Filling Methodology

Diunggah oleh

helloitskalaiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Filling Methodology

Diunggah oleh

helloitskalaiHak Cipta:

Format Tersedia

METHODOLOGY FOR SOIL FILLING

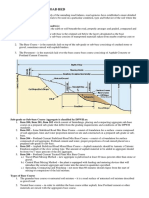

PURPOSE: The purpose of this document to explain methodology for the filling work at canals and wells in the specified area SCOPE: The scope of the work involves clearing and grubbing the area, providing temporary access, back filling by soil including leveling and compaction to the required level at specified area PROCEDURE: A) CLEARING AND GRUBBING: a) This work consist of cutting, removing and disposing of all materials such as trees, bushes, shrubs, stumps, grass, roots and lop organic soil not exceeding 150mm thickness. b) Precautions shall be taken against soil erosion and dewatering shall be carried out if necessary. c) Equipments shall be used as to have the adequate capacity and provisions to remove the thick vegetation, stumps and roots. d) All the disposable material shall be cleared away from the site and disposed in order to avoid mixing of material with usable materials. e) All the work shall be carried out as per MoRTH specification clause 201. B) BACKFILLING: a) Ramp with necessary width shall be provided to access the area by filling the gravel, levelling and compaction as directed. b) To the extent available, selected surpluses soil from the adjacent area within the site shall be used as backfill. Fill material shall be free from clods, salts, sulphates, organic or other foreign materials. All clods of earth shall be broken or removed. Where available material is mostly rock, the boulders shall be broken into pieces not larger than 150 mm size mixed with properly graded fine materials consisting of murrum or earth fill up the voids and the mixture used for filling. c) The material shall be brought from outside source if necessary. d) The material shall not be an organic soil or highly plastic clay having plasticity index and liquid limit more than 20 and 40 respectively. All the physical and organic characteristics shall be according to the MoRTH.

e) Backfilling shall be done for all the down area and the fill material shall be deposited in layers of 150mm loose thickness, watered and compacted as per the standard specification. f) The embankment shall be cut and sectioned for correct profile. The top surface of the embankment shall be cut to 150mm down from the filling top level with 500mm width and filled with backfill material to match the canal filling to provide proper compaction to the edges of filling. g) Wells shall be filled with the murrum and consolidation shall be done by watering to the certain time period to allow the settlement and same filling and consolidation shall be done to fill upto the ground level. h) Necessary equipments are to be used to excavate the material at source, dumpers for transport, dozer, grader and vibratory roller with adequate capacity for compaction.

QUALITY CONTROL: The work shall be carried out to meet the requirement as per the relevant IS codes and MoRTH Specification.

SAFETY: The work shall be carried out by taking all necessary safety measures and maintaining the EHS norms.

Anda mungkin juga menyukai

- Construction Methodology - Rearing FoundationDokumen6 halamanConstruction Methodology - Rearing FoundationEngr Benalito A Catap IIIBelum ada peringkat

- Soil Investigation and Foundation DesignDari EverandSoil Investigation and Foundation DesignPenilaian: 4.5 dari 5 bintang4.5/5 (9)

- 2 Constructing The Roadbed WTH Assignments PDFDokumen4 halaman2 Constructing The Roadbed WTH Assignments PDFAngelo John R. Javinez50% (2)

- Check List For Clearing and Grubbing: Pre-Construction StageDokumen35 halamanCheck List For Clearing and Grubbing: Pre-Construction StageAnimesh Narayan SinghBelum ada peringkat

- SP6-Steel Hand BookDokumen209 halamanSP6-Steel Hand BookAmit87% (15)

- Methodology For Filter MediaDokumen3 halamanMethodology For Filter MediaLaxminarayana Sastry100% (1)

- 5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepDokumen21 halaman5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepArup NathBelum ada peringkat

- Construction of RoadbedDokumen34 halamanConstruction of RoadbedJohn Mark TaborBelum ada peringkat

- INDIAN CULTURE - Final PDFDokumen204 halamanINDIAN CULTURE - Final PDFhelloitskalaiBelum ada peringkat

- Appendix G3 Construction Method StatementDokumen4 halamanAppendix G3 Construction Method StatementsotheaBelum ada peringkat

- Bored Piling: Method StatementDokumen8 halamanBored Piling: Method StatementKMHoBelum ada peringkat

- Section 23 - Excavation and BackfillDokumen7 halamanSection 23 - Excavation and BackfillAjay SinghBelum ada peringkat

- Civil Work SpecificationDokumen143 halamanCivil Work Specificationgea alifa amorynaBelum ada peringkat

- Recognition Programs 3-07Dokumen19 halamanRecognition Programs 3-07helloitskalaiBelum ada peringkat

- Method Statement - BORED PILINGDokumen5 halamanMethod Statement - BORED PILINGTAHER AMMAR100% (2)

- Soils for Landscape Development: Selection, Specification and ValidationDari EverandSoils for Landscape Development: Selection, Specification and ValidationPenilaian: 5 dari 5 bintang5/5 (1)

- Railway EngineeringDokumen4 halamanRailway Engineeringhelloitskalai67% (3)

- Embankment Construction MethodologyDokumen16 halamanEmbankment Construction MethodologyTinwin HtutBelum ada peringkat

- Construction MethodDokumen20 halamanConstruction MethodtriciaBelum ada peringkat

- Steps For Construction of Earth RoadsDokumen2 halamanSteps For Construction of Earth RoadsRohit Rangnekar83% (6)

- Clearing, Grubbing and ExcavationDokumen11 halamanClearing, Grubbing and ExcavationArah Louise ApostolBelum ada peringkat

- HUD Data Sheet 79gDokumen3 halamanHUD Data Sheet 79gKen Su100% (1)

- Highway Engineering ReportDokumen17 halamanHighway Engineering ReportJerick Magalang GallanoBelum ada peringkat

- Tender No.: 21/Bvn/ Box Culvert/2018 (Re Invite)Dokumen77 halamanTender No.: 21/Bvn/ Box Culvert/2018 (Re Invite)raj kumarBelum ada peringkat

- EarthworkDokumen3 halamanEarthworkSaibatul As-syahidahBelum ada peringkat

- Constructing The Roadbed (BSCE3-EC1)Dokumen6 halamanConstructing The Roadbed (BSCE3-EC1)Jayson J. PagalBelum ada peringkat

- Constructing The Roadbed (BSCE3-EC1)Dokumen6 halamanConstructing The Roadbed (BSCE3-EC1)Jayson J. PagalBelum ada peringkat

- DPWH Monitoring Guide For RoadsDokumen19 halamanDPWH Monitoring Guide For RoadsChristian SesoBelum ada peringkat

- Method Statement FOR Earthwork: ProjectDokumen6 halamanMethod Statement FOR Earthwork: ProjectKelvin Lau Hin HuatBelum ada peringkat

- Construction of Box Culvert and Road Work On Nala From PWD Road To Dargah Near Sat Beno's Temple at Lignite Mines BhavnagarDokumen10 halamanConstruction of Box Culvert and Road Work On Nala From PWD Road To Dargah Near Sat Beno's Temple at Lignite Mines Bhavnagarraj kumarBelum ada peringkat

- Construction of Prefabricated CulvertsDokumen2 halamanConstruction of Prefabricated CulvertsJonah ScottBelum ada peringkat

- Housing For Jazan Infrastructure & Utility Buildings P09-67400 02222-1 EmbankmentsDokumen5 halamanHousing For Jazan Infrastructure & Utility Buildings P09-67400 02222-1 Embankmentstamer5046882Belum ada peringkat

- Specification For Engineered FillsDokumen6 halamanSpecification For Engineered Fillsamirriyyah100% (1)

- Subgrade Specification PDFDokumen48 halamanSubgrade Specification PDFSyed Ab Rahim Syed BurhanuddinBelum ada peringkat

- Field Investigations - in SoilDokumen4 halamanField Investigations - in SoilparthBelum ada peringkat

- Item 804 - Embankment 804.1 DescriptionDokumen9 halamanItem 804 - Embankment 804.1 DescriptionEster MarianBelum ada peringkat

- Important SpecificationsDokumen10 halamanImportant Specificationspradeep naikBelum ada peringkat

- Draft Technical Document On The Code of Practice For Construction of Food Grain Storage StructuresDokumen16 halamanDraft Technical Document On The Code of Practice For Construction of Food Grain Storage Structureslakshmi1011100% (1)

- 09-Technical Specification For Items in Schedule-B1Dokumen99 halaman09-Technical Specification For Items in Schedule-B1hardik sorathiyaBelum ada peringkat

- 2.2 Method Statement - SubgradeDokumen4 halaman2.2 Method Statement - SubgradeDHARMENDRA KUMAR NAGARBelum ada peringkat

- CMT 2 ReadingsDokumen17 halamanCMT 2 ReadingsAnthony AlarillaBelum ada peringkat

- Clearing, Grubbing and ExcavationDokumen25 halamanClearing, Grubbing and ExcavationArah Louise ApostolBelum ada peringkat

- Checklist For EarthworksDokumen4 halamanChecklist For EarthworksEmmanuel Mends FynnBelum ada peringkat

- Earth WorksDokumen14 halamanEarth WorksJam100% (1)

- PRED BCG (Building Construction Guidelines)Dokumen28 halamanPRED BCG (Building Construction Guidelines)p manjunathBelum ada peringkat

- 30.sec.3000 (Maintenance of Road)Dokumen7 halaman30.sec.3000 (Maintenance of Road)aalignup arc & const. pvt ltdBelum ada peringkat

- Compaction and FillDokumen8 halamanCompaction and FillDaniel HamiltonBelum ada peringkat

- General Specs For Building (HK)Dokumen26 halamanGeneral Specs For Building (HK)PcEngBelum ada peringkat

- Assignment 05 - 20221101Dokumen10 halamanAssignment 05 - 20221101group 6Belum ada peringkat

- Project SpecificationsDokumen23 halamanProject SpecificationsMydeen ThangalBelum ada peringkat

- Earthwork ExcavationDokumen24 halamanEarthwork ExcavationGabriella PrathapsonBelum ada peringkat

- 7-4 Grading and Maintenance of Untreated SurfaceDokumen10 halaman7-4 Grading and Maintenance of Untreated SurfaceJobay Guden0% (1)

- SPECSDokumen4 halamanSPECSThabaswini SBelum ada peringkat

- BOQ For Astu Landscape, Clinic and Shade Final August 22 With Rate'Dokumen70 halamanBOQ For Astu Landscape, Clinic and Shade Final August 22 With Rate'Freedom Love NabalBelum ada peringkat

- General Instructions and SpecificationsDokumen28 halamanGeneral Instructions and SpecificationsAnna Rose PueblaBelum ada peringkat

- Aggregate Turf PavementDokumen6 halamanAggregate Turf PavementDevrim GürselBelum ada peringkat

- ExcavationDokumen5 halamanExcavationmagic handsBelum ada peringkat

- Arch. Karen G. FeliasDokumen8 halamanArch. Karen G. FeliasKelly Manlangit Jr.Belum ada peringkat

- EARTHWORKDokumen7 halamanEARTHWORKANISBelum ada peringkat

- Technical Specs LandscapingDokumen22 halamanTechnical Specs LandscapingManish KumarBelum ada peringkat

- Turf Wall Architecture and Turf Furniture Assembly GuideDari EverandTurf Wall Architecture and Turf Furniture Assembly GuideBelum ada peringkat

- Civil CutoffDokumen1 halamanCivil CutoffhelloitskalaiBelum ada peringkat

- Dra Mech 2015Dokumen12 halamanDra Mech 2015helloitskalaiBelum ada peringkat

- Current and IR NotesDokumen238 halamanCurrent and IR NoteshelloitskalaiBelum ada peringkat

- DBM Report VPRDokumen2 halamanDBM Report VPRhelloitskalai100% (1)

- Road SpeciDokumen100 halamanRoad SpecihelloitskalaiBelum ada peringkat