Diametral Pitch Spur Gears

Diunggah oleh

abhishekghatgeDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Diametral Pitch Spur Gears

Diunggah oleh

abhishekghatgeHak Cipta:

Format Tersedia

Call us at (800) 491-1073 and ask for Design Support * commercialgear.

com

DIAMETRAL PITCH SPUR GEARS

TO GET Module HAVING Diametral pitch RULE Divide 25.4 by the diametral pitch Divide 25.4 by the module Divide by the circular pitch FORMULA m = 25.4 / Pd

Module Circular pitch Pitch diameter and number of teeth Diametral pitch Outside of gear and number of teeth

Pd = 25.4 / m Pd = / P

Divided the number of teeth Pd = N / D by pitch diameter Divide number of teeth plus 2 by the outside diameter Divide the base pitch by the cosine of the pressure angel then divide by

Pd = N + 2 / Do

Base pitch and pressure angle

Pd=(Pb / cos. ) /

Operating diametral pitch

Center distance between 2 gears and number of teeth in both

Add the number of teeth in both gears and divide dp = (n1 + n2 / by 2, then divide 2) / C by center distance Divide the base diameter by cos. = Db / D

Pressure angle

Base diameter and pitch

diameter Base pitch and diametral pitch

pitch diameter Divide by diametral pitch, then divide by the base pitch Divide the base pitch by the circular pitch = cosine pressure angle cos. = Pb / (/Pd)

Base pitch and circular pitch

cos = Pb / P

Divide the Number of teeth number of teeth and diametral D = N / Pd by the diametral pitch pitch Divide the product of the Number of teeth outer diameter D = N * Do / n and outer and number of +2 diameter teeth by number of teeth +2 Pitch diameter Subtract from the outside diameter, the quotient of 2 divided by the diametral pitch Multiply addendum by the number of teeth Divide the base diameter by the cosine of the pressure angle

Outside diameter and diametral pitch

D = Do - 2 / pd

Addendum and number of teeth

D=a*n

Base diameter and pressure angle Outside diameter

dp = Db / cos.f

Divide number Number of teeth of teeth plus 2 and diametral Do = N + 2 / Pd by the diametral pitch pitch

Pitch diameter and diametral pitch

Add the pitch diameter to the quotient of 2 divided by the diametral pitch

Do = D + 2 / Pd

Pitch diameter and number of teeth

Divide the number of teeth plus 2 by the Do = N + 2 / N / quotient of D number of teeth divided by the pitch diameter

Multiply the Number of teeth number of teeth Do = (N + 2) a plus 2 by and addendum addendum Pitch diameter and diametral pitch Number of teeth Outside diameter and diametral pitch Multiply pitch diameter by the diametral pitch Multiply outside diameter by the diametral pitch and subtract 2 N = D * Pd

N = Do * Pd - 2

Std. thickness of Diametral pitch tooth Std. addendum Diametral pitch

Divide 1.5708 by the diametral t = 1.5708 / Pd pitch Divide 1 by the diametral pitch a = 1 / Pd

Std. dedendum

Diametral pitch

Divide 1.157 (or 1.25) by the b = 1.157 / Pd diametral pitch Divide 2.157 (or 2.25) by the ht = 2.157 / Pd diametral pitch Divide .157 (or .250) by the diametral pitch c = .157 / Pd

Std. whole depth

Diametral pitch

Clearance

Diametral pitch Thickness of

Divide thickness c = t / 10

tooth

of tooth at pitch line by 10 Add number of teeth in both gears together and divide by 2, then divide result by the normal diametral pitch Add the number of teeth in both gears together and divide by 2, then divide results by operating diametral pitch Multiply the pitch diameter by cosine of the pressure angle Divide the diametral pitch by , then multiply by cosine of pressure angle

Center distance

Normal diametral pitch and number of teeth in both gears

dp = ((n1 + n)2 / 2) / Pnd

Operating diametral pitch Operating center and number of distance teeth in both gears

dp = (n1 + n2 / 2) / Pod

Base diameter

Pitch diameter and pressure angle

Db = D * cos.

Base pitch

Diametral pitch and pressure angle

Pb = cos. * / Pd

DISCLAIMER AND LIMITED LIABILITY Commercial Gear and Sprocket Company, Inc. has provided this Designers & Engineers Resource in an effort to help you conceptualize your design. Due to the complex nature of designing and its interaction with an assortment of components, Commercial Gear and Sprocket Company, Inc. does not warrant that the usage of this site and the information therein is completely error free or fit for your specific design. Commercial Gear and Sprocket Company, Inc. makes no warranties, express or implied, with respect to the usage of the information provided or as to its fitness for any particular purpose. Commercial Gear and Sprocket Company, Inc. shall not be liable for any damage or loss of any kind, whether direct or indirect, incidental or consequential, regardless of whether such liability is based in Tort, Contract or otherwise including without limitation damages for loss of business, business profits, business interruption, or any other pecuniary loss arising out of or relating to the use of this site. Commercial Gear and Sprocket Company, Inc. is however, standing by to assist you or design and fabricate to your specifications. Our third generation family owned company has been producing quality gears and other power transmission products at competitive prices since 1946. Call us at (800) 491-1073 and ask for Design Support

Anda mungkin juga menyukai

- Basic Gear Terminology and CalculationDokumen10 halamanBasic Gear Terminology and CalculationTesseract spyderBelum ada peringkat

- Engineers Precision Data Pocket ReferenceDari EverandEngineers Precision Data Pocket ReferencePenilaian: 3 dari 5 bintang3/5 (1)

- Astm D2467-2013Dokumen8 halamanAstm D2467-2013Renato CorrêaBelum ada peringkat

- Gear FormulaeDokumen13 halamanGear Formulaeian_newBelum ada peringkat

- Rack and PinionDokumen16 halamanRack and PinionjeronimoisraelBelum ada peringkat

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Dari EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Penilaian: 4.5 dari 5 bintang4.5/5 (5)

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingDari EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingBelum ada peringkat

- Gear Tooth Thickness MeasurmentDokumen7 halamanGear Tooth Thickness MeasurmentYohannes Mengistu AbebeBelum ada peringkat

- DFM Guidebook Sheetmetal Design Guidelines Issue XVIII PDFDokumen11 halamanDFM Guidebook Sheetmetal Design Guidelines Issue XVIII PDFNandang KuroshakiBelum ada peringkat

- Polymers and Polymers BlendsDokumen51 halamanPolymers and Polymers Blendsziradagreat539Belum ada peringkat

- 1 - Vastu Principles (Ankit Mishra-08010381364) PDFDokumen100 halaman1 - Vastu Principles (Ankit Mishra-08010381364) PDFSampath Kumar100% (2)

- Spur Gear CalculationsDokumen2 halamanSpur Gear CalculationsPuneet Verma100% (2)

- Drawing of GearboxDokumen1 halamanDrawing of GearboxRisira Erantha KannangaraBelum ada peringkat

- Gears, Splines, and Serrations: Unit 24Dokumen8 halamanGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- SolidWorks 2017 Black Book: SolidWorks Black BookDari EverandSolidWorks 2017 Black Book: SolidWorks Black BookPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- SolidWorks 2016 Learn by doing 2016 - Part 3Dari EverandSolidWorks 2016 Learn by doing 2016 - Part 3Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- VendorList 1Dokumen27 halamanVendorList 1मनोज चौधरीBelum ada peringkat

- Spur Gear Calculations and FormulasDokumen2 halamanSpur Gear Calculations and FormulasBilal Tayyab100% (2)

- Spur Gear Calculations and FormulasDokumen3 halamanSpur Gear Calculations and FormulasTan CheehouBelum ada peringkat

- OmniGear Tech Info BinderDokumen86 halamanOmniGear Tech Info BinderMiguel Matias ReineroBelum ada peringkat

- Diametral PitchDokumen2 halamanDiametral Pitchbrpnaidu2157Belum ada peringkat

- Basic Gear Terminology and Calculation - KHK Gears PDFDokumen8 halamanBasic Gear Terminology and Calculation - KHK Gears PDFMinhas ArshadBelum ada peringkat

- Basic Gear Terminology and Calculation - KHK GearsDokumen8 halamanBasic Gear Terminology and Calculation - KHK GearsSuyandi SinagaBelum ada peringkat

- BASIC GEAR TERMINOLOGY AND CALCULATION EXPLAINEDDokumen14 halamanBASIC GEAR TERMINOLOGY AND CALCULATION EXPLAINEDAnimesh ManiBelum ada peringkat

- Safari - May 16, 2022 at 9:00 PMDokumen1 halamanSafari - May 16, 2022 at 9:00 PMDagneBelum ada peringkat

- a R i z m mn b α β fo c x Ψ Ψm ΨyDokumen6 halamana R i z m mn b α β fo c x Ψ Ψm ΨykuttuasrBelum ada peringkat

- Gear Dimension Calculation Tips DP CP ModDokumen3 halamanGear Dimension Calculation Tips DP CP ModGilbertoUGOBelum ada peringkat

- Circular Pitch Spur GearsDokumen1 halamanCircular Pitch Spur Gearsਗਗਨ ਜੋਤBelum ada peringkat

- Basic Gear Terminology and Calculation - KHK GearsDokumen10 halamanBasic Gear Terminology and Calculation - KHK GearsJoab Max Apaza MartinezBelum ada peringkat

- Gear Formulae - Engineers EdgeDokumen2 halamanGear Formulae - Engineers EdgeleovenuBelum ada peringkat

- Spur Gear CalculatorDokumen16 halamanSpur Gear CalculatorMinh Trí KnightBelum ada peringkat

- Gears PDFDokumen8 halamanGears PDFmgualdiBelum ada peringkat

- Chapter 05Dokumen15 halamanChapter 05Muhammad Nur IkhwanBelum ada peringkat

- 8mm HTD Timing Belt Pulley PD and OD ChartDokumen2 halaman8mm HTD Timing Belt Pulley PD and OD ChartNikolas FabryBelum ada peringkat

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDokumen3 halamanExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkTran DucBelum ada peringkat

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDokumen3 halamanExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDhian WijayaBelum ada peringkat

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDokumen3 halamanExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkAgil RamadhanBelum ada peringkat

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDokumen3 halamanExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkMoorthy GanesanBelum ada peringkat

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDokumen4 halamanExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkRichard De Medeiros CastroBelum ada peringkat

- Module Gear DataDokumen2 halamanModule Gear DataMuhammad HaiderBelum ada peringkat

- Design of Spur Gears in 38 CharactersDokumen29 halamanDesign of Spur Gears in 38 CharactersAishwarya RameshBelum ada peringkat

- Bending Formulas For Tube Bending ToolsDokumen3 halamanBending Formulas For Tube Bending ToolsVikash SharmaBelum ada peringkat

- DFM Guidebook Sheetmetal Design Guidelines Issue XVDokumen11 halamanDFM Guidebook Sheetmetal Design Guidelines Issue XVRushil ShahBelum ada peringkat

- RDT High Torque ConnectionsDokumen4 halamanRDT High Torque ConnectionsJohan Medina TovarBelum ada peringkat

- Straight Spur Gears and RACKSDokumen10 halamanStraight Spur Gears and RACKSIRONSAVIORBelum ada peringkat

- Formular Formula - HTMDokumen3 halamanFormular Formula - HTMTomy GeorgeBelum ada peringkat

- Elements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasDokumen13 halamanElements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasRakeshvb10Belum ada peringkat

- ACME Threads PDFDokumen2 halamanACME Threads PDFzbhdzpBelum ada peringkat

- ACME Threads TypeDokumen2 halamanACME Threads TypeCahya Adi YeftaBelum ada peringkat

- DJJ 10033-Chapter 5.GEARDokumen34 halamanDJJ 10033-Chapter 5.GEARStepianus JtBelum ada peringkat

- DJJ 10033-Chapter 5Dokumen45 halamanDJJ 10033-Chapter 5Abbas SeuBelum ada peringkat

- Inventor-Gears - Jeffery J Jensen Wiki PDFDokumen30 halamanInventor-Gears - Jeffery J Jensen Wiki PDFEndalkachew Abate100% (1)

- AcmeDokumen2 halamanAcmeShatish KumarBelum ada peringkat

- 2 Gear BasicsDokumen6 halaman2 Gear BasicsMohamed Adel RizkBelum ada peringkat

- Mechanical Gear Measurements and MetrologyDokumen4 halamanMechanical Gear Measurements and Metrologykathir drayBelum ada peringkat

- GearsDokumen10 halamanGearsUmer Iftikhar AhmedBelum ada peringkat

- Rack & Pinion Gear Tooth ChartDokumen2 halamanRack & Pinion Gear Tooth ChartIonescuTeodora50% (2)

- INST 6150: Communication Instruction and The Learning ProcessDokumen12 halamanINST 6150: Communication Instruction and The Learning ProcesssarumadamanaBelum ada peringkat

- Worms Worm Gears-Formulas Self Locking PDFDokumen1 halamanWorms Worm Gears-Formulas Self Locking PDFalexdisu4510Belum ada peringkat

- Spur Gears Level 2Dokumen2 halamanSpur Gears Level 2rahul_patil85Belum ada peringkat

- Geometric Entities: Basic Gear TerminologyDokumen5 halamanGeometric Entities: Basic Gear TerminologyMatija RepincBelum ada peringkat

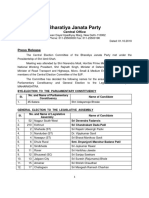

- 1st List of BJP Candidate For Maharashtra Legislative Assembly Election October 2019 On 01.10.2019Dokumen5 halaman1st List of BJP Candidate For Maharashtra Legislative Assembly Election October 2019 On 01.10.2019Sukanya RayBelum ada peringkat

- Ashirvad ColumnpipesDokumen44 halamanAshirvad ColumnpipescsudhaBelum ada peringkat

- Autodesk Moldflow Insight Standard: Tushar P ChaudhariDokumen1 halamanAutodesk Moldflow Insight Standard: Tushar P Chaudhariमनोज चौधरीBelum ada peringkat

- "Standard"Hopper Dryer - SHDDokumen28 halaman"Standard"Hopper Dryer - SHDमनोज चौधरीBelum ada peringkat

- 3p2 PRINT PDFDokumen52 halaman3p2 PRINT PDFमनोज चौधरीBelum ada peringkat

- Module Gear DataDokumen2 halamanModule Gear DataMuhammad HaiderBelum ada peringkat

- Industial Training Report.Dokumen3 halamanIndustial Training Report.मनोज चौधरीBelum ada peringkat

- Full Page PhotoDokumen1 halamanFull Page Photoमनोज चौधरीBelum ada peringkat

- Design Engineer Seats Closure (M F) Pune (Hinjawadi Village) Test 990Dokumen1 halamanDesign Engineer Seats Closure (M F) Pune (Hinjawadi Village) Test 990मनोज चौधरीBelum ada peringkat

- Property Test Method Units Polypropylene CopolymerDokumen1 halamanProperty Test Method Units Polypropylene Copolymerमनोज चौधरीBelum ada peringkat

- Temperature Measurements With Thermocouples: How-To Guide: Document Type NI Supported Publish DateDokumen6 halamanTemperature Measurements With Thermocouples: How-To Guide: Document Type NI Supported Publish DateDilip PatelBelum ada peringkat

- Property Test Method Units Polypropylene CopolymerDokumen1 halamanProperty Test Method Units Polypropylene Copolymerमनोज चौधरीBelum ada peringkat

- Manhunt PlacementDokumen1 halamanManhunt Placementमनोज चौधरीBelum ada peringkat

- Resignation Letter 2Dokumen1 halamanResignation Letter 2मनोज चौधरी0% (1)

- Engineering MaterialsDokumen93 halamanEngineering MaterialsVinaya Almane DattathreyaBelum ada peringkat

- Digimat For Automotive ApplicationsDokumen52 halamanDigimat For Automotive Applicationsमनोज चौधरीBelum ada peringkat

- PP Molding Conditions USADokumen3 halamanPP Molding Conditions USAमनोज चौधरीBelum ada peringkat

- Automation and Situation Awareness - EndsleyDokumen11 halamanAutomation and Situation Awareness - Endsleyमनोज चौधरीBelum ada peringkat

- Seniority Report: Directorate of Employment and Self EmploymentDokumen1 halamanSeniority Report: Directorate of Employment and Self Employmentमनोज चौधरीBelum ada peringkat

- AkulonK224G6 enDokumen6 halamanAkulonK224G6 enमनोज चौधरीBelum ada peringkat

- C 100008Dokumen2 halamanC 100008मनोज चौधरीBelum ada peringkat

- 01 Introduction To Industrial Automation and ControlDokumen18 halaman01 Introduction To Industrial Automation and ControlPallavi SinglaBelum ada peringkat

- Mechanical Engineering 2006 Sem VIDokumen7 halamanMechanical Engineering 2006 Sem VIRahul Raveendran PillaiBelum ada peringkat

- Assembly Design Guidelines for Simplified ManufacturingDokumen5 halamanAssembly Design Guidelines for Simplified ManufacturingChethan SkBelum ada peringkat

- Ug Drafting Basic OperationsDokumen3 halamanUg Drafting Basic Operationsdinesh_apkBelum ada peringkat