CV

Diunggah oleh

DGHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CV

Diunggah oleh

DGHak Cipta:

Format Tersedia

@

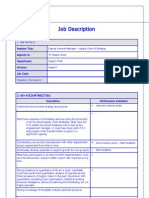

POSITION SOUGHT: QUALIFICATIONS:

Position in Demand Planning / SCM APICS CSCP Candidate Scored more than 85% in Web based test of APICS CSCP MBA (Final yr ) from ICFAI University PG Diploma in Business Management ICFAI Business School 2010 Bachelor of Science (Mathematics) Sri Venkateswara University 1994 Scion International LLC 3 - 4 Weeks Sharjah Dubai English + Indian Holds valid UAE Driving License

EMPLOYERS: AVAILABILITY: CURRENTLY RESIDES: PREFERRED LOCATION: LANGUAGES: UAE LICENSE

Objective Analytical Power: APICS Certified Supply Chain Candidate

Involved in S&OP , demand planning , production planning , sales and distribution planning , inventory management Participated in regional Sales and Operations Planning processes in a matrix organization structure. Previous experience managing Asia-based vendors / Suppliers Expert proficient in JD Edwards ERP A keen planner & strategist with expertise in Materials & controlling the production operations as per the capacity available. Experienced in both Purchase and Planning activities with SCM exposure Proficient in Excel, Word and Power Point, Writes Blog for Excel in Linked in Outstanding communication skills (written and verbal), have demonstrated ability to manage total costs, execute, lead and implement process improvements, solid analytical skills, and the ability to work effectively within a fast-paced, team environment. Expertise in materials management including planning, sourcing, procurement and maintaining MIS. Significant experience in contributing to the formulation & execution of the units business plans. Exposure to central planning and handled capacity & supply planning, business distribution & network planning, demand planning & inventory management

EMPLOYMENT HISTORY: Asst. Manager, DEMAND PLANNING & SUPPLY CHAIN October 2008 - Present

Basic Functions:

Develop demand forecasts (operational forecasts) at multiple levels of aggregation for multiple time horizons as part of a demand planning function. Review historical sales trends, research demand drivers, prepare forecast data, develop statistical forecast models, and evaluate forecast results. Coordinate cross-functional research activities to reconcile significant variances and refine the forecast model to reflect updated sales and marketing assumptions.

Page 1

Interact with sales, marketing, and customer finance to understand demand forecast drivers.

Key Performance Indicators (KPI) Forecast accuracy for product family mix & category mix Levels of bias in the country demand plan Gross Margin forecast accuracy Customer service levels Demand & Inventory Planning Primary responsibilities include Demand forecasting, inventory analysis

Receive FC form sales / Group Companies Generate sales forecasts by entering demand information into planning software to deliver accurate concentrate and material requirements to manufacturing, purchasing or scheduling operations; Managing the demand forecasting process in coordination with the sales, marketing and the supply chain teams Collaborate with New Products, Product Commercialization, Sales and Marketing to increase forecast accuracy; Establish performance criteria by tracking the performance of service agents, analyzing trends and benchmarking to identify areas for improved customer service Project short and long term volume estimates, using input from Sales, Production Plants, Distribution and Marketing to provide the system with accurate volumes to be used in budgeting; Challenge and validate FC based on full understanding of Scion supply capabilities and constraints Full understanding of Customers planning cycles and Supply chains , to ensure realistic demand flowing into the system Document the agreed process in SLAs. Provide support and consultancy to Sales planning teams when required Monitors Production delivery against demand plan Preparing reports to be presented in S & OP meetings Monitors and reports , slow moving stocks and leads liquidation plans with Sales team Represents commercial team targets in discussion with Supply and vice versa Leads FC accuracy enhancement project Identify , present and implement relevant Forecasting tools and modules Review historic sales trends, research of demand drivers, and preparation of forecast and evaluation of results Actively participate and contribute in Product Review, Demand Review & Supply Review of Integrated Business Planning (IBP) cycle. Conducting monthly Demand Review with the sales team Actively participate and contribute in monthly Product Review of IBP (Integrated Business Planning) cycle with sales & marketing team. Collaborative Contribution includes: Demand plan for new products based on target markets and geographies. Phase-in plan for new products and Phase-out plan for discontinued/selling off products. Product changeover plan Schemes/promotion finalization and impact on demand Rationalization of phased-out products Contribution towards: Actively participate and contribute in monthly Supply Review with Supply Chain and manufacturing team. Forward 8 months Sales-Production- Inventory planning Month end Inventory and future cover Supply performance - RSL (Range Service Level) & VSL (Volume Service Level) Production performance and capacity Utilization Work-out plans with marketing, logistics and finance team to reduce Cholesterol, Slow Moving and obsolete inventory from the system. Conducting S&OP to monitor performance and outcome of product review, Demand Review and supply review and action planning for improvement

Supply Planning Page 2

Central planning, responsible for supply planning, business distribution & network planning, capacity and production planning. This involved working closely with product development team, sales and marketing function and factories. Production and Distribution Planning for more than 2250 SKUs manufactured in 3 plants and distributed across US/ Europe / Far East & Indian Subcontinent markets. Redistribution planning from Central to Satellite warehouses. Yearly, monthly, weekly & daily production planning & scheduling. Monitor service levels and stock availability. Stock rebalancing plan in order to control cholesterol inventory. SKU Categorization- ABC & XYZ and replenishment strategy MTS, MTO Derivation of norms for each Plan-SKU and replenishing based on strategy. Improvement of availability of raw materials from 85% to 95%. Applying the Pull strategy for Customized Production ( especially for MTO items) Responsible for driving Pre-SOP (Pre - Sales & Operations Planning) meeting with the entire supply chain team

Purchase & Inventory Controller

Managed AED 2 -3 million inventory of more than 50,000 line items including short shelf lives SKUs. Primary responsibility includes Demand forecasting, inventory analysis involving main active 1000 SKUs with 25% new SKUs added per year Managed the demand forecasting process in coordination with the Sales team & Catering business teams. Projecting the demand on the sales history and preparing the material replenishment orders. Review of historic sales trends, research of demand drivers, preparation of forecast and evaluation of results Plans and conducts physical inventory verifications. & verifies adequacy of material preservation in the warehouse and recommends changes where necessary. Generate reports for management to make effective business decision. Effectively generate and monitor KPIs such as Levels of Safety Stock, Weeks of Sales in Inventory, forecast accuracies, and at the product, customer or market level, Average Order Value, Average number of SKUs per purchase.

Chennai, India Feb 1999 to Jul 1999

Responsible for managing the inventory levels of nearly 1400 SKUs of locally produced finished goods. Improved accuracy and timely delivery of supply chain metrics analysis and forecast results. Worked closely with sales, marketing, finance divisions and with regional offices creating and deploying cross-divisional systems in order to improve operational efficiency and effectiveness. Solved operational problems by analyzing feedback from customer service and operations teams. Reduced inventory holdings and delivery time of key products by developing suppliers located close to the site. Provided dept level information and ad hoc reports at the vendor / group / classification levels to assist in the planning of the advertising. Marketing, Promotions and special events

Chennai, India Aug 1996 to Feb 1999 Production Planning Executive Coordinating with the Deputy General Manager in planning and forecasting the production of the drives according to the Shipment Order.

@gmail.com

Page 3

Giving the required instructions and following the production & stores departments for the timely production & packing of the Finished Hard Disc Drives. Coordinating with the IQC (Incoming Quality Control) Dept. for the clearance of the goods and to transfer the goods to the production dept with the help of Stores. Preparing the dispatch plans for the FG to European Distributors.

Page 4

Anda mungkin juga menyukai

- Practical CS ProcessingDokumen483 halamanPractical CS ProcessinganAMUstudent100% (2)

- Massey Ferguson MF7600 Technician Workshop ManualDokumen798 halamanMassey Ferguson MF7600 Technician Workshop Manualgavcin100% (5)

- Director Materials Supply Chain in CA Resume Sue ThorntonDokumen3 halamanDirector Materials Supply Chain in CA Resume Sue ThorntonSueThornton1Belum ada peringkat

- DocxDokumen18 halamanDocxXavar XanBelum ada peringkat

- SNOPDokumen31 halamanSNOPSai BhaktBelum ada peringkat

- Lecture Notes - Sales & Operations PlanningDokumen7 halamanLecture Notes - Sales & Operations Planningmushtaque61Belum ada peringkat

- Drill Bit Classifier 2004 PDFDokumen15 halamanDrill Bit Classifier 2004 PDFgustavoemir0% (2)

- HBS - Zara Fast Fashion Case Write UpDokumen4 halamanHBS - Zara Fast Fashion Case Write Upaaronhwalton100% (1)

- Welding and Heat Treatment Requirements For Equipment and PipingDokumen34 halamanWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesBelum ada peringkat

- CV of Lihle ShongweDokumen6 halamanCV of Lihle ShongweLihle ShongweBelum ada peringkat

- Manager Demand PlanningDokumen3 halamanManager Demand Planningapi-78491037Belum ada peringkat

- Pushkar 110 UpdatedDokumen4 halamanPushkar 110 UpdatedPushkar MaheshwariBelum ada peringkat

- Saud+Bin+Zoman++CV+April 22Dokumen5 halamanSaud+Bin+Zoman++CV+April 22scpkaiser11Belum ada peringkat

- Demand PlannerDokumen2 halamanDemand PlannerJirani smartBelum ada peringkat

- Notes - SCMDokumen96 halamanNotes - SCMDavid BusinelliBelum ada peringkat

- 106128-ERP Production Management MidTerm Assessment Fall-2020 - StudID - 58549 StudName - Shariq Ahmed KhanDokumen12 halaman106128-ERP Production Management MidTerm Assessment Fall-2020 - StudID - 58549 StudName - Shariq Ahmed KhanShariq Ahmed Khan 0332 : Alnoor SocietyBelum ada peringkat

- Supply Chain Manager in Rochester NY Resume Chris BohlerDokumen2 halamanSupply Chain Manager in Rochester NY Resume Chris BohlerChrisBohlerBelum ada peringkat

- TSC - SC CBO (Comm) Senior Manager Grade12 - InSWA OUDokumen3 halamanTSC - SC CBO (Comm) Senior Manager Grade12 - InSWA OUAbhishek DeshpandeBelum ada peringkat

- Chaitanya Sharma: Location: Milwaukee, WIDokumen3 halamanChaitanya Sharma: Location: Milwaukee, WIAnkit TrivediBelum ada peringkat

- Top 10 Success Factors For Sales and Operations PlanningDokumen28 halamanTop 10 Success Factors For Sales and Operations PlanningRamesh PoshalaBelum ada peringkat

- Sales & Operations Planning: An Introduction Sales & Operations Planning: An IntroductionDokumen36 halamanSales & Operations Planning: An Introduction Sales & Operations Planning: An IntroductionkeimmaBelum ada peringkat

- GM PurchaseDokumen4 halamanGM PurchaseSaikumar SelaBelum ada peringkat

- Sr. Production PlannerDokumen2 halamanSr. Production PlannerHina jamilBelum ada peringkat

- Capgemini JDsDokumen4 halamanCapgemini JDsPalash AroraBelum ada peringkat

- Tamquita Johnson Resume PortfolioDokumen2 halamanTamquita Johnson Resume Portfolioapi-731292513Belum ada peringkat

- What Is Supply Chain ManagementDokumen13 halamanWhat Is Supply Chain ManagementJane Caranguian AgarroBelum ada peringkat

- Supply Chain Planning ManagerDokumen6 halamanSupply Chain Planning ManagerPerry AshleyBelum ada peringkat

- Manish Kulkarni - ResumeDokumen3 halamanManish Kulkarni - Resumemanishkul-100% (1)

- Resume GopalakrishnanDokumen2 halamanResume GopalakrishnansymongkryshBelum ada peringkat

- Georgemaia Resume Merch ManagerDokumen2 halamanGeorgemaia Resume Merch Managerapi-340666755Belum ada peringkat

- Surya Kiran Singh ResumeDokumen4 halamanSurya Kiran Singh Resumesurya kiranBelum ada peringkat

- Implementing A Sales and Operations PlanningDokumen7 halamanImplementing A Sales and Operations PlanningMuhammad Shahadat Kabir ReZuBelum ada peringkat

- HRM NestleDokumen7 halamanHRM NestleAbdulahad MemonBelum ada peringkat

- CV Jimena ZumaetaDokumen1 halamanCV Jimena ZumaetaJimena ZumaetaBelum ada peringkat

- Director Purchasing Procurement Manager in Oklahoma City OK Resume Jeff AmendDokumen3 halamanDirector Purchasing Procurement Manager in Oklahoma City OK Resume Jeff AmendJeffAmendBelum ada peringkat

- Purchasing Manager or Materials Manager or Supply Chain ManagerDokumen3 halamanPurchasing Manager or Materials Manager or Supply Chain Managerapi-78792797Belum ada peringkat

- Typical Supply Chain Management (SCM) Intern ResponsibilitiesDokumen2 halamanTypical Supply Chain Management (SCM) Intern Responsibilities1921 Vishwanath PakhareBelum ada peringkat

- SAP ERP Implementation in Pantaloons: - Abhinav Bharati - Ankita Dubey - Bijan Kumar - Deepika J - Gokul Kini - Kruthika PDokumen23 halamanSAP ERP Implementation in Pantaloons: - Abhinav Bharati - Ankita Dubey - Bijan Kumar - Deepika J - Gokul Kini - Kruthika PAjinkya S DevBelum ada peringkat

- Vice President Supply Chain in Charlotte North Carolina Resume Alan WeberDokumen3 halamanVice President Supply Chain in Charlotte North Carolina Resume Alan Weberalanweber1100% (1)

- Job Description: Internal & External AuditsDokumen2 halamanJob Description: Internal & External AuditsRahul BoseBelum ada peringkat

- Aggregate PlanningDokumen46 halamanAggregate PlanningSatyajeet ChauhanBelum ada peringkat

- Supply Chain Operations Manager in Melbourne FL Resume Leslie DahringDokumen2 halamanSupply Chain Operations Manager in Melbourne FL Resume Leslie DahringLeslieDahringBelum ada peringkat

- Sales and Operations Planning - Roles and AgendasDokumen5 halamanSales and Operations Planning - Roles and AgendasjaimediazsanchezBelum ada peringkat

- Prateek Khare Resume PDFDokumen2 halamanPrateek Khare Resume PDFPrateek khareBelum ada peringkat

- Preparing Your Production PlanDokumen6 halamanPreparing Your Production Planbhevsz009Belum ada peringkat

- Ahmed HassanDokumen4 halamanAhmed HassanAhmed MohamedBelum ada peringkat

- 1 Overview 01 APR 2014Dokumen20 halaman1 Overview 01 APR 2014Denis CBelum ada peringkat

- Azhar Bani - ResumeDokumen8 halamanAzhar Bani - ResumeAzhar BaniBelum ada peringkat

- Demand ManagementDokumen61 halamanDemand ManagementDivyansh TripathiBelum ada peringkat

- Shaukat Ali CVDokumen6 halamanShaukat Ali CVSerena DicksonBelum ada peringkat

- Minh Soumitta v1Dokumen5 halamanMinh Soumitta v1soumitta elisabeth minhBelum ada peringkat

- CGAVIN - HRMResume 2010Dokumen2 halamanCGAVIN - HRMResume 2010crisgavin23Belum ada peringkat

- Senior Purchasing Manager Director in San Antonio TX Resume Edward RiveraDokumen3 halamanSenior Purchasing Manager Director in San Antonio TX Resume Edward RiveraEdwardRiveraBelum ada peringkat

- Regional Supply Business Area SpecialistDokumen3 halamanRegional Supply Business Area Specialistasmaa mohmedBelum ada peringkat

- ResumeBarnendraChaudhuri - 6apr2024Dokumen3 halamanResumeBarnendraChaudhuri - 6apr2024Barnendra ChaudhuriBelum ada peringkat

- Resume GopalakrishnanDokumen2 halamanResume GopalakrishnansymongkryshBelum ada peringkat

- Mark Plano: SAP Controlling ConsultantDokumen2 halamanMark Plano: SAP Controlling ConsultantKrishnaBelum ada peringkat

- CV RaDokumen5 halamanCV Raameey207Belum ada peringkat

- Matthew Biggs: TrainingDokumen3 halamanMatthew Biggs: TrainingMatthew BiggsBelum ada peringkat

- Resume WordedDokumen4 halamanResume WordedKarim El-AbbasyBelum ada peringkat

- Sales and Operations Planning - APICS Exam WarehouseDokumen6 halamanSales and Operations Planning - APICS Exam Warehousevishalyerawar100% (1)

- Juthathip Thanatawee: ObjectiveDokumen6 halamanJuthathip Thanatawee: ObjectiveMohamed SalahBelum ada peringkat

- Supply Chain ManagementDokumen8 halamanSupply Chain ManagementManoj AgarwalBelum ada peringkat

- Objective:: Course Institution / College Board / University Percentage YearDokumen2 halamanObjective:: Course Institution / College Board / University Percentage YearDGBelum ada peringkat

- Template Cover LetterDokumen1 halamanTemplate Cover LetterDGBelum ada peringkat

- 1.samsung Galaxy Tab S 10.5 2.samsung Galaxy Tab S 8.4 3.sony Xperia Z3 Tablet Compact 4.sony Xperia Z4 Tablet 5Dokumen1 halaman1.samsung Galaxy Tab S 10.5 2.samsung Galaxy Tab S 8.4 3.sony Xperia Z3 Tablet Compact 4.sony Xperia Z4 Tablet 5DGBelum ada peringkat

- CV Cover Letter FormatDokumen1 halamanCV Cover Letter FormatDGBelum ada peringkat

- Demand Plannnig ProcessDokumen3 halamanDemand Plannnig ProcessDGBelum ada peringkat

- VLook Up Multiple Columns - 2Dokumen1 halamanVLook Up Multiple Columns - 2DGBelum ada peringkat

- Presention RevisedDokumen162 halamanPresention RevisedDGBelum ada peringkat

- CfoDokumen13 halamanCfocarmen pirvanBelum ada peringkat

- Bank OD Account in Tally 1Dokumen3 halamanBank OD Account in Tally 1yashusahu180Belum ada peringkat

- 3rd Quarter SUMMATIVE TEST in MAPEHDokumen3 halaman3rd Quarter SUMMATIVE TEST in MAPEHzaile felineBelum ada peringkat

- The Incidence of COVID-19 Along The ThaiCambodian Border Using Geographic Information System (GIS), Sa Kaeo Province, Thailand PDFDokumen5 halamanThe Incidence of COVID-19 Along The ThaiCambodian Border Using Geographic Information System (GIS), Sa Kaeo Province, Thailand PDFInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Simple Love Spells That WorkDokumen14 halamanSimple Love Spells That Workagg24ankitBelum ada peringkat

- 064 DIR - Launching Whipping Creme & Skimmed Milk Di Channel Horeka (Subdist Masuya)Dokumen3 halaman064 DIR - Launching Whipping Creme & Skimmed Milk Di Channel Horeka (Subdist Masuya)indra sapta PrahardikaBelum ada peringkat

- Intermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageDokumen11 halamanIntermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageRickCy Perucho PccbsitBelum ada peringkat

- Stitch2421 1 Kit PDFDokumen8 halamanStitch2421 1 Kit PDFJoshua Robertson100% (1)

- G2A Glitch DONT LEAK 2Dokumen7 halamanG2A Glitch DONT LEAK 2qDeficiencyBelum ada peringkat

- Module 1Dokumen64 halamanModule 1Jackyson RajkumarBelum ada peringkat

- SRM 7 EHP 4 Release Notes PDFDokumen18 halamanSRM 7 EHP 4 Release Notes PDFMOHAMMED SHEHBAAZBelum ada peringkat

- Wa200-8 Venss06304 1904 PDFDokumen24 halamanWa200-8 Venss06304 1904 PDFOktiano BudiBelum ada peringkat

- Imcp - RocketbookDokumen11 halamanImcp - Rocketbookapi-690398026Belum ada peringkat

- U04 Fxs of Humeral ShaftDokumen88 halamanU04 Fxs of Humeral Shaftadrian_mogosBelum ada peringkat

- A Review On Different Yogas Used in The Management of Mandali Damsa Vrana W.S.R. To KriyakaumudiDokumen11 halamanA Review On Different Yogas Used in The Management of Mandali Damsa Vrana W.S.R. To KriyakaumudiTiya TiwariBelum ada peringkat

- Bubble SortDokumen6 halamanBubble SortRollin RevieBelum ada peringkat

- KPI's Troubleshooting GuideDokumen27 halamanKPI's Troubleshooting GuideMohamed SayedBelum ada peringkat

- Englis 123Dokumen39 halamanEnglis 123Cindy EysiaBelum ada peringkat

- (IGC 2024) 2nd Circular - 0630Dokumen43 halaman(IGC 2024) 2nd Circular - 0630VictoriaBelum ada peringkat

- (Essential Skills For Nurses Series) Philippa Sully - Joan Dallas-Essential Communication Skills For Nursing and Midwifery-Mosby - Elsevier (2010) PDFDokumen250 halaman(Essential Skills For Nurses Series) Philippa Sully - Joan Dallas-Essential Communication Skills For Nursing and Midwifery-Mosby - Elsevier (2010) PDFRetno SumaraBelum ada peringkat

- 01 C. Toolbar and Message BoxDokumen10 halaman01 C. Toolbar and Message Boxradu.iacobBelum ada peringkat

- Helical Coil FlowDokumen4 halamanHelical Coil FlowAshish VermaBelum ada peringkat

- Luyện nghe Tiếng Anh có đáp án: I/ Listen and complete the textDokumen3 halamanLuyện nghe Tiếng Anh có đáp án: I/ Listen and complete the textVN LenaBelum ada peringkat

- Cases To Examine - EuthanasiaDokumen1 halamanCases To Examine - EuthanasiadamianmackytBelum ada peringkat

- FE 208 Lab #4 - Profile Leveling: CrewDokumen4 halamanFE 208 Lab #4 - Profile Leveling: CrewJefferson Himson0% (1)