Hot Work Procedures

Diunggah oleh

Muhammad Sajid ShamsDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hot Work Procedures

Diunggah oleh

Muhammad Sajid ShamsHak Cipta:

Format Tersedia

HOT WORK PROCEDURE

Responsible Officer

AFW - Health & Safety Officer

Document Control

Unrestricted Distribution

File Number

TRIM -

REFERENCE DOCUMENTS AS/NZS 2865:2009 CONFINED SPACES AS 1940:2004 THE STORAGE AND HANDLING OF FLAMMABLE AND COMBUSTIBLE LIQUIDS AS 1674.1:1997 SAFETY IN WELDING AND ALLIED PROCESSES AS 1470:1986 HEALTH & SAFETY AT WORK PRINCIPLES AND PRACTICES AS 4041:2006 PRESSURE PIPING HB 13:2007 ELECTRICAL EQUIPMENT FOR HAZARDOUS AREAS 1. AIM The use of welding, grinding and abrasive equipment has been the cause of many fires and explosions at work sites, especially where these processes do not form part of the day to day activities of an organisation. As the School of Agriculture, Food and Wine recognises the risks involved with hot work processes these Hot Work Guidelines and Hot Work Permit system have been developed to minimise the risk to people and property during any hot work procedures undertaken within the School. SCOPE This procedure provides guidance for the precautions and preparations that should be followed to ensure any work covered by a Hot Work Permit is carried out in a safe manner without risk to people or property. A Hot Work Permit authorises any person/s to undertake specific work, in a defined area, as detailed on that permit. These procedures should be read in conjunction with The University of Adelaide policies and procedures;

http://www.adelaide.edu.au/policies/153/ - Occupational Health, Safety and Welfare Policy http://www.adelaide.edu.au/hr/ohs/handbook/temperature_extremes/ -SAFETY WHILE WORKING IN TEMPERATURE EXTREMES

2.

These guidelines are applicable to all University staff, Co-Location Partner staff, Contractor or Visitor who may undertake work within any School of Agriculture, Food & Wine (AFW) facility or location including Field Work and/or Field Trips. These guidelines do not constitute a Job Safety Analysis or Risk Assessment and the issuing of a Hot Work Permit does not in itself make a job safe. Neither this procedure nor the issuing of a Hot Work Permit takes precedence over any other University or School procedure such as Working at Height, Confined Spaces or Electrical work that may have other authorising processes. 3. DEFINITIONS Hazardous Area Any area in which flammable or combustible liquids, vapours, gases, dusts, fibres and/or explosive substances may be present. Flammable Substances Liquids, mixtures of liquids or mixtures of liquids and solids (e.g. paints and varnishes) which give off flammable vapours at temperatures less than 65.6oC Combustible Substances material that can maintain combustion without the addition of an external heat source. Hot Work Any process involving Grinding, Welding, Brazing, Oxy Cutting, Heat Treatment or any other similar process that generates heat or continuous stream of sparks. Responsible Officer Trade Supervisor, Trade Foreperson, Project Manager, Tradesperson or Contractor who has sufficient knowledge of the fire, explosion and/or toxicity hazards associated with Hot Work Processes who will supervise all hot work procedures described in the Hot Work Permit. Confined Space Any enclosed space that has been defined as a Confined Space in line with Australian Standard 2865.2001. Note: See AFW Confined Space Register or refer to AFW Confined Space Assessment

Sheet

Uncontrolled if Printed Produced By TJ MacKenzie Effective Date 25/3/2010

Version 1.1 Page 1 of 4 Date of Next Review - 25/3/2012

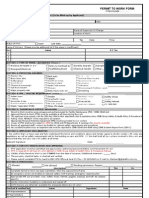

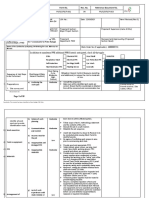

HOT WORK PROCEDURE

4. Energy Source Electricity, Systems under pressure such as gases, oil, water, air, steam or other Stored Energy equipment such as flywheels, gravitational and kinetic systems that pose a threat to people and their safety. Field Site is any area external to the precincts of either Waite or Roseworthy Campuses on which AFW staff or students are required to undertake work, this includes any land holding not under the control of AFW. Contaminated Ground Any area that has been contaminated by spilled flammable or combustible liquids or solids. Lock-out The use of a lock and authority system that prevents an energy source from being inadvertently turned on during equipment maintenance or repair. Tag-out A system utilising warning tags indicating an item of plant or equipment that has been isolated for maintenance and may not be turned on or used. Supervisor Any person who undertakes to guide or instruct another person in any work process. Fire Watcher A person assigned to work with the people conducting the hot work processes, normally located outside the work area, to watch for any fires resulting from the hot work process. HOT WORK PERMIT An application for an AFW Hot Work Permit must be made prior to the commencement of any procedure that requires hot work to be undertaken in any hazardous area, confined space or field site. As many occasions of hot work will involve agricultural machinery there will be a potential for contact with diesel or petrol fumes, therefore there is an increased need for vigilance during these procedures. Similarly, there needs to be a raised level of awareness when undertaking hot work in the field during harvesting as there will be a large expanse of dry fuel in the fields that may quickly get out of control. Hot Work undertaken in any AFW area that is specifically designed for hot work (such as engineering workshop welding bays) do not require the issuing of a Hot Work Permit. All requirements and precautions laid out in the Hot Work Permit must be met prior to the commencement of any hot work procedure. Application for a Hot Work Permit must be made through the office of the Technical Services Co-ordinator of the School of Agriculture, Food & Wine. Property Services Contractors are exempt from applying for any AFW Hot Work Permit as they are guided by the Property Services Hot Work Permit To Work Instructions & Hot Work Permit To Work systems. 5. RESPONSIBLE OFFICERS RESPONSIBILITIES Responsible Officers must be aware of the work to be undertaken for which the permit is being sought and understand all isolation and tagging procedures ensure that a permit is granted prior to the commencement of any work ensure that any person undertaking a Hot Work process is appropriately qualified ensure that all combustible and/or flammable substances are removed from the hot work area and if this is not possible see that it is adequately covered by fire resistant shielding understand and ensure that all appropriate checks are undertaken prior to and during the period of the permit ensure that all tags, warning signs and the permit to undertake Hot Work are prominently displayed ensure that prior to any field work all emergency numbers are obtained and are readily available to all persons working within the hot work area ensure that, when undertaking hot work within a building the Building Warden, area Health & Safety Representative and local building occupants have been informed of the intended work ensure that adequate first aid kit/s and/or facilities are readily available at the hot work area

http://www.adelaide.edu.au/hr/ohs/handbook/first_aid/ - First Aid Policy & Guidelines

Uncontrolled if Printed Produced By TJ MacKenzie Effective Date 25/3/2010 Version 1.1 Page 2 of 4 Date of Next Review - 25/3/2012

http://www.adelaide.edu.au/hr/ohs/handbook/plant_safety/ Plant Management- Danger (Lockout) and Out of Service Tag Procedure

http://www.adelaide.edu.au/hr/ohs/handbook/chemical/ - Chemical Safety Management Policy and Guidelines

HOT WORK PROCEDURE

ensure that appropriate persons are informed when the work described in the permit is completed, suspended or cancelled RESPONSIBILITIES OF PERSONS UNDERTAKING WORK Responsible person/s must satisfy themselves that they understand all of the requirements of the permit ensure they are competent to carry out the work required, including the use of any Personal Protective ensure they are aware of any hazards that exist in the work area and that all necessary controls are in place and all Lock-out and Tag-out systems are in place

http://www.adelaide.edu.au/hr/ohs/handbook/hazard/ - Hazard Management Policy and Procedure http://www.adelaide.edu.au/hr/ohs/handbook/plant_safety/ Plant Management- Danger (Lockout) and Out of Service Tag Procedure

6.

ensure that fully charged and operable fire extinguishers, appropriate to the work being undertaken, are kept in the immediate vicinity of the hot work area, during the term of the Hot Work Permit ensure that any equipment used within the work area is of an approved type and in a good state of repair and that manufacturers procedures/recommendations for that equipment are followed ensure that the work area is a restricted work area and appropriate precautions are taken to limit access by unauthorised persons ensure that all fire resistant shielding is in place and if spark generating welding is being undertaken that flash screens are in place ensure that all work is performed in the safest manner possible 7. FIRE WATCH REQUIREMENTS Fire watch procedures will be implemented whenever hot work is being conducted within 10 meters of any combustible material regardless of the protection provided. A qualified person proficient in the operation of fire extinguishing equipment and conversant with the local area emergency procedures will observe the hot work area. The purpose of the Fire Watcher is to detect and prevent the spread of any fire produced by the hot work process. The fire watch process should be maintained for at least 30 minutes after the completion of the hot work processes. Fire Watch personnel are mandatory during any Hot Work procedure undertaken in any field or farm holding. FIRE ALARM ISOLATION Any person undertaking Hot Work must ensure that all fire detection systems are isolated within the area for the duration of the hot work and ensure that they are reinstated at the completion of the Hot Work processes. Isolation of any fire detection system installed in AFW facilities must be undertaken through Campus Security; Waite Campus ph 8303 7200 Roseworthy Campus ph 8303 7999 9. ENVIRONMENTAL CONDITIONS Any Responsible Officer applying for a Hot Work Permit, must give due consideration to all environmental conditions for the duration of the permit. A Hot Work Permit may be refused, cancelled or withdrawn if weather conditions are considered extreme and/or hazardous to any person/s or property during a hot work procedure. Hot Work Permits will not be issued for any external hot work procedure to be undertaken on a Total Fire Ban Day.

8.

10. FIRST AID Responsible Officers must ensure that the location of adequate first aid kit/s and facilities are known and are readily accessible. If adequate first aid is not readily accessible a compliant first aid kit must be provided at the hot work area. Responsible officers must ensure that all emergency control numbers are clearly posted at the hot work area.

Uncontrolled if Printed Produced By TJ MacKenzie Effective Date 25/3/2010 Version 1.1 Page 3 of 4 Date of Next Review - 25/3/2012

HOT WORK PROCEDURE

11. PERMIT AUTHORISATION, CANCELLATION OR WITHDRAWAL Application for a Hot Work Permit must be made through the office of the Technical Services Co-ordinator of the School of Agriculture, Food & Wine. Authorisation and/or Cancellation of a Hot Work Permit may only be effected through the office of the Technical Services Co-ordinator of the School of Agriculture, Food & Wine. Withdrawal of a Hot Work Permit may be undertaken by the Responsible Officer named on the permit at any time during the term of the permit. Any permit withdrawn from use must be returned to the original point of issue. 12. PERMIT APPLICATION BY TELEPHONE Application for a Hot Work Permit may only be authorised over a telephone for one off emergency situations that may occur, such as equipment failure during seeding or harvesting field trips. Hot Work Permits will not be authorised over the telephone for any activity undertaken at either Waite or Roseworthy Campuses, these applications must be made either in person, by e-mail or by fax. 13. DOCUMENT CONTROL All Hot Work Permits and associated Confined Space Permit/s, Risk Assessment/s, Safe Operating Procedure/s and Job Safety Analysis shall be saved and stored in accordance with the AFW document control guidelines and record management procedures. 14. INCIDENT REPORTING All incidents that arise out of, or in the course of any University sponsored activity must be reported. The immediate supervisor of the injured person/s is responsible for ensuring that the correct processes are followed. The University has developed an Incident and Near Miss Report and Investigation Form, commonly known as the yellow card. This form addresses the requirements of AS 1885.1, Workplace injury and disease recording standard. Forms are available from secretaries, Health & Safety Officers, Health and Safety Representatives (HSR), and the OH&S Unit. http://www.adelaide.edu.au/hr/ohs/handbook/incident_near_miss/ - Incident, Near Miss Reporting and Investigation Policy and

Guidelines

Uncontrolled if Printed Produced By TJ MacKenzie Effective Date 25/3/2010

Version 1.1 Page 4 of 4 Date of Next Review - 25/3/2012

Anda mungkin juga menyukai

- Title: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Dokumen5 halamanTitle: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Adeyinka MichealBelum ada peringkat

- Hot Work: Standard Operating ProceduresDokumen4 halamanHot Work: Standard Operating Proceduresdroffilcz27Belum ada peringkat

- 26 - Hot Work Procedure V2Dokumen18 halaman26 - Hot Work Procedure V2Hussain AhmedBelum ada peringkat

- VEDANTA LIMITED SULPHATE REMOVAL PLANT HOT WORK PROCEDUREDokumen30 halamanVEDANTA LIMITED SULPHATE REMOVAL PLANT HOT WORK PROCEDUREOws Anish100% (2)

- TANK REPAIR SAFETY STEPSDokumen19 halamanTANK REPAIR SAFETY STEPSPerwez21100% (1)

- Hse Guide: Statement of Policy On Health, Safety and EnvironmentDokumen2 halamanHse Guide: Statement of Policy On Health, Safety and EnvironmenttissaanuradhaBelum ada peringkat

- Safty PlanDokumen91 halamanSafty Planmujahid1137100% (1)

- Hot Work Permits: Corporate Environment Safety & HealthDokumen17 halamanHot Work Permits: Corporate Environment Safety & HealthBv Rao100% (1)

- Permit To Work EOH-SP-FORM 531.01Dokumen2 halamanPermit To Work EOH-SP-FORM 531.01Brad EubankBelum ada peringkat

- Fire Extingisher Inspection ProcedureDokumen2 halamanFire Extingisher Inspection ProcedurewaheedBelum ada peringkat

- Work Instruction - 09 Hot WorkDokumen6 halamanWork Instruction - 09 Hot Workbabu nair100% (2)

- DRG International HSE Policy for Construction ContractingDokumen1 halamanDRG International HSE Policy for Construction ContractingHassan Ali Hassan100% (1)

- Vinati Organics waste management procedureDokumen4 halamanVinati Organics waste management procedurejulio_salas_59Belum ada peringkat

- Hot Work Permit FormDokumen2 halamanHot Work Permit FormN.JBelum ada peringkat

- Job Safety AnalysisDokumen1 halamanJob Safety AnalysisWati KaBelum ada peringkat

- Project HSE Action Plan SummaryDokumen101 halamanProject HSE Action Plan SummaryArya RozaanBelum ada peringkat

- HSE InductionDokumen16 halamanHSE InductionChethan100% (4)

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDokumen2 halamanCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankBelum ada peringkat

- Excavation Safety ProcedureDokumen8 halamanExcavation Safety ProcedureJamilBelum ada peringkat

- Excavation Procedure & Permitting GuideDokumen4 halamanExcavation Procedure & Permitting GuideTengku & Wan ResourcesBelum ada peringkat

- Tool Box Talk Waste SegregationDokumen1 halamanTool Box Talk Waste SegregationNgel EvnsBelum ada peringkat

- Excavation Work PermitDokumen1 halamanExcavation Work PermitAndy Sayco100% (1)

- HSE 25 Safety SignageDokumen6 halamanHSE 25 Safety SignageAmine Faid100% (1)

- Form Report Safety CampaignDokumen1 halamanForm Report Safety CampaignErlan Gus HermawanBelum ada peringkat

- HSE Plan TemplateDokumen8 halamanHSE Plan Templatederson50% (2)

- Job Safety Analysis Construction, EtcDokumen3 halamanJob Safety Analysis Construction, EtcCamilo Salvadora MasbateBelum ada peringkat

- HSE HandbookDokumen53 halamanHSE Handbookmuthuswamy77Belum ada peringkat

- Control of Substances Hazardous To Health and Safety Risk Assessment FormDokumen3 halamanControl of Substances Hazardous To Health and Safety Risk Assessment Formhemanth_chaturvedulaBelum ada peringkat

- PTWDokumen2 halamanPTWMazhairil Paet100% (1)

- Life Saving Rules FAQsDokumen7 halamanLife Saving Rules FAQsArulboy123100% (1)

- JOB SAFETY ANALYSIS REPORTDokumen1 halamanJOB SAFETY ANALYSIS REPORTr0shBelum ada peringkat

- EHS PolicyDokumen29 halamanEHS PolicyAli AlhaikBelum ada peringkat

- Bhate & Raje Construction Co. Pvt. LTD: Electrical Work PermitDokumen1 halamanBhate & Raje Construction Co. Pvt. LTD: Electrical Work Permitvinayak salve100% (1)

- Heat Stress Management Inspection ChecklistDokumen1 halamanHeat Stress Management Inspection ChecklistrexivyBelum ada peringkat

- 5 Stop Work PolicyDokumen3 halaman5 Stop Work PolicyJEYES BELMENBelum ada peringkat

- ToolBox Talk 5Dokumen2 halamanToolBox Talk 5bashirdarakBelum ada peringkat

- Office Safety Checklist: Housekeeping Yes No N/ADokumen2 halamanOffice Safety Checklist: Housekeeping Yes No N/Aahmar javed100% (1)

- Working at HeightDokumen28 halamanWorking at HeighteustaquipaixaoBelum ada peringkat

- Contractor Safety Orientation EssentialsDokumen68 halamanContractor Safety Orientation EssentialsdethscrimBelum ada peringkat

- ALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESDokumen2 halamanALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESsauspy100% (1)

- Construction Assessment Checklist: Green TagDokumen2 halamanConstruction Assessment Checklist: Green TagRyan GillespieBelum ada peringkat

- Work at HeightDokumen1 halamanWork at HeightVikas Yamagar100% (2)

- HSE Monthly Report For XXXX2 ProjectDokumen30 halamanHSE Monthly Report For XXXX2 ProjectAhmed Hassan Sabry80% (5)

- JSA Evaluation 2011Dokumen2 halamanJSA Evaluation 2011case013Belum ada peringkat

- Confined Space Procedure PDFDokumen16 halamanConfined Space Procedure PDFdidikBelum ada peringkat

- Confined Space ProcedureDokumen16 halamanConfined Space ProcedureRey Gaballo Jr67% (3)

- HSES HandbookDokumen48 halamanHSES HandbookNorman Ainomugisha100% (1)

- 04 Jsa For Camp Constn & Associated FacilitysDokumen5 halaman04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- Basic Hse TrainingDokumen33 halamanBasic Hse Trainingnsankar71100% (3)

- Hot WorkDokumen20 halamanHot WorkmarceloBelum ada peringkat

- JSA Template 5 - Plumbing and Wastewater System InspectionsDokumen13 halamanJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Heat Stress Assessment Checklist: Section IDokumen3 halamanHeat Stress Assessment Checklist: Section IninisaisBelum ada peringkat

- BBTTCC Safety Observation CardDokumen1 halamanBBTTCC Safety Observation CardKaavi MaharajBelum ada peringkat

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDari EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemBelum ada peringkat

- Battery Room VentilationDokumen6 halamanBattery Room VentilationNiong DavidBelum ada peringkat

- Commissioning of DC & UPS SystemsDokumen61 halamanCommissioning of DC & UPS Systemshajimak100% (2)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Injury & Illness Prevention Program: Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed byDokumen1 halamanInjury & Illness Prevention Program: Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed byMuhammad Sajid ShamsBelum ada peringkat

- Aerial LiftDokumen1 halamanAerial LiftMuhammad Sajid ShamsBelum ada peringkat

- Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEDokumen1 halamanPicture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEMuhammad Sajid ShamsBelum ada peringkat

- Electrical SafetyDokumen34 halamanElectrical SafetyMuhammad Sajid ShamsBelum ada peringkat

- 1 1 3Dokumen186 halaman1 1 3ahmediqbalawan100% (1)

- Confined Space NarrativeDokumen8 halamanConfined Space NarrativeKhalid MahmoudBelum ada peringkat

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Dokumen15 halamanJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanBelum ada peringkat

- Oil Industry Safety ResumeDokumen5 halamanOil Industry Safety Resumesudeesh kumarBelum ada peringkat

- Daily Tool Box TalkDokumen55 halamanDaily Tool Box Talkmehtab uddin100% (1)

- Bosiet Huet FoetDokumen56 halamanBosiet Huet FoetsumnertingBelum ada peringkat

- Risk Assesment - RT-PTDokumen6 halamanRisk Assesment - RT-PTJohn Eric OliverBelum ada peringkat

- Aws Safety and Health Fact Sheet Bundle: For Chemical Industry WeldingDokumen13 halamanAws Safety and Health Fact Sheet Bundle: For Chemical Industry WeldingBalakumarBelum ada peringkat

- Benchmarking Safety Data 2020Dokumen15 halamanBenchmarking Safety Data 2020Orlando PiñasBelum ada peringkat

- Is 15183 1 2002 PDFDokumen20 halamanIs 15183 1 2002 PDFDr. Shantanu PaulBelum ada peringkat

- Job Safety Analysis for Pipeline ReconditioningDokumen5 halamanJob Safety Analysis for Pipeline Reconditioningshinto Lawrence100% (2)

- CABLE PULLING SAFETYDokumen13 halamanCABLE PULLING SAFETYchiat mingBelum ada peringkat

- PR 1515Dokumen36 halamanPR 1515REGUIEGBelum ada peringkat

- SE Contractor Safety Handbook 2021-2023Dokumen57 halamanSE Contractor Safety Handbook 2021-2023Muhmed Abdel AlimeBelum ada peringkat

- Fabrication Site Construction Safety Recommended Practice - Hazardous ActivitiesDokumen44 halamanFabrication Site Construction Safety Recommended Practice - Hazardous ActivitiesnessieanatashaBelum ada peringkat

- UTP Chemical Engineering HSE Course OverviewDokumen4 halamanUTP Chemical Engineering HSE Course OverviewJeffery ChiaBelum ada peringkat

- Land PTW Procedure SummaryDokumen36 halamanLand PTW Procedure Summarysenator100% (1)

- Authorised Gas Tester Training Level 1 Gas Testing Including Confined Space Testing PDFDokumen42 halamanAuthorised Gas Tester Training Level 1 Gas Testing Including Confined Space Testing PDFahmedBelum ada peringkat

- Agitator WeightDokumen66 halamanAgitator Weighttiffanyyy00Belum ada peringkat

- Ocp-24-Dust and Fume ControlDokumen1 halamanOcp-24-Dust and Fume ControlZubair KhanBelum ada peringkat

- Contractor Hse Plan Guideline - EditedDokumen11 halamanContractor Hse Plan Guideline - EditedMohd Azro Mohd NorBelum ada peringkat

- MIT Pressure Vessel ProceduresDokumen9 halamanMIT Pressure Vessel ProceduresMonica WijayaBelum ada peringkat

- Annex 06 - ODS HSE Plan 0236-22-HRR-K - Mirawa 1 Rev.3 - IGDokumen47 halamanAnnex 06 - ODS HSE Plan 0236-22-HRR-K - Mirawa 1 Rev.3 - IGFahmi AbdullahBelum ada peringkat

- OSHA Fact Sheet On Confined Space ProceduresDokumen2 halamanOSHA Fact Sheet On Confined Space ProceduresRauf HuseynovBelum ada peringkat

- Job Hazard Analysis Safety ControlsDokumen18 halamanJob Hazard Analysis Safety ControlsBNCH100% (3)

- Code: Mech 100.0 Risk Assessment - GrindingDokumen2 halamanCode: Mech 100.0 Risk Assessment - Grindingste23571Belum ada peringkat

- eكتيب السلامة للمقاولين ISS-03Dokumen40 halamaneكتيب السلامة للمقاولين ISS-03SAEED ALGHAMDIBelum ada peringkat

- L4-QAT-087C Method Statement For Patch Repair WorkDokumen10 halamanL4-QAT-087C Method Statement For Patch Repair WorkrajaBelum ada peringkat

- RSIM - Part 1 Inspection Policy and ProceduresDokumen28 halamanRSIM - Part 1 Inspection Policy and Proceduresandy milchemBelum ada peringkat

- Nebosh IGC 3 Observation Sheet 00218445 FinalDokumen16 halamanNebosh IGC 3 Observation Sheet 00218445 FinalMichael Amane88% (94)