PENSTOCK Optimization Research

Diunggah oleh

Anjan SigdelDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PENSTOCK Optimization Research

Diunggah oleh

Anjan SigdelHak Cipta:

Format Tersedia

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 2. No. 6. November, 2010, Part II

OPTIMIZATION ON PENSTOCK DIMENSION OF AMPEL GADING HYDRO ELECTRICAL POWER, INDONESIA

Endang Purwati , Herlien Indra Wahyun

1 2 1 2

Water Resources Department, Civil Engineering Department, Faculty of Engineering, Brawijaya University, Malang (INDONESIA)

ABSTRACT This paper studied the optimization dimension of penstock of hydro electrical power. The case study was at Ampel Gading, Tawangsari Weir at Grojogan River, Indonesia. The methodology consisted of dimensioning optimized penstock diameter due to hydraulics structure constraints. Diameter and thickness of the penstock were designed at this study. Result was used to build the hydraulic structure of hydro electrical power at this location. Key words: penstock; diameter; thickness 1. INTRODUCTION Local hydraulic phenomena to the vicinity of channel junction are of considerable practical importance as they may be effect the flow condition in the combining channel [1]. A circular cross section has long been recognized as a very efficient section for the transport of fluids. However, it does not imply that the same cross section is suitable for stimulating pipelines [2]. The question of solvability of pipe networks requires some clarification. There is no restriction on the number of the equality constraints and associated parameter calculations as long as a oneto-one relation is maintained [3]. Project of Ampel Gading hydro electrical power was intended to build a power station that used a natural potency advantage region. This research plan was to dimension penstock that was crucial part of water power electrical structure. Penstock was usually made of steel material which was able to sustain high pressure and bearer flow from the head race to turbine. The research constitute a diameters as a treatment and then analyzed an optimum diameter pipe (concordant to economical and technical aspect), and determined a thickness of pipe for tension control regarded to the permit tension. ( < ijin ). 2. MATERIALS AND METHODS Tawangsari Spillway at Bebek River and Grojogan Spillway at Grojogan River still at the region that could 3 use for supplying electric and it got a discharge of 5 m /s at Ampel Gading hydro electrical power. Gross head was 229,20 m to get up electrical power, set down at downstream river. The length of water way from storage to penstock L = 307 m. The power could be get up 9602.334 KW, so that was hoped to give electrical capacity addition. The steps of this study was to analyze 1) theoretical power; 2) theoretical diameter; 3) head losses that were instead of major and minor head losses, this section was intended to get effective head; 4) economical diameter of penstock, this section was carried out by analyzing water hammer and optimum diameter of penstock; 5) minimum thickness of penstock (pipe was made of steel). Some formulations were used to design penstock. The formulations that were used in this study were as below [4]: Daaland formula was used to calculate pipe diameter D = 0,176 ( P ) 0.466 . H eff Wave velocity was calculated with the formula:

c 1 w1 D g k E .

The formula of pipe thickness: 1 1 D .

Ec Eb Ep . t

3. RESULTS AND DISCUSSION Theoritical power: P = 9,8 . Q. Heff (kw), Q = 5,0 m /s, hydraulic efficiency was 95 %, H brutto = 229,20 m, 0,466 Heff = 217,74 m. P = 9602,334 Kw = 12867,1276 HP. Diameter of penstock: D = 0,176. ( 12867,1276 ) = 1,18 m. 217,74

3

308 | www.ijar.lit.az

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 2. No. 6. November, 2010, Part II

Diameter of penstock due to empirical formula: 1,18 m. Economical diameter was trialed and was got at approximately 1,18 m and it was selected the economics one, the calculation was as Table 1, 2, 3, 4, and 5 Table 1. Total of head losses at UpStream

Dn (m) hf he hb hv hl 1,00 0,4934 0,103 0,103 0,310 1,009 1,20 0,3869 0,050 0,050 0,150 0,637 1,40 0,3151 0,027 0,027 0,081 0,450 1,60 0,2637 0,016 0,016 0,047 0,343 1,80 0,2254 0,001 0,001 0,030 0,257 2,00 0,1958 0,007 0,007 0,019 0,229

Table 2. Total of head losses at Down Stream

Dn (m) hf he hb hv hl 1,00 0,627 0,103 0,103 0,310 1,143 1,20 0,492 0,050 0,050 0,150 0,742 1,40 0,400 0,027 0,027 0,081 0,535 1,60 0,335 0,016 0,016 0,047 0,414 1,80 0,286 0,001 0,001 0,030 0,318 2,00 0,249 0,007 0,007 0,019 0,282

Table 3. Analyzing of economical pipe at Up Stream

Dn (m) minimum thickness (m) weight of pipe value of pipe 6 [@Rp.1,10 /ton] head losses (m) power losses (kw) energy losses (kwh) value of energy head losses [@Rp.168/kwh] Total value economical ranking 1,0 0,007 34,0770 34.077.000 1,009 44,497 384453,216 64.588.140 98.665.140 4 1,2 0,007 45,4606 45.460.600 0,637 28,092 242712,288 40.775.664 86.236.264 1 1,4 0,007 58,3668 58.366.800 0,450 19,845 171460,800 28.805.414 87.172.214 2 1,6 0,007 72,7958 72.795.800 0,343 15,126 130691,232 21.956.127 94.751.927 3 1,8 0,007 88,7476 88.747.600 0,257 11,334 97923,168 16.451.092 2,0 0,007 106,2220 106.222.000 0,229 10,099 87254,496 14.658.755

105.198.692 120.880.755 5 6

Table 4. Analyzing of economical pipe at Down Stream

Dn (m) minimum thichness (m) weight of pipe alue of pipe 6 [@Rp.1,10 /ton] head losses (m) power losses (kw) energy losses (kwh) alue of head energy losses [@Rp.168/kwh] Total value economical ranking 1,0 0,007 43,2900 43.290.000 1,143 50,406 435510,432 73.165.753 1,2 0,007 57,7512 57.751.200 0,742 32,722 282719,808 47.496.928 1,4 0,007 74,1468 74.146.800 0,535 23,594 203847,840 34.246.437 1,6 0,007 92,4768 92.476.800 0,414 18,257 157743,936 26.500.981 1,8 0,007 112,7412 2,0 0,007 134,9400

112.741.200 134.940.000 0,318 14,024 121165,632 20.355.826 0,282 12,436 107448,768 18.051.393

116.455.753 105.248.128 108.393.237 118.977.781 133.097.026 152.991.393 3 1 2 4 5 6

Table 5. Stress of Pipe

No I II a b c d Type of stress Strees of Tangent Strees paralel to pipe as Stress due to pipe position Stree due to the empty weight of pipe Stress due to the move between pipe and position Stress due to pressure force at the expand connection Stress (kg/cm ) 339,233 75,391 0,581 1183,443 36,346

2

B a k u , A z e r b a i j a n | 309

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

4. CONCLUSIONS

Vol. 2. No. 6. November, 2010, Part II

Based on analyzing as above, economical diameter penstock was 1.40 m, the thickness = 7.0 mm and 2 2 stress was 1339.431 kg/cm (< ultimate stress = 1.400 kg/cm ). The result was due to the pressure of water hammer and it was controlled with the existing stress. REFERENCES 1. Chan-Lin Chin and David W. Murray. 1992. Variation of Velocity Distribution along Non uniform Open-Channel Flow. Journal of Hydraulic Engineering, Vol 118, No 7, page 993-1100 2. George C. Christodoulou. 1993. Incipient Hydraulic Jump at Channel Junction. Journal of Hydraulic Engineering, Vol 119 No 3, page 409-421 3. Yee Meng Chiew. 1992. Effect of Spoilers on Scour at Submarines Pipelines. Journal of Hydraulic Engineering, Vol 119 No 9, page 1311-1317 4. Weber, N.B. 1971. Fluid Mechanics for Civil Engineers. New York: John Wiley # Sons, Inc.

310 | www.ijar.lit.az

Anda mungkin juga menyukai

- Piping Stress Man Hour EstimationDokumen3 halamanPiping Stress Man Hour EstimationDayo IdowuBelum ada peringkat

- PenstockDokumen7 halamanPenstockmodest_dhuBelum ada peringkat

- Pipe Dimensions and Friction FactorDokumen24 halamanPipe Dimensions and Friction FactorJuan Pablo ApazaBelum ada peringkat

- Penstock Surge ConsiderationDokumen29 halamanPenstock Surge ConsiderationoctatheweelBelum ada peringkat

- LEC-8 Water Hammer and Penstock DesignDokumen37 halamanLEC-8 Water Hammer and Penstock DesignAziz ul HakeemBelum ada peringkat

- Normalizing NPSH: Calculating Suction Specific SpeedDokumen5 halamanNormalizing NPSH: Calculating Suction Specific Speedorchids28Belum ada peringkat

- AFT Evaluating Pipe Dynamic Loads Caused by WaterhammerDokumen24 halamanAFT Evaluating Pipe Dynamic Loads Caused by WaterhammerroyalcomBelum ada peringkat

- Penstock Water Hammer CalculationDokumen2 halamanPenstock Water Hammer CalculationChris Angelo G CaadlawonBelum ada peringkat

- Air Valve 460Dokumen6 halamanAir Valve 460amrezzatBelum ada peringkat

- Catalouge Page PDFDokumen12 halamanCatalouge Page PDFAdra EventsBelum ada peringkat

- Pump Calc ExampleDokumen21 halamanPump Calc ExampleMohammad Usman HabibBelum ada peringkat

- Cane Shredder 2Dokumen9 halamanCane Shredder 2Dirajen Pullay MardayBelum ada peringkat

- WRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionDokumen5 halamanWRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionmsmrizhwanBelum ada peringkat

- Pumps DefinitionsDokumen31 halamanPumps DefinitionsFortuna JohnBelum ada peringkat

- Surge Tank Thoma and Svee CriteriaDokumen79 halamanSurge Tank Thoma and Svee CriteriaManikandanBelum ada peringkat

- Igor J. Karassik (1911-1995): Pioneering Pump EngineerDokumen2 halamanIgor J. Karassik (1911-1995): Pioneering Pump EngineervcockscribdBelum ada peringkat

- Is.11625.1986 Penstock DesignDokumen20 halamanIs.11625.1986 Penstock DesignMutuga JosephBelum ada peringkat

- Caesar II User Manual PDF - Google XXXDokumen2 halamanCaesar II User Manual PDF - Google XXXjasonwu1115Belum ada peringkat

- Orifice Plate Showing VenaDokumen6 halamanOrifice Plate Showing VenahugepotatoBelum ada peringkat

- Design Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDokumen12 halamanDesign Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDavid DelgadoBelum ada peringkat

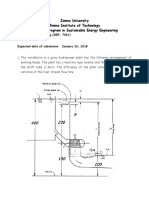

- Jimma University Hydropower Engineering AssignmentDokumen4 halamanJimma University Hydropower Engineering AssignmentAmexTesfayeKoraBelum ada peringkat

- Mechanical Component - PumpsDokumen28 halamanMechanical Component - PumpsLijo ThoamsBelum ada peringkat

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDokumen12 halamanStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackBelum ada peringkat

- Voith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesDokumen8 halamanVoith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesAshutosh VashishthaBelum ada peringkat

- Increase Allowable Stress CodeDokumen9 halamanIncrease Allowable Stress Codewenny_tpdBelum ada peringkat

- Shell Thickness CalcDokumen1 halamanShell Thickness CalcDidi KurniadiBelum ada peringkat

- Me 2204 Fluid Mechanics and Machinery LiDokumen8 halamanMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanBelum ada peringkat

- Diesel Electric Fire Pumpset Manual 2Dokumen68 halamanDiesel Electric Fire Pumpset Manual 2ds_engenharia8817Belum ada peringkat

- Paper Pulp and Fibre PumpingDokumen6 halamanPaper Pulp and Fibre PumpingetmvmartBelum ada peringkat

- Plunger Pump M18Dokumen4 halamanPlunger Pump M18Pipe LopezBelum ada peringkat

- Transient Flow AnalysisDokumen14 halamanTransient Flow Analysiscpsankar100% (1)

- Piping and Pipelines Assessment Guide453Dokumen1 halamanPiping and Pipelines Assessment Guide453Vetti PayanBelum ada peringkat

- OutoKumpu SS Pipe-2010Dokumen124 halamanOutoKumpu SS Pipe-2010ahmedalishBelum ada peringkat

- Calculate Steam Pipe Sizing and CapacityDokumen2 halamanCalculate Steam Pipe Sizing and CapacityjoeljdiazBelum ada peringkat

- Cooling System Surge Analysis With AFT ImpulseDokumen2 halamanCooling System Surge Analysis With AFT ImpulsektejankarBelum ada peringkat

- Mew R6 2016Dokumen33 halamanMew R6 2016MujtabaBelum ada peringkat

- Platewithshear&anchorbolts NPTEL PDFDokumen5 halamanPlatewithshear&anchorbolts NPTEL PDFMadhubalan AlagarBelum ada peringkat

- Standards/Manuals/ Guidelines For Small Hydro DevelopmentDokumen30 halamanStandards/Manuals/ Guidelines For Small Hydro DevelopmentIfnu SetyadiBelum ada peringkat

- PAS-JBG-400-D-001 Pipe Stress Report For Line Pipe Fuel Gas System Supply To GTCP 2020A Rev BDokumen8 halamanPAS-JBG-400-D-001 Pipe Stress Report For Line Pipe Fuel Gas System Supply To GTCP 2020A Rev BElias EliasBelum ada peringkat

- Design of The HVA Water TunnelDokumen10 halamanDesign of The HVA Water TunnelSjoerd_BBelum ada peringkat

- Cavitation and Pipe DetailsDokumen34 halamanCavitation and Pipe DetailsSANDIP ROYBelum ada peringkat

- Mechanical Design Calculation of Pipe Rack Under Pass 1Dokumen7 halamanMechanical Design Calculation of Pipe Rack Under Pass 1tobeeprassBelum ada peringkat

- Leaching Facilities Design: Rosemont CopperDokumen241 halamanLeaching Facilities Design: Rosemont CopperRosdalina BasriBelum ada peringkat

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDokumen13 halamanComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1Belum ada peringkat

- p21 006 P 02 (Support Load Data)Dokumen3 halamanp21 006 P 02 (Support Load Data)Trishul Nath PallayBelum ada peringkat

- Basic Calculations PDFDokumen1 halamanBasic Calculations PDFSanthosh Kumar100% (1)

- Dimensions of Bolts and Nuts BS3692Dokumen6 halamanDimensions of Bolts and Nuts BS3692azam RazzaqBelum ada peringkat

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterDokumen4 halamanv1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212Belum ada peringkat

- PumpDokumen109 halamanPumppavankumar001Belum ada peringkat

- Optimal Penstock Sizing for Increased FlowDokumen1 halamanOptimal Penstock Sizing for Increased FlowPhyu Mar Thein KyawBelum ada peringkat

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDari EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionBelum ada peringkat

- Cross Flow Open ChannelDokumen7 halamanCross Flow Open ChannelRafael Malheiro FerreiraBelum ada peringkat

- Determine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFDokumen10 halamanDetermine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFLuis Pereira PeñaBelum ada peringkat

- Determine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFDokumen10 halamanDetermine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFLuis Pereira PeñaBelum ada peringkat

- 48-55 PublDokumen10 halaman48-55 PublLorence CardenasBelum ada peringkat

- Durshal SampleDokumen18 halamanDurshal SampleArsalanAhmadBelum ada peringkat

- PipeFlow PracticeProblemsDokumen23 halamanPipeFlow PracticeProblemsFawaz PartoBelum ada peringkat

- Diseño de BushingsDokumen6 halamanDiseño de BushingsIWueBelum ada peringkat

- Head-Discharge Relationships For Rectangular Flat-Crested Slit WeirDokumen6 halamanHead-Discharge Relationships For Rectangular Flat-Crested Slit Weirشيماء الهاشميBelum ada peringkat

- Design Considerations For GatesDokumen1 halamanDesign Considerations For GatesAnjan SigdelBelum ada peringkat

- ACSR Data SheetDokumen13 halamanACSR Data Sheetdksaxena_in7962Belum ada peringkat

- Pressure Pipe Design-Moser CH 4 ExrptDokumen8 halamanPressure Pipe Design-Moser CH 4 ExrptAnjan SigdelBelum ada peringkat

- Chipmunk Creek ExampleDokumen30 halamanChipmunk Creek ExampleAnjan SigdelBelum ada peringkat

- Sludge ValvesDokumen17 halamanSludge ValvesAnjan SigdelBelum ada peringkat

- Sludge ValvesDokumen17 halamanSludge ValvesAnjan SigdelBelum ada peringkat

- CREATE A CORRECTLY SCALED NETWORK FROM SCRATCHDokumen5 halamanCREATE A CORRECTLY SCALED NETWORK FROM SCRATCHMauricio Senior RamírezBelum ada peringkat

- Trafo 40 Mva PDFDokumen719 halamanTrafo 40 Mva PDFeug_manu8Belum ada peringkat

- Temperature Effect On Voc and IscDokumen5 halamanTemperature Effect On Voc and IscAnonymous bVLovsnBelum ada peringkat

- Lesson Statement Sheet.Dokumen2 halamanLesson Statement Sheet.Anya AshuBelum ada peringkat

- Experiment List (FEE)Dokumen5 halamanExperiment List (FEE)bpkeleBelum ada peringkat

- Water Quality Study of Kallai RiverDokumen43 halamanWater Quality Study of Kallai Riverpratheesh thekedanBelum ada peringkat

- Equipment DetailsDokumen10 halamanEquipment Detailsimranjani.skBelum ada peringkat

- Quizlet-Philippine Electrical CodeDokumen2 halamanQuizlet-Philippine Electrical Codena zafira0% (1)

- Lab 5-Activity DiagramDokumen19 halamanLab 5-Activity Diagramsayed omranBelum ada peringkat

- Complex Numbers: Problem-SolvingDokumen2 halamanComplex Numbers: Problem-SolvingK TariBelum ada peringkat

- Module 6 The HypothesisDokumen14 halamanModule 6 The HypothesisJester Guballa de LeonBelum ada peringkat

- Step 1: State The Null and Alternative HypothesisDokumen3 halamanStep 1: State The Null and Alternative HypothesisChristine Joyce BascoBelum ada peringkat

- BUS STAT Chapter-3 Freq DistributionDokumen5 halamanBUS STAT Chapter-3 Freq DistributionolmezestBelum ada peringkat

- Focal Points: Basic Optics, Chapter 4Dokumen47 halamanFocal Points: Basic Optics, Chapter 4PAM ALVARADOBelum ada peringkat

- Report Navigation Prashanth RamadossDokumen1 halamanReport Navigation Prashanth RamadossaustinvishalBelum ada peringkat

- Chemistry Paper (Chap 1-4)Dokumen2 halamanChemistry Paper (Chap 1-4)XarOonBelum ada peringkat

- Binder 1Dokumen36 halamanBinder 1BobbyBelum ada peringkat

- Westfalia Separator Installation DiagramDokumen68 halamanWestfalia Separator Installation DiagramOno Jr Araza100% (3)

- Short Term Load Forecast Using Fuzzy LogicDokumen9 halamanShort Term Load Forecast Using Fuzzy LogicRakesh KumarBelum ada peringkat

- 100 kWp Rooftop Solar PV Plant Project Report for Ghaziabad FactoryDokumen25 halaman100 kWp Rooftop Solar PV Plant Project Report for Ghaziabad FactoryvikashBelum ada peringkat

- Deep Glow v1.4.6 ManualDokumen6 halamanDeep Glow v1.4.6 ManualWARRIOR FF100% (1)

- Drum RudimentsDokumen4 halamanDrum Rudimentsmaame nyarkoaBelum ada peringkat

- Lesson Planning Product-Based Performance TaskDokumen8 halamanLesson Planning Product-Based Performance TaskMaricarElizagaFontanilla-LeeBelum ada peringkat

- Grundfosliterature 5439390Dokumen108 halamanGrundfosliterature 5439390ptlBelum ada peringkat

- Parts of The NailDokumen22 halamanParts of The NailMariel Balmes Hernandez100% (1)

- An Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringDokumen15 halamanAn Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringKrinta AlisaBelum ada peringkat

- EE - Revision Through Question - GATE - 2020 PDFDokumen138 halamanEE - Revision Through Question - GATE - 2020 PDFRamesh KumarBelum ada peringkat

- Shipboard: Micrpoclimate' Coolin SysemsDokumen47 halamanShipboard: Micrpoclimate' Coolin Sysemsjakalae5263Belum ada peringkat

- EE6010-High Voltage Direct Current TransmissionDokumen12 halamanEE6010-High Voltage Direct Current Transmissionabish abish0% (1)

- EDOC-Benefits & Advantages of Applying Externally Gapped Line ArrestersDokumen20 halamanEDOC-Benefits & Advantages of Applying Externally Gapped Line ArrestersEl Comedor BenedictBelum ada peringkat