Is 280 - Gi Wire Technical Specification

Diunggah oleh

Bhavesh KeraliaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Is 280 - Gi Wire Technical Specification

Diunggah oleh

Bhavesh KeraliaHak Cipta:

Format Tersedia

SECTION-I (G.I.PLAIN WIRE) TECHNICAL SPECIFICATION FOR G. I.

WIRE (1) SCOPE :This Specification provides for manufacture, testing before dispatch at manufacturer's work and supply and delivery of 3.15mm and 4mm solid heavily coated Galvanized solid steel wire to any of our Regional Stores in Gujarat State as intimated by the Board time to time. (2) STANDARD :The G. I. wires shall comply with the following Indian standards (subject in all cases to latest revision/amendments currently in force) a) IS : 280/1978 (IIIrd revision). Specification for Mild Steel Wire for general engineering purpose. "Specification for Hot Dipped Galvanized coating on round b) IS : 4826/1979 (Ist revision ). steel wires." c) IS : 1867/1967 (Ist revision). 'General requirements for the supply to metallurgical materials.' d) IS : 7887/1992 Specification for Mild Steel Wire Rods for general engineering purpose. e) IS : 1521/1972 (Ist revision) 'Method for tensile testing of steel wires. f) IS : 1755/1983 'Method for wrapping test of wire'. g) IS : 2633/1986 (Ist revision) 'Methods for testing uniformity of coating on zinc coated articles'. h) IS : 6745/1972 'Methods of determination of weight of zinc coating on zinc coated iron and steel articles'. i) IS : 209/1992 (IVth revision) 'Specification for zinc.' j) IS : 2629/1985 'Recommended practice for hot dip galvanising of steel and iron'. MATERIAL :General requirement relating to the supply of Mild Steel Wire shall be as per IS:1387/1967. The wire shall be drawn from the Wire rods confirming to IS: 7887/1992. The wire shall be sound-free from splits, surface flares rough, jagged and imperfect edges and other harmful surface defect.

D:\My Documents\tender\ugvcl-sp-2322222\GI WIRE TECHNICAL SPECIFICATION.doc

3.

-1-

4.

SIZES :-

(a) 3.15 mm dia. (b) 4.00 mm dia.

5.

QUALITY :Both the sizes of G. I. wires shall be of soft drawn quality confirming to IS: 280/1978.

6.

TENSILE STRENGTH.: The tensile strength of the G. I. wire when tested in accordance with IS : 1821/1972 shall be between 450-550 N/mm2.

7.

ZINC COATING :The wire shall be galvanized in accordance with IS:2629/1986 and the zinc to be used for Hot dip galvanizing shall confirm to grade Zn-98, specified in IS:209/1992. The coating shall be uniform, smooth and free from visual defect. Such as flash and dress inclusion bare patches black spots, pimples, lumpiness, rust strains, bulky white deposit and bistros. The coating shall be "HEAVELY COATED QUALITY'.

8.

TESTS :The following acceptance tests shall be carried out on each and every lot at manufacturers premises at the manufacturer's cost. The manufacturer must be fully equipped to carry out the tests at his premises in presence of Board's Inspectors.

a) b) c) d) e) f) g)

Visual examination. Checking of diameters of wires. Tensile Strength. Wrapping test. Mass of zinc coating. Uniformity of zinc coating. Adhesion of zinc coating.

As per relevant ISS specified para -2 hereof.

The manufacturer shall have to submit Test Certificates with every lot for the Chemical composition of the Steel rocs from which the wires are drawn. 9) SAMPLES : The sampling for Acceptance Test shall be carried out as per Appendix -'A' of IS : 280/1978 (Third revision)

D:\My Documents\tender\ugvcl-sp-2322222\GI WIRE TECHNICAL SPECIFICATION.doc

-2-

10.

PACKING :The G. I. Wire shall be supplied in coils. The weight of the coil shall be 50 Kg. to 80 Kg. Each coil shall be wrapped in hession to avoid surface damage to the wire during transport and for protection against pollution. Each coil shall be supplied with a metallic tag on which the following particulars shall be printed itched with waterproof ink/itched.

(1) (2) (3) (4) (5) (6) (7) 11.

Name of Manufacturer. Size of Wire. Weight of Coil (approx.) Kg. Coil Serial No. A/T No. & Date,. ISI Mark if any. Property of UGVCL SEALING : The manufacturer shall keep coils ready with seal wire and lead seal so as to enable the Board's inspectors to seal the inspected material immediately. Wrapping of coils with hession shall be done after inspection but before despatch.

12.

GUARANTEED TECHNICAL PARTICULARS. :The tenderers shall submit the Guaranteed Technical Particulars as per the proforma SECTION-II attached herewith only. The offers without technical particulars shall be ignored.

13.

DEVIATION FROM SPECIFICATION :No deviation in the above specification shall be allowed.

D:\My Documents\tender\ugvcl-sp-2322222\GI WIRE TECHNICAL SPECIFICATION.doc

-3-

SECTION-II (G.I. PLAIN WIRE ) Name of Manufacturer : & Address. GUARANTEED TECHNICAL PARTICULARS. Technical information and guaranteed Technical Particulars for supply of G. I. Wire size 3.15mm dia and 4.00 mm dia. PART -A BIDDER HAS TO CONFIRM FOLLOWING IMPORTANT REQUIREMENT : Sr. No. Particulars. 1) The G I. Wire of 3.15mm dia x 4.00mm dia with tolerance of +or- 2.5 % in dia as per IS:280/1978 with latest amendment/revision if any. 2) The G. I. Wire shall drawn from soft wire having tensile strength 450-550 N/mm2 3) Breaking Load shall be as under : for G. I. Wire 3.15mm dia - 339.3 to 459.2 for G. I. Wire 4.00 mm dia- 544 to 740.54 4) Zinc coating shall be as under i) Heavy coating IS : 4826/78 ii) Hot dip galvanizing, weight of zinc coating when tested IS : 4826/79 iii) The quality of zinc shall be as per IS : 209/1992 iv) No. of dip guaranteed. 3 Nos. of 1 minute dips & 1 No. 1/2 minute dip as per IS:2633/1986 5) 6) Confirmation Yes

Yes

Yes Yes Yes Yes Yes Yes Yes

Weight of coils shall be from 50 Kg. to 80 Kg. Yes Packing condition as per clause No. 10 of Tender Yes specification.

D:\My Documents\tender\ugvcl-sp-2322222\GI WIRE TECHNICAL SPECIFICATION.doc

-4-

PART - B (ENCLOSERS)

BIDDER HAS TO ENCLOSE FOLLOWING DOCUMENTS AND HAS TO CONFIRM FOR THE SAME: Sr. No. 1) 2) 3) Particulars. Confirmation List of Plant and Machinery. Yes List of Testing Equipments. Yes List of Orders pending / executed atleast for past two years for the item offered: (A) With G.E.B. Yes (B) With the purchase other then G.E.B. Yes.

PART - C BIDERS HAVE TO MENTION TECHNICAL DEVIATION IF ANY, QUOTING RELEVANT CLAUSE OF SPECIFICATION.

SIGNATURE & SEAL OF TENDERER.

D:\My Documents\tender\ugvcl-sp-2322222\GI WIRE TECHNICAL SPECIFICATION.doc

-5-

Anda mungkin juga menyukai

- Led Light Curb Installation Instruction 2017 PDFDokumen6 halamanLed Light Curb Installation Instruction 2017 PDFFibin HaneefaBelum ada peringkat

- Is 2547Dokumen11 halamanIs 2547Vivek GosaviBelum ada peringkat

- Concrete ReinforcementDokumen5 halamanConcrete Reinforcementsethu1091Belum ada peringkat

- Is.1285.2002 Standard For Aluminium Extruded Tubes PDFDokumen14 halamanIs.1285.2002 Standard For Aluminium Extruded Tubes PDFAditya VuthaBelum ada peringkat

- Birla Aerocon AAC Blocks - Literature V01 PDFDokumen4 halamanBirla Aerocon AAC Blocks - Literature V01 PDFdhruvBelum ada peringkat

- Is 1948 1961 R 1996Dokumen21 halamanIs 1948 1961 R 1996Nagaraju Chinta100% (4)

- Is-4826 Hot Dipped Galvanized CoatingsDokumen11 halamanIs-4826 Hot Dipped Galvanized CoatingspankajnbiBelum ada peringkat

- SECTION 2000 FinalDokumen9 halamanSECTION 2000 FinalSurya LalithaBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen23 halamanDisclosure To Promote The Right To InformationmaheshBelum ada peringkat

- (Third Revision: Indian StandardDokumen24 halaman(Third Revision: Indian StandardbappadasjuBelum ada peringkat

- SECTION 2700 FinalDokumen17 halamanSECTION 2700 Finalkartick adhikaryBelum ada peringkat

- 783 Hume Pipe LayingDokumen83 halaman783 Hume Pipe LayingAmit Ghorpade100% (2)

- IS.10773.1995-Copper Tubes and PipesDokumen11 halamanIS.10773.1995-Copper Tubes and Pipessuresh kumarBelum ada peringkat

- 2721 Chain LinkDokumen8 halaman2721 Chain LinkPankaj GargBelum ada peringkat

- Is-12330 For Sulphate Resistance CementDokumen12 halamanIs-12330 For Sulphate Resistance CementBscpl Repalle to EeppurpalemBelum ada peringkat

- 2 TS Maintenance Free Earthpit R1Dokumen5 halaman2 TS Maintenance Free Earthpit R1sandeepbhallaBelum ada peringkat

- Specification of Indian Standard Sand - TAMINDokumen1 halamanSpecification of Indian Standard Sand - TAMINanpyaaBelum ada peringkat

- Is 6441 5 1972Dokumen13 halamanIs 6441 5 1972Indira BanerjeeBelum ada peringkat

- Prestressed Concrete Poles - State-of-the-Art PDFDokumen52 halamanPrestressed Concrete Poles - State-of-the-Art PDFEduardo QuintanaBelum ada peringkat

- Is-1566-1982 (2000)Dokumen15 halamanIs-1566-1982 (2000)hhr2412100% (1)

- Ceramic Tiles - Definitions, Classifications, Characteristics and MarkingDokumen12 halamanCeramic Tiles - Definitions, Classifications, Characteristics and MarkingAnuradhaPatraBelum ada peringkat

- Hot Dip Galvanized ProcessDokumen1 halamanHot Dip Galvanized Processkh88hmiBelum ada peringkat

- BS 1722 - FenceDokumen2 halamanBS 1722 - Fence11 Sqn RERBelum ada peringkat

- Timberpanelledandglazed Shutters-Specification: Indian StandardDokumen18 halamanTimberpanelledandglazed Shutters-Specification: Indian Standardnavin263Belum ada peringkat

- Micro Silica Data Sheet.1 PDFDokumen2 halamanMicro Silica Data Sheet.1 PDFBapsy EhsanovićBelum ada peringkat

- IS COdeDokumen41 halamanIS COdeKritamMaharjanBelum ada peringkat

- Concrete HistoryDokumen4 halamanConcrete Historytest100% (1)

- Specifying Visual ConcreteDokumen23 halamanSpecifying Visual Concretebala subramanyamBelum ada peringkat

- Is 2212 1991Dokumen29 halamanIs 2212 1991Gotcha148Belum ada peringkat

- Is 13517 1992 PDFDokumen9 halamanIs 13517 1992 PDFIndira BanerjeeBelum ada peringkat

- After How Much Time Concrete Should Be RejectedDokumen7 halamanAfter How Much Time Concrete Should Be RejectedDEBOPRASAD BISWAS100% (1)

- Is 1661 1972 PDFDokumen33 halamanIs 1661 1972 PDFPrasanna S KulkarniBelum ada peringkat

- Is 12594-1988 PDFDokumen7 halamanIs 12594-1988 PDFSaurabh PatilBelum ada peringkat

- IS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete BlocksDokumen21 halamanIS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete Blocksmanish_shashikantBelum ada peringkat

- Is 16720 Product Manual Fuel AshDokumen7 halamanIs 16720 Product Manual Fuel AshKolkata PIUBelum ada peringkat

- Insights Into AAC Blocks Manufacturing Space in IndiaDokumen10 halamanInsights Into AAC Blocks Manufacturing Space in Indiasaurabh323612Belum ada peringkat

- Is 2721 2003Dokumen11 halamanIs 2721 2003Eidrish Shaikh100% (1)

- Is 4218 4 2001Dokumen9 halamanIs 4218 4 2001Milan PitrodaBelum ada peringkat

- Non Destructive Testing BRIDGES NO. 355, 366, 388 & 390 Mumbai Division of W. RDokumen30 halamanNon Destructive Testing BRIDGES NO. 355, 366, 388 & 390 Mumbai Division of W. RArindam NandyBelum ada peringkat

- Is 12843 1989 PDFDokumen8 halamanIs 12843 1989 PDFRajaram JayaramanBelum ada peringkat

- Is 4923 1997Dokumen19 halamanIs 4923 1997Akhil GargBelum ada peringkat

- 0005 India Regulation On CoatingDokumen33 halaman0005 India Regulation On Coatingagustinusset100% (2)

- Deleterious Materials in AggregatesDokumen2 halamanDeleterious Materials in Aggregatesvaleidshafik100% (1)

- Disclosure To Promote The Right To InformationDokumen22 halamanDisclosure To Promote The Right To InformationVoyants Solution pvt. ltd.Belum ada peringkat

- Fly Ash ClasificationDokumen15 halamanFly Ash ClasificationprabhuwbBelum ada peringkat

- Permeability Test On Concrete PDFDokumen1 halamanPermeability Test On Concrete PDFNidDouBelum ada peringkat

- DETAIL OF FOUNDATION 132 KV CIRCUIT BREAKERDokumen1 halamanDETAIL OF FOUNDATION 132 KV CIRCUIT BREAKERManas MondalBelum ada peringkat

- Strip Chart StructureDokumen5 halamanStrip Chart StructureBrijesh MishraBelum ada peringkat

- G I Wire No. 8 & 10Dokumen5 halamanG I Wire No. 8 & 10Dharmendra KumarBelum ada peringkat

- Stay Wire Specifications 7-2.5mmDokumen5 halamanStay Wire Specifications 7-2.5mmVatsalBelum ada peringkat

- TS For 4Cx10 SQ - MM Armoured CableDokumen8 halamanTS For 4Cx10 SQ - MM Armoured CableAshish bhattBelum ada peringkat

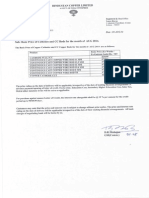

- Maharashtra State Electricity Distribution Co. LTDDokumen8 halamanMaharashtra State Electricity Distribution Co. LTDraj_stuff006Belum ada peringkat

- 11kv CablesDokumen46 halaman11kv CablesS.k. RathBelum ada peringkat

- PDIL Cable Tray RackDokumen6 halamanPDIL Cable Tray Rack9044nksBelum ada peringkat

- G S Earth WireDokumen10 halamanG S Earth WiresaratBelum ada peringkat

- Dgvcl/Sp/11004/ Stay Wire /tech - Speci and GTP 7/12 (2.50Mm) 1/5Dokumen5 halamanDgvcl/Sp/11004/ Stay Wire /tech - Speci and GTP 7/12 (2.50Mm) 1/5Export SwastikaBelum ada peringkat

- Stay Wire SpecificationDokumen4 halamanStay Wire Specificationshivaanem100% (1)

- Tech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Dokumen6 halamanTech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Bilal AhmadBelum ada peringkat

- HT Cable RFQ Specifications PDFDokumen7 halamanHT Cable RFQ Specifications PDFAshil ThomasBelum ada peringkat

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- AWG To SQMMDokumen1 halamanAWG To SQMMBhavesh KeraliaBelum ada peringkat

- LAN CableDokumen7 halamanLAN CableBhavesh KeraliaBelum ada peringkat

- Apdcl TSDokumen18 halamanApdcl TSBhavesh KeraliaBelum ada peringkat

- AWG To MetricDokumen3 halamanAWG To MetricBhavesh KeraliaBelum ada peringkat

- Cable GlossaryDokumen66 halamanCable GlossaryBhavesh KeraliaBelum ada peringkat

- Polaris Cable QAP As Per IS 694Dokumen3 halamanPolaris Cable QAP As Per IS 694Bhavesh KeraliaBelum ada peringkat

- August 14Dokumen2 halamanAugust 14Bhavesh KeraliaBelum ada peringkat

- Daily LME - MAY 16.Pdf1Dokumen1 halamanDaily LME - MAY 16.Pdf1Bhavesh KeraliaBelum ada peringkat

- IEEMA Circular No.160 Dated 4th Nov'2014Dokumen2 halamanIEEMA Circular No.160 Dated 4th Nov'2014Bhavesh KeraliaBelum ada peringkat

- IndexDokumen4 halamanIndextstrivedi12053Belum ada peringkat

- Sagitaur Karnataka Solar ParkDokumen9 halamanSagitaur Karnataka Solar ParkBhavesh KeraliaBelum ada peringkat

- Devyani InvoiceDokumen2 halamanDevyani InvoiceBhavesh KeraliaBelum ada peringkat

- Total Technical Specs PDFDokumen259 halamanTotal Technical Specs PDFBhavesh KeraliaBelum ada peringkat

- Daily Lme - Feb.12Dokumen1 halamanDaily Lme - Feb.12Bhavesh KeraliaBelum ada peringkat

- Gate Valve Class T Size 2 inDokumen2 halamanGate Valve Class T Size 2 inIrfan IsmailBelum ada peringkat

- Lecture 7Dokumen29 halamanLecture 7Hanoee AbdBelum ada peringkat

- Pipe Material Selection PDFDokumen1 halamanPipe Material Selection PDFMoh'd KhadBelum ada peringkat

- Steel Magnetic PropertiesDokumen3 halamanSteel Magnetic PropertiesArtur MirandaBelum ada peringkat

- Literature Review 1.2Dokumen17 halamanLiterature Review 1.2Alias FirdausBelum ada peringkat

- HSB English v1 0 0 - Chapter - 10000 00 PDFDokumen320 halamanHSB English v1 0 0 - Chapter - 10000 00 PDFAdina CiopataBelum ada peringkat

- Production and Operations Management MCQ With Answers1Dokumen6 halamanProduction and Operations Management MCQ With Answers1Pranoy Sarkar0% (1)

- Is 6863 2005Dokumen11 halamanIs 6863 2005sarath6725Belum ada peringkat

- BMP5 Anti Piracy EquipmentDokumen1 halamanBMP5 Anti Piracy EquipmentGaurav SoodBelum ada peringkat

- PA-002A-r2 Chainlink Safety FenceDokumen1 halamanPA-002A-r2 Chainlink Safety Fencesarkawt muhammadBelum ada peringkat

- Bright Foundries & Machine Shop - One Page PresentationDokumen2 halamanBright Foundries & Machine Shop - One Page PresentationPrakash viswanathanBelum ada peringkat

- 4 Building Road BridgeDokumen176 halaman4 Building Road BridgeSalim TadaviBelum ada peringkat

- Ferrous Metals - Galvanized Iron SteelDokumen9 halamanFerrous Metals - Galvanized Iron SteelKenneth ChuaBelum ada peringkat

- 4d Application of Complexometric TitrationDokumen16 halaman4d Application of Complexometric TitrationnajwaBelum ada peringkat

- Vendor Inspection ExampleDokumen4 halamanVendor Inspection Examplefarez baktiBelum ada peringkat

- F.2.6 Installation, Operating & Maintenance Manual MINITEK Impressed Current Hull Protection System 20 Amps SystemDokumen70 halamanF.2.6 Installation, Operating & Maintenance Manual MINITEK Impressed Current Hull Protection System 20 Amps Systembanda agungBelum ada peringkat

- Din en 10130Dokumen14 halamanDin en 10130Ricardo VitorianoBelum ada peringkat

- Equipment - Factors Affecting SelectionDokumen35 halamanEquipment - Factors Affecting SelectionAnusuya KuppuswamyBelum ada peringkat

- Australian Standard: Structural and Pressure Vessel Steel-Quenched and Tempered PlateDokumen7 halamanAustralian Standard: Structural and Pressure Vessel Steel-Quenched and Tempered Platechris vilguzBelum ada peringkat

- Stainless Steel Welding ProcedureDokumen18 halamanStainless Steel Welding Procedurealfian leoanakBelum ada peringkat

- EZ Series Slurry Pump: Excellence Pump Industry Co., LTDDokumen7 halamanEZ Series Slurry Pump: Excellence Pump Industry Co., LTDAgung Bakdo TriyonoBelum ada peringkat

- Alnico Magnets: Types Features Applications Manufacturing Process Magnetizing Graphical Representation PropertiesDokumen18 halamanAlnico Magnets: Types Features Applications Manufacturing Process Magnetizing Graphical Representation PropertiesparthpatelparthBelum ada peringkat

- MSS SP-88 2010Dokumen16 halamanMSS SP-88 2010Marcelo PiresBelum ada peringkat

- Failures Modes of Riveted JointsDokumen5 halamanFailures Modes of Riveted JointsGokul Goku SanthiBelum ada peringkat

- Low Alloy Steel - An OverviewDokumen10 halamanLow Alloy Steel - An OverviewhaharameshBelum ada peringkat

- 303 Stainless Steel Material Data SheetDokumen3 halaman303 Stainless Steel Material Data SheetBlack LotusBelum ada peringkat

- VALVULA CHECK Dorot PDFDokumen1 halamanVALVULA CHECK Dorot PDFGustavo RomanBelum ada peringkat

- Reinforcement C-WPS OfficeDokumen7 halamanReinforcement C-WPS OfficeNoah Oluwatoyin AderiyikeBelum ada peringkat

- Weld RepairsDokumen40 halamanWeld Repairsவிஷ்ணு ராஜசெல்வன்Belum ada peringkat

- CZ122 (CW617N) : Technical DatasheetDokumen1 halamanCZ122 (CW617N) : Technical Datasheetasad144Belum ada peringkat