Ex 16

Diunggah oleh

Jordana ColmanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ex 16

Diunggah oleh

Jordana ColmanHak Cipta:

Format Tersedia

Chemical Engineering Science 62 (2007) 27502764

www.elsevier.com/locate/ces

Optimumreference temperature for reparameterization of the Arrhenius

equation. Part 1: Problems involving one kinetic constant

Marcio Schwaab, Jos Carlos Pinto

Programa de Engenharia Qumica/COPPE, Universidade Federal do Rio de Janeiro, Cidade Universitria-CP: 68502, Rio de Janeiro, RJ 21941-972, Brazil

Received 7 December 2006; received in revised form 3 February 2007; accepted 13 February 2007

Available online 24 February 2007

Abstract

The Arrhenius equation is one of the most well-known equations in the chemical eld and is widely used to describe the temperature

dependence of kinetic constants. This equation contains two parameters, the frequency factor and the activation energy, which are usually

estimated from experimental data. However, the correlation between the two parameter estimates is usually very high and in many cases is

practically equal to one. This makes the precise identication of the parameter values very difcult. The high parameter correlation can be

diminished through reparameterization of the Arrhenius equation and denition of a reference temperature. For problems involving a single

kinetic constant, it is shown here both analytically and through numerical examples that the proper denition of the reference temperature

allows for estimation of the parameters of the Arrhenius equation without correlation and with minimum relative error, leading to improvement

of the parameter estimation procedure.

2007 Elsevier Ltd. All rights reserved.

Keywords: Arrhenius equation; Reparameterization; Parameter estimation; Correlation; Kinetics; Modeling

1. Introduction

In the end of the 19th century, several equations were devel-

oped to describe the temperature dependence of reaction rates

(Logan, 1982). One of the most important and well-known

equations in the chemical eld came from this period: the

Arrhenius equation:

k =k

0

exp

_

E

RT

_

, (1)

where k is the rate constant (or the specic reaction rate), T is

the absolute temperature, R is the ideal gas constant, k

0

is the

frequency (or pre-exponential) factor and E is the activation

energy. Both k

0

and E are the parameters of the Arrhenius

equation, usually estimated from experimental data.

Arrhenius and other researchers also attempted to give phys-

ical signicance to the parameters of Eq. (1). By assuming that

Corresponding author. Tel.: +55 21 25628337; fax: +55 21 25628300.

E-mail address: pinto@peq.coppe.ufrj.br (J.C. Pinto).

0009-2509/$ - see front matter 2007 Elsevier Ltd. All rights reserved.

doi:10.1016/j.ces.2007.02.020

the rate constant represents a transformation between two states

(the reaction) that is controlled by an intermediate high-energy

excited state, it can be said that the parameter E represents the

energy difference between the initial state and the intermediate

state (activated species). In this case, the parameter k

0

repre-

sents the frequency of collisions between the reactants.

According to the Collision Theory, the rate constant k should

be proportional to [T

1/2

exp(E/RT )]. On the other hand, the

Transition State Theory asserts that k should be proportional

to [T exp(E/RT )]. Both theories can be summarized in the

following equation (Levenspiel, 1999):

k =k

0

T

m

exp

_

E

RT

_

, (2)

where m is an additional parameter, also estimated from avail-

able experimental data. m is frequently in the range 0 <m<1,

but in some cases it may be greater than 1 (Levenspiel, 1999).

However, it is important to notice that the inuence of T

m

on

k in Eq. (2) is very small when compared to the inuence of

the exponential term [exp(E/RT )]. Besides, extremely pre-

cise data is required to detect the effect of T

m

on k in Eq.

(2) (Froment and Bischoff, 1990). In practice, the Arrhenius

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2751

equation can provide very good ts for most reactions and the

exceptions are relatively few, as in high temperature combustion

reactions (Bendtsen et al., 1998).

The most frequent difculty associated with the application

of the Arrhenius equation is the proper estimation of its two pa-

rameters from experimental data. The mathematical structure

of the Arrhenius equation, involving the exponentiation of the

reciprocal of the absolute temperature, introduces a high cor-

relation between the two parameter estimates and makes pa-

rameter estimation very difcult, particularly during numerical

minimization of the objective function that weighs the squared

difference between measured and calculated data.

The usual way to overcome this difculty is to represent the

Arrhenius equation in the linear form (Hill, 1977). This proce-

dure consists in estimating k values at some different temper-

atures and then computing the best linear t for ln(k) in the

form:

y =ln(k) =ln(k

0

)

E

R

1

T

=a +bx. (3)

This way, the parameter estimates are obtained as the slope

(E/R) and the intercept [ln(k

0

)] of the linear t. As the lin-

ear least squares problem has analytical solution, the difcul-

ties associated with numerical minimization of the objective

function are avoided.

The use of the so-called linear form of the Arrhenius equa-

tion is very controversial and has been the subject of an in-

volving debate (Chen and Aris, 1992; Curl, 1993; Brauner and

Shacham, 1997; Kli cka and Kub cek, 1997; Sundberg, 1998).

In our opinion, the linear representation of the Arrhenius

equation should be avoided. First of all, the parameter estima-

tion procedure must preserve statistical meaning (for instance,

by using the maximum likelihood method, Bard, 1974). In

this case, the error structure of the experimental observations

should be known and should be preserved during the estimation

of the model parameters. As k is not measured experimentally,

its error structure is normally unknown. For simple linear rate

models, the error structure of k can be obtained from the error

structure of available experimental data. However, for nonlinear

models the error structure of the kinetic constant can be very

complex. Schwaab et al. (2007) studied the condence regions

of kinetic constants in nonlinear models and observed that the

condence regions can be nonconvex, open and constituted by

disconnected regions. For this reason, it is recommended that

the Arrhenius equation be inserted into the kinetic rate expres-

sions and that all parameters be estimated simultaneously using

the complete set of available experimental data. Although the

simultaneous estimation of many model parameters may be

difcult sometimes, the use of heuristic algorithms, such as the

genetic algorithm (Goldberg, 1989; Park and Froment, 1998),

the simulated annealing (Kirkpatrick et al., 1983; Eftaxias

et al., 2002) and the particle swam optimization (Kennedy and

Eberhart, 1995; Kennedy and Eberhart, 2001), can efciently

provide both the parameter estimates and a rigorous statistical

evaluation of condence regions (Schwaab et al., 2007).

In order to minimize the high correlation between the

parameters of the Arrhenius equation, one may perform

the reparameterization of the Arrhenius equation in one of the

following suggested forms (Box, 1960; Himmelblau, 1970;

Kittrell, 1970; Pritchard and Bacon, 1975; Agarwal and Brisk,

1985):

k =k

T

ref

exp

_

E

R

_

1

T

1

T

ref

__

, (4a)

k =exp

_

A

E

R

_

1

T

1

T

ref

__

, (4b)

k =k

T

ref

exp

_

B

_

T T

ref

T

__

, (4c)

k =exp

_

A +B

_

T T

ref

T

__

, (4d)

where the parameters of the reparameterized equations can be

related to the parameters of the traditional Arrhenius equation

in the form:

k

T

ref

=k

0

exp

_

E

RT

ref

_

, (5a)

A =ln(k

T

ref

) =ln(k

0

)

E

RT

ref

, (5b)

B =

E

RT

ref

. (5c)

One should observe that k

T

ref

is the specic reaction rate at

the reference temperature T

ref

. Besides, if the reference temper-

ature is innite, Eq. (4a)(4d) becomes equal to Eq. (1). There-

fore, the frequency factor k

0

of the original Arrhenius equation

can be understood as the specic reaction rate at innite tem-

perature. One should also observe that the parameters k

T

ref

, A

and B depend on the denition of the reference temperature.

Besides allowing for reduction of the parameter correlation,

reparameterization of the Arrhenius equation can also dimin-

ish the computational effort required for minimization of the

objective function (Espie and Macchietto, 1988) and improve

the elliptic representation of the parameter condence regions

(Watts, 1994) during estimation of model parameters.

One must observe that all proposed reparameterized forms

of the Arrhenius equation depend on a new parameter T

ref

,

which is the reference temperature. Little attention has been

given in the literature to the value of the reference temperature,

which is commonly dened as the average temperature of the

analyzed experimental range. It is shown here both analytically

and through numerical examples that the proper selection of

the reference temperature in Eq. (4) can allow for estimation of

uncorrelated parameters and for simultaneous improvement of

the precision of the parameter estimates in problems involving

a single kinetic constant.

2752 M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764

2. Parameter estimation

The parameter estimation procedure involves the minimiza-

tion of some objective function through manipulation of the

model parameters. Assuming that independent variables x are

free of errors, that experiments are performed independently

and that dependent variables y are subject to experimental uc-

tuations that follow the normal distribution with known covari-

ance matrix, the maximum likelihood estimation consists in

minimizing the following equation:

S() =

NE

i=1

[y

e

i

y

m

i

(x

i

, )]

T

V

1

i

[y

e

i

y

m

i

(x

i

, )], (6)

where S() is the objective function to be minimized with re-

spect to the parameter vector , y

e

i

and y

m

i

are the vector of

experimental observations and model predictions of the depen-

dent variables at experimental condition i and NE is the total

number of experiments. V

i

is the covariance matrix of experi-

mental observations at experimental condition i. The objective

function should be minimized with the help of appropriate nu-

merical procedures, such as the traditional Newton methods

(Edgar and Himmelblau, 1988; Nocedal and Wright, 1999) or

the recent heuristic optimization methods (Park and Froment,

1998; Eftaxias et al., 2002; Schwaab et al., 2007).

The signicance of the parameter estimates may be charac-

terized through the covariance matrix dened as (Bard, 1974):

V

=

_

NE

i=1

B

T

i

V

1

i

B

i

_

1

, (7)

which assumes that the model equations may be linearized at

the optimum parameter estimates. B

i

is the sensitivity matrix

of model responses with respect to the parameters at the exper-

imental condition i and is dened as

B

i

=

jy

1,i

j

1

jy

NP,i

j

1

.

.

.

.

.

.

.

.

.

jy

NY,i

j

1

jy

NY,i

j

NP

, (8)

where NP is the number of parameters and NY is the number

of model responses.

The main diagonal of the covariance matrix contains the vari-

ances of the parameter estimates, while the off-diagonal ele-

ments characterize the covariance between pairs of parameters,

which is a measure of the dependence between the parameter

estimates. In order to normalize the importance of this depen-

dence, the correlation matrix of parameter estimates should be

calculated from the covariance matrix of parameter estimates as

ij

=

v

ij

v

ii

v

jj

, (9)

where v

ij

is the element ij of the covariance matrix of param-

eter estimates. The values of all

ij

are in the range [1, 1].

As the absolute values of

ij

get closer to 1, the parameters

become more correlated and the parameter estimation becomes

poorer. The high correlation between parameter estimates can

be originated from different reasons, such as an inappropri-

ate model representation, a bad experimental design and/or the

model nonlinearities. This is exactly the case of the Arrhenius

equation, as the exponentiation of the reciprocal of the absolute

temperature inserts a high correlation between the frequency

factor and the activation energy.

Based on the covariance matrix of parameter estimates, a

condence region of parameter estimates can be dened as a

hyper-ellipsoid in the parameter space. When parameters are

not correlated, the axes of the hyper-ellipsoid are parallel to

the parameter axes; however, for highly-correlated parameters,

the axes of the hyper-ellipsoid are not parallel to the param-

eter axes. It must be noticed that the elliptical approximation

of the condence region of parameter estimates is exact for

linear models only. Depending on the degree of nonlinearity

of the model, the condence region can present very complex

shapes (Donaldson and Schnabel, 1987; Schwaab et al., 2007).

When the Arrhenius equation is used without reparameteriza-

tion, the condence regions are curved and the elliptical ap-

proximation may be worthless. The use of a proper reference

temperature and the reparameterization of the Arrhenius equa-

tion can improve the elliptical representation of the condence

regions (Watts, 1994).

3. The optimum reference temperature

Let us assume that the following mass balance equation rep-

resents a rst order irreversible reaction:

dC

A

dt

=kC

A

, C

A

(t =0) =C

A0

, (10)

which has an analytical solution when k is constant (that is,

when experiments are performed at isothermal conditions):

C

A

=C

A0

exp(kt ). (11)

If Eq. (4a) is inserted into Eq. (11), then:

C

A,i

=C

A0,i

exp

_

t

i

k

T

ref

exp

_

E

R

_

1

T

i

1

T

ref

___

, (12)

where i denotes the analyzed ith experimental condition. As-

suming that the variances of experimental uctuations are the

same for all experimental conditions, the objective function of

Eq. (6) can be written as

S() =

NE

i=1

[C

e

A,i

C

m

A,i

(x

i

, )]

2

. (13)

In this case, the covariance matrix of parameter estimates

can be written as

V

=s

2

(B

T

B)

1

, (14)

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2753

where s

2

is the constant variance of the experimental uctua-

tions. If the model is perfect, then the residuals can be used to

determine s

2

(Draper and Smith, 1998):

s

2

=S(

)/(NE NP), (15)

where S(

) is the minimum value of the least squares function

(Eq. (13)) calculated with optimum parameter estimates , NE

is the number of experiments and NP is the number of param-

eters. For single response models containing only one kinetic

constant, the sensitivity matrix of model responses with respect

to the parameters can be written as

B =

jy

1

jk

T

ref

jy

1

jE

.

.

.

.

.

.

jy

NE

jk

T

ref

jy

NE

jE

(16)

so that the covariance matrix of parameter estimates can be

written as

V

=s

2

NE

i=1

_

jC

A,i

jk

T

ref

_

2

NE

i=1

_

jC

A,i

jE

__

jC

A,i

jk

T

ref

_

NE

i=1

_

jC

A,i

jk

T

ref

__

jC

A,i

jE

_

NE

i=1

_

jC

A,i

jE

_

2

1

.

(17)

After inversion of the term between brackets, Eq. (17) becomes

V

=

s

2

det(B

T

B)

NE

i=1

_

jC

A,i

jE

_

2

NE

i=1

_

jC

A,i

jE

__

jC

A,i

jk

T

ref

_

NE

i=1

_

jC

A,i

jk

T

ref

__

jC

A,i

jE

_

NE

i=1

_

jC

A,i

jk

T

ref

_

2

.

(18)

The main objective here is determining the best value of T

ref

that leads to =0; that is, that makes the correlation between

parameters k

T

ref

and E equal to zero and allows for independent

estimation of the model parameters. As the parameter correla-

tion is proportional to the parameter covariance (element v

12

of

matrix V

), elimination of the parameter correlation is equiv-

alent to nding the value of T

ref

that satises the following

equation:

NE

i=1

jC

A,i

jk

T

ref

jC

A,i

jE

=0. (19)

As the derivatives of model responses in respect to the model

parameters are

jC

A,i

jk

T

ref

=

C

A,i

ln(C

A,i

/C

A0,i

)

k

T

ref

, (20)

jC

A,i

jE

=

_

1

T

i

1

T

ref

_

C

A,i

ln(C

A,i

/C

A0,i

)

R

. (21)

Eq. (19) becomes

NE

i=1

1

k

T

ref

R

_

1

T

i

1

T

ref

_

[C

A,i

ln(C

A,i

/C

A0,i

)]

2

=0. (22)

The solution of Eq. (22) leads to:

1

T

ref

=

NE

i=1

[C

A,i

ln(C

A,i

/C

A0,i

)]

2

T

i

NE

i=1

[C

A,i

ln(C

A,i

/C

A0,i

)]

2

(23)

or

T

ref

=

NE

i=1

[C

A,i

ln(C

A,i

/C

A0,i

)]

2

NE

i=1

[C

A,i

ln(C

A,i

/C

A0,i

)]

2

T

i

. (24)

Eq. (23) shows that 1/T

ref

is a weighted average of the 1/T

i

values used to perform the experiments and that the weights

depend on the concentration values and on the initial concen-

tration. It must be emphasized that the reference temperature is

normally dened as the midpoint T value in the analyzed range

of temperatures, while Eq. (23) clearly shows that the optimum

reference temperature is the reciprocal of the weighted average

of the 1/T

i

. Eq. (24) denes the reference temperature that al-

lows for estimation of uncorrelated parameters. The values of

C

A,i

used in Eq. (24) are the ones calculated from the model

with the optimum parameters. As these values are unknown a

priori, the values of C

A,i

in Eq. (24) can be made equal to the

experimental values and the reference temperature can be cal-

culated exactly afterwards.

It is important to notice that all proposed reparameteriza-

tions presented in Eqs. (4a)(4d) lead to the same solution for

T

ref

. Therefore, independently of the particular reparameteri-

zation considered, the reference temperature that leads to un-

correlated model parameters is the same (see the Appendix).

For this reason, the analysis performed here is concentrated

on Eq. (4a). The other reparameterization forms are analyzed

here only when they lead to distinct numerical performances,

as discussed below.

At this point one should observe that the parameter corre-

lation is indeed a function of the experimental data, of the

parameter estimates and of the reference temperature. There-

fore, the calculation of the optimum reference temperature can

be dened implicitly as

(x

e

, y

e

,

, T

ref

) =0. (25)

Eq. (25) can be solved numerically, so that Eq. (24) can be

seen as a particular analytical solution of Eq. (25), obtained for a

particular kinetic problem. In order to illustrate this point, let us

assume that the reaction temperature is allowed to vary linearly

from an initial value T

0

with a heating rate of , as performed

in typical temperature programmed experiments (Hedrick and

Chuang, 1998; Bhering et al., 2002; Kanervo et al., 2006):

T =T

0

+t . (26)

2754 M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764

Inserting Eq. (26) into Eq. (10), one gets:

dC

A

dt

=k

T

ref

exp

_

E

R

_

1

T

0

+t

1

T

ref

__

C

A

,

C

A

(t =0) =C

A0

. (27a)

As dT/dt = , Eq. (27a) can be rewritten as

dC

A

dT

=

k

T

ref

exp

_

E

R

_

1

T

1

T

ref

__

C

A

,

C

A

(T =T

0

) =C

A0

. (27b)

Eq. (27b) is used more often than Eq. (27a) for interpretation

of real experiments, as temperature can be related more easily

to catalyst characteristics than time. Anyway, the integration

of Eq. (27a) or (27b) must be performed numerically. As a

consequence, an analytical solution for a T

ref

value that leads to

uncorrelated model parameters is not possible. However, given

a set of experimental data (C

A0

, , T

0

, t and C

A

) and of model

parameters (k

T

ref

and E), can be computed for any value

of T

ref

. Therefore, one may devise the following numerical

procedure:

1. an initial guess for T

ref

is provided (for instance, the mid-

point T value in the analyzed range of temperatures);

2. model parameters (which are probably correlated) are esti-

mated with the available set of experimental data and the

value provided for T

ref

;

3. Eq. (25) is solved for T

ref

, using the available experimen-

tal data and the set of estimated model parameters (for in-

stance, using a direct search method or a NewtonRaphson

procedure).

In practice, Eq. (25) is a function of the reference temperature

only. First, for a given set of experimental data, the values of x

e

and y

e

are xed. Second, for a xed set of experimental data,

the kinetic parameter k is the one that minimizes the objective

function, regardless of the proposed reparameterization. For

instance, let us assume that two distinct values T

ref 0

and T

ref 1

are compared. As

k =k

T ref 0

exp

_

E

0

R

_

1

T

1

T

ref 0

__

=k

T ref 1

exp

_

E

1

R

_

1

T

1

T

ref 1

__

(28)

then it can be concluded that

E

1

=E

0

, (29a)

k

T ref 1

=k

T ref 0

exp

_

E

0

R

_

1

T

ref 1

1

T

ref 0

__

. (29b)

In other words, if the parameter estimates (k

T ref 0

, E

0

) are

known for a certain reparameterization variable (T

ref 0

), then

they can be readily updated (k

T ref 1

, E

1

) when the values of

the reparameterization variables change (to T

ref 1

) without af-

fecting the model performance. Therefore, once the parameters

are estimated with a specic reference temperature (T

ref 0

) and

a specic reparameterization form, the parameters of an alter-

native reparameterization form become functions of the new

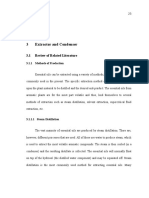

Initial guess for T

ref

0

Set k = 0

Estimate the model

parameters

Calculate the

covariance matrix of

parameter estimates

Calculate the

parameter correlation

Is the

parameter

correlation

null?

END

Update the T

Tref

k

Recalculate the

parameters

k

Tref

k

and E

k

YES

NO

T

ref

k

, k

Tref

k

, E

k

k = k + 1

Fig. 1. A schematic representation of the procedure for optimum reference

temperature determining.

T

ref

only. For this reason, the steps 13 of the proposed algo-

rithm must be performed only once, as the parameter estimation

(step 2) does not have to be repeated after modication of T

ref

(step 3). This procedure is illustrated in Fig. 1. It is important

to emphasize that after the parameter estimation (step 2), the

values of parameters k

T ref 0

and E

0

for a reference tempera-

ture T

ref 0

become available. Starting from these values, one

can readily calculate the parameter values for any other T

ref

values and reparameterization forms. Then, the covariance ma-

trix of parameter estimates can be recalculated (Eq. (8)) and

the parameter correlation can be updated (Eq. (9)). A suitable

numerical procedure can be used for searching the value of T

ref

that leads to uncorrelated model parameters. Alternatively, one

can allow T

ref

to vary and, after recalculation of the covari-

ance matrix of parameter estimates, observe how the parameter

correlation and parameter errors are affected by the changing

valuebreak of T

ref

.

As a matter of fact, reparameterization does affect step 2 of

the proposed algorithm because parameter correlation affects

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2755

the performance of the minimization procedure (Agarwal and

Brisk, 1985, 1986; Rimensberger and Rippin, 1986; Espie and

Macchietto, 1988). If the parameter correlation is too high, it

may be difcult to nd the minimum of Eq. (6), which means

that steps 2 and 3 should be performed iteratively until conver-

gence in order to guarantee attainment of optimum parameter

estimates without correlation. This procedure is indicated in

Fig. 1 by a dashed line, where the parameter estimation step is

included in the iterative procedure.

When there are N >1 independent kinetic constants, then

the number of reference temperatures that must be dened by

the user is equal to N, while the number of independent pa-

rameter correlations is equal to N(2N 1), which may be

much larger than N. Therefore, it cannot be guaranteed that the

proposed reparameterization scheme can allow for the simul-

taneous removal of all parameter correlations. However, the

minimization of parameter correlation effects can be performed

with the proposed numerical scheme (Fig. 1) if a proper norm

of the parameter correlation matrix is provided by the user

(for instance, the sum of the squares of all correlations terms).

An analysis of this multi-dimensional problem is beyond the

scope of this text and will be the subject of future communica-

tions in this series. In the following examples, it is shown that

the proposed numerical scheme can handle one-dimensional

problems satisfactorily and that one is encouraged to propose

similar schemes to handle more involving multi-dimensional

problems.

4. Examples

In the two following examples, the parameter estimation

procedure was performed through combination of the parti-

cle swarm optimization (Kennedy and Eberhart, 1995) and tra-

ditional Newton procedures (Noronha et al., 1993). The rst

method is characterized by a global minimization character that

avoids local minima. The method can also be used for construc-

tion of the likelihood condence regions, providing a more rig-

orous statistical evaluation of the parameter estimates (Schwaab

et al., 2007). Other methods have been proposed in the literature

to allow for construction of the likelihood condence regions

(Lobry et al., 1991; Klepper and Hendrix, 1994), but the use

of particle swarm optimization should be preferred due its ca-

pability for solving high-dimensional and multi-minima prob-

lems. Proling t-plots (Bates and Watts, 1988) can be used for

construction of the likelihood condence intervals for parame-

ter estimates, but the condence regions can only be obtained

through interpolation. Besides, when particle swarm optimiza-

tion is used, the likelihood condence regions of parameter

estimates are obtained with the objective function evaluations

performed during the previous optimization steps. This means

that PSO does not require any additional calculation for com-

putation of condence regions, so that one has only to select

the previously evaluated points that satisfy the likelihood cri-

teria (Schwaab et al., 2007).

The second method is a GaussNewton-based proce-

dure that uses the best point provided by the particle

swarm optimization method as the initial guess, assuring

Table 1

Experimental data used in Example 1

t (min) T (K) y t (min) T (K) y

120.0 600 0.900 60.0 620 0.802

60.0 600 0.949 60.0 620 0.802

60.0 612 0.886 60.0 620 0.804

120.0 612 0.785 60.0 620 0.794

120.0 612 0.791 60.0 620 0.804

60.0 612 0.890 60.0 620 0.799

60.0 620 0.787 30.0 631 0.764

30.0 620 0.877 45.1 631 0.688

15.0 620 0.938 30.0 631 0.717

60.0 620 0.782 30.0 631 0.802

45.1 620 0.827 45.0 631 0.695

90.0 620 0.696 15.0 639 0.808

150.0 620 0.582 30.0 639 0.655

60.0 620 0.795 90.0 639 0.309

60.0 620 0.800 25.0 639 0.689

60.0 620 0.790 60.1 639 0.437

30.0 620 0.883 60.0 639 0.425

90.0 620 0.712 30.0 639 0.638

150.0 620 0.576 30.0 639 0.659

90.4 620 0.715 60.0 639 0.449

120.0 620 0.673

the precision of the point estimate and giving the nal

covariance matrix of parameter estimates, used for con-

struction of the elliptical condence regions. The deriva-

tives used for minimization of the objective function and

for calculation of the covariance matrix of parameter esti-

mates were evaluated numerically through central difference

approximations.

Finally, parameter correlation and the relative error of

parameter estimates were obtained as illustrated in Fig. 1.

After initial parameter estimation with a guess for T

ref 0

, the

reference temperature was allowed to vary and the covariance

matrix of parameter estimates was recalculated for every new

T

ref

value, allowing us to show how the parameter correlation

and the relative errors of parameter estimates depend on T

ref

.

This way, one can obtain very good approximations of the

T

ref

values that lead to uncorrelated model parameters or to

minimum relative parameter errors. As discussed, alternative

numerical procedures could be used for searching the optimum

value of T

ref

. In this case, some concern should be given to

the initial guess of the reference temperature, as it may exert

a signicant inuence on the convergence of the numerical

procedure.

4.1. Example 1analytical solution

In order to illustrate the application of the solution obtained

for the rst order kinetics, the thermal isomerization of the

bicycle[2.1.1]hexane is considered (Srinivasan and Levi, 1963).

The available data are the remaining fraction of reactant y (that

is, C

A

/C

A0

) for different times t and temperatures T, as reported

by Englezos and Kalogerakis (2001) and shown in Table 1.

2756 M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Predicted Values

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

O

b

s

e

r

v

e

d

V

a

l

u

e

s

Fig. 2. Observed values versus model prediction in Example 1.

560 580 600 620 640 660 680 700

T

ref

[K]

-1.00

-0.75

-0.50

-0.25

0.00

0.25

0.50

0.75

1.00

C

o

r

r

e

l

a

t

i

o

n

Fig. 3. Correlation behavior as a function of the reference temperature in

Example 1.

Therefore, the rst order kinetic model is written as

y

i

=exp

_

t

i

k

T

ref

exp

_

E

R

_

1

T

i

1

T

ref

___

, (30)

where the reparameterization formdened in Eq. (4a) was used.

The optimum reference temperature is

T

ref

=

NE

i=1

[y

i

ln(y

i

)]

2

NE

i=1

[y

i

ln(y

i

)]

2

T

i

. (31)

The least squares objective function (Eq. (13)) was used for

estimation of the model parameters and its minimum value was

equal to 1.028 10

3

. It is important to emphasize that the

model responses and, consequently, the model performance are

not sensitive to reparameterization, so that Fig. 2 illustrates the

model behavior independently of the used reparameterization.

In order to observe the effect of the reference temperature on

the parameter correlation and on the parameter relative errors

(dened in the Appendix, Eqs. (A.6) and (A.7)), the reference

temperature was allowed to vary, as shown in Figs. 3 and 4.

Fig. 3 shows that uncorrelated model parameters can indeed be

achieved. Parameter correlation is close to 1.0 for low refer-

ence temperatures and increases continuously as T

ref

increases,

approaching the value of +1.0 for high values of T

ref

.

400 500 600 700 800 900 1000 1100 1200 1300

T

ref

[K]

0.0

20.0

40.0

60.0

80.0

100.0

R

e

l

a

t

i

v

e

E

r

r

o

r

[

%

]

Fig. 4. Relative error behavior of parameters k

T

ref

(line) and E (dashed line)

as functions of the reference temperature in Example 1.

Fig. 4 shows how the relative errors of parameters k

T

ref

and E

change, as functions of the reference temperature. The relative

error of parameter E is independent of the reference tempera-

ture and is equal 3.37%. However, for parameter k

T

ref

the rela-

tive error attains its minimum value of 2.29% at the reference

temperature value that also leads to null parameter correlation.

(This can be proved analytically, as shown in the Appendix.)

This point can be determined by Eq. (31), and this optimum ref-

erence temperature is equal to 628.45 K, where the parameters

k

T

ref

and E are equal to 6.808 10

3

min

1

and 229.8 kJ/mol.

Using Eqs. (29a)(29b) one can calculate these parameters

for any other reference temperature and reparameterization

form.

As discussed previously, when the reference temperature

tends to innity, the reparameterized form of the Arrhenius

equation becomes equal to the traditional form. One should ob-

serve in Fig. 3 that the parameter correlation approaches the

value +1.0 for the traditional form of the Arrhenius equation.

Fig. 4 also shows that the relative error increases for the tra-

ditional form of the Arrhenius equation, showing again that it

may be advantageous to use Eq. (4). In fact, if the traditional

form of the Arrhenius equation is used in this case, the parame-

ter correlation becomes equal to 0.999881 and the relative error

of parameter k

T

ref

becomes equal to 148.4%.

For calculation of the reference temperature in Eq. (31),

model outputs should be used, leading to the value of 628.45 K.

If model outputs are replaced by the experimental measure-

ments, then the value of the reference temperature obtained

with Eq. (31) becomes equal to 628.54 K, which leads to pa-

rameter correlation of 0.01 and relative error of parameter k

T

ref

of 2.29%. These values are very close to the best ones, indicat-

ing that experimental data can be indeed used to provide very

good initial guesses for T

ref

. In this particular case, the good

agreement between model predictions and available experimen-

tal data, shown in Fig. 2, supports the use of the experimental

data for calculation of T

ref

.

If the reference temperature of 620 K is used (the midpoint

temperature value within the analyzed experimental range), the

parameter correlation becomes equal to 0.66 and the relative

error of parameter k

T

ref

becomes equal to 3.06%. These values

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2757

-1.0 0.0 1.0 2.0 3.0 4.0 5.0 6.0

k

Tref

[10

+17

min

-1

]

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 5. Elliptical and likelihood condence regions of parameters k

T

ref

and

E with an innite reference temperature (traditional Arrhenius equation) in

Example 1.

-0.5 0.0 0.5 1.0 1.5 2.0 2.5

k

Tref

[10

-13

min

-1

]

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 6. Elliptical and likelihood condence regions of parameters k

T

ref

and

E with a reference temperature of 400 K in Example 1.

are certainly worse than the ones obtained with the optimum

reference temperature.

It is interesting to observe that the reparameterization of the

Arrhenius equation also improves the elliptical approximation

of the condence region. For the traditional form of the Arrhe-

nius equation, the elliptical approximation of the condence

region is very inadequate and leads to the conclusion that pa-

rameter k

T

ref

is not signicant (the condence interval crosses

the zero), as shown in Fig. 5. It can also be seen in Fig. 5 that

the likelihood condence region is narrow and curved, char-

acterizing the poor approximation of the elliptical condence

region. Similar results are obtained when a low reference tem-

perature is used, as shown in Fig. 6.

When the reparameterized Arrhenius equation is used with

the adequate reference temperature, the elliptical approxima-

tion is improved very signicantly and becomes very close

to the likelihood condence region. This can be observed in

Figs. 7 and 8, where the reference temperatures are equal to

620 and 628.45 K. In both gures, the elliptical approximation

of the condence region is very close to the likelihood con-

dence region, showing that the statistical characterization of

the parameter estimates is much easier after reparameterization.

3.5 3.6 3.7 3.8 3.9 4.0

k

Tref

[10

3

min

-1

]

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 7. Elliptical and likelihood condence regions of parameters k

T

ref

and

E with a reference temperature of 620 K in Example 1.

6.5 6.6 6.7 6.8 6.9 7.0 7.1

k

Tref

[10

-3

min

-1

]

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 8. Elliptical and likelihood condence regions of parameters k

T

ref

and

E with the optimum reference temperature of 628.45 K in Example 1.

Fig. 8 shows, however, that the axes of the ellipses are parallel

to the parameter axes, due to removal of parameter correlation.

If Eq. (4b) is for reparameterization, the rst order kinetic

model can be written as

y

i

=exp

_

t

i

exp

_

A

E

R

_

1

T

i

1

T

ref

___

. (32)

As expected, the model performance is not affected by the

reparameterization. Similarly, the parameter correlation and the

relative error of parameter E respond equally to perturbations

of T

ref

. However, the behavior of the relative error of parame-

ter A presents some different aspects, as shown in Fig. 9. The

relative error of parameter A presents a minimum at a T

ref

value that is similar (although, not the same) to the T

ref

value

that leads to uncorrelated parameters. As T

ref

increases, the

relative error also increases and goes to innity. An additional

increase of T

ref

causes the asymptotic decrease of the relative

error. This means that, although the different reparameteriza-

tion forms lead to similar reference temperatures when one is

interested in nullifying the parameter correlations, the perfor-

mances may be different when one is also interested in min-

imizing the relative error content of the pre-exponential term.

By comparing Figs. 4 and 9, one may conclude that inclusion of

k

T

ref

into the exponential term may be benecial for improving

2758 M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764

400 500 600 700 800 900 1000 1100 1200 1300

T

ref

[K]

0.0

3.0

6.0

9.0

12.0

15.0

R

e

l

a

t

i

v

e

E

r

r

o

r

[

%

]

Fig. 9. Relative error behavior of parameters A (line) and E (dashed line) as

functions of the reference temperature in Example 1.

the performance of numerical procedures but may be deleteri-

ous for nal statistical interpretation of parameter estimates.

The relative error of parameter A (Eq. (A.6)) is a function

of the reference temperature and, as shown in the Appendix,

presents three critical points; that is, three points where the

derivatives of the relative error with respect to T

ref

are null,

which are

T

ref

=

[E/ ln(k

0

)R]

N

i=1

[y

i

ln(y

i

)]

2

T

i

N

i=1

[y

i

ln(y

i

)]

2

[E/ ln(k

0

)R]

N

i=1

[y

i

ln(y

i

)]

2

T

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

i

,

(33a)

T

ref

=

E

ln(k

0

)R

, (33b)

T

ref

=, (33c)

where the value of ln(k

0

) can be computed with the help of

Eq. (5b) and the values of the parameters A and E are valid for

one specic reference temperature.

Eq. (33a) denes the condition of minimum relative error

(T

ref

= 627.13 K), which leads to parameter correlation of

0.14. In this case, the point where the relative error attains the

minimum is slightly smaller than the value that leads to uncor-

related parameters (T

ref

=628.45 K). Eq. (33b) represents the

point where parameter A becomes equal to zero, causing the

relative error to become innite. Eq. (33c) is the result obtained

when the effect of the reference temperature is eliminated. The

relative error of parameter A decreases asymptotically as the

reference temperature goes to innity, where the relative error

of parameter A becomes equal to 3.81% and the parameter cor-

relation becomes equal to 0.999881, the same values found for

the rst reparameterization form.

When T

ref

is equal to innity for the rst analyzed param-

eterization, the relative error of parameter k

T

ref

is equal to

148.4%, which is much larger than the relative error of param-

eter A for this second form. Besides, Fig. 5 shows that the el-

liptic approximation of the condence region is inadequate in

the rst case. When the second reparameterization form of the

37 38 39 40 41

A

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 10. Elliptical and likelihood condence regions of parameters A and E

with an innite reference temperature in Example 1.

-31.5 -31.0 -30.5 -30.0 -29.5 -29.0 -28.5

A

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 11. Elliptical and likelihood condence regions of parameters A and E

with a reference temperature of 400 K in Example 1.

Arrhenius equation is used (Eq. (4b)), the elliptic condence

region becomes very close to the likelihood condence region,

as shown in Fig. 10. The same behavior is observed in Fig. 11

for a low reference temperature. These results seem to indicate

that inclusion of k

T

ref

into the exponential term may be bene-

cial for improving the performance of numerical procedures

and for nal statistical interpretation of parameter estimates si-

multaneously, contradicting expectations raised from Fig. 9.

As observed by Watts (1994) and in the rst part of this

example, the denition of a reference temperature improves

the reliability of the elliptical approximation of the condence

regions. When Eq. (4b) is used, even without denition of a

reference temperature (the reference temperature is equal to in-

nity), the elliptical approximation of the condence regions

becomes very similar to the likelihood condence regions. Un-

fortunately, the high correlation between the parameters is still

present and can only be eliminated after the proper denition

of the reference temperature, as shown in Fig. 12 and discussed

here for the rst time.

4.2. Example 2numerical solution

In order to illustrate the case where an analytical solution

for the optimum reference temperature is not available, a

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2759

-5.04 -5.02 -5.00 -4.98 -4.96 -4.94

A

215

220

225

230

235

240

245

E

[

k

J

/

m

o

l

]

Fig. 12. Elliptical and likelihood condence regions of parameters A and E

with the optimum reference temperature of 628.45 K in Example 1.

temperature programmed experiment is considered. Temper-

ature programmed experiments are widely used for catalysts

characterization (Bhering et al., 2002), study of transient kinet-

ics (Kanervo et al., 2006) and for characterization of polymeric

materials (Hedrick and Chuang, 1998). The proper mathemat-

ical interpretation of these experiments can encourage the de-

velopment of new applications and improve the understanding

of the kinetic mechanisms of the studied phenomena.

For a temperature programmed reduction (TPR), the cata-

lyst (generally, a metal oxide supported onto an inert support)

is exposed to a reducible atmosphere (like a mixture of 5% H

2

in N

2

). As the temperature increases, the metal oxide is con-

verted into the metal state, which is believed to be active for

a particular reaction. This procedure is used for catalyst acti-

vation. Assuming the perfect control of the temperature, the

model equations that describe this type of experiments can be

written as

r =k

T

ref

exp

_

E

R

_

1

T

0

+t

1

T

ref

__

C

S

C

H

2

, (34)

dC

S

dt

=r, (35)

C

in

H

2

C

H

2

(V/q)r =0, (36)

where Eq. (4a) was used as a reparameterization form of the

Arrhenius equation, r is the reaction rate, C

S

is the concentra-

tion of reducible catalyst specie, C

H

2

is the hydrogen concen-

tration in the gas phase and C

in

H

2

is the hydrogen concentration

in the feed. V is the catalyst volume, q is the volumetric ow

rate, T

0

is the initial temperature and is the heating rate. The

model equation for the gas phase (Eq. (36)) assumes quasi-

steady state, since the dynamics of the gas phase is negligible

when compared to the dynamics of the solid phase transforma-

tions. The independent measured variables are the time t and

the temperature T, assumed to be precisely measured. The hy-

drogen concentration at the reactor outlet C

H

2

is the dependent

variable, whose error measurement is assumed to be constant.

The experimental data used here were generated from the

model equations described in Eqs. (34)(36). Parameters k

T

ref

and E were set equal to 10 m

3

/mol/s and 100 kJ/mol, with T

ref

400 450 500 550 600 650 700 750 800

T [K]

0.06

0.07

0.08

0.09

0.10

C

H

2

[

1

0

-

3

m

o

l

/

m

3

]

Fig. 13. Simulated experimental data (points) and obtained model predictions

(line) in Example 2.

400 450 500 550 600 650 700 750 800 850 900

T

ref

[K]

-1.00

-0.75

-0.50

-0.25

0.00

0.25

0.50

0.75

1.00

C

o

r

r

e

l

a

t

i

o

n

Fig. 14. Correlation behavior as a function of the reference temperature in

Example 2.

equal to 573.15 K. was equal to 0.167 K/s (10 K/min), T

0

was equal to 373.15 K, V/q was equal to 1 s and C

in

H

2

equal

to 10

4

mol/m

3

. Random errors with normal distribution and

standard deviation equal to 10

6

mol/m

3

were added to the

simulated hydrogen concentration values in order to simulate

the experimental deviation. These values are in accordance with

published material (Bhering et al., 2002).

Model tting consisted in estimating the parameters k

T

ref

and E that minimize the least squares function of the hydro-

gen concentrations measured along the time. The simulated ex-

perimental data and the obtained tted model are presented in

Fig. 13. The initial value of T

ref

was the same one used for

data generation (T

ref 0

= 573.15 K). With this reference tem-

perature, the estimated values of parameters k

T

ref

and E were

equal to 9.55 m

3

/mol/s and 9.66 kJ/mol, while the parameter

correlation was equal to 0.773 and the relative errors of pa-

rameters k

T

ref

and E were equal to 1.25% and 0.787%. Then,

the procedure presented in Fig. 1 was used both to determine

the optimum reference temperature and to observe how the pa-

rameter correlation and parameter relative errors were affected

by T

ref

.

Figs. 14 and 15 show the parameter correlation and the rel-

ative error of model parameters as functions of the reference

2760 M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764

400 500 600 700 800 900

T

ref

[K]

0.0

3.0

6.0

9.0

12.0

15.0

R

e

l

a

t

i

v

e

E

r

r

o

r

[

%

]

Fig. 15. Relative error behavior of parameters k

T

ref

(line) and E (dashed line)

as functions of the reference temperature in Example 2.

0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7

k

Tref

[10

+10

m

3

/mol/s]

97

98

99

100

101

102

E

[

k

J

/

m

o

l

]

Fig. 16. Elliptical and likelihood condence regions of parameters k

T

ref

and

E with an innite reference temperature (traditional Arrhenius equation) in

Example 2.

temperature. In both cases, obtained results are similar to the

ones obtained in Example 1. The parameter correlation is close

to 1.0 for small values of T

ref

, increasing asymptotically to

+1.0 as T

ref

increases. Uncorrelated parameters can be clearly

obtained for an intermediate value of T

ref

. The relative error

of parameter E is the same for all T

ref

values, while param-

eter k

T

ref

presents a minimum amount of error for the same

T

ref

value where the parameter correlation becomes null. The

optimum reference temperature for this problem is equal to

608.88 K, where the parameter correlation is null, the relative

error of parameter k

T

ref

is equal to 1.56% and the relative error

of parameter E is equal to 1.55%. If the traditional form of the

Arrhenius equation is used, obtained parameter correlation is

equal to 0.9987, with a relative error of parameter k

T

ref

equal

to 30.5%.

The condence regions presented in Figs. 16 and 17 clearly

show the effect of the adequate determination of the reference

temperature. Although in this example the likelihood and the

elliptic condence regions are similar in all analyzed cases,

when the optimum reference temperature is used (Fig. 17)

the agreement is higher than when the traditional form of the

Arrhenius equations is used (Fig. 16).

31.5 32.0 32.5 33.0 33.5

k

Tref

[m

3

/mol/s]

97

98

99

100

101

102

E

[

k

J

/

m

o

l

]

Fig. 17. Elliptical and likelihood condence regions of parameters k

T

ref

and

E with the optimum reference temperature of 608.88 K in Example 2.

400 500 600 700 800 900

T

ref

[K]

0.0

3.0

6.0

9.0

12.0

15.0

R

e

l

a

t

i

v

e

E

r

r

o

r

[

%

]

Fig. 18. Relative error behavior of parameters A (line) and E (dashed line)

as functions of the reference temperature in Example 2.

When Eq. (4b) is used for the reparameterization of the Ar-

rhenius equation, Eq. (34) can be rewritten as

r =exp

_

A

E

R

_

1

T

0

+t

1

T

ref

__

C

S

C

H

2

. (37)

As in the rst example, the change of the reparameteriza-

tion form affects neither the parameter correlation nor the rela-

tive error of parameter E, but the relative error of parameter A

(Fig. 18) presents a more complex behavior.

Fig. 18 shows the asymptotic behavior of the relative error of

parameter A at very low and very high reference temperatures

and the singular value when A is equal to 0 (T

ref

=517.29 K).

When T

ref

is equal to 618.00 K, the relative error of parameter

A attains the minimum value of 0.430% and the parameter cor-

relation becomes equal to 0.277. Uncorrelated parameters are

obtained when the reference temperature is equal to 608.88 K.

At this point, the relative error of parameter A is equal 0.448%.

The relative error of parameter A when T

ref

is innite is equal

to 1.31%.

Fig. 19 shows the elliptical and the likelihood condence re-

gions for an innite T

ref

value. The good agreement between

the condence regions, in accordance with the result obtained

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2761

22.7 22.8 22.9 23.0 23.1 23.2 23.3 23.4 23.5 23.6

A

97

98

99

100

101

102

E

[

k

J

/

m

o

l

]

Fig. 19. Elliptical and likelihood condence regions of parameters A and E

with an innite reference temperature in Example 2.

3.45 3.46 3.47 3.48 3.49 3.50 3.51

A

97

98

99

100

101

102

E

[

k

J

/

m

o

l

]

Fig. 20. Elliptical and likelihood condence regions of parameters A and E

with the optimum reference temperature of 608.88 K in Example 2.

in Example 1 (Fig. 10), supports the conclusion that the use of

Eq. (4b) can improve the reliability of the elliptical approxi-

mation for the condence regions, even when innite reference

temperatures are used. Despite that, very high parameter cor-

relation can still be present if the reference temperature is not

selected appropriately. Using the optimum reference tempera-

ture of 608.88 K, the parameter correlation becomes null, as

shown in Fig. 20.

5. Conclusions

The reparameterization of the Arrhenius equation through

denition of a reference temperature allows for minimization

of parameter correlation and makes parameter estimation and

interpretation much easier. As shown in this work both ana-

lytically and numerically, the proper choice of the reference

temperature allows for estimation of uncorrelated parameters

with minimum relative error. For dynamic models where an

analytical solution is not available, a closed analytical solution

cannot be derived and a numerical procedure can be used to

determine the optimum reference value. The numerical proce-

dure comprises two steps. In the rst one, parameter estimates

are obtained after denition of an initial guess of the reference

value. In the second step, the reference temperature is updated

in order to make the parameter correlation equal to zero. The

procedure can be repeated iteratively to lead to uncorrelated

parameters with minimum error content.

Acknowledgment

The authors thank CNPqConselho Nacional de Desen-

volvimento Cientco e Tecnolgiafor providing scholar-

ships and for supporting this work.

Appendix

The covariance matrix of parameter estimates V

is dened

in Eq. (6). If the covariance matrix of experimental deviation is

diagonal (errors are independent) and the variance is the same

in all observations (diagonal elements are equal), the covariance

matrix of parameter estimates can be written as

V

=s

2

(B

T

B)

1

. (A.1)

For single response models containing only one kinetic con-

stant, as described in Examples 1 and 2 of this manuscript, the

sensitivity matrix of model responses with respect to the pa-

rameters can be written as

B =

jy

1

j

1

jy

1

j

2

.

.

.

.

.

.

jy

NE

j

1

jy

NE

j

2

, (A.2)

where

1

stands for the parameters k

T

ref

or A and

2

stands for

the parameters E or B, depending on the considered reparame-

terization form. The covariance matrix of parameter estimates

can be written as

V

=s

2

NE

i=1

_

jy

i

j

1

_

2

NE

i=1

_

jy

i

j

2

__

jy

i

j

1

_

NE

i=1

_

jy

i

j

1

__

jy

i

j

2

_

NE

i=1

_

jy

i

j

2

_

2

1

.

(A.3)

After inversion of the term between brackets, one gets:

V

=

s

2

det(B

T

B)

NE

i=1

_

jy

i

j

2

_

2

NE

i=1

_

jy

i

j

2

__

jy

i

j

1

_

NE

i=1

_

jy

i

j

1

__

jy

i

j

2

_

NE

i=1

_

jy

i

j

1

_

2

,

(A.4)

where det(B

T

B) is the determinant dened as

det(B

T

B) =

NE

i=1

_

jy

i

j

1

_

2

NE

i=1

_

jy

i

j

2

_

2

_

NE

i=1

_

jy

i

j

1

_

NE

i=1

_

jy

i

j

2

_

_

2

. (A.5)

Therefore, one can use Eqs. (A.3) or (A.4) to obtain the

covariance matrix of parameter estimates. For simple models, as

2762 M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764

used in Example 1, the derivatives can be obtained analytically.

For more complex models, as the one presented in Example

2, the derivatives must be calculated numerically or through

integration of the sensitivity equations (Bard, 1974).

The elements of the covariance matrix of parameter estimates

give the variances of model parameters (v

11

and v

22

). Assuming

a normal distribution for the parameters estimates, the relative

errors of each parameter can be dened as (Himmelblau, 1970):

e

1

=

t

(1+)/2

NENP

v

11

=

t

(1+)/2

NENP

_

s

2

det(B

T

B)

NE

i=1

_

jy

i

j

2

_

2

,

(A.6)

e

2

=

t

(1+)/2

NENP

v

22

=

t

(1+)/2

NENP

_

s

2

det(B

T

B)

NE

i=1

_

jy

i

j

1

_

2

,

(A.7)

where t

(1+)/2

NENP

is the t-Student distribution value with a con-

dence level equal to (always equal to 0.95 in this work) and

with NE NP degrees of freedom.

In Example 1, it is possible to develop an analytical solu-

tion for the optimum value of T

ref

that leads to uncorrelated

model parameters, as shown in Section 3 and described in

Eq. (24). This optimum value is the same for all the reparam-

eterization forms of the Arrhenius equation, because the opti-

mum value does not depend on the model parameters, but only

on the model outputs. However, when one considers the rel-

ative errors of parameter estimates, distinct solutions can be

obtained, depending on the particular form of the reparameter-

ization. Initially, the reparameterization of Arrhenius equation

(dened in Eq. (4a)) is considered:

k

i

=k

T

ref

exp

_

E

R

_

1

T

i

1

T

ref

__

. (A.8)

In Example 1:

y

i

=exp(t

i

k

i

). (A.9)

The derivatives of the model response with respect to the

model parameters are

jy

i

jk

T

ref

=

y

i

ln(y

i

)

k

T

ref

, (A.10)

jy

i

jE

=

_

1

T

i

1

T

ref

_

y

i

ln(y

i

)

R

(A.11)

so that the determinant dened in Eq. (A.5) becomes

det(B

T

B) =

N

i=1

[y

i

ln(y

i

)]

2

k

2

T

ref

N

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

R

2

2

_

N

i=1

_

1

T

i

1

T

ref

_

[y

i

ln(y

i

)]

2

Rk

T

ref

_

2

. (A.12)

Expanding and simplifying Eq. (A.12), one nds the follow-

ing equation:

det(B

T

B) =

1

(Rk

T

ref

)

2

i=1

[y

i

ln(y

i

)]

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

2

i

_

N

i=1

[y

i

ln(y

i

)]

2

T

i

_

2

, (A.13)

where the term inside the braces does not depend on the ref-

erence temperature. Inserting Eqs. (A.11) and (A.13) into Eq.

(A.6), one obtains:

e

k

T

ref

=C

_

NE

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

, (A.14)

where

C =

s t

(1+)/2

NENP

N

i=1

[y

i

ln(y

i

)]

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

i

_

2

(A.15)

is constant with respect to the reference temperature. The

reference temperature that leads to the minimum relative error

of parameter k

T

ref

is the value that minimizes the square of

the relative error of parameter k

T

ref

(that is, the square of Eq.

(A.14)):

e

2

kT

ref

=C

2

NE

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

. (A.16)

Differentiation of Eq. (A.16) with respect to T

ref

gives

je

2

kT

ref

jT

ref

=2C

2

NE

i=1

_

1

T

i

1

T

ref

_

[y

i

ln(y

i

)]

2

T

2

ref

. (A.17)

In order to obtain the value of T

ref

that minimizes the relative

error of parameter k

T

ref

, the following equation must be solved:

NE

i=1

_

1

T

i

1

T

ref

_

[y

i

ln(y

i

)]

2

T

2

ref

=0 (A.18)

leading to:

T

ref

=

NE

i=1

[y

i

ln(y

i

)]

2

NE

i=1

[y

i

ln(y

i

)]

2

T

i

(A.19)

One can observe that Eq. (A.19) is equal to Eq. (31), which

means that the reference temperature that eliminates the param-

eter correlation also leads to minimum relative error content of

k

T

ref

.

M. Schwaab, J.C. Pinto / Chemical Engineering Science 62 (2007) 27502764 2763

The relative error of parameter E can be derived with the

help of Eqs. (A.7), (A.10) and (A.13):

e

E

=

s t

(1+)/2

NENP

E/R

NE

i=1

[y

i

ln(y

i

)]

2

N

i=1

[y

i

ln(y

i

)]

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

i

_

2

. (A.20)

One should observe that the relative error of the parameter E

does not depend on the T

ref

value, as shown in the Examples.

Considering now the second reparameterization form (Eq.

(4b))

k

i

=exp

_

A

E

R

_

1

T

i

1

T

ref

__

. (A.21)

In Example 1, the derivatives of the model response with

respect to the parameters are

jy

i

jA

=y

i

ln(y

i

), (A.22)

jy

i

jE

=

_

1

T

i

1

T

ref

_

y

i

ln(y

i

)

R

(A.23)

so that the determinant dened in Eq. (A.5) becomes

det(B

T

B) =

N

i=1

[y

i

ln(y

i

)]

2

N

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

R

2

_

N

i=1

_

1

T

i

1

T

ref

_

[y

i

ln(y

i

)]

2

R

_

2

. (A.24)

Expanding and simplifying Eq. (A.24), one nds the follow-

ing equation:

det(B

T

B) =

1

R

2

i=1

[y

i

ln(y

i

)]

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

2

i

_

N

i=1

[y

i

ln(y

i

)]

2

T

i

_

2

(A.25)

that does not depend on the reference temperature.

Inserting Eqs. (A.11) and (A.25) into Eq. (A.6) one obtains:

e

A

=

C

A

_

NE

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

, (A.26)

where C is the constant dened in Eq. (A.15). The minimum of

the relative error of parameter A is found through minimization

of the square of Eq. (A.26):

e

2

kT

ref

=

C

A

2

2

NE

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

. (A.27)

One should observe that parameter A is an implicit func-

tion of the reference temperature (Eq. (5b)) and should be

written as

A =ln(k

0

)

E

RT

ref

, (A.28)

where k

0

is the specic reaction rate at innite temperature.

Inserting Eq. (A.28) into Eq. (A.27) and differentiating with

respect to T

ref

gives

je

2

A

jT

ref

=2C

2

A

NE

i=1

_

1

T

i

1

T

ref

_

[y

i

ln(y

i

)]

2

T

2

ref

E

R

NE

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

T

2

ref

A

3

. (A.29)

In order to obtain the value of T

ref

that minimizes the relative

error of parameter A, the numerator of Eq. (A.29) must be equal

to zero. Therefore,

A

NE

i=1

_

1

T

i

1

T

ref

_

[y

i

ln(y

i

)]

2

T

2

ref

E

R

NE

i=1

_

1

T

i

1

T

ref

_

2

[y

i

ln(y

i

)]

2

T

2

ref

=0. (A.30)

Eq. (A.30) has three solutions, as discussed previously:

T

ref

=

[E/ ln(k

0

)R]

N

i=1

[y

i

ln(y

i

)]

2

T

i

N

i=1

[y

i

ln(y

i

)]

2

[E/ ln(k

0

)R]

N

i=1

[y

i

ln(y

i

)]

2

T

2

i

N

i=1

[y

i

ln(y

i

)]

2

T

i

,

(A.31a)

T

ref

=

E

ln(k

0

)R

, (A.31b)

T

ref

=. (A.31c)

The minimum relative error of parameter A is obtained with

the rst solution, given by Eq. (A.31a). However, this solution