Determining Affinity Between Aggregate and Bitumen

Diunggah oleh

John Prashanth VadlapatiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Determining Affinity Between Aggregate and Bitumen

Diunggah oleh

John Prashanth VadlapatiHak Cipta:

Format Tersedia

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

METHODS FOR DETERMINATION OF AFFINITY BETWEEN AGGREGATE AND BITUMEN

Dauk Pavol, Hadvinov Marcela, Viovsk Jozef

Slovak University of Technology , Faculty of Chemical and Food Technology , Institute of Organic Chemistry, Catalysis and Petrochemistry , Department of Crude Oil Technology and Petrochemistry,Radlinskho 9, 812 34 Bratislava, Slovakia

Abstract: Methtods for determination of the affinity between aggregate and bitumen apply various ways of aggregates coating, straining conditions and processes of evaluation of bintumen layer on the aggregate surface. The work describes the differences of particular methods and presents advantages of the method EN 12 297-11 Bituminous mixtures. Test methods for hot mix asphalt. Part 11: Determination of the affinity between and bitumen. Key words: Bitumen, aggregate, affinity

INTRODUCTION It is well known that adhesion at the interface between bitumen and aggregate is one of the principal functional properties to guarantee durability of asphalt mixes. But the adhesion can be reduced and the cohesion within asphalt lost through the presence of water at the bitumen/stone interface. The phenomenon is known as stripping. It is known from experience and through experiments that some aggregates possess characteristics that allow very good adhesion. Other stone types on the other hand display bad adhesion. Furthermore, the adhesion is also affected by the properties of the bitumen. Nevertheless, it is known that the origin and properties of the mineral aggregate have a dominant effect compared to the origin of the bitumen [1]. Mostly, the reduced resistance against stripping of a certain aggregate can be improved by adding hydrated lime (or filler containing hydrated lime) to the asphalt mix. The use of additives in the bitumen can also improve the adhesion, but work in general more selectively and depend on the aggregate/bitumen combination. Many methods have been developed and applied to predict the susceptibility of moisture to asphalt mixtures. These methods can be classified into two categories: qualitative tests and quantitative strength tests. The Boiling Water Test [2,3] and Static Immersion Test [3,4] are qualitative tests, while the Lottman Test [5], Tunnicliff and Root [6], Modified Lottman Test [7], Texas Freeze-Thaw Pedestal Test [8] and Immersion-Compresion Test [9] are quantitative strength tests [Roberts, Kandhal, Brown, Lee, Kenedy 1996]. The strength tests allow a numerical comparison to be made between hot mix asphalts (HMA) mixtures. Research of the stripping effect can be further subdivided into three levels of investigation: the micro, meso and macro levels [1].

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

On a micro-scale level, Plancher et al [10] looked for components in bitumen, which display a particular ability to adhere to specific components in the aggregate structure. The polarity of these components can explain a strong polar bond. A polar bond is a bond where components with opposite electrical loading/charge attract each other. Normally these types of bonds are very strong. However, these more polar components seem soluble and vulnerable to the polar solvent action of water, which has the effect of removing polar bond. On a meso-scale level, Nsler [11] conducted research into the objective quantification of the remaining percentage of bitumen-coated aggregates after the mix was exposed to miscellaneous humid conditions. Here the emphasis was on avoiding visual determination in favour of analysis employing a photometric method. Furthermore, he quantified the objective adhesion by measuring the loss of the E-Modulus of compacted asphalt samples by using a Nottingham Asphalt Tester (NAT). With this method the same asphalt samples were tested before and after the water treatment. On a macro-scale level, Rand D.A. et al [12] have tried to quantify the effects on functional properties by performing wheel-tracking (or rutting tests) under water. Several aggregate types were investigated, and are able to be categorised in mineral families such as Quartsite, Porphyry, Limestone, Granite, and others. Among these standards the Rolling Bottle Test according to the European Standard [13] is common to sort out good from bad bitumen-aggregate systems. Even though the boundary conditions of the test are specified in detail, the residual degree of bitumen coverage is estimated from visual inspection. This European Standard specifies procedures for the determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. This property is intended to be of assistance to the designer for mixture design rather than as a type test. Susceptibility to stripping, as determined by these procedures, is an indirect measure of the power of a binder to adhere to various aggregates, or of various binders to adhere to a given aggregate. The procedures can also be used to evaluate the effect of moisture on a given aggregate-binder combination with or without adhesion agents including liquids, such as amines, and fillers, such as hydrated lime or cement. In the rolling bottle method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after influence of mechanical stirring action in the presence of water. The rolling bottle test is a simple but subjective test and suitable for routine testing. It is not appropriate for aggregates that are highly abrasive. In the static test method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after storage in water. The static test is a simple but subjective test that is less precise generally but can cope with high PSV-aggregates. In the boiling water stripping test method, the affinity is expressed by determining the degree of bitumencoverage on uncompacted bitumen-coated aggregate after immersion in boiling water under specified conditions.

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

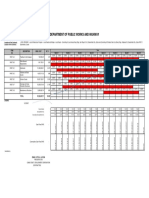

The boiling water stripping test is an objective test and has a high precision. However, it is a more specialist test because it requires greater skill of the operatives and uses chemicals as reagent. RESULTS Samples of modified bitumen were prepared by mixing of bitumen N4326 with five modificators (4% m/m). Properties of the modified bitumen N4632 are in Table 1. Table 1. Characteristics of bitumen samples Softening point Penetration Break point Sample Bitumen+Modificator RB at 25C Fraass No. [C] [0,1mm] [C] 1 N4632 + SBS-Rubber1 76 88 -15 2 N4632 + SBS-Rubber2 72 94 -21 3 N4632 + Crumb rubber 46 87 -10 4 N4632 + EVA 53 92 -10 5 N4632 + PE 47 86 -12 6 N4632* 44 122 -11 * Bitumen N4632 without modificator, EVA ethylene-vinylacetate, PE polyethylene, SBS styrene-butadiene-styrene copolymer. Bottle rollig test The rolling bottle test according to the European standard [3] was used to evaluate the influence of modificators on the affinity between bitumen N4632 and aggregate Solonica 8/11. The mixing temperature of agregate (510g) and bitumen (16g) was 165C. The mixed material was split into three parts each weighting 150 2g. The first part of the sample was transferred into the bottle with distilled water. The bottle, with glass rod inside, was placed on the roling machine and the rolling procedure was started. The rolling of the bottle at the room temperature was stopped after 6 hours. Three operators carried out a visual determination of the bitumen coverage independently. The whole has been repeated with the two remaining 150g samples. Table 2 Visual determination of area covered by bitumen Sample Operator No. O1 1. 2. 3. 4. 5. 6. 2 1 3 5 4 6 Operator O2 4 1 3 5 2 6 Area Operator = coverage O3 O1+O2+O3 % 1 7 40 2 4 45 5 11 30 4 14 25 3 9 35 6 18 25 Ranking 2 1 4 5 3 6

Surface of the aggregate particles covered by bitumen have been also estimated using a photographic record (example on Figure 1). The Photoshop

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

software program was used for the determination of bitumen-covered and free areas of aggregate, the results are shown in Table 3. Table 3. Evaluation of bitumen agregate affinity using a photographic record

Sample No. 1. 2. 3. 4. 5. 6. Pixels corresponding to total area on to covered area on aggregate aggregate 1,244912E+06 5,759480E+05 1,357360E+06 5,060120E+05 1,184856E+06 3,957420E+05 1,314639E+06 3,496940E+05 1,314622E+06 4,009600E+05 1,322527E+06 3,716300E+05 Area covered by bitumen [%] 46,3% 37,3% 33,4% 26,6% 30,5% 28,1% Ranking 1 2 3 6 4 5

Figure 1. Sample 4 after the rolling test After the visual and photographic mesurements the samples were extracted by toluene. The amount of the extracted bitumen was used for a further estimation of the area of the aggregate covered by bitumen (see Table 4). Table 4. Evaluation of the bitumen agregate affinity by the toluene extraction Weight [g] Bitumen Agregate Sample Covered Extracted extract after test No. Covered Bitumen agregate bitumen after test Ranking agregate and after after test after test % m/m extraction 1 159,675 4,852 159,509 155,558 3,951 81 2 2 164,630 5,003 164,482 160,234 4,248 85 1 3 155,980 4,735 155,651 152,306 3,344 71 4 4 159,427 4,846 159,317 156,055 3,262 67 5 5 156,793 4,727 155,397 151,973 3,424 72 3 6 156,793 4,760 156,475 153,567 2,908 61 6

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

The Boiling Water Test First step of this test [3] is a 10 minutes bath of a 200g of aggregate sample covered with bitumen in boiling water. Afterwards the aggregate sample stays in contact for five minutes with hydrochloric acid of a given concentration and amount. Finally, the acidometric titration is used for the estimation of volume of the hydrochloric acid consumed by the reaction with the free surface of the aggregate. The dependence of the free area on the consumption of the hydrochloric acid for 200g of aggregate - bitumen system is shown on Figure 2.

120 S (% Area not covered) 100 80 60 40 20 0 0,00 1,00 2,00 3,00 4,00 5,00 y = 0,7015x2 + 19,145x - 3,7766 R 2 = 0,9965

V [ml - 0,1M HCl]

Figure 2. Calibration curve of the free area for 200g of aggregate S (% Area not covered) = f(V ml - 0,1HCl ) Table 5. Results of the Boiling Water Test of the bitumen aggregate affinity using the calibration curve shown in Figure 2 0,1M HCl Area Ranking Consumption Sample No. free covered [ml] 1 2,70 48 52 3 2 3,03 55 45 4 3 3,13 57 43 5 4 2,51 45 55 2 5 2,38 42 58 1 6 3,83 70 30 6 CONCLUSIONS The EN 12697-11 : 2005 standard specifies procedures for the determination of the affinity between aggregate and bitumen and/or the susceptibility to stripping. This procedures are intended to be of assistance for the aggregate bitumen - modificator mixture design rather than a type test. Susceptibility to stripping, as determined by these procedures, is an indirect measure of the power of a binder to adhere to various aggregates, or of various binders to

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

adhere to a given aggregate. The procedures can also be used to evaluate the effect of moisture on a given aggregate-binder combination with or without adhesion agents including liquids, such as amines and fillers, such as hydrated lime or cement. The bottle rolling test is based on a relatively long lasting (6 - 24 hours) mechanical stress of the sample (aggregate coated with bitumen) in water of temperature 20 - 25 C. The evaluation of the free area of the aggregate has yield good agreement between the visual and photographic methods, though both methods rely only on the analysis of one surface of the sampled aggregate. Furthermore, the visual approach is biased with the subjective judgments of the operators. Regardless of the mentioned drawbacks the best results were obtained for the SBS modificators in the bottle rolling test. In addition, the extraction of the remaining bitumens from the aggregate samples after the bottle rolling test has shown that only a small part of bitumen is removed from aggregate during the test. Rather the extratcion indicates that bitumen on the surface of the aggregate changes the shape (collaguates) and thus covers a smaller surface. This is why the amounts of bitumen obtained by the extraction do not correlate with the bitumen covered surface which were determined by the visual and/or photographic methods. The boiling water test is focused on a high temperature (100 C) - short period (10 minutes) stress of the sample. The titration method has been used to analyze the area of aggregate covered by bitumen. The EVA modificator has yield the best results (smallest free area of the aggregate) in the case of the boiling water test. It is noteworthy that the titration methods is unbiased, by means of the subjective judgment of an operator and the entire surface of the aggregate is analyzed, what are quite interesting advantages in comparison to the visual or photographic methods. The titration method could be also employed for the evaluation of the aggregate free surface in the bottle rolling test. Nevertheless, the titration method is not mentioned within the EN 1269711 : 2005 standard, in which case the visual estimation is preferred. REFERENCIES [1] Hunter E. R., Ksaibati K.: Evaluating moisture susceptibility of asphalt mixes, 2002, http://www.mountain-plains.org/pubs/pdf/MPC02-138.pdf [2] ASTM D3625 - 96(2005) Standard Practice for Effect of Water on Bituminous-Coated Aggregate Using Boiling Water [3] EN 12697-11:2005 Bituminous mixtures - Test methods for hot mix asphalt - Part 11: Determination of the affinity between aggregate and bitumen [4] American Association of State Highway and Transportation Officials, AASHTO T 182: Standard Method of Test for Coating and Stripping of Bitumen-Aggregate Mixtures 1984 [5] ASTM D4867/MN DOT MODIFIED Revised 2/19/99: Standard Test for Effect of Moisture on Asphalt Concrete Paving Mixtures [6] ASTM D4867 / D4867M - 09 Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures [7] American Association of State Highway and Transportation Officials: AASHTO T 283: Standard Method of Test for Resistance of Compacted Hot Mix Asphalt (HMA) to Moisture-Induced Damage, 2007

45th International Petroleum Conference, June 13, 2011, Bratislava, Slovak Republic

[8] Kennedy T.W.: Texas freeze-thaw pedestal test for evaluating moisture susceptibility for asphalt mixtures Volume 253: 1982 [9] American Association of State Highway and Transportation Officials: AASHTO T 165: Standard Method of Test for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures, 2002 [10] Plancher I. H., Dorrence S.M, Petersen J.C.:Identification of Chemical types in asphalts strongly adsorbed at the asphalt aggregate interface and their relative displacement by water, AAPT, p. 151, vol 46, 1977. [11] Nsler I.: A Contribution to the Objective and Quantitative Measurement of the Adhesion between Aggregates and Bitumen, Thesis Work, 1999, University of Wuppertal, Institute of Road Construction. [12] Rand D. A.: HMA Moisture Sensitivity, Past, Present & Future, TxDOT Experiences, Paper presented in Session 3, Field Observations and Validation, Designed Tests and Forensic Analysis, Moisture Damage Symposium, Petersen Asphalt Research Conference, 39th Annual Meeting, Laramie, Wyoming, July 15-17, 2002. ACKNOWLEDGEMENT The Slovak Research and Development Agency supported this work under contract No. APVV-20-0367705.

Anda mungkin juga menyukai

- Construction Material Lab Manual2Dokumen44 halamanConstruction Material Lab Manual2VitoPascasioBelum ada peringkat

- Theory Costant Head MethodDokumen4 halamanTheory Costant Head MethodsyathirohBelum ada peringkat

- AGGREGATE ABRASION TEST VALUESDokumen6 halamanAGGREGATE ABRASION TEST VALUESAbdur RazzakBelum ada peringkat

- ASTM D 2937-00 Standard Test Method For Density of Soil in Place by The Drive-Cylinder MethodDokumen5 halamanASTM D 2937-00 Standard Test Method For Density of Soil in Place by The Drive-Cylinder MethodPablo Antonio Valcárcel Vargas100% (1)

- Aggregate Bitumen Adhesion Test: Presented By: Group 5Dokumen20 halamanAggregate Bitumen Adhesion Test: Presented By: Group 5jennifer FernanBelum ada peringkat

- Soil Mechanics FundamentalsDokumen12 halamanSoil Mechanics Fundamentalsmichalakis483Belum ada peringkat

- Consolidation TestDokumen2 halamanConsolidation TestTenzinKesang100% (1)

- LabEx No. 7 Los Angeles Abrasion TestDokumen4 halamanLabEx No. 7 Los Angeles Abrasion TestianzkieeBelum ada peringkat

- CE 121 LAB REPORT DENSITY & SPECIFIC GRAVITYDokumen14 halamanCE 121 LAB REPORT DENSITY & SPECIFIC GRAVITYNatsu RefilBelum ada peringkat

- Ductility Test PDFDokumen4 halamanDuctility Test PDFAshishJamadarBelum ada peringkat

- Asphalt Tests PDFDokumen9 halamanAsphalt Tests PDFdishkuBelum ada peringkat

- Liquid Limit and Plastic Limit Tests - Lab ExperimentsDokumen8 halamanLiquid Limit and Plastic Limit Tests - Lab ExperimentsbilalBelum ada peringkat

- Aggregate Angularity NumberDokumen5 halamanAggregate Angularity NumberAdnan AhmadBelum ada peringkat

- 3.1) Soil Compaction - Methods, Tests and EffectDokumen18 halaman3.1) Soil Compaction - Methods, Tests and EffectJoseph AsfourBelum ada peringkat

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDokumen8 halamanPreparation of Asphalt Mixture Specimens Using Marshall ApparatusAnbuchelvan CBelum ada peringkat

- Nanyang Technological University School of Civil and Structural EngineeringDokumen44 halamanNanyang Technological University School of Civil and Structural EngineeringZhwan AnwarBelum ada peringkat

- HMA Mix Design Report-2Dokumen11 halamanHMA Mix Design Report-2yustinokwingwa100% (1)

- Comparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionDokumen5 halamanComparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionIAEME PublicationBelum ada peringkat

- Compaction TestDokumen9 halamanCompaction TestFernando PascualBelum ada peringkat

- Ecg354-Aggregate Impact TestDokumen7 halamanEcg354-Aggregate Impact TestNurin AdlinaBelum ada peringkat

- Plastic LimitDokumen9 halamanPlastic LimitPoovan Rajaratnam100% (1)

- Chapter 1 (Sandy Lean Clay)Dokumen17 halamanChapter 1 (Sandy Lean Clay)John Raymund TanugaBelum ada peringkat

- Cube TestDokumen10 halamanCube Testridhuanzainal100% (1)

- Sieve AnalysisDokumen8 halamanSieve AnalysisMonika KshetriBelum ada peringkat

- Normal ConsistencyDokumen22 halamanNormal ConsistencyMujahid MzîrîBelum ada peringkat

- Sand Cement Brick Containing Recycled PDFDokumen7 halamanSand Cement Brick Containing Recycled PDFsyakirohBelum ada peringkat

- Ce 210 L Expt 04 Specific Gravity of SoilDokumen2 halamanCe 210 L Expt 04 Specific Gravity of SoilheidibguerraBelum ada peringkat

- M.E QuestionsDokumen7 halamanM.E QuestionsStephen John ClementeBelum ada peringkat

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Method of Test ForDokumen8 halamanBulk Density ("Unit Weight") and Voids in Aggregate: Standard Method of Test ForYago MendozaBelum ada peringkat

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDokumen12 halamanQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- Relative Density Test on Granular SoilsDokumen6 halamanRelative Density Test on Granular SoilsMazharYasinBelum ada peringkat

- Soil testing methods guideDokumen2 halamanSoil testing methods guideDr Wong Kim YuenBelum ada peringkat

- Name: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Dokumen17 halamanName: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Deoraj ToolsieBelum ada peringkat

- Aggregate Testing ProcechureDokumen19 halamanAggregate Testing ProcechureBalaNguyentriBelum ada peringkat

- Experiment Twelve Coefficient of Permeability TestDokumen5 halamanExperiment Twelve Coefficient of Permeability TestMelissa SammyBelum ada peringkat

- 5.section-Xi Interim Report On Geotechnical InvestigationDokumen27 halaman5.section-Xi Interim Report On Geotechnical InvestigationRaghavBelum ada peringkat

- Oedometer Test: Soil Mechanics 2 CE PC 504Dokumen26 halamanOedometer Test: Soil Mechanics 2 CE PC 504SumanHaldarBelum ada peringkat

- Grain Size Analysis 2Dokumen25 halamanGrain Size Analysis 2chiemenaBelum ada peringkat

- CEGB231 EXP 7 Compaction TestDokumen11 halamanCEGB231 EXP 7 Compaction TestNur FarehaBelum ada peringkat

- Utilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsDokumen11 halamanUtilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsApoorva AgarwalBelum ada peringkat

- L1-Physical Characteristic of SoilDokumen78 halamanL1-Physical Characteristic of SoilTAN PANG ZORBelum ada peringkat

- California Bearing RatioDokumen8 halamanCalifornia Bearing RatioairpavsetBelum ada peringkat

- LAB REPORT Rebound Hammer TestDokumen24 halamanLAB REPORT Rebound Hammer TestZahidahBelum ada peringkat

- Factors Affecting Workability of ConcreteDokumen7 halamanFactors Affecting Workability of ConcreteNeseth Eleuterio Badato100% (1)

- Hyper CreteDokumen2 halamanHyper CretedjgiumixBelum ada peringkat

- Calibrate Venturi and Orifice Flow MetersDokumen12 halamanCalibrate Venturi and Orifice Flow MetersAaron Fraka Riches100% (1)

- Permeabilidad en Celda TriaxialDokumen7 halamanPermeabilidad en Celda TriaxialLuis Lemus MondacaBelum ada peringkat

- Afolayan2021 Article CharacterizationOfBariteReservDokumen22 halamanAfolayan2021 Article CharacterizationOfBariteReservUtibe EdemBelum ada peringkat

- Laboratory Manual On Geotechnical Engineering/Foundation Engineering/Soil Mechanics:Test of SoilDokumen18 halamanLaboratory Manual On Geotechnical Engineering/Foundation Engineering/Soil Mechanics:Test of SoilSantosh KumarBelum ada peringkat

- HW II - Chapter 5 - Unbound Pavement MaterialsDokumen45 halamanHW II - Chapter 5 - Unbound Pavement MaterialsbulchaBelum ada peringkat

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Dokumen10 halamanMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnBelum ada peringkat

- Specific Gravity of SoilsDokumen8 halamanSpecific Gravity of Soilsradi_ashrafBelum ada peringkat

- Determination of The Specific Gravity and Water Absorption of The Aggregates.Dokumen5 halamanDetermination of The Specific Gravity and Water Absorption of The Aggregates.Shaheer Ahmad100% (2)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Dari EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Belum ada peringkat

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1Dari EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1Belum ada peringkat

- Unbound Aggregates in RoadsDari EverandUnbound Aggregates in RoadsR.H. JonesBelum ada peringkat

- Utilization of Silicone Maintenance Materials To Improve The Moisture SensitivityDokumen6 halamanUtilization of Silicone Maintenance Materials To Improve The Moisture SensitivityDavid PeñaBelum ada peringkat

- Long-term aging performance of asphalt compositionsDokumen9 halamanLong-term aging performance of asphalt compositionsNatalia KovalovaBelum ada peringkat

- Experimental Study On Concrete Carbonation To Work Out Performance-Based SpecificationsDokumen5 halamanExperimental Study On Concrete Carbonation To Work Out Performance-Based Specificationscap3000Belum ada peringkat

- 8042303Dokumen72 halaman8042303John Prashanth VadlapatiBelum ada peringkat

- PPP - Advantages & DisadvantagesDokumen33 halamanPPP - Advantages & DisadvantagesJohn Prashanth Vadlapati88% (8)

- Airport Layout ComponentsDokumen6 halamanAirport Layout ComponentsJohn Prashanth Vadlapati100% (1)

- Frog and EarthwormDokumen1 halamanFrog and EarthwormJohn Prashanth VadlapatiBelum ada peringkat

- 07 3Cock-Respiratory SystemDokumen2 halaman07 3Cock-Respiratory SystemJohn Prashanth VadlapatiBelum ada peringkat

- Total Station: Instruction ManualDokumen62 halamanTotal Station: Instruction ManualDavid SchneiderBelum ada peringkat

- Pavement Geometric Characteristics (Upto Cross Sectional Elements)Dokumen37 halamanPavement Geometric Characteristics (Upto Cross Sectional Elements)John Prashanth VadlapatiBelum ada peringkat

- How Fish Breathe Through GillsDokumen10 halamanHow Fish Breathe Through GillsJohn Prashanth Vadlapati0% (1)

- 07 3Cock-Respiratory SystemDokumen2 halaman07 3Cock-Respiratory SystemJohn Prashanth VadlapatiBelum ada peringkat

- Rankem Certificate - PEG 200Dokumen1 halamanRankem Certificate - PEG 200John Prashanth VadlapatiBelum ada peringkat

- Bitumen - Must KnoeDokumen2 halamanBitumen - Must KnoeJohn Prashanth VadlapatiBelum ada peringkat

- Performance Related TestsDokumen62 halamanPerformance Related TestsJohn Prashanth VadlapatiBelum ada peringkat

- AppscDokumen42 halamanAppscct021Belum ada peringkat

- Performance Related TestsDokumen62 halamanPerformance Related TestsJohn Prashanth VadlapatiBelum ada peringkat

- Airport Layout ComponentsDokumen6 halamanAirport Layout ComponentsJohn Prashanth Vadlapati100% (1)

- Pow and Dupa Roads SirumaDokumen16 halamanPow and Dupa Roads SirumarrpenolioBelum ada peringkat

- Mercedes C-Class Coupe ANCAPDokumen2 halamanMercedes C-Class Coupe ANCAPcarbasemyBelum ada peringkat

- Bus Service Will Be Suspended Friday, July 3Dokumen4 halamanBus Service Will Be Suspended Friday, July 3mishadoktorBelum ada peringkat

- San Andreas Penal Code Section Code 1 Transportation & Road ServicesDokumen20 halamanSan Andreas Penal Code Section Code 1 Transportation & Road ServicesMartinnjayBelum ada peringkat

- Colregs Handout Mars III Ror PC Study SheetDokumen9 halamanColregs Handout Mars III Ror PC Study SheetMuhammadHaris100% (1)

- Steel Product GuideDokumen32 halamanSteel Product Guideabdulkerim aBelum ada peringkat

- Evaluating Bridge Approach Pavement Thickness Using Road Pavement Design ManualDokumen7 halamanEvaluating Bridge Approach Pavement Thickness Using Road Pavement Design ManualelmanpangalinanBelum ada peringkat

- A4-P 1.0 enDokumen141 halamanA4-P 1.0 enmkpqBelum ada peringkat

- Determining Potential Transit-Oriented Development Stations Along Addis Ababa's LRTDokumen17 halamanDetermining Potential Transit-Oriented Development Stations Along Addis Ababa's LRTHerland MalauBelum ada peringkat

- Department of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractDokumen1 halamanDepartment of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractAdrian Louie Laganzo AquinoBelum ada peringkat

- Transition Track PDFDokumen1 halamanTransition Track PDFMohamad SaquibBelum ada peringkat

- Evaluation of Rapid Repair of Concrete Pavements Using Precast Concrete Technology A Sustainable and Cost-Effective SolutionDokumen22 halamanEvaluation of Rapid Repair of Concrete Pavements Using Precast Concrete Technology A Sustainable and Cost-Effective SolutionIrvebry AyuBelum ada peringkat

- 1502298L Craftsman 917.20403 Garden Tractor User ManualDokumen80 halaman1502298L Craftsman 917.20403 Garden Tractor User ManualsowabarBelum ada peringkat

- Design of PCC Abutment - Open FoundationDokumen31 halamanDesign of PCC Abutment - Open FoundationAnantPawarBelum ada peringkat

- INTERSECTION STRUCTURE LABELING GUIDELINESDokumen29 halamanINTERSECTION STRUCTURE LABELING GUIDELINESSomeshwar AgaseBelum ada peringkat

- Scheuerle Intercombi: Dimensions and SpecificationsDokumen2 halamanScheuerle Intercombi: Dimensions and SpecificationsSebastian ZarzyckiBelum ada peringkat

- EMPL Recovery Vehicle Operating ManualDokumen160 halamanEMPL Recovery Vehicle Operating ManualSayel MokhaimerBelum ada peringkat

- Bus Advertising: With GMTADokumen4 halamanBus Advertising: With GMTALinda MustafaBelum ada peringkat

- Updated Checklist of HYWA, ROLLERDokumen2 halamanUpdated Checklist of HYWA, ROLLERparthaBelum ada peringkat

- Peoria County Booking Sheet 10/27/13Dokumen8 halamanPeoria County Booking Sheet 10/27/13Journal Star police documentsBelum ada peringkat

- RFP KharagpurDokumen312 halamanRFP Kharagpurlenkapradipta2011Belum ada peringkat

- Anglu KontrolinisDokumen4 halamanAnglu KontrolinisAgneta GaidytėBelum ada peringkat

- Concrete - Draft - Manual DrawingDokumen3 halamanConcrete - Draft - Manual DrawingSiska LieBelum ada peringkat

- Satellic Service Points160303171245Dokumen4 halamanSatellic Service Points160303171245Gelu UrdaBelum ada peringkat

- Civil Engineering: Bachelor of TechnologyDokumen20 halamanCivil Engineering: Bachelor of TechnologysknagarBelum ada peringkat

- Bus Company Liable for Fatal AccidentDokumen14 halamanBus Company Liable for Fatal AccidentJaysieMicabaloBelum ada peringkat

- 2015 Yukon Denali Owner ManualDokumen445 halaman2015 Yukon Denali Owner ManualAndreea DinuBelum ada peringkat

- Installation Guide: Onlane™ Lane Departure Warning (LDW) System Installation GuideDokumen6 halamanInstallation Guide: Onlane™ Lane Departure Warning (LDW) System Installation GuidearstjunkBelum ada peringkat

- Fracasso VolkmannDokumen96 halamanFracasso VolkmannNuraBelum ada peringkat

- Based On Lto Records Hereunder Is The List of Pmvic ApplicantsDokumen17 halamanBased On Lto Records Hereunder Is The List of Pmvic ApplicantsAladino BernaldezBelum ada peringkat