Lightening The Soliders Load Nov 2010

Diunggah oleh

Jeremy GilesDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lightening The Soliders Load Nov 2010

Diunggah oleh

Jeremy GilesHak Cipta:

Format Tersedia

Lightening the SoLdierS Load

adS, inC. OPERATIONAL EQUIPMENT & LOGISTICS SOLUTIONS

Wednesday, November 10 2010 by Eric Graves, Editor Soldier Systems Daily

Based on the challenges of extended foot patrols in Afghanistans Korengal Valley, members of the Armys Asymmetric Warfare Group set about to look at ways to make Soldiers more mobile and agile while operating in mountainous terrain. The resulting project, dubbed the Soldiers Load Assessment, saw an entire ensemble of individual equipment undergoing an evaluation in Afghanistan with two battalions of troops during the summer of 2009. Within weeks of the assessments beginning, other units began to seek out the same equipment. Even today, many items from the assessment continue to be sought after by deploying units. The problem was simple and still remains to this day. The American Soldier is loaded with critical yet heavy lifesaving equipment such as body armor and radios. This makes him sluggish on the battlefield. Even during Viet Nam our Army faced the same problem. In fact, a program called Lightweight Individual Clothing & Equipment (LINCLOE) was initiated in 1965 to rapidly field equipment solutions. Work conducted under this program led to the adoption of lighter equipment manufactured from new materials that were more

water and rot resistant. But even earlier than this, work dates back to World War II and BG SLA Marshalls seminal work, The Soldiers Load and Mobility of a Nation, required reading for any serious student of the tactical fight. Marshalls analysis revealed that Soldiers who carried more than 35% of their weight were less effective in combat and more prone to injury. Prior to the Load Assessment, COL Bob Shaw, commander of the Asymmetric Warfare Group, commented on the issue during an interview with Military Times, Weve got the enemy running around in a man dress with a gun and flip-flops, able to run up and down the mountains because they live there. He went on to say, Theyve got the advantage on us, especially if we are weighted down with all this gear. Endurance, agility, being an effective soldier in the mountainsit really has to do with whats on your back. His team took these comments to heart when they developed a list of key commercial technologies that could be rapidly

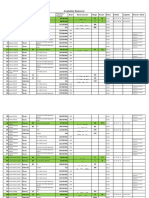

fielded to assess their effectiveness at improving Soldier performance. To get the ball rolling, the AWG utilized a unique capability; an in-house REF Direct Support branch called the Asymmetric Product Office (APO). They can leverage quick turnaround procurement of promising technologies to give our warfighters the edge in the war. AWG/APO was able to leverage their mission partnership with the REF to rapidly turn a materiel response coupled with a non-materiel answer which was to become the Planning Guidance for Lightening the Soldiers Load. Then, they selected a Brigade from the 4th Infantry Division to conduct an assessment of the equipment under actual combat conditions. AWG also enlisted the assistance of the Johns Hopkins Applied Physics Lab (JHU/APL) to conduct data collection and convert the raw data into usable metrics to support decision making. To acquire these items from various vendors, kit them, and assist with issue, the REF turned to ADS, who was tasked initially with gathering

ADS, Inc. Lynnwood Plaza 621 Lynnhaven Drive Virginia Beach, VA 23452 Suite 400

800.948.9433 ADSINC.COM

2010 ADS, Inc. The ADS logo is a registered trademark of ADS, Inc. F0186

Lightening the SoLdierS Load

adS, inC. OPERATIONAL EQUIPMENT & LOGISTICS SOLUTIONS

Afghanistan. ADS ordered and stored all of the equipment on the contract in their 75,000 sq. ft. kitting warehouse awaiting shipment to theater. Based on specific information for each individual Soldier in the battalion, such as name, rank, boot size, waist size, chest size, duty position (e.g. M240 gunner), etc, ADS created the 560 kits in large kit bags that were secured with TSA locks, and barcoded with the Soldiers information. Due to unforeseen delays, the Armys plan changed and a new unit still in CONUS was chosen to receive the equipment. The Army asked ADS to unkit the equipment and move it to Ft Carson, CO for issue there. ADS unpacked the kits, loaded the equipment onto trailers, and sent it to Ft Carson along with a team of six specialists from their headquarters in Virginia Beach to prepare an issuing facility, in conjunction with members of the unit and members of the Armys AWG and REF. In four days, the team was able to outfit the entire battalion of 490 soldiers with the new gear. During the issue, ADS team members also ensured that sized equipment was properly fitted. Any variance was immediately corrected either with spare sizes that ADS had brought with them or via overnight shipment from various vendors. No Soldier deployed to Afghanistan without his gear or with ill-fitting equipment. This is a testament to the level of expertise that ADS brings to the logistics arena. To conduct the actual assessment in Afghanistan, AWG deployed a Special Assessment Team (SAT)

Planning Considerations for Lightening the Soldiers Load PDF

Modular Body Armor Vest Kit

specifications (weights, dimensions, etc) for legacy individual soldier equipment, such as body armor and plate carriers, helmets, boots, packs, and so on. Then they were asked to provide the same information on comparable COTS items for each piece of equipment. In just over a week, ADS gathered the data and submitted it to AWG, who was then able to create a new equipment kit that cut approximately 25 lbs. off a standard Soldiers load. The initial contract in January 2009 called for 560 individual kits and ADS was asked to outfit a battalions worth of soldiers that were already in

composed of Subject Matter Experts (SMEs) and Operational Advisers (OAs) who are capable of embedding with units to ascertain the Combat Effectiveness of candidate solutions. AWGs SME/OAs are all trained Combat Developers whose job it is to conduct product development to meet asymmetric threats and then assess the capabilitys utility in the field. During this assessment, the SAT used JHU/APL metrics developed to measure Soldier acceptance, combat effectiveness, and overall durability of the proposed candidate solutions. The SAT deployed two teams to embed with 4-4 IN in both Nuristan (COP Bostick/Kamdesh) and the Korengal Valley. Numerous lessons were learned from the Soldiers Load Assessment including the development of a handbook for small unit commanders called Planning Considerations for Lightening the Soldiers Load, which details how to tailor equipment in order to increase mobility and decrease fatigue. Additionally, the data collected is being used to help develop an automated

ADS, Inc. Warehouse

Fort Carson Kitting Operation

ADS, Inc. Lynnwood Plaza 621 Lynnhaven Drive Virginia Beach, VA 23452 Suite 400

800.948.9433 ADSINC.COM

2010 ADS, Inc. The ADS logo is a registered trademark of ADS, Inc. F0186

Lightening the SoLdierS Load

adS, inC. OPERATIONAL EQUIPMENT & LOGISTICS SOLUTIONS

GENIII MultiCam Levels I - VII

decision making tool that will take the guesswork out of preparing packing lists. What many do not know is that the assessment was so successful, the Army ordered another 1,500 kits as well as an additional 1,000 plate carriers through ADS. Mountain boots were also a challenge for this assessment. No single vendor was able to support the totality of the requirement for this specialized footwear. Based on the performance of the various models, requirement specifications were collected and the Army is preparing to field a Berry Compliant solution. Other technologies from the project have also been adopted by the Army, although, they too may not be the same brand that was used during the initial assessment. For example, units have procured some of the items for issue to Afghanistan-bound troops such as lightweight GPS systems from Garmin and polymer rifle magazines from Magpul. The point being, that as the industrial base continues to develop and refine products, deploying Soldiers can rely on the latest advances.

immediately evident and Soldiers can rest assured that their equipment was crafted by a fellow American. Additionally, products are now available in the Armys newly adopted Operation Enduring Freedom Camouflage Pattern (OCP) which is the hugely successful MultiCam from Crye Precision. This pattern has not only been adopted by USSOCOM but also the Army and Air Force.

Danner Combat Hiker Boots

Now, a year later, and based on feedback from the Soldiers Load Assessment, ADS now offers an entire complement of equipment that is not only Berry Compliant but also incorporates the latest in Soldier Systems technology. Berry Amendment compliance cannot be stressed enough. This means that the equipment is manufactured in the USA using American materials. The commitment to quality is not only

ADSs special skills were crucial to the success of the Soldiers Load Assessment. They remain poised to rapidly assemble equipment from disparate vendors, kit it, and deliver it for issue at short notice, anywhere in the world whether at home station or in a deployed environment. This is why organizations seeking solutions to unique problems turn to ADS. Combined with their veritable think tank of Subject Matter Experts who will assist the client to find solutions for their problems, ADS has a work force with over 1500 years of combined Government and industry experience.

Eric Graves is the Editor of Soldier Systems Daily, a web-based publication of the tactical industry. He is a retired Air Force officer who also saw service as a non-commissioned officer in the US Army. Following his military service he worked for a period in the defense technology arena and started Soldier Systems Daily in 2008.

All trademarks used in this article are the property of and subject to the and of their respective owners.

ADS, Inc. Lynnwood Plaza 621 Lynnhaven Drive Virginia Beach, VA 23452 Suite 400

800.948.9433 ADSINC.COM

2010 ADS, Inc. The ADS logo is a registered trademark of ADS, Inc. F0186

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- DCS Yak-52 Manual enDokumen194 halamanDCS Yak-52 Manual enJeremy GilesBelum ada peringkat

- DCS L-39ZA Albatros GuideDokumen85 halamanDCS L-39ZA Albatros GuideJeremy GilesBelum ada peringkat

- Army Dress Manual AL5 - 1 PDFDokumen641 halamanArmy Dress Manual AL5 - 1 PDFjoelBelum ada peringkat

- SOCOM - DEVGRU - A3 - V 1.6 READMEDokumen7 halamanSOCOM - DEVGRU - A3 - V 1.6 READMEaaronsmith812732Belum ada peringkat

- Arc'Teryx: Entries in ApparelDokumen7 halamanArc'Teryx: Entries in ApparelFrankie HungBelum ada peringkat

- 511 Catalog 2011 Noprice 01LDokumen84 halaman511 Catalog 2011 Noprice 01LHK_SupremecoBelum ada peringkat

- 2021 Crye Precision Catalog WebDokumen56 halaman2021 Crye Precision Catalog WebJosselin BeaumontBelum ada peringkat

- U.S. Cavalry Twenty TEN Spring CatalogDokumen84 halamanU.S. Cavalry Twenty TEN Spring CatalogUSCavalry67% (3)

- Camouflage PatternS OEFDokumen4 halamanCamouflage PatternS OEFLUDICOVEK100% (1)

- Ocie Guide (Pa2400) 2012Dokumen88 halamanOcie Guide (Pa2400) 2012nguymike100% (1)

- PM Clothing Individual Equipment American ApparelDokumen18 halamanPM Clothing Individual Equipment American ApparelPredatorBDU.comBelum ada peringkat

- Blue Force Gear Catalog PDFDokumen50 halamanBlue Force Gear Catalog PDFGILBERT MOY100% (1)

- Photosimulation Camouflage Detection TestDokumen37 halamanPhotosimulation Camouflage Detection TestChristian Lowe100% (1)

- Painting Guide MulticamDokumen2 halamanPainting Guide Multicamjohn doeBelum ada peringkat

- Crye Precision 2020 Catalog WebDokumen110 halamanCrye Precision 2020 Catalog Websquad bravo50% (4)

- FirstSpear Catalog - Summer 2012Dokumen43 halamanFirstSpear Catalog - Summer 2012solsys0% (1)

- 2020 Civilian and Military Camouflage Patterns BookletDokumen23 halaman2020 Civilian and Military Camouflage Patterns BookletPablo Allosia100% (1)

- XCameraUser Guide 2.3.1Dokumen76 halamanXCameraUser Guide 2.3.1Jeremy GilesBelum ada peringkat

- American Healthcare ActDokumen66 halamanAmerican Healthcare ActBrett LoGiurato100% (1)

- DCS World List of All Available Beacons enDokumen9 halamanDCS World List of All Available Beacons enJeremy GilesBelum ada peringkat

- Ca 11Dokumen2 halamanCa 11Jeremy GilesBelum ada peringkat

- Mind The Gap Between Rhetoric and RealityDokumen37 halamanMind The Gap Between Rhetoric and RealityJeremy GilesBelum ada peringkat

- Soldier's Load Assessment Equipment ListDokumen2 halamanSoldier's Load Assessment Equipment ListJeremy Giles100% (1)

- FirstSpear Commercial CatalogDokumen23 halamanFirstSpear Commercial CatalogsolsysBelum ada peringkat

- Team Danger Zone Uniform Standards and Practices Required Equipment Per DivisionDokumen2 halamanTeam Danger Zone Uniform Standards and Practices Required Equipment Per Divisionrp1858009462Belum ada peringkat

- Camouflages in A NutshellDokumen14 halamanCamouflages in A NutshellAndres19962Belum ada peringkat

- Army Dress Manual - 0Dokumen631 halamanArmy Dress Manual - 0Jaryll Ong100% (1)

- Cheap Universal Soldier III Unfinished Business Film Download92 BR Universal Soldier Iii62 BR Download Universal Soldier III Unfinished Business Online61.20121205.005507Dokumen2 halamanCheap Universal Soldier III Unfinished Business Film Download92 BR Universal Soldier Iii62 BR Download Universal Soldier III Unfinished Business Online61.20121205.005507anon_359137338Belum ada peringkat

- Tactical JacketDokumen51 halamanTactical JacketBenja BenjaBelum ada peringkat

- Wuhan Fronter Industrial Co.,Ltd: Product Catalog & Price ListDokumen7 halamanWuhan Fronter Industrial Co.,Ltd: Product Catalog & Price ListAmadou DialloBelum ada peringkat

- Universal Soldier III Unfinished Business HD Movie80 BR Watch Universal Soldier III Movie12 BR Watch Universal Soldier III Unfinished Businesshigh Quality90.20121205.013005Dokumen2 halamanUniversal Soldier III Unfinished Business HD Movie80 BR Watch Universal Soldier III Movie12 BR Watch Universal Soldier III Unfinished Businesshigh Quality90.20121205.013005anon_713687963Belum ada peringkat

- Co PD 02 02g ChestrigDokumen61 halamanCo PD 02 02g ChestrigRTSLLCBelum ada peringkat

- ContinueDokumen4 halamanContinueLIVE3ORDIEBelum ada peringkat

- 12 Operation Enduring Freedom Camouflage Pattern$ A Rapid Response To A Complex Need 201004 PDFDokumen4 halaman12 Operation Enduring Freedom Camouflage Pattern$ A Rapid Response To A Complex Need 201004 PDFLorenzo MontaniBelum ada peringkat