rivestimenti elettrolitici/Revtement lectrolytiques/ Revestimientos electrolticos/Elektrolytische berzge Code system/Sistema di codifica/Systme de codification/sistema de codificacin/Kodifizierungssystem 1. Scope and field of application These technical conditions are in particular related to threaded fasteners (mainly bolts and nuts), but are also applicable to the whole range of mechanical fasteners. 2. Electroplated coatings An electrolytically applied coating shall be defined as a protective metallic layer being deposited onto the surface of metal articles by immersing these parts in an aqueous solution through which an electrical current is passed. Note: The use of the nomenclature galvanizing for this treatment is not correct. This information on electroplated coatings corresponds with DIN 267 Part 9 and ISO 4042. 3. Code system The electroplated coatings of mechanical fasteners are designated by a code consisting of a combination of two capital letters and a number. This callout system is built up as follows: a capital letter for the coating metal (Table 1) a number for the minimum layer thickness (coating structure) (Table 2) a capital letter for the degree of gloss and after-treatment (Table 3) Table 1. Coating metal Code Coating metal Symbol Zinc Zn Cadmium Cd Copper Cu Brass CuZn Nickel Ni Nickel-chrome 1) NiCr Copper-nickel CuNi Copper-nickel-chrome H 1) CuNiCr J Tin Sn K Copper-tin CuSn L Silver Ag N Copper-silver CuAg P Zinc-Nickel 3) ZnNi Q Zinc-Cobalt 3) ZnCo R Zinc-iron 3) ZnFe 1) Thickness of chrome layer 0,3 m 3) Not in ISO 4042 letter A B C D E F G Table 2. Minimum layer thickness (coating structure) Layer thickness (coating structure) in m Code number 1 coating metal 0 1) 1 3 2 5 3 8 4 12 5 15 6 20

2 coating metals 2+ 3 3+ 5 4+ 8 5+10 8+12

7 2) 25 10+15 8 2) 32 12+18 9 2) 40 16+24 3) 1) Code number 0 applies to screw threads below M 1.6, where no specific layer thickness can be specified. 2) Does not apply to threaded components. 3) Not in ISO 4042

1 of 3

1/9/2012 3:01 PM

Maryland Metrics: Standard Platings - Surface Coatings

http://mdmetric.com/tech/267part9.htm

Table 3. Degree of gloss and after-treatment Degree of Chromating in accordance with DIN 50 941 Self-color of chromate layer Codeletter gloss Process group passivation by chromate mt (dull) A (mat) none 1) none mt (dull) B (mat) B bluish to bluish iridescent 2) mt (dull) yellowish glistening to yellowishC (mat) C brown,iridescent mt (dull) D (mat) D olive green to olive brown E bk (bright) none 1) none F bk (bright) B bluish to bluish iridescent 2) yellowish glistening to yellowishG bk (bright) C brown,iridescent H bk (bright) D olive green to olive brown J gl (glossy) none 1) none K gl (glossy) B bluish to bluish iridescent 2) yellowish glistening to yellowishL gl (glossy) C brown,iridescent M gl (glossy) D olive green to olive brown hgl (high N gloss) none bel as for process group B, C or D P (optional) B, C or D 3) at manufacturer's discretion mt (dull) R (mat) F brownish black to black S bk (bright) F brownish black to black T gl (glossy) F brownish black to black U all finishes no chromate treatment 1) In the case of Zn 3) Process groups B, C or D in accordance and Cd with DIN 50 941 only apply to however, process cadmium and zinc coatings. In the case of group A other electroplated coatings, "P" 2) Only applies to in the code symbol signifies "degree of Zn coatings gloss optional". Ordering code for electroplated coatings for commercial fasteners Coating Degree of gloss Nominal size inch < 3/16 " 3/16" < 3/8 " > 3/8 " Zinc-chromated Glossy Color bluish A1K A2K A3K Copper Nickel nickel Glossy Glossy Glossy Glossy Color Color yellowish black A1L A1T E1J G2J A2L A2T E2J G2J A3L A3T E3J G3J

Nominal size metric < 5 mm 5 < 10 mm > 10 mm

Glossy Color none A1J A2J A3J

Example of coding: A3L means zinc-plating (A in Table 1) with a minimum layer thickness of 8 m (3 in Table 2) and yellow-chromated with a glossy degree of gloss (L in Table 3). Callout Example: Hexagon bolt DIN 931 - M12 x 50 - 8.8 - A3L. Chromate (passivate) effected immediately after electroplating by short immersing in chromic acid solutions. The chromating process increases the corrosion protection and prevents a starting and a discolouring of the zinc layer. The protective effect of the chromate layer is different depending upon group of procedures (see table).

Click for: (Ref. ISO 4092) Plating thicknesses for threaded metric fasteners

THINK!- MARYLAND METRICS - The One-Stop Source for Metric & British Sized Fasteners, Wrenches, Cutting, & Measuring Tools, Metal Shapes, Oil Seals, O-Rings, Mechanical Power Transmission Equipment,

2 of 3

1/9/2012 3:01 PM

Maryland Metrics: Standard Platings - Surface Coatings

http://mdmetric.com/tech/267part9.htm

Bearings, Hydraulic And Pneumatic Fittings & Tubing, Workholding Components, Plumbing Fittings, & Some Electrical & Electronic Components. Click to go to Maryland Metrics home page

Phones: (800) 638-1830 or (410) 358-3130 are available Monday-Friday 8:30 AM to 5:30 PM Eastern time. Faxes: (800) 872-9329 or (410) 358-3142 & E-mail are available anytime. Warehouse & showroom hours are Monday-Friday 10 AM to 5:30 PM. [ To: Maryland Metrics home page ] [ To: Maryland Metrics Product Guide ] [ e-mail to Maryland Metrics ] Please note that all Trademarks and Tradenames are the property of their respective owners. copyright 2006, 2011 maryland metrics -- all rights reserved -- ver gg07fCD 267part9.htm

3 of 3

1/9/2012 3:01 PM

Anda mungkin juga menyukai

- Adiabatic Shear Localization: Frontiers and AdvancesDari EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddBelum ada peringkat

- European Standard Norme Européenne Europäische NormDokumen21 halamanEuropean Standard Norme Européenne Europäische NormCentravis100% (2)

- Quality 11Smn30: Lucefin GroupDokumen1 halamanQuality 11Smn30: Lucefin GroupPaulo ZechinBelum ada peringkat

- EN 760 (Flux-SAW)Dokumen2 halamanEN 760 (Flux-SAW)HoangBelum ada peringkat

- Corporate Overview Daniel I GroupDokumen34 halamanCorporate Overview Daniel I GroupRoccoFEBelum ada peringkat

- Thread Data ChartsDokumen4 halamanThread Data Chartsrasinv100% (1)

- Dos A OilDokumen5 halamanDos A OilimranBelum ada peringkat

- EN ISO 15792-1 (2008) A1 (2011) (E) CodifiedDokumen3 halamanEN ISO 15792-1 (2008) A1 (2011) (E) CodifiedQuality Team50% (2)

- Domex 100 XF Data SheetDokumen2 halamanDomex 100 XF Data Sheetzubblwump5063Belum ada peringkat

- Welding Guide 2008 enDokumen515 halamanWelding Guide 2008 engokeyemiBelum ada peringkat

- Bosch Norm 4 497 037 031 - N67F - CM-ZN-2Dokumen18 halamanBosch Norm 4 497 037 031 - N67F - CM-ZN-2davi mooreBelum ada peringkat

- Free Cutting SteelDokumen5 halamanFree Cutting SteelRodney AlmeidaBelum ada peringkat

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDokumen2 halaman16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinBelum ada peringkat

- Material Data Sheet en Aw 6082 Almgsi1Dokumen1 halamanMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502Belum ada peringkat

- Measurement of Decarburization PDFDokumen6 halamanMeasurement of Decarburization PDFnayefamkBelum ada peringkat

- En Iso 377: Steel and Steel Products - Location and Preparation of Samples and Test Pieces For Mechanical TestingDokumen29 halamanEn Iso 377: Steel and Steel Products - Location and Preparation of Samples and Test Pieces For Mechanical TestingKarol WalczykBelum ada peringkat

- WELDING CONSUMABLES-Hardfacing PDFDokumen18 halamanWELDING CONSUMABLES-Hardfacing PDFmanuel_plfBelum ada peringkat

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesDokumen5 halamanNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliBelum ada peringkat

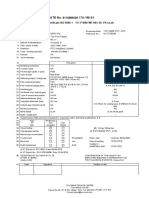

- Certificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDokumen1 halamanCertificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDeepak Das100% (1)

- RJR PMMTDokumen16 halamanRJR PMMTArun PrasadBelum ada peringkat

- FEB09SSIDokumen24 halamanFEB09SSILouHew100% (2)

- Astm B 240-07 PDFDokumen4 halamanAstm B 240-07 PDFRamsi AnkziBelum ada peringkat

- The Fundamental Aspects of Electroless Nickel Plating: Glenn MalloryDokumen56 halamanThe Fundamental Aspects of Electroless Nickel Plating: Glenn MalloryPeter BergmannBelum ada peringkat

- Norma DIN-50190P2 - enDokumen4 halamanNorma DIN-50190P2 - enWelington Volpatto MoraisBelum ada peringkat

- Bes MSDokumen1 halamanBes MSasdBelum ada peringkat

- Iso 7452 2013 en PDFDokumen8 halamanIso 7452 2013 en PDFfahmi aballiBelum ada peringkat

- 1 7335Dokumen5 halaman1 7335stamatsBelum ada peringkat

- ASTM F593: MaterialsDokumen1 halamanASTM F593: MaterialsBilly DBelum ada peringkat

- En Iso 17642 - 1 (E)Dokumen5 halamanEn Iso 17642 - 1 (E)mustafa gözüaçıkBelum ada peringkat

- xDIN ISO 34804-2002.10-ENDokumen5 halamanxDIN ISO 34804-2002.10-ENAustine ChrisBelum ada peringkat

- En 10025-2Dokumen4 halamanEn 10025-2Sebastián Araya MoraBelum ada peringkat

- Effective Filtration of Steel CastingsDokumen40 halamanEffective Filtration of Steel CastingsWalter Hartwell WhiteBelum ada peringkat

- An Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalDokumen5 halamanAn Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalKhin Aung ShweBelum ada peringkat

- Chemical and Mechanical PropertiesDokumen5 halamanChemical and Mechanical PropertiesAristotle MedinaBelum ada peringkat

- Copper CatalogDokumen2 halamanCopper CatalogYogesh AnapBelum ada peringkat

- Equivalences Certified Welder According ASME EN ISO 14732 - 2013 - GleDokumen1 halamanEquivalences Certified Welder According ASME EN ISO 14732 - 2013 - Gleer_wenBelum ada peringkat

- 2370 Ed1 ENDokumen5 halaman2370 Ed1 ENanhthoBelum ada peringkat

- TL-DSV 2012-05 Engl Br-1Dokumen5 halamanTL-DSV 2012-05 Engl Br-1Dorota HOBelum ada peringkat

- Geomet 500bDokumen1 halamanGeomet 500bellisforheroesBelum ada peringkat

- T E F A: HE Uropean Oundry SsociationDokumen0 halamanT E F A: HE Uropean Oundry SsociationpkjenaleoBelum ada peringkat

- Astm E415 2008 PDFDokumen9 halamanAstm E415 2008 PDFInês FerrazBelum ada peringkat

- Shell Permeability PresentationDokumen29 halamanShell Permeability Presentationbilalabbasi1990Belum ada peringkat

- Aerospace Material Specification: Plating, Nickel General PurposeDokumen8 halamanAerospace Material Specification: Plating, Nickel General PurposeSURYAS63Belum ada peringkat

- Astm G 101Dokumen8 halamanAstm G 101El_Proesor100% (1)

- Norma Ps Fiat 50116Dokumen6 halamanNorma Ps Fiat 50116Hatada FelipeBelum ada peringkat

- FiatDokumen10 halamanFiatrgi178100% (1)

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDokumen5 halamanMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhBelum ada peringkat

- FT Grease 22Dokumen2 halamanFT Grease 22Edgar Leonel CortésBelum ada peringkat

- Iso AnnealingDokumen2 halamanIso AnnealingPurushottam Sutar100% (1)

- S355 European Standard SteelDokumen7 halamanS355 European Standard SteelmaiquelernBelum ada peringkat

- 701 Steel InclusionRating DIN-50602Dokumen1 halaman701 Steel InclusionRating DIN-50602ksathisBelum ada peringkat

- Coating Din4762Dokumen10 halamanCoating Din4762motiBelum ada peringkat

- Abrasion (Mechanical)Dokumen29 halamanAbrasion (Mechanical)stallone21Belum ada peringkat

- DIN EN ISO 9013 - Angular Deviation PDFDokumen1 halamanDIN EN ISO 9013 - Angular Deviation PDFflorinelvvBelum ada peringkat

- Simufact Welding PDFDokumen8 halamanSimufact Welding PDFDele TedBelum ada peringkat

- Din Etg 100Dokumen1 halamanDin Etg 100durgeshdesignBelum ada peringkat

- Corrosion Protection - Electroplated CoatingsDokumen1 halamanCorrosion Protection - Electroplated CoatingsMM LEBelum ada peringkat

- Electrodeposited Coatings of Zinc With Passivation On SteelDokumen4 halamanElectrodeposited Coatings of Zinc With Passivation On Steelradule021Belum ada peringkat

- Ti 165 PDFDokumen1 halamanTi 165 PDFHugoBelum ada peringkat

- Copper Alloy Spec SheetsDokumen1 halamanCopper Alloy Spec SheetsvinodmysoreBelum ada peringkat

- CuZn6 Corrosion ProperiesDokumen5 halamanCuZn6 Corrosion ProperiesvinodmysoreBelum ada peringkat

- CuSn6 Bronze - Hard MaterialDokumen2 halamanCuSn6 Bronze - Hard MaterialvinodmysoreBelum ada peringkat

- DIN-6912-Socket Head Screw Low Head With Pilot Recess Mfa CatalogueDokumen4 halamanDIN-6912-Socket Head Screw Low Head With Pilot Recess Mfa CataloguevinodmysoreBelum ada peringkat

- Avdel RevetDokumen104 halamanAvdel RevetvinodmysoreBelum ada peringkat

- Markets and Commodity Figures: Total Market Turnover StatisticsDokumen6 halamanMarkets and Commodity Figures: Total Market Turnover StatisticsTiso Blackstar GroupBelum ada peringkat

- Nocturne 2024Dokumen162 halamanNocturne 2024Peter JonesBelum ada peringkat

- Moatiz Riaz - Area Sales ManagerDokumen1 halamanMoatiz Riaz - Area Sales ManagerMoatiz RiazBelum ada peringkat

- Students List - All SectionsDokumen8 halamanStudents List - All SectionsChristian RiveraBelum ada peringkat

- CPP CheatsheetDokumen10 halamanCPP CheatsheetPrakash GavelBelum ada peringkat

- Intro To Semiology Reading NotesDokumen6 halamanIntro To Semiology Reading NotesRyan DrakeBelum ada peringkat

- Professional Education: St. Louis Review Center, IncDokumen10 halamanProfessional Education: St. Louis Review Center, IncEarshad Shinichi IIIBelum ada peringkat

- China Email ListDokumen3 halamanChina Email ListRosie Brown40% (5)

- Comparative Genomics 2 - PART 1Dokumen31 halamanComparative Genomics 2 - PART 1NnleinomBelum ada peringkat

- This I BeleiveDokumen3 halamanThis I Beleiveapi-708902979Belum ada peringkat

- Living GraceDokumen227 halamanLiving GraceÁdám NógrádiBelum ada peringkat

- Ef3 Englisch 04 14 08052014Dokumen20 halamanEf3 Englisch 04 14 08052014PiPradoBelum ada peringkat

- Acd 1Dokumen3 halamanAcd 1Kath LeynesBelum ada peringkat

- Satellite Motion NotesDokumen23 halamanSatellite Motion NotesVarshLok100% (1)

- Soil MechDokumen21 halamanSoil MechAhsan AbbasBelum ada peringkat

- Commentary On The Book of NahumDokumen9 halamanCommentary On The Book of NahumRev Dr Jeffry Camm JP, MIEPR, MISOPBelum ada peringkat

- End-Of-Chapter Questions: CambridgeDokumen17 halamanEnd-Of-Chapter Questions: CambridgeMido MidoBelum ada peringkat

- LEASE CONTRACT Taytay Residentialhouse Kei Inagaki Nena TrusaDokumen6 halamanLEASE CONTRACT Taytay Residentialhouse Kei Inagaki Nena TrusaJaime GonzalesBelum ada peringkat

- Agne Vs Director of LandsDokumen7 halamanAgne Vs Director of LandsLee SomarBelum ada peringkat

- Senate - Investigating - Committee - On - Education California Textbooks 1948 120pgs GOV EDU - SML PDFDokumen115 halamanSenate - Investigating - Committee - On - Education California Textbooks 1948 120pgs GOV EDU - SML PDFdragan346382902Belum ada peringkat

- Floline Size eDokumen4 halamanFloline Size eNikesh ShahBelum ada peringkat

- Curriculum in MalaysiaDokumen37 halamanCurriculum in MalaysiaEmily Ling100% (1)

- TaxationDokumen26 halamanTaxationReynamae Garcia AbalesBelum ada peringkat

- 35.ravi Gupta Writs (CLE)Dokumen22 halaman35.ravi Gupta Writs (CLE)Ravi GuptaBelum ada peringkat

- WearebecausewebelongDokumen3 halamanWearebecausewebelongapi-269453634Belum ada peringkat

- Tutorial 2 - Financial EnvironmentDokumen5 halamanTutorial 2 - Financial EnvironmentShi ManBelum ada peringkat

- Uplifting Hauora Maori RealDokumen32 halamanUplifting Hauora Maori RealFano AsiataBelum ada peringkat

- How To Write Effective Sex ScenesDokumen4 halamanHow To Write Effective Sex ScenesAria DiemBelum ada peringkat

- Kids Cooking Teams: That's FreshDokumen74 halamanKids Cooking Teams: That's FreshNCB School of Herbalism & Holistic HealthBelum ada peringkat

- Reflection PseudoscienceDokumen3 halamanReflection PseudoscienceSuganthi RamasamyBelum ada peringkat