Biofilter Treatment of Aquaculture Water For Reuse Applications

Diunggah oleh

David BorgesDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Biofilter Treatment of Aquaculture Water For Reuse Applications

Diunggah oleh

David BorgesHak Cipta:

Format Tersedia

PII: S0043-1354(01)00036-7

Wat. Res. Vol. 35, No. 13, pp. 30973108, 2001 # 2001 Elsevier Science Ltd. All rights reserved Printed in Great Britain 0043-1354/01/$ - see front matter

BIOFILTER TREATMENT OF AQUACULTURE WATER FOR REUSE APPLICATIONS

LEI YANG1*, LIN-SEN CHOU1 and WEN K. SHIEH2

Department of Marine Environment and Engineering, National Sun Yat-sen University, Kaohsiung, Taiwan 804, Republic of China and 2 Department of Systems Engineering, University of Pennsylvania Philadelphia, PA 19104-6315, USA (First received 30 March 2000; accepted in revised form 22 December 2000) Abstract}Biotreatment of aquaculture water for recirculation purposes is a sensible mean to support the further growth of aquaculture industry without excessive water demands that are environmentally unsustainable. This study evaluates the ecacy of biolter treatment of an eel (Anguilla japonica) culture pond water using dierent lter media and ow scheme arrangements. The experimental results demonstrate that biolter systems packed with suitable lter media are capable of improving the quality of euents for recirculation applications. The characteristics of the lter media appear to be more critical than biolter ow scheme arrangements in aecting the ecacy of the biolter treatment. Filter media with surface and structural characteristics are conducive to the development of biolms and the capture of organic suspended matter are desirable to ensure good and consistent biolter performance. Under such circumstances, the bacterial consortia in the biolter are capable of utilizing the captured organic suspended matter as an alternative substrate to support their metabolic activities when the concentration of the primary substrate (i.e., BOD) is low. For the eel pond water, a biolter packed with lter media having cross-link structures and a high bed porosity, followed by another biolter packed with a type of lter media having rough surfaces, produced the best results under the conditions tested. Moreover, a preliminary cost-benet analysis conrms its cost advantages. # 2001 Elsevier Science Ltd. All rights reserved Key words}aquaculture, biolter, eel (Anguilla japonica), recirculation, cost-benet analysis

1

INTRODUCTION

Overshing, pollution, and destruction of habi tats have greatly diminished the outputs from world ocean sheries (McGinn, 1998). Total world sh production reached 120 million metric tons in 1996, of which farmed sh production (or aquaculture) accounted for approximately 25% (McGinn, 1998). It is expected that, in the next millennium, aquaculture will be critical in total world sh production because of increasing acceptance of sh as a viable protein source (McGinn, 1998). In 1998, the aquaculture industry in Taiwan produced approximately 286,000 metric tons of sh that amounted to about US$12 million (ROCEPA, 1998). At the same time, this operation also translates into a great amount of water demand and a serious dependence on shallow aquifers for clean water supplies. In addition, unregulated expansion of sh farms in Taiwan has destroyed many coastal wetlands resulting in serious environmental impact. In

*Author to whom all correspondence should be addressed. Tel.: +886-7-525-2000 ext: 5068; fax: +886-7-5255068; e-mail: leiyang@mail.nsysu.edu.tw (L. Yang)

fact, the situation is now so acute that water pollution, water shortage, seawater incursion, and ground subsidence are common phenomena for most sh farms. A signicant reduction of the water consumption by sh farms can be one of the steps to be taken to solve these problems, so that the water resources in Taiwan can be sustained for a long-term. The limiting factors to water quality of pond culture, including pH, dissolved oxygen (DO), suspended solids (SS), residual organics (BOD), alkalinity, and nitrogenous compounds (NH3 and NO), should be reduced in order to maintain a good 2 culture environment (Wickins, 1976; Boyd et al., 1979; Chiba, 1980). Losordo et al. (1992) thus suggested some general guidelines, shown in Table 1, for pond water quality for recirculating sh culture systems. Generally, the biotreated pond water was found a feasible tool to satisfy these guidelines for reuse applications (Losordo et al., 1992; Luchetti and Gray, 1988; Muri, 1981). In addition to reducing water demands for aquaculture, reuse of pond water could decrease the discharge of carbonaceous and nitrogenous matter into receiving water bodies by as much as 90%, thereby alleviating water pollution problems (Losordo et al., 1992). In many cases,

3097

3098

Lei Yang et al. and treatment systems, respectively. The samples were then transported immediately to the laboratory and stored in a refrigerator in order to preserve its quality.

Table 1. General water quality guidelines for recirculating sh culture systems (Losordo et al., 1992) Water quality parameter Dissolved oxygen (DO) Carbon dioxide (CO2) pH Alkalinity BOD5 Suspended solids (SS) NH3 NO 2 NO 3 Unit Water quality guidelines >0.6 520 6.09.0 >20 55 510 0.020.5 0.25.0 51000

mg/L mg/L mg/L as CaCO3 mg/L mg/L mg/L mg/L mg/L

Biolter schemes and biolter media Three biolters, packed with dierent media, were used as biological treatment systems in this study. The rst biolter (R1) was packed with plastic particular media of double-cross Pall RingsTM (diameter: 1.5 cm), while the second one (R2) was packed with the plastic media of beehive-shape plate block (15 cm 15 cm 25 cm). However, the last biolter (R3) was packed with natural media of crushed coke pieces. The characteristics of these three types of media are summarized in Table 2. R1 and R3 (downow) were identical plastic columns (diameter: 20 cm, length: 100 cm), whereas R2 (horizontal-ow) was a plastic rectangular box (45 cm 15 cm 45 cm). The biolters were equipped with aerators for oxygenation and were wrapped with aluminum foil to curtail the growth of algae. Four ow schemes, which consist of these three types of biolters, were tested in this study. They were: R1 ! R2 ! R3 (Type 1), R1 ! R3 (Type 2), R2 ! R3 (Type 3) and R3 (Type 4). Figure 1 shows the Type 1 ow scheme. As seen from this gure, the ow scheme of R1 ! R2 is already included in this type of ow system.

physical and chemical processes are employed in conjunction with biological ones in order to achieve better and stable removal of pollutants from pond water (Losordo et al., 1992; Ho, 1988; Sun, 1984; Tseng et al., 1995). Meske (1976) demonstrated that the sh growth was normal in the recycled pond water treated by an activated sludge system, however, the activated sludge system performed unsatisfactorily when NH3 concentrations were low. Liu (1993) demonstrated that rotating biological contactors (RBCs) could eectively remove NH3, NO, and 2 PO3 from the pond water of eel farms. Sedimenta4 tion tanks were used to remove suspended solids (SS) originated from both uneaten feed and euent waters. Previous studies (Chen, 1990) showed that biolters were capable of achieving good and stable removal of SS, BOD and NH3 from sh pond waters without excessive area requirements (Jiang, 1989; Liu, 1993; Losordo et al., 1992; Luchetti and Gray, 1988; Tseng et al., 1995; Yu et al., 1990). In addition, maintaining adequate DO levels in culture ponds is also an important issue in recirculating systems design (Boyd, 1982; Boyd and Watten, 1989). Owing to aeration, the euents from aerobic biolters are thought to be able to maintain high DO levels before they are recirculated back to the ponds. However, frequent backwashing is needed in many cases because of excessive accumulation of biomass and entrapment of feed SS in biolters (US EPA, 1993). Biolters packed with three dierent lter media, and arranged in dierent ow schemes, were evaluated in this study for their treatment ecacy of sh pond water for reuse applications.

Biolter inoculation and startup The activated sludge, taken from a local municipal wastewater treatment plant, was used to seed the three biolters. During biolter startup, R1 and R2 were supplemented by glucose with concentration of 20 mg/L (as 18.6 mg/L of COD) in addition to being fed with the pond water in order to facilitate the growth of heterotrophic biolms. This number was about twice larger than the average value of dissolved COD that we tested in the original eel pond water. Meanwhile, since R3 was designed to let nitrication become dominant, ammonium chloride (NH4Cl) with concentration of 1 mg/L as N, which was about four times higher than the value tested in the eel pond water, was added to this reactor to stimulate the growth of slow-growing nitrication bacterial consortium. The startup process was terminated after two months when the biolm in biolters were formed.

Experimental design The experimental design involved four ow schemes with the individual biolter empty bed hydraulic retention time (HRT) as the main variable. Type 1 scheme was rst tested using R1 as the unit to remove the bulk of feed SS and BOD, R2 as a polishing unit, and R3 as a nitrication unit to remove NH3 from the pond water prior to reuse. Five HRTs were tested: 30, 20, 10, 5, and 2.5 h. At each HRT, the following parameters in untreated pond water (inuent) and euent from each biolter were monitored/analyzed daily over a 1-month period, to obtain the pseudo-steady-state data: pH, temperature, dissolved oxygen (DO), SS, BOD, Total Kjeldahl nitrogen (TKN), NH3N, NO 2N, 2 NO 2N, and PO3 . The same experimental procedures 3 4 were followed in the subsequent experiments except that HRT was controlled at 2.5 h. Moreover, in both Types 2 and 3 ow schemes, only two biolters were included, in which the rst one was used to remove SS and BOD, while the second one was used as nitrication unit. However, in Type 4 scheme R3 was used as a combined carbon oxidation and nitrication unit. The experimental design and procedures for all Type schemes were the same as for the Type 1 scheme.

MATERIALS AND METHODS

Aquaculture pond water The water taken from an outdoor pond farming Japanese eels (Anguilla japonica) was used in this study. The bottom of the pond was characterized as a soil-type. The groundwater pumped from a local aquifer was the main water supply of the eel pond. During the tests, part of the pond water was pumped continuously into the lab-scale biological treatment systems installed beside the pond. The biotreated pond water was then discharged back into the pond. During each test run, the water was sampled from the culture pond

Biological treatment of aquaculture water

Table 2. Characteristics of the media packed in the biolters Characteristics Material Specic surface area (m2/m3) Void (%) Blockability (B) Density (g/cm3) Double-cross pall ringsTM Plastic (PE) 351 87 4.03 1.06 Beehive-shape plate block Plastic (PE) 140 95 1.57 1.35

3099

Crushed coke pieces Carbon 82 35 2.34 1.86

Fig. 1. Type 1 ow scheme. Selection of optimal type of ow scheme based on BOD and NH3N removal We calculated the volumetric loading rates (g/m3 day) of BOD and NH3N from all the experimental results of this study. These results were achieved under the conditions of ve dierent HRTs of 30, 20, 10, 5 and 2.5 h controlled for Type 1 bioltering system, and one HRT of 2.5 h controlled for Types 1, 2, 3 and 4 bioltering systems. The volumetric loading rates were calculated by the equation as follows: inuent ow rate (m3/day) contaminant concentration (g/ m3) void space volume of biolter (m3), while the contaminant removal rates were calculated by the following equation: inuent ow rate (m3/day) [inuent contaminant concentration (g/m3) euent contaminant concentration (g/m3)] void space volume of biolter (m3). Analytical techniques According to Standard Methods (APHA et al., 1985), a Hach (Model DR-2000) spectrophotometer was used to measure the dierent nitrogen forms colorimetrically including: NH3N (Nessler method, 425 nm), NO 2N 2 (diazotization method, 507 nm), and NO 2N (cadmium 3 reduction method, 400 nm). TKN was determined by digestion and distillation to convert organic nitrogen species to NH3N for subsequent measurements using the Nessler method. The ascorbic method was employed to colorimetrically measure PO3 at 880 nm using a spectrophot4 ometer Shimatsu (Model UV-160 A). The measurements of BOD and SS were also performed following the procedures specied in Standard Methods (APHA et al., 1985). Cost-benet analysis of bioltration systems The amount of water that is necessary for the biolter treatment is 1000 m3/day ha based on the assumptions of 1 m depth of the pond and 10% replacement of the pond water by groundwater each day. The HRT in all the bioltration systems is assumed to be 2.5 h. Thus, based on the porosity of the media (Table 2) packed into dierent biolters, the volume per unit pond surface area required for R1, R2 and R3 biolters are calculated equal to 120, 110, and 300 m3/ha, respectively (1000 m3/day ha 2.5 h 1/ 24 day/h HRT 1=e (porosity)). The other assumptions for cost-benet analysis are as following: (1) The capital cost of constructing R1, R2 and R3 biolters on site: US$35,000/ha, US$30,000/ha, and US$35,000/ha, respectively (based on the gures obtained from a chemical plant using similar biolter designs for wastewater treatment); (2) The capital cost for one pump: US$120/ha; (3) The capital cost for one air compressor: US$1,500/ha; (4) The cost of plastic rings of double-cross Pall RingsTM: US$60/m3 (total cost: US$7,200/ha); (5) The cost of beehive-shape plate block: US$30/m3 (total cost: US$3,300/ha); (6) The cost of crushed coke particles: US$7.5/m3 (total cost: US$2,250/ha); (7) The total shaft-power of one pump (except for operation units, must plus one standby unit) required to pump the pond water into the biolters: 1.0 kW/ha (based on a total dynamic head (TDH) of 7.0 m, a pump eciency of 0.8, a safe factor of 0.1, and a ow rate of 1000 m3/day-ha); (8) The annual cost of electricity used in pumping (1.0 kW/ ha for one pump) based on an assumption of electricity charge of US$0.06/kW-h: US$525/ha-year; (9) The power required for aeration using one compressor (except for operation units, must plus one standby unit): 0.11 kW (based on an oxygen transfer eciency of 2.25 kg O2/kW-h and the oxygen consumption rate of 0.25 kg O2/h); (10) The annual cost of electricity used in aeration (0.11 kW/ ha for one compressor) based on an assumption of electricity charge of US$0.06/kW-h: US$58/ha-year; and (11) Assuming that the loan for biolter construction was amortized over a 10-year period at an interest of 9%.

RESULTS AND DISCUSSION

Type 1 Flow Scheme Figures 2 and 3 summarize the results from the Type 1 scheme experiments. According to Fig. 2, we

3100

Lei Yang et al.

Fig. 2. The average data and condence range of SS, BOD, NH3N in Type 1 scheme experiments. (I: inuent; R1: euent from R1; R2: euent from R2; R3 euent from R3).

found that SS concentrations in the untreated pond water (inuent) were relatively high (i.e., 60120 mg/ L). Those solids might come from the following sources: the bottom sediment resuspended by the

agitating action of surface aerators used for oxygenation, the fecal matter produced by the eel population, the uneaten feed, and the algal population stimulated by the subtropical climate at the location. However,

Biological treatment of aquaculture water

3101

Fig. 3. The average data and condence range of NO , NO and PO3 in Type 1 scheme experiments. 2 3 4 (I: inuent; R1: euent from R1; R2: euent from R2; R3: euent from R3).

under all conditions tested in Type 1 system, suspended matter was removed with >73% eciency and as a result, the nal euent SS concentrations from R3 were consistently 520 mg/ L. In particular, the entrapment eciency of SS in this treatment system was highly eective at HRTs>10 h, resulting in low SS levels (510 mg/L)

in the nal euent, the numbers that were under the guideline of SS for pond water are shown in Table 1. At HRTs 55 h, however, the washout of captured solids from all three biolters in Type 1 system was evident, causing the SS concentrations in the nal euent to become higher than this guideline. Hence, a lower SS loading of 0.21 Kg/m3-day, measured by

3102

Lei Yang et al.

ow rate (void reactor volume/HRT) and average concentration of SS in inuent, was suggested to be applied to Type 1 bioltering treatment system. As shown in Fig. 2, we also found that R2 was more ineective in capturing SS than both R1 and R3 under all conditions controlled, which was due to the characteristics of the lter media (i.e., beehive-shaped block) packed for R2. The particular forms of media of double-cross Pall RingsTM and crushed coke pieces, packed in R1 and R3, respectively, were indigenously characterized for capture of SS. However, the low void ratio of crushed coke particles (35%) might cause a clogging problem in R3, while it would not usually occur in R1 due to a high void ratio of 87% for the packed plastic particular media of double-cross Pall RingsTM. Thus, in Type 1 system the original pond water was designed treated by R1, R2 and R3 in series to eliminate the clogging problem. The data illustrated in Fig. 2 showed that the Type 1 treatment system performed well to remove BOD under all conditions tested. The total BOD removal eciencies could reach 72% at least. The longer the HRTs controlled, or the lower the organic loadings applied, in the system, the higher the removal eciencies were achieved. However, the levels of BOD in the nal euents controlled at dierent conditions were all lower than the guideline of culture pond water quality (5 mg/L) listed in Table 1. It was thus suggested that this recirculating treatment system could remove the limiting factor of residual organics for pond culture eectively even at an organic loading rate as high as 83 g BOD/m3-day (i.e., HRT 2.5 h). According to Fig. 2, we also found that most of BOD was removed by R1 and R3, while in R2 the observed BOD removal was insignicant for all conditions tested, which was due to the characteristics of the media packed in these three biolters. The particular media, packed in both R1 and R3, could entrap more biological solids to let more biomass accumulate in the lters than the block media, packed in R2. Therefore, in Type 1 system R2 was generally regarded as a polish unit for both SS and BOD removals. The treatment eciencies for systems without installing R2 will be discussed in Section 3.2. In total, the ecacy of biolter treatment of the eel pond water could be conrmed by consistent low euent BOD and SS concentrations even in the presence of a 12-fold increase in hydraulic loadings. The inorganic nitrogen data, shown in Figs 2 and 3, suggest that oxidized nitrogen species NO 2N 3 accounted for >90% of total inorganic nitrogen present in the original untreated pond water (by weight). On the other hand, the aqueous NH3N concentrations in the original untreated pond water were simply too low (50.5 mg/L) to support a signicant growth of nitrifying bacteria in all three biolters, despite the attempt made during biolter startup (R3) to increase the nitrifying bacterial

population, by adding supplemental NH4Cl. The reason why there were low and high levels of NH3N and NO 2N, simultaneously, in the original un3 treated pond water was believed because of nitrication occurring in the culture pond. However, the primary source of NO 2N in the pond water was 3 also possibly from the groundwater used to replenish the eel pond, which was situated in an agricultural region where chemical fertilizers were heavily used to boost crop yields. The fact that both feed and euent NO 2N concentrations were virtually identical 3 suggested that denitrication activities in the biolters were negligible for this treatment system due to an aerobic operation. Like NH3N, we found that aqueous NO 2N concentrations were also low in the 2 original untreated pond water; however, NO 2N 2 could be removed more than NH3N by the Type 1 system (Figs. 2 and 3). Thus, it was inferred that nitratication, conducted by Nitrobacter, was more signicant than nitritication, conducted by Nitrosomonas, in the all the three biolters. All the levels of NH3N, NO 2N and NO 2N in the original pond 2 3 water were found below the guidelines of water quality in pond culture suggested in Table 1. Hence, it seemed that it was not necessary to remove the inorganic nitrogenous compounds from the pond water in this study. However, the results, shown in Figs 2 and 3, still indicate that the bioltering treatment system used in this study has a potential to oxide both NH3N and NO 2N by nitrifying 2 bacteria as long as the supply of NH3N is sucient in the feed. The Type 1 treatment system exhibited no treatment eects for PO3 (Fig. 3). However, the PO3 4 4 concentrations increased slightly during biolter treatment which was perhaps caused by the lysis of biolm fragments that were removed from the biolters. The PO3 concentrations in the original 4 untreated pond water are surprisingly low, indicating that local groundwater (water source for the culture pond) contains less PO3 for the possible reason that 4 the soil is not yet saturated with the phosphate in the chemical fertilizers used. Comparisons of biolter ow schemes The experimental data obtained in the Type 1 scheme experiments indicated that biolters performed equally well at all empty bed HRTs tested. As a result, the empty bed HRT of the subsequent experiment, which involved four ow schemes, was maintained at 2.5 h. The results are illustrated in Fig. 4. In addition, since the ow scheme of R1 ! R2 has been included in Type 1 scheme, we can use the data, tested under the condition of HRT of 2.5 h to compare with the other four ow schemes. The data illustrated in Fig. 4 suggest that media characteristics appeared to be a more critical factor than ow scheme arrangements in determining the eectiveness of SS capture and entrapment achieved

Biological treatment of aquaculture water

3103

Fig. 4. Comparison of the average data and condence range of SS, BOD and NH3N for four biolter ow schemes. (I:inuent; R1, R2 and R3: euents from R1, R2 and R3).

in biolters. For instance, the crushed cork particles, which had numerous crevices on their rough surfaces, were so eective that R3 (Type 4 scheme) alone was capable of handling the solid loadings as high as 12 g/

L-day without showing serious clogging problems during the course of this experiment. The data also conrmed that the absence of bed clogging problems was, in a large part, possible because of the ability

3104

Lei Yang et al.

of bacterial consortia to utilize the captured organic suspended matter as an alternative substrate indirectly through hydrolysis rst by extracellular hydrolysis enzymes secreted by the bacteria. The removal of BOD and NH3N was largely identical among the four biolter ow schemes tested which was anticipated because of low BOD and NH3N concentrations in the pond water (Fig. 4). However, the data obtained on the basis of SS removal did not provide the experimental evidence required to support this claim. The reason might be that the media should be equally eective in BOD removal and nitrication for the aqueous BOD and NH3N by the biolm attached on the media, but not for the suspended forms which were removed mainly through mechanical clogging by the media. According to Fig. 4 and the results of calculation from original data, the removal eciencies of SS in Types 2 and 3 were 98.8 and 98.5%, respectively. Following the same steps, we calculated the removal eciencies of BOD in Types 2 and 3 equal to 80.2 and 90.4%, respectively. Thus, the removal eciency of SS in Type 2 is little higher than that in Type 3, while the removal eciency of BOD in Type 3 is higher than that in Type 2. However, due to the variation of inuent quality pumped from the eel pond, we might not conclude which type of bioltering system was better according to their relative removal eciencies. According to the results of the rst part of experiment of this study (Type 1 system with ve dierent HRTs applied), the Beehive-Shape Plate Block media packed in R2 mostly presented less eect on SS removal than the media of Double-Cross Plastic Rings (particular media) packed in R1. In order to let the bioltering system operated well in all BOD, NH3 and SS removals, it was suggested to use Type 2 system to treat the eel pond water for recirculation. Besides, the complicated cross-linking media structures prevailing in R1 provided a conducive environment that reduced the shearing eects of the owing water on biolms. At the same time, the relatively high bed porosity in R1 (i.e., 87%) also helped to mitigate bed clogging problems brought about by bacterial growth and SS accumulation. On the other hand, R3 lacked the required resistance to clogging because of its low bed porosity (i.e., 35%). The beehive-shaped block used in R2, while providing a high bed porosity at 87%, was unsatisfactory in terms of SS removal because of its geometry. It appeared that, based on this consideration, the Type 2 scheme was perhaps the best one among the four ow schemes tested. By having R1 and R3 arranged in tandem, the bulk of incoming suspended matter could be removed in R1, and R3 could be used as a polishing unit to capture the suspended matter washed out of R1 at higher hydraulic loadings. At the same time, the surface and structural characteristics of the media used would ensure good biolm growth and retention

(Shieh and Keenan, 1986; Shieh and Hsu, 1996; Yee et al., 1992). Selection of optimal type of ow scheme based on performance of single biolter In order to realize which biolter, packed with dierent media, performed better to remove the contaminants from the recirculated eel pond water, the relationship between volumetric loading rates and amounts of contaminants removed in each single biolter will be discussed. The contaminants selected in this study were BOD and NH3N for the reason that they were important factors aecting the DO in culture ponds and exhibiting toxicity to sh, respectively. The analytical results are shown in Figs 57. All the data shown in these two gures were calculated from experimental results in this study including the tests of Type 1 system controlled at ve dierent HRTs and Types 14 systems controlled at HRT of 2.5 h. According to Figs 5 and 6, positively linear relationships are observed for both the biolters R1 and R3 for BOD removal, while R1 shows positively linear, R3 presents nonlinear relationships for NH3N removal. However, according to Fig. 7, we found that the biolter R2 exhibited negatively linear relationships between the volumetric loading rates and amounts removed for both BOD and NH3N, which meant that R2 could not achieve well in higher loading of BOD and NH3N. The reason might be that the media packed into the R2 biolter was beehive-shape plate block, on which we observed that a lesser biolm was formed. The reason why the microorganisms were so dicult to grow and accumulate on the surface of media in R2 was the strong shearing force conducted by the water ow through the lter with high velocities. The force could slough o the microbial biomass from the biolm. The shorter the HRT (i.e. larger ow rate) was controlled, the more signicant slough o eect on biolm was observed. Hence, the small amount of biomass in R2 would result in less microbial activities to make the biolter unable to handle higher loading rates for both BOD and NH3N removals. The biolm sloughing o eect was observed to be insignicant in both of the biolters R1 and R3, on which were packed particulate forms of media of plastic rings and crushed coke, respectively. This was because the complicated cross-linking structure of the particulate media in both lters might decrease the velocity of water owing through and thus depress the shearing force on the biolm. However, this complicated cross-linking structure also caused clogging problem in both R1 and R3, especially R3 such that crushed coke presented low porosity (35%). Although R2 would not have the clogging problem due to its high porosity (>95%) and beehive-shape of media, we still preferred to select R1 or R3 as recirculating treatment system for aquacultural pond water. That is because both biolters can handle

Biological treatment of aquaculture water

3105

Fig. 5. The relationship between BOD and NH3N removal and loading rates in the biolter R1.

Fig. 6. The relationship between BOD and NH3N removal and loading rates in the biolter R3.

3106

Lei Yang et al.

Fig. 7. The relationship between BOD and NH3N removal and loading rates in the biolter R2.

higher loading rates and present larger removal eciencies for SS, BOD and NH3N, simultaneously. In order to solve the clogging problem in R3, a two-stage bioltering treatment system composed of R1 and R3, the Type 2 system (R1 ! R3) mentioned previously in this study, which was used to treat the recirculated pond water is suggested. The reason is that R1 can remove most of the SS from the pond water with less clogging occurring inside it due to its high porosity of medium (87%) before the pond water enters R3. Comparison of bioltration and mechanical ltration Yu et al. (1991) used oyster shells as media for their mechanical ltration system to treat the recirculated water from an outdoor eel culture. Their results showed that the removal eciencies of both BOD and NH3N were lower than 20%, while turbidity exhibited a high eciency (82%) under an HRT controlled at 12 h. Comparing with the Type 2 bioltration system used in this study, we found that even though the HRT controlled at a value as high as 2.5 h, both BOD and NH3N showed higher removal eciencies than the mechanical ltration system mentioned previously. However, the two systems had similar removal eciencies for suspended solids (SS) or turbidity. Other studies (Yu and Chang, 1989;

Yu et al., 1990), in which dierent media of sand, charcoal, and slag were used packed into the mechanical ltraters, respectively, also showed similar experimental results achieved in the previous study (Yu et al., 1991). Thus, it is concluded that mechanical ltration systems perform well for SS removal only, while all three parameters of BOD, NH3N and SS exhibit signicant removal eciencies in bioltration systems even operated under a low HRT (2.5 h). Preliminary cost-benet analysis of bioltration systems A preliminary cost analyses from Type 1 to Type 4 ow schemes, by using the capital (construction and purchase) and operation cost data, are summarized in Table 3. According to this table, although the total annual cost of Type 4 bioltration system (R3 biolter only) is estimated to be the cheapest one, due to clogging problems, the maintenance cost may be higher than the other three types of bioltration systems as mentioned previously. Although Type 1 system (R1 ! R2 ! R3) may not have a clogging problem and perform well to remove BOD and NH3 N, it is not economical to apply it to treat recirculated pond water due to high total annual cost. Finally, even though the annual cost of Type 2 system (R1 ! R3) is a little higher than Type 3

Biological treatment of aquaculture water

Table 3. Operation and cost data used for preliminary cost analyses of bioltration systems Cost analyses parameters Capital cost of constructing biolters (US$/ha) Capital cost of pumping systems (US$/ha) Capital cost of aeration systems (US$/ha) Capital cost of purchasing media (US$/ha) Annual loan payment (US$/ha-year)a Operation cost of pumping systems (US$/ha-year) Operation cost of aeration systems (US$/ha-year) Total cost (US$/ha-year)b

a b

3107

Type 1 1,00,000 480 6000 12,750 18,500 2100 232 20,832

Type 2 70,000 360 4500 9450 13,100 1575 174 14,894

Type 3 65,000 360 4500 5550 11,750 1575 174 13,499

Type 4 35,000 240 3000 2250 6300 1050 116 7466

Annual loan payment=(Total capital cost) r1 rn =1 rn 1, r interest n loan period. Total cost=annual loan payment+total operation cost.

system (R2 ! R3), we still prefer to select Type 2 system as the one to treat the recirculated pond water due to its higher removal eciencies of all SS, BOD and NH3N. On the other hand, if the groundwater was charged at US$0.06/m3, the annual cost for operating the eel pond without the biolter treatment system would be about US$21,900/ha-year (1000 m3/ day-ha 365 days/year US$0.06/m3), which was higher than the annual costs of using all these four types of bioltration systems. The economic incentives of using the biolter treated, recirculated water is therefore evident.

CONCLUSIONS

followed by another biolter packed with a type of lter media having rough surfaces but with a low bed porosity (i.e., 35%) produced the best results under the conditions tested. This arrangement (Type 2 ow scheme) allowed the capture of the bulk of incoming suspended matter (SS) in the rst biolter which was less sensitive to clogging, and the second biolter was used as a polishing unit to capture the suspended matter that escaped at higher hydraulic loadings. Moreover, a preliminary costbenet analysis conrmed its cost advantages.

Acknowledgements}The authors acknowledge the assistance of Mr. J. M. Yeh, manager of the Fong-Rong Aquaculture Co., Pingtung, Taiwan in this study. This project was nancially supported by the Agriculture Council of the Government of Republic of China (84T-2-28-F-04).

Biotreatment of aquaculture water for recirculation purposes is a sensible tool to support the further growth of aquaculture industry without excessive water demands that are environmentally unsustainable. This study evaluated the ecacy of the biolter treatment of the water of eel pond culture using dierent lter media and ow scheme arrangements. The following conclusions can be drawn (1) Biolter systems packed with suitable lter media were capable of producing high quality euents for recirculation applications. For all the ow schemes tested, the biolters performed equally well at empty bed HRTs as low as 2.5 h. (2) The characteristics of lter media appeared to be more critical than biolter ow scheme arrangements in aecting the ecacy of biolter treatment. Filter media with surface and structural characteristics conducive to the development of biolms and the capture of organic suspended matter were important to ensure good and consistent biolter performance. Under such circumstances, the bacterial consortia in the biolter were capable of utilizing the captured organic suspended matter as an alternative substrate to support their metabolic activities when the concentration of the primary substrate (i.e., BOD) was low. (3) For the eel pond treated water, a biolter packed with a type of lter media having cross-link structures and a high bed porosity (i.e., 87%),

REFERENCES

APHA, AWWA and WPCF (1985) Standard Methods for the Examination of Water and Wastewater 23, 16th ed., pp. 374532. Washington, DC, USA. Boyd C. E. (1982) Water Quality Management for Fish Pond Fish Culture, p. 318. Elsevier Scientic Publishing Co., Amsterdam, Netherlands. Boyd C. E., Romaire R. P. and Johnston E. (1979) Water quality in channel catsh production ponds. J. Environ. Qual. 18(3), 423429. Boyd C. E. and Watten B. J. (1989) Aeration systems in aquaculture. CRC Crit. Rev. Aquat. Sci. 1(3), 425472. Chen J. J. (1990) The study of treatment of polluted water resources by biological nitrication and denitrication. M.S. Thesis, Dept. of Environmental Engineering, National Cheng Kung University, Tainan, Taiwan, pp. 3248. Chiba K. (1980) Eective utilization of water in various sh culture methods. Fish Culture and Water Supply. Jpn. Sci. Fish. Soc., 3046. Ho W. S. (1988) The design and application of the automatic valveless gravity lter for the water reuse system in eel pond. Bul. Agric. Engr. 34, 7791. Jiang H. C. (1989) Treatment of pond aquaculture water and its recirculating use. Fisheries Special Publication 35, Agriculture Council, Taipei, Taiwan, 4354. Liu F. K. (1993) Development of technology of recirculating water in eel ponds. In Fisheries Special Publication, Vol. 52, pp. 101125. Agriculture Council, Taipei, Taiwan. Losordo T. M., Masser M. and Rakocy J. (1992) Recirculating aquaculture tank systems. Southern Regional Aquaculture Center (SRAC) Pub. 51, 18.

3108

Lei Yang et al. Tseng K. F., Chiou J. H., Chou S. J., Shu C. J. and Liau Y. J. (1995) Application of wastewater treatment technology in aquaculture. Proceedings of the 20th Wastewater Treatment Technology Conference, Tainan, Taiwan, pp. 6166. US EPA. (1993) Nitrogen Control, EPA/625/R-93/010, Washington, DC, USA, pp. 231235. Wickins J. F. (1976) The tolerance of warm-water prawns to recirculated water. Aquaculture 9, 1937. Yee C. J., Hsu Y. and Shieh W. K. (1992) Eects of microcarrier pore characteristics on methanogenic uidized bed performance. Water Res. 26, 11191125. Yu T. C. and Chang Y. K. (1989) Studies on circulating water-reuse systems for aquaculture}the eciency of hearth-stone lter and with ozon applied to Tilapia culture. Bul. Taiwan Fish. Res. Inst. 42, 231241. Yu T. C., Shie C. C. and Chang Y. C. (1991) Use of owing ground water or recirculation water systems in outdoor eel (Angulla japonica) culture. Bul. Taiwan Fish. Res. Inst. 50, 93101. Yu T. C., Tseng R. H. and Chang Y. C. (1990) Comparison of the owing ground water or recirculation water systems in outdoor eel (Angulla japonica) culture. Bul. Taiwan Fish. Res. Inst. 48, 145150.

Luchetti G. L. and Gray G. A. (1988) Water reuse systems: a review of principle components. Progressive FishCulturist 50, 16. McGinn A. P. (1998) Rocking the boat: conserving sheries and protecting jobs. In Worldwatch Paper, Vol. 142, pp. 2326. Worldwatch Institute, Washington, DC, USA. Meske C. (1976) Fish culture in recirculation system with water treatment by activated sludge. Adv. Aquaculture 54, 527531. Muri J. F. (1981) Management and cost implications in recirculating water systems. Proceedings of the Bio-engineering Symposium for Fish Culture, pp. 116127. Fish Culture Section, American Fisheries Society, Bethesda, MD, USA. ROCEPA. (1998) Yearbook of Environmental Protection in Taiwan. Environmental Protection Agency, Taipei, Taiwan, 8283. Shieh W. K. and Hsu Y. (1996) Biomass loss from an anaerobic uidized bed reactor. Water Res. 30, 12531257. Shieh, W. K., Keenan, J. D. (1986) Fluidized bed biolm, reactor for wastewater treatment. In: Advances in Biochemical Engineering/Biotechnology, ed A. Fiechter, pp. 132-169. Springer, Berlin. Sun L. T. (1984) Investigation of water quality in water recirculating system of pond aquaculture. China Fish. 372, 1720.

Anda mungkin juga menyukai

- Yokogawa Rota MassDokumen274 halamanYokogawa Rota MassZikireya79Belum ada peringkat

- Rotamass Yokogawa PDFDokumen24 halamanRotamass Yokogawa PDFbambang ismailBelum ada peringkat

- Trelleborg Users Chart 2011Dokumen13 halamanTrelleborg Users Chart 2011hemontoyBelum ada peringkat

- Process Design Strategies for Biomass Conversion SystemsDari EverandProcess Design Strategies for Biomass Conversion SystemsBelum ada peringkat

- Model Scheme On Integrated Fish Farming With Dairy in BiharDokumen13 halamanModel Scheme On Integrated Fish Farming With Dairy in BiharDrivers ForumBelum ada peringkat

- JC 3000s Clamp-On Ultrasonic FlowmeterDokumen4 halamanJC 3000s Clamp-On Ultrasonic FlowmeterXu EmilyBelum ada peringkat

- UreaDokumen40 halamanUreaBrigette Pavillar100% (1)

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsDari EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsBelum ada peringkat

- Roshan Kuckian: Piping Design EngineerDokumen1 halamanRoshan Kuckian: Piping Design EngineerRoshanKuckianBelum ada peringkat

- Sanitary Engineer II: Passbooks Study GuideDari EverandSanitary Engineer II: Passbooks Study GuideBelum ada peringkat

- Selection Process For Hazardous Area Cable Glands According To IecDokumen5 halamanSelection Process For Hazardous Area Cable Glands According To Iecaugur886Belum ada peringkat

- Specific MS Signing Page (KTM)Dokumen4 halamanSpecific MS Signing Page (KTM)Yogeswaran SegarBelum ada peringkat

- EC79 Regulation of Hydrogen For EU PDFDokumen15 halamanEC79 Regulation of Hydrogen For EU PDFhung nguyenBelum ada peringkat

- SS 72-2014 - PreviewDokumen9 halamanSS 72-2014 - Previewaru100% (1)

- Copra Oil Mill Process FlowDokumen3 halamanCopra Oil Mill Process FlowJohn WilrichBelum ada peringkat

- Solids Removal From Aquacultural RacewaysDokumen8 halamanSolids Removal From Aquacultural RacewaysHatem AbdelnabiBelum ada peringkat

- Chlorine Contact Basin Design: White's Handbook of Chlorination and Alternative Disinfectants, 5th EditionDokumen5 halamanChlorine Contact Basin Design: White's Handbook of Chlorination and Alternative Disinfectants, 5th Editionmaicana building100% (1)

- Thermal Pyrolysis of Polypropylene Plastic Waste IDokumen7 halamanThermal Pyrolysis of Polypropylene Plastic Waste IDiego CamachoBelum ada peringkat

- Waste and Wastewater Trip ReportDokumen15 halamanWaste and Wastewater Trip ReportAira Ariana100% (4)

- Water Quality Impact of Flow Station Effluent in A Receiving CreekDokumen7 halamanWater Quality Impact of Flow Station Effluent in A Receiving CreekIJEAB JournalBelum ada peringkat

- Biopolymers: New Materials for Sustainable Films and CoatingsDari EverandBiopolymers: New Materials for Sustainable Films and CoatingsDavid PlackettBelum ada peringkat

- Supercritical Fluid Cleaning: Fundamentals, Technology and ApplicationsDari EverandSupercritical Fluid Cleaning: Fundamentals, Technology and ApplicationsSamuel P. SawanBelum ada peringkat

- Coagulants and Natural Polymers: Perspectives For The Treatment of WaterDokumen8 halamanCoagulants and Natural Polymers: Perspectives For The Treatment of Waterhuonggiangnguyen3011Belum ada peringkat

- A Review On The Use of Rapid Small Scale Column Test (RSSCT)Dokumen9 halamanA Review On The Use of Rapid Small Scale Column Test (RSSCT)Evelin KochBelum ada peringkat

- Carbery Infrastructure Pte LTD: Lalitpur Super Thermal Power Project - 3 X 660 MW Lalitpur, Uttar PradeshDokumen39 halamanCarbery Infrastructure Pte LTD: Lalitpur Super Thermal Power Project - 3 X 660 MW Lalitpur, Uttar Pradeshvenka07Belum ada peringkat

- Managing Cyanide in Metal FinishingDokumen31 halamanManaging Cyanide in Metal FinishingWONG TSBelum ada peringkat

- A Practical Approach to Water Conservation for Commercial and Industrial FacilitiesDari EverandA Practical Approach to Water Conservation for Commercial and Industrial FacilitiesBelum ada peringkat

- Water Waste Water Engineering 9Dokumen93 halamanWater Waste Water Engineering 9ofreneo_joshua4437Belum ada peringkat

- ZEOLITA Vs CARBON ACTIVADO PDFDokumen3 halamanZEOLITA Vs CARBON ACTIVADO PDFJose Marval RodriguezBelum ada peringkat

- Performance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExampleDokumen6 halamanPerformance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExamplejatecconsultBelum ada peringkat

- Hot & Dry ClimateDokumen16 halamanHot & Dry ClimateCollenne Kaye-Lie Garcia UyBelum ada peringkat

- Topic 9Dokumen60 halamanTopic 9伟铭Belum ada peringkat

- Chapter 3 - ERT314 BIOREACTOR SYSTEM (Types of Bioreactors) PDFDokumen51 halamanChapter 3 - ERT314 BIOREACTOR SYSTEM (Types of Bioreactors) PDFHaru MasaBelum ada peringkat

- Aerobic Granular Sludge Treatment of AntibioticsDokumen14 halamanAerobic Granular Sludge Treatment of AntibioticsvincecarloBelum ada peringkat

- Design and Optimization of Innovative Food Processing Techniques Assisted by Ultrasound: Developing Healthier and Sustainable Food ProductsDari EverandDesign and Optimization of Innovative Food Processing Techniques Assisted by Ultrasound: Developing Healthier and Sustainable Food ProductsFrancisco J. BarbaBelum ada peringkat

- Biogas PDFDokumen142 halamanBiogas PDFmracneaBelum ada peringkat

- Mechanic Engineer (Static Equipment)Dokumen2 halamanMechanic Engineer (Static Equipment)An AnBelum ada peringkat

- 2008 February Treatment of Municipal Solid Waste Anaerobic Digestion TechnologiesDokumen50 halaman2008 February Treatment of Municipal Solid Waste Anaerobic Digestion TechnologiesRex RenovadoBelum ada peringkat

- Anaerobic Digestion of Animal Manures Methane Production Potential of Waste MaterialsDokumen4 halamanAnaerobic Digestion of Animal Manures Methane Production Potential of Waste MaterialsR S PappuBelum ada peringkat

- Modeling of Activated Sludge With ASM1 Model, Case Study On Wastewater Treatment Plant of South of IsfahanDokumen10 halamanModeling of Activated Sludge With ASM1 Model, Case Study On Wastewater Treatment Plant of South of IsfahanAnish GhimireBelum ada peringkat

- Process of Ready Mixed ConcreteDokumen27 halamanProcess of Ready Mixed ConcreteN P SrinivasaraoBelum ada peringkat

- Project Report On Citric Acid and Lemon Oil From LemonDokumen7 halamanProject Report On Citric Acid and Lemon Oil From LemonEIRI Board of Consultants and PublishersBelum ada peringkat

- Biofilm Case StudyDokumen2 halamanBiofilm Case StudySouth Santee Aquaculture100% (2)

- Microborganisms Role in Industrial Microbiology and BiotechnologyDokumen36 halamanMicroborganisms Role in Industrial Microbiology and BiotechnologyManu InnocentBelum ada peringkat

- GR - Tech - Book2 - Green Chemistry & TechnologyDokumen562 halamanGR - Tech - Book2 - Green Chemistry & TechnologyKhoa PhamBelum ada peringkat

- 1bottles Group Production of Bisphenol-ADokumen112 halaman1bottles Group Production of Bisphenol-AJames BelciñaBelum ada peringkat

- BFV KF Butterfly ValveDokumen12 halamanBFV KF Butterfly ValvelangtuBelum ada peringkat

- Prodution of Ferrous Sulfate From SteelmakingDokumen7 halamanProdution of Ferrous Sulfate From SteelmakinganaazizBelum ada peringkat

- KeepingWaterOutofYourStorageSystem Updated 2Dokumen13 halamanKeepingWaterOutofYourStorageSystem Updated 2haifuleddyBelum ada peringkat

- 2020 Saudi Arabia Environmental Law - EnglishDokumen24 halaman2020 Saudi Arabia Environmental Law - EnglishJose SahuquillozBelum ada peringkat

- Turtle Walk WaiverDokumen1 halamanTurtle Walk Waiverrebecca mott0% (1)

- Hunting the Chimera–the end of O'Reilly v Mackman_ -- Alder, John -- Legal Studies, #2, 13, pages 183-20...hn Wiley and Sons; Cambridge -- 10_1111_j_1748-121x_1993_tb00480_x -- 130f73b26a9d16510be20781ea4d81eb -- Anna’s ArchiveDokumen21 halamanHunting the Chimera–the end of O'Reilly v Mackman_ -- Alder, John -- Legal Studies, #2, 13, pages 183-20...hn Wiley and Sons; Cambridge -- 10_1111_j_1748-121x_1993_tb00480_x -- 130f73b26a9d16510be20781ea4d81eb -- Anna’s ArchivePrince KatheweraBelum ada peringkat

- AJWS Response To July 17 NoticeDokumen3 halamanAJWS Response To July 17 NoticeInterActionBelum ada peringkat

- HDFC Bank Summer Internship Project: Presented By:-Kandarp SinghDokumen12 halamanHDFC Bank Summer Internship Project: Presented By:-Kandarp Singhkandarp_singh_1Belum ada peringkat

- Crime and Punishment Vocabulary 93092Dokumen2 halamanCrime and Punishment Vocabulary 93092Rebeca Alfonso Alabarta50% (4)

- Holiday/Vacation Policy: Annual HolidaysDokumen18 halamanHoliday/Vacation Policy: Annual HolidaysmalaysianheartBelum ada peringkat

- CH 1 QuizDokumen19 halamanCH 1 QuizLisa Marie SmeltzerBelum ada peringkat

- Pineapples Export's To Copenhagen, DenmarkDokumen13 halamanPineapples Export's To Copenhagen, DenmarkMuhammad SyafiqBelum ada peringkat

- Project ManagementDokumen37 halamanProject ManagementAlfakri WaleedBelum ada peringkat

- Susan Rose's Legal Threat To Myself and The Save Ardmore CoalitionDokumen2 halamanSusan Rose's Legal Threat To Myself and The Save Ardmore CoalitionDouglas MuthBelum ada peringkat

- "A Study On Services Offered by State Bank of India": Final ProjectDokumen59 halaman"A Study On Services Offered by State Bank of India": Final ProjectShabana KarimBelum ada peringkat

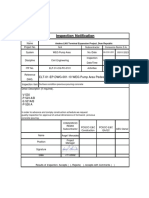

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDokumen5 halamanIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoBelum ada peringkat

- General Concepts and Principles of ObligationsDokumen61 halamanGeneral Concepts and Principles of ObligationsJoAiza DiazBelum ada peringkat

- Chapter 12Dokumen72 halamanChapter 12Samaaraa NorBelum ada peringkat

- The Mystical Number 13Dokumen4 halamanThe Mystical Number 13Camilo MachadoBelum ada peringkat

- JournalofHS Vol11Dokumen136 halamanJournalofHS Vol11AleynaBelum ada peringkat

- EIB Pan-European Guarantee Fund - Methodological NoteDokumen6 halamanEIB Pan-European Guarantee Fund - Methodological NoteJimmy SisaBelum ada peringkat

- People v. Bandojo, JR., G.R. No. 234161, October 17, 2018Dokumen21 halamanPeople v. Bandojo, JR., G.R. No. 234161, October 17, 2018Olga Pleños ManingoBelum ada peringkat

- International PositioningDokumen37 halamanInternational PositioningMansi A Kathuria100% (1)

- 2 Quiz of mgt111 of bc090400798: Question # 1 of 20 Total Marks: 1Dokumen14 halaman2 Quiz of mgt111 of bc090400798: Question # 1 of 20 Total Marks: 1Muhammad ZeeshanBelum ada peringkat

- Before The Judge - Roger EDokumen26 halamanBefore The Judge - Roger ELexLuther1776100% (4)

- Eicher HR PoliciesDokumen23 halamanEicher HR PoliciesNakul100% (2)

- Jive Is A Lively, and Uninhibited Variation of The Jitterbug. Many of Its Basic Patterns AreDokumen2 halamanJive Is A Lively, and Uninhibited Variation of The Jitterbug. Many of Its Basic Patterns Aretic apBelum ada peringkat

- DepEd Red Cross 3 4 Seater Detached PoWs BoQsDokumen42 halamanDepEd Red Cross 3 4 Seater Detached PoWs BoQsRamil S. ArtatesBelum ada peringkat

- CKA CKAD Candidate Handbook v1.10Dokumen28 halamanCKA CKAD Candidate Handbook v1.10Chiran RavaniBelum ada peringkat

- Analysis of Business EnvironmentDokumen6 halamanAnalysis of Business EnvironmentLapi Boy MicsBelum ada peringkat

- Pentesting ReportDokumen14 halamanPentesting Reportazeryouness6787Belum ada peringkat

- QuickRecharge - Ae Is Launched by Paynet - OneDokumen2 halamanQuickRecharge - Ae Is Launched by Paynet - OnePR.comBelum ada peringkat

- The Approach of Nigerian Courts To InterDokumen19 halamanThe Approach of Nigerian Courts To InterMak YabuBelum ada peringkat

- PAPER 2 RevisedDokumen36 halamanPAPER 2 RevisedMâyúř PäťîĺBelum ada peringkat