API-1000-11 Rev 0

Diunggah oleh

Mahesh MishraDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

API-1000-11 Rev 0

Diunggah oleh

Mahesh MishraHak Cipta:

Format Tersedia

API WELDING PROCEDURE SPECIFICATION WPS: API 1000-11 REV. NO.

: 0 PROCESS: SMAW API Group 1 DATE: 9/9/2004

Diameter: Thickness: Material: Positions:

2.375 o.d. thru 12.75 o.d. 0.187 thru 0.750 X

API-1104 QUALIFIED RANGES Filler Metal Group: Joint Type:

Butt/fillet/socket Down

Yield greater than 42 kip to less than or equal to 65 kip Fixed: Rolled: N/A Progression:

NOTE: This WPS shall be used in conjunction with the applicable sections of the Los Alamos National Laboratories Welding Standards Manual (GWS) WELD JOINT: Joint Description: Sketch Number: Type: Butt Class: Full Penetration

Open Butt single V- welded from one side only. See pg. 2 for typical sketch and bead sequence. API Group No.: F No.: 3 1 AWS Class: Sizes (s): 1/8 E-6010

FILLER MATERIALS: SFA Class: 5.1 Number of Beads:

5/32

See pg. 2 for typical number and of beads Spec: API 5L X42 /X52 to to N/A to to 1 Spec: API 5L X42 /X52 2.375 o.d. thru 12.75 o.d. pipe Group: N/A 1

BASE MATERIALS: Thickness Welded: Pipe Diameter: ASME P No.: POSITIONS: Progression: PREHEAT: NOTE: INTERPASS TEMP.: 1 Fixed: Down

0.187 - 0.750 2.375 o.d. thru 12.75 o.d. pipe Group: X Rolled:

0.187 - 0.750

Pipe Diameter P No.: 1

PWHT:

Time @ F Temp.: N/A N/A

Temperature Range F: 70 GAS: Flow Rate: Shielding: N/A CFH

Minimum Temp F: N/A

Backing: N/A

See time between passes.

Composition:

N/A

ELECTRICAL CHARACTERISTICS: Current: DC Polarity: See pg. 2 EP N/A Travel/IPM Ranges Amps: Volts: See pg. 2 See pg. 2 See pg. 2 Transfer Mode: N/A Electrode size and Type WFS/IPM:

MAX. TIME BETWEEN PASSES:

5 minutes between root pass and second pass.

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

WPS No.:

API-1000-11

Rev. No.:

Date:

9/9/2004

WELDING TECHNIQUE: Line-Up Clamp: Optional, if used line-up clamp shall be left until 50% of root bead is complete.

Stringer or Weave Bead: (S) Cleaning and/or Grinding:

(W)

Single Pass

N/A

Multi Pass

Power or hand wire brush, grinder or file Charpy V Notch N/A NDTT N/A D.T. N/A

PROCEDURE QUALIFIED FOR: Maximum K/J Heat Input: N/A

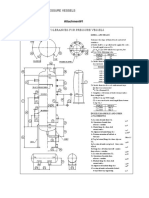

JOINT SKETCH AND BEAD NUMBER AND SEQUENCE

37.5 Bevel t thickness varies

0 3/32 land 1/16 3/32 gap

NOTE: Weld layers are representative only actual number of passes and layer sequence may vary due to variation in joint design, thickness and fit-up. Pass Filler/ Electrode Number E-6010 1 2 3 4 5 6 7 8 E-6010 E-6010 E-6010 E-6010 E-6010 E-6010 E-6010 TYPICAL WELDING PARAMETERS Travel Speed Amps Volts in/min. 70 -100 22 - 26 9 12 125 132 125 132 125 132 125 132 125 132 125 132 125 132 22 - 26 22 - 26 22 - 26 22 - 26 22 - 26 22 - 26 22 - 26 9 13 9 13 9 13 9 13 9 13 9 13 9 13

Size 1/8 5/32 5/32 5/32 5/32 5/32 5/32 5/32

Other

PREPARED BY: APPROVED BY:

Kelly Bingham Signature on File Tobin Oruch Signature on File

DATE: DATE:

9/9/2004 9/9/2004

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

API-1000-11

REV.: 0

PAGE 3 OF 3

DATE: 9/9/2004

API WELDING SPECIFICATION PROCEDURE TEST PARAMETERS Point Type: Thickness: Material: Position:

Full Penetration Single V Butt 0.322 wall API 5L X42 /X52 5G Fixed

Diameter: 8.644 o.d. Filler: Preheat: Current: Volts:

1/8 & 5/32 70F DCEP 22-26 Amps: 70-125 E-6010

Progression: Down

No. 1. 2. 3. 4.

Type Face Root Face Root

GUIDED BEND TESTS Result No. Type Result Accept no indications 5. N/A Accept no indications Accept no indications Accept no indications 6. 7. 8. N/A N/A N/A

No. 1. 2. 3. 4.

Specimen Type Figure 4 Figure 4 N/A N/A

Area Sq./ in .3726 .3217

Applied Load 23,530 21,745

TENSILE TESTS Ultimate Tensile 63,144 67,581

Character of failure and location Base metal cup and cone

No. 1. 2. 3.

Type Figure 5 Figure 5 N/A

NICK-BREAK TESTS Remarks on Nick-Break tests Acc. Break is clean. Acc. Break is clean

N/A 4. Welders Name: Scott Simonich Tests Conducted By: Brett McNeil

Z No.: 200360

Stamp: SC002

We certify that the statements herein are correct and that the tests were conducted in accordance with API-1104. Authorized By: Kelly Bingham ___________________ Date: 10/30/03 Signature on File

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

Anda mungkin juga menyukai

- WPS Sa 517Dokumen2 halamanWPS Sa 517DHANANNJAI SINGH -Belum ada peringkat

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDokumen11 halaman14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonBelum ada peringkat

- Tech SpecDokumen16 halamanTech SpecKingston RivingtonBelum ada peringkat

- Marching Chart JHBDPL, DAPL Section - II, ORISSA Region (118.23 To 206.59 KM)Dokumen2 halamanMarching Chart JHBDPL, DAPL Section - II, ORISSA Region (118.23 To 206.59 KM)Gururaj P Kundapur100% (1)

- Thread Types and UsesDokumen1 halamanThread Types and UsesJDPNetoBelum ada peringkat

- ITP For Piping SystemsDokumen6 halamanITP For Piping SystemssojeckBelum ada peringkat

- Refinery InspectionDokumen44 halamanRefinery InspectiongamadiyaBelum ada peringkat

- Approved Itp-Dss - 28 Sep 2016Dokumen4 halamanApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianBelum ada peringkat

- Approved Weld Procedure SpecificationsDokumen38 halamanApproved Weld Procedure SpecificationsJohan0001Belum ada peringkat

- Qualification Procedure No. 7: SSPC: The Society For Protective CoatingsDokumen6 halamanQualification Procedure No. 7: SSPC: The Society For Protective CoatingsRinush SinagaBelum ada peringkat

- 2G & 5GDokumen2 halaman2G & 5GRahul MoottolikandyBelum ada peringkat

- 57 PQRDokumen13 halaman57 PQRAbdul Tri Hamdani HamdaniBelum ada peringkat

- Itp Electrical SwitchgearDokumen4 halamanItp Electrical SwitchgearpertmasterBelum ada peringkat

- Technical Specification: GID-PIP-TS-630 - (E)Dokumen41 halamanTechnical Specification: GID-PIP-TS-630 - (E)santiagoBelum ada peringkat

- Utoc Preliminary Wps Shell Project 270807 PDFDokumen55 halamanUtoc Preliminary Wps Shell Project 270807 PDFErick HoganBelum ada peringkat

- Tolerances For Pressure VesselsDokumen2 halamanTolerances For Pressure VesselsolekBelum ada peringkat

- Spherical TankDokumen30 halamanSpherical TankNuzuliana EnuzBelum ada peringkat

- (0209) 031801Dokumen12 halaman(0209) 031801Sixto Gerardo Oña AnaguanoBelum ada peringkat

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDokumen4 halamanProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarBelum ada peringkat

- ZA0-2 35,0ae-03 00Dokumen15 halamanZA0-2 35,0ae-03 00Marcos Dos Santos VieiraBelum ada peringkat

- NCTL Project: Proposal Welding Procedure SpecificationDokumen4 halamanNCTL Project: Proposal Welding Procedure SpecificationRotimi Shitta-BeyBelum ada peringkat

- Ducting QAP R02 080822Dokumen2 halamanDucting QAP R02 080822Pavul RajBelum ada peringkat

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Dokumen6 halamanInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaBelum ada peringkat

- HDPE Butt Fusion Weld Inspection and Imaging PDFDokumen19 halamanHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdBelum ada peringkat

- PWHT Procedure For Petrol Steel - CoreDokumen9 halamanPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluBelum ada peringkat

- Hydro Testing + Post Weld Heat TreatmentDokumen20 halamanHydro Testing + Post Weld Heat TreatmentRafia ZafarBelum ada peringkat

- Technical Standards For Insulation-Mineral Wool-RockwoolDokumen2 halamanTechnical Standards For Insulation-Mineral Wool-RockwooljaganBelum ada peringkat

- What TitleDokumen17 halamanWhat TitleBernathTurnipBelum ada peringkat

- Pressure Vessel Hydrotest Procedure - Google SearchDokumen3 halamanPressure Vessel Hydrotest Procedure - Google SearchAsad KhanBelum ada peringkat

- Pressure Vessel PlateDokumen4 halamanPressure Vessel PlateYetkin ErdoğanBelum ada peringkat

- Field Hydrostatic Testing of Piping Systems-EGDokumen9 halamanField Hydrostatic Testing of Piping Systems-EGYusufBelum ada peringkat

- QAP For Conical StrainerDokumen2 halamanQAP For Conical StrainersatishchidrewarBelum ada peringkat

- Piping Spec: CS150 TFS 1021: Engineering StandardDokumen4 halamanPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16Belum ada peringkat

- COPI - Welding Spec For Flowlines To API 1104-1999Dokumen12 halamanCOPI - Welding Spec For Flowlines To API 1104-1999AdvisBelum ada peringkat

- The NEW Company ProfileDokumen26 halamanThe NEW Company ProfilewisandhaBelum ada peringkat

- 9.Mb21 5f Externally Finned TubesDokumen4 halaman9.Mb21 5f Externally Finned Tubesyulianus_srBelum ada peringkat

- Boiler 2 Boiler1 Ro Plant: Steam Line 2" Wall StackDokumen1 halamanBoiler 2 Boiler1 Ro Plant: Steam Line 2" Wall StackZubair NawazBelum ada peringkat

- FInal QAP HDPE WeldingDokumen2 halamanFInal QAP HDPE Weldingkannagi198Belum ada peringkat

- Marine Painting CourseDokumen57 halamanMarine Painting CourseMin SoeBelum ada peringkat

- WeldDocs WPSDokumen2 halamanWeldDocs WPSMDSIKKU_2005Belum ada peringkat

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDokumen18 halamanInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiBelum ada peringkat

- Piping Isometric Check ListDokumen2 halamanPiping Isometric Check ListPaulo SousaBelum ada peringkat

- QAP For PQR'S - For Impact TestingDokumen3 halamanQAP For PQR'S - For Impact TestingDries VandezandeBelum ada peringkat

- Piping and Pipelines Network DesignDokumen3 halamanPiping and Pipelines Network DesignOmar EzzatBelum ada peringkat

- CCUG P91 Fabrication Guidelines Dave Buzza-1Dokumen22 halamanCCUG P91 Fabrication Guidelines Dave Buzza-1Ranjith KumarBelum ada peringkat

- WPS PQRDokumen126 halamanWPS PQRBuditama ChandranegaraBelum ada peringkat

- Wps Pip Gtaw - ArabianDokumen1 halamanWps Pip Gtaw - ArabianIshack MohammedBelum ada peringkat

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDokumen1 halamanWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedBelum ada peringkat

- WPS Asme Ix PDFDokumen4 halamanWPS Asme Ix PDFSergiu LungBelum ada peringkat

- A F E S: Process Piping 670.200Dokumen17 halamanA F E S: Process Piping 670.200puwarin najaBelum ada peringkat

- SA 387 Grade 91 Class 2Dokumen4 halamanSA 387 Grade 91 Class 2briang-2Belum ada peringkat

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDokumen5 halamanInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80Belum ada peringkat

- Tips Wps FormatDokumen5 halamanTips Wps FormatWaqas WaqasBelum ada peringkat

- Pictures Related To NCR NO.100: Picture 1 (B667) Picture 2 (B642)Dokumen2 halamanPictures Related To NCR NO.100: Picture 1 (B667) Picture 2 (B642)Mohamed Reda HusseinBelum ada peringkat

- Gas Pipeline and Gas Metering and Regulating Station ProjectDokumen18 halamanGas Pipeline and Gas Metering and Regulating Station ProjectAnonymous 7vljJzH100% (1)

- Welding Procedure Specification (WPS) : in The Outer TubeDokumen1 halamanWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaBelum ada peringkat

- PWPS Eksperimen Super DuplexDokumen33 halamanPWPS Eksperimen Super Duplexryan.sBelum ada peringkat

- Coating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04Dokumen16 halamanCoating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04lemuel bacsaBelum ada peringkat

- Weld Restoration of Disk - Example of Elliott Repair TechnologyDokumen49 halamanWeld Restoration of Disk - Example of Elliott Repair TechnologyMachineryengBelum ada peringkat

- DWL-G120: Before You BeginDokumen12 halamanDWL-G120: Before You BeginMark TeaterBelum ada peringkat

- Health Care Facilities and Medical Gas and VacuumDokumen27 halamanHealth Care Facilities and Medical Gas and VacuumStephen TabiarBelum ada peringkat

- List of Accredited Service Center - ProtechDokumen1 halamanList of Accredited Service Center - ProtechLarryMatiasBelum ada peringkat

- Articles TurbineDokumen442 halamanArticles TurbineKevin RichardBelum ada peringkat

- Concrete Making MaterialsDokumen55 halamanConcrete Making Materialsjaffna100% (1)

- SLM 1 CARPENTRY 10 Revalidated and Language 1st QuarterDokumen8 halamanSLM 1 CARPENTRY 10 Revalidated and Language 1st Quarterash hshsBelum ada peringkat

- Masterfill 300Dokumen2 halamanMasterfill 300Anonymous DVtgSEpMVBelum ada peringkat

- MZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalDokumen59 halamanMZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalFaiyazsulthanBelum ada peringkat

- Foreword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveDokumen3 halamanForeword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveJoao Paulo MouraBelum ada peringkat

- 0108E - Report of Welders-OperatorsDokumen6 halaman0108E - Report of Welders-OperatorsErick AlvarezBelum ada peringkat

- Hangzhou Chenrui Air Separator Installation Manufacture CO., LTDDokumen10 halamanHangzhou Chenrui Air Separator Installation Manufacture CO., LTDTonyBelum ada peringkat

- CMM 23-70-04 CVR Fa2100 L3Dokumen334 halamanCMM 23-70-04 CVR Fa2100 L3Romain ANGUELU100% (1)

- Mechanical Design of Overhead Transmission LinesDokumen35 halamanMechanical Design of Overhead Transmission LinesElias BeyeneBelum ada peringkat

- Basic NetworkingDokumen21 halamanBasic NetworkingMina Ilagan RazonBelum ada peringkat

- CPT 31624 Cci EditsDokumen2 halamanCPT 31624 Cci Editsravip3366Belum ada peringkat

- Carrier SelectionDokumen13 halamanCarrier SelectionRanesh SinglaBelum ada peringkat

- Aerocore PropertiesDokumen2 halamanAerocore PropertieskflimBelum ada peringkat

- CSC204 - Chapter 3.1Dokumen30 halamanCSC204 - Chapter 3.1Alif HaiqalBelum ada peringkat

- BUTLER 1924 PAPER Studies in Heterogeneous EquilibriaDokumen6 halamanBUTLER 1924 PAPER Studies in Heterogeneous Equilibriaglen19Belum ada peringkat

- LAPORAN PRAKTIK KERJA LAPANGAN - Id.enDokumen25 halamanLAPORAN PRAKTIK KERJA LAPANGAN - Id.enAhmad JupriBelum ada peringkat

- WAM-The Weighted Average Method or Predicting The Performance of Systems With Bursts of Customer SessionsDokumen10 halamanWAM-The Weighted Average Method or Predicting The Performance of Systems With Bursts of Customer SessionsArunBelum ada peringkat

- Off Budgell FRCR - VerificationDokumen46 halamanOff Budgell FRCR - VerificationAmr MuhammedBelum ada peringkat

- MW tt2600 3000 Fuzzy Cel GB PDFDokumen10 halamanMW tt2600 3000 Fuzzy Cel GB PDFVentsislav TsatsarovBelum ada peringkat

- Quadrosense - ManualDokumen22 halamanQuadrosense - ManualdannraduBelum ada peringkat

- Tetrathiafulvalene - The Advent of Organic MetalsDokumen3 halamanTetrathiafulvalene - The Advent of Organic MetalsEduardo SilvaBelum ada peringkat

- Flow Meters Butt WeldDokumen3 halamanFlow Meters Butt WeldPan GulfBelum ada peringkat

- Uncoated SteelDokumen2 halamanUncoated SteelBui Chi TamBelum ada peringkat

- Lista Comandi Tk1m06Dokumen3 halamanLista Comandi Tk1m06Shahram SherkatBelum ada peringkat

- Senthil Kumaran ResumeDokumen3 halamanSenthil Kumaran ResumeRamkumar SelvarajBelum ada peringkat

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 1: Cooling TowerDokumen20 halamanCPB 20104 Mass Transfer 2 UniKL MICET Experiment 1: Cooling TowerSiti Hajar Mohamed100% (6)