Strojniški Vestnik - Journal of Mechanical Engineering Volume (Year) No, StartPage-EndPage

Diunggah oleh

Samad NadJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Strojniški Vestnik - Journal of Mechanical Engineering Volume (Year) No, StartPage-EndPage

Diunggah oleh

Samad NadHak Cipta:

Format Tersedia

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage UDC xxx.yyy.

Paper received: 00.00.200x Paper accepted: 00.00.200x

Influence of input parameters on characteristics of EDM process

Mohammadreza Shabgard1,* - Mirsadegh Seyedzavvar1 - Samad Nadimi Bavil Oliaei2 1 Department of Mechanical Engineering, University of Tabriz, Tabriz, Iran 2 Department of Mechanical Engineering, Middle East Technical University, Ankara, Turkey This paper presents the results of experimental studies carried out to conduct a comprehensive investigation on the influence of Electrical Discharge Machining (EDM) input parameters on characteristics of EDM process. The studied process characteristics included machining features, embracing material removal rate, tool wear ratio, and arithmetical mean roughness, as well surface integrity characteristics comprising of the thickness of white layer and the depth of heat affected zone of AISI H13 tool steel as workpiece. The experiments performed under the designed full factorial procedure, and the considered EDM input parameters included pulse on-time and pulse current. The results of this study could be utilized in the selection of optimum process parameters to achieve the desired EDM efficiency, surface roughness, and surface integrity when machining AISI H13 tool steel. 2011 Journal of Mechanical Engineering. All rights reserved. Keywords: electrical discharge machining (EDM), material removal rate (MRR), tool wear ratio (TWR), surface roughness (Ra), white layer thickness, depth of heat affected zone 0 INTODUCTION Considering the challenges brought on by advanced technology, the Electrical Discharge Machining (EDM) process is one of the best alternatives for machining an ever increasing number of high-strength, non-corrosion, and wear resistant materials [1 and 2]. AISI H13 tool steel is considered a significant one of these materials that has a widespread application in mold industries [3]. Electrical discharge machining utilizes rapid, repetitive spark discharges from a pulsating direct-current power supply between the workpiece and the tool submerged into a dielectric liquid [4]. The thermal energy of the sparks leads to intense heat conditions on the workpiece causing melting and vaporizing of workpiece material. Due to the high temperature of the sparks, not only work material is melted and vaporized, but the electrode material is also melted and vaporized, which is known as tool wear. The tool wear process is quite similar to the material removal mechanism of the workpiece as the tool and the workpiece are considered as a set of electrodes in EDM process. Due to this wear, tool loses its dimensions resulting in inaccuracy of the cavities formed on the workpiece. Consequently, during the EDM process, the main machining output parameters are the material removal rate (MRR), tool wear ratio (TWR) and surface roughness (Ra) of the workpiece. It is desirable to obtain the maximum MRR with minimum TWR and surface roughness [5]. Furthermore, at the end of each discharge, depending on the plasma flushing efficiency (%PFE) or the ability of plasma channel in removing molten material from the molten material crater, collapsing of the plasma channel causes very violent suction and severe bulk boiling of some of the molten material and removing them from the molten crater [6]. The material remaining in the crater re-solidifies, which is called the white layer or recast layer, and develops a residual stress that often causes micro cracks. An annealed Heat Affected Zone (HAZ) lay directly below the recast layer. The micro cracks created in the white layer could penetrate into the HAZ. Additionally, this layer is softer than the underlying base material. This annealed zone could weaken prematurely and cause the material to develop stress fractures that could lead to anything from a minor malfunction to a catastrophic failure. Since the quality of an ED machined surface is becoming more and more important to satisfy the increasing demands of sophisticated component performance, longevity and reliability [7 and 8], the optimum utilization of the EDM process requires the selection of an appropriate set of machining parameters that would result in the minimum thickness of the recast layer and depth of heat affected zone [9]. This paper aims to fill the gap in the existing literature with respect to the processing of AISI H13 tool steel with EDM. In particular, 1

*Corr. Author's Address: Department of Mechanical Engineering, Tabriz University, Tabriz, Iran, mrshabgard@tabrizu.ac.ir

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

EDM machining experiments were conducted on AISI H13 samples having a hardness of 52.7HRC using copper electrode to investigate the correlations between the EDM parameters (pulse on-time and current) and the EDM characteristics of such a workpiece. The output factors investigated were the material removal rate, tool wear ratio, surface roughness, as well as the thickness of white layer and depth of heat affected zone of EDMed workpiece. This experimental study results in the selection of optimum process parameters to achieve the desired EDM efficiency, surface roughness, and

surface integrity when machining such workpiece material. 1 EXPERIMENTAL SETUP AND PROCEDURE

The workpiece material used in this study was AISI H13 tool steel. Prior to EDM processing, the workpiece was cut in a cylindrical shape with a length of 20mm and a diameter of 20mm. The main mechanical and physical properties of such a workpiece material at different temperatures are given in Table 1.

Table 1. Mechanical and physical properties of AISI H13 [10]. Temperature Density Specific heat Electrical resistivity Modulus of elasticity [C] [kg/dm3] [J/(kg .K)] [Ohm.mm2/m] [N/mm2] 20C 7.80 460 0.52 215103 500C 7.64 550 0.86 176103 600C 7.60 590 0.96 165103 Liquidus temperature 1454C Solidus temperature Table 2. Physical properties of copper electrode [11]. Physical properties Copper Thermal conductivity [W/m.K] 380.7 Melting point [C] 1083 Boiling temperature [C] 2595 Specific heat [cal/g.C] 0.092 Specific gravity at 20C [g/cm3] 8.9 Coefficient of thermal expansion 17 [10-6 (1/C)] The tool material was forged commercial pure copper with the main properties given in Table (2). The experiments were performed on a die sinking EDM machine (CHARMILLES ROBO-FORM200) which operates with an isopulse generator. Machining tests were carried out at five pulse current settings, as well as four pulse on-time settings. As a result, 20 experiments could be designed. Each machining test was performed for 15 minutes. Table 3 presents the experimental test conditions. A digital balance (CP2245-Surtorius) with a resolution of 0.1mg was used for weighing the workpieces before and after the machining process. The tool wear ratio is defined as the volume of material removed from the tool (VE) divided by the volume of material removed from 2

Thermal conductivity [W/m.K] 24.30 27.70 27.50 1315C

the workpiece (VW). Eqs. (1) and (2) show the calculations used for assessing the values of MRR and TWR. MRR=(M1-M2)/(w.T), (1) TWR=(VE/VW).100% (2) where M1 and M2 are the weight of workpiece before and after machining [g], respectively. w is the density of workpiece [g/mm3], and T is the machining time [min]. Table 3. Experimental test conditions. Iso-pulse Generator type (ROBOFORM 200) Dielectric fluid Oil Flux ELF2 Flushing type Normal submerged Power supply 200 voltage [V] Reference 70 voltage [V] Pulse current [A] 8; 12; 16; 20; 24 Polarity Positive Pulse on-time 12.8; 25; 50; 100 [s] Pulse interval 6.4 [s] Tool material Commercial pure copper Cylindrical Tool shape (18.3mm and L=20mm)

M.R. Shabgard, M. Seyedzavvar, S. Nadimi Bavil Oliaei

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

According to Lee and Tai [12], the amount of white layer thickness (WT) has been measured by measuring this layers thickness at 30 different points by utilizing VEGA\\TESCAN scanning electron microscopy (SEM) and accounting for their average (Figs. 1 to 3). So the machined specimens were sectioned transversely by a wire electrical discharge machine and prepared under a standard procedure for metallographic observation. Etching was performed by immersing the specimens in 5% Nital reagent. On the other hand, according to Hascalyk and Caydas [13], since there are not much

significant differences between HAZ and parent material in the microscopic images that could be identified by, measuring of micro-hardness is a reasonable way to obtain the depth of heat affected zone (HD). With this in mind, microhardness from cross-section of machined specimens was measured to determine the depth of heat affected zone. The micro-hardness of specimens was measured by the OLyMPUS LM700 micro-harness tester. The values of WT and HD are represented in Table (4).

Table 4. The average values for the white layer thickness (WT) and depth of heat affected zone (HD) at different machining settings Average Average Average Average Settings Settings WT [m] HD [m] WT [m] HD [m] 8 A, 12.8 s 7.3 12.0 16 A, 50 s 17.75 23.5 8 A, 25 s 8.6 15.7 16 A, 100 s 22.5 32.7 8 A, 50 s 19.3 24 20 A, 12.8 s 7 12 8 A, 100 s 23.4 34.4 20 A, 25 s 10 16.2 12 A, 12.8 s 7.5 12.5 20 A, 50 s 16 21.5 12 A, 25 s 11 16.5 20 A, 100 s 20 30.2 12 A, 50 s 18.8 23 24 A, 12.8 s 6.5 11 12 A, 100 s 22.3 34.8 24 A, 25 s 8.3 15 16 A, 12.8 s 7.7 13 24 A, 50 s 14.2 21 16 A, 25 s 10.7 17.8 24 A, 100 s 20.5 29.6 2 RESULTS AND DISCUSSION 2.1 Effect of Pulse on-Time and Pulse Current on Machining Characteristics The correlation between machining characteristics and pulse on-time in machining of AISI H13 tool steel using copper electrode are shown in Figs. 4 to 6. According to these figures, an increase in the pulse on-time causes an increase in the MRR and Ra, but a decrease in the TWR. By the increase in pulse on-time, the discharge energy of the plasma channel and the period of transferring of this energy into the electrodes increase. This phenomenon leads to the formation of a bigger molten material crater on the workpiece which results in a higher surface roughness. However, the dimension of plasma channel and the effect of thermal conductivity of electrodes in dispersing the thermal from the spark collision position increase by the increase in pulse on time. Consequently, by the dispersing more heat from the spark stricken position and increasing the amount of heat transferred from the plasma channel to the electrodes, the plasma channels efficiency in removing molten material from the molten crater at the end of each pulse decreases, while the dimensions of the molten crater on the electrodes increases. This effect is more pronounced for copper electrode, since its thermal conductivity is much higher than the workpiece's. As a result, the tool wear ratio decreases by increase in pulse on-time. Figures 7 to 9 show that MRR, TWR, and Ra increase with augments of the pulse current. Such results were expected as it is obvious that a higher current causes a stronger spark which results in more eroded material for both electrodes. At a low current, a small quantity of heat is generated and a substantial portion of it is absorbed by the surroundings, as a result, the amount of utilized energy in melting and vaporizing the electrodes is not so intense. But by the increase in pulse current and with a constant amount of pulse on-time, a stronger spark with 3

Influence of input parameters on characteristics of EDM process

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

higher thermal energy is produced, and a substantial quantity of heat will be transferred into the electrodes. Furthermore, as the pulse current increases, discharge strikes the surface of the sample more intensely, and creates an impact force on the molten material in the crater and causes more molten material to be ejected out of the crater, so the surface roughness of the machined surface increases.

WT

from the experimental results (Figs. 10 and 11). The justification for this phenomenon is that the plasma flushing efficiency has a strict effect on the white layer thickness. With an increase in pulse on-time, plasma flushing efficiency decreases, as a result, the ability of plasma channel for ejecting the molten material from the molten puddle decreases. Subsequently, this remained molten material in the molten puddle re-solidifies and forms the white layer upon the machined surface. Furthermore, the increase of discharge duration increases the amount of the conducted heat into the workpiece during each discharge, and consequently, more underlying material is affected by the high temperature. Overly, this phenomenon causes the increase in the white layer thickness and heat affected zone.

Fig. 1 SEM micrograph showing the white layer of EDMed workpiece (I = 8 A and Ti = 25 s)

WT

WT Fig. 3 SEM micrograph showing the white layer of EDMed workpiece (I = 24 A and Ti = 100 s)

Fig. 2 SEM micrograph showing the white layer of EDMed workpiece (I = 24 A and Ti = 50 s)

2.2 Effect of Pulse on-Time and Pulse Current on Surface Integrity The increase in the thickness of white layer and depth of heat affected zone by the increase in pulse on-time can be obviously seen 4

In other words, better explanation is that the amount of molten material which can be flushed away at the end of each discharge is dependent on the plasma flushing efficiency (%PFE). Clearly the %PFE is dependent on the discharge energy (W), energy gradient (dW/dt), geometrical dimensions of the gap and molten material crater, pressure of the gap (P), and gap pressure gradient (dP/dt). Depending on the amount of mentioned parameters, plasma flushing efficiency decreases as pulse on-time increases. The cause of this phenomenon could be justified by this reason that the increase in pulse on-time causes to decrease in the energy changing rate, as this causes a major increase in diameter while not

M.R. Shabgard, M. Seyedzavvar, S. Nadimi Bavil Oliaei

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

much increase in the average temperature of the plasma channel, which leads to decrease in the pressure of the gap and its changing rate. So, regarding to the mechanism of bulk boiling phenomena, the amount of molten material, which is ejected from the molten material crater at the end of discharged, decreases and as a result, the %PFE decreases.

the surface of workpiece. Since an increase in the penetrating depth of heat into the workpiece and plasma flushing efficiency counterbalance each other's effect, an increase in the pulse current has no significant effect on the depth of the heat affected zone.

MRR [mm3/min]

Ra [m]

pulse on-time [s] Fig. 6 Ra vs. pulse on-time pulse on-time [s] Fig. 4 MRR vs. pulse on-time MRR [mm3/min]

%TWR

pulse current [A] Fig. 7 MRR vs. pulse current pulse on-time [s] Fig. 5 TWR vs. pulse on-time From Figs. 12 and 13 it is clear that, increasing the pulse current has a very small effect on the white layer thickness and depth of heat affected zone. Although an increase in pulse current leads to the increase in the dimensions of the molten crater and the heat penetrating depth, the plasma flushing efficiency increases as pulse current increases. The increase in plasma flushing efficiency causes more molten material to be swept away from the molten crater, therefore thinner layer of re-deposited material appears on Furthermore, with an increase in the pulse current and with a constant amount of pulse ontime, causing sharp rise in average temperature of the plasma channel [14], the energy gradient increases which leads to increase in the pressure of gap. So, regarding about the mechanism of bulk boiling phenomenon, the amount of molten material, which is ejected from the molten puddle at the end of each discharge, increases and as a result, the %PFE increases (Ref. [15]) as the reports of Marafona et al. prove this matter [10].

Influence of input parameters on characteristics of EDM process

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

HD [m]

%TWR

pulse current [A] Fig. 8 TWR vs. pulse current

pulse on-time [s] Fig. 11 HD vs. pulse on-time

Ra [m]

pulse current [A] Fig. 9 Ra vs. pulse current

WT [m]

pulse current [A] Fig. 12 WT vs. pulse current

WT [m]

pulse on-time [s] Fig. 10 WT vs. pulse on-time

HD [m]

pulse current [A] Fig. 13 HD vs. pulse current

M.R. Shabgard, M. Seyedzavvar, S. Nadimi Bavil Oliaei

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

3 CONCLUSION Results from an experimental investigation on the effect of machining parameters on EDM process characteristics have been presented. The leading conclusions are as follows: 1. The increase in pulse on-time leads to the increase in the material removal rate, surface roughness, as well the white layer thickness and depth of heat affected zone. 2. The increase in pulse current leads to the sharp increase in the material removal rate and surface roughness. 3. The tool wear ratio decreases by the increase of pulse on-time, and increases by the increase in the pulse current. 4. Slight decrease could be observed in the white layer thickness by an increase in the pulse current. 5. By constant level of discharge energy, high pulse current and low pulse on-time leads to reduction in the white layer thickness and depth of heat affected zone on the surface of EDMed workpiece. 4 ACKNOWLEDGEMENTS The authors of this study are indebted to the Razi Metallurgical Laboratory, Metallurgical Laboratory of Sahand University of Technology, universal workshop of Training Center of Iran Tractor Manufacturing Company, and advance machining workshop of Manufacturing Engineering Department of University of Tabriz. Also, we would like to appreciate the help of authors Professors J. Khalil Allafy, T.B. Navid Chakharlu, as well Mr. A. Nejat Ebrahimi for their invaluable technical support. 6 REFERENCES [1] Abu Zeid, O.A. (1997). On the effect of electro-discharge machining parameters on the fatigue life of AISI D6 tool steel. J. Mater. Process. Technol., vol. 68, p. 27-32. [2] Merdan, M.A.E.R., Arnell, R.D. (1991). The surface integrity of a die steel after electro-

discharge machining, 2. residual stress distribution. Surf. Eng., vol. 7, p. 154-158. [3] Castro, G., Fernandez-Vicente, A. Cid, J. (2007). Influence of the nitriding time on the wear behavior of an AISI H13 steel during a crankshaft forging process. J. Wear., vol. 263, p. 1375-1385. [4] Abdullah, A., Shabgard, M.R. (2008). Effect of ultrasonic vibration of tool on electrical discharge machining of cemented tungsten carbide (WC-Co). Int. J. Adv. Manuf. Technol., vol. 38, p. 1137-1147. [5] Khan, A.A. (2008). Electrode wear and material removal rate during EDM of aluminum and mild steel using copper and brass electrodes. Int. J. Adv. Manuf. Technol., vol. 39, p. 482-487. [6] Dibitoto, D.D., Eubank, Ph.T., Patel, M.R., Barrufet, M.A. (1989). Theoretical models of the electrical discharge machining process, I. A simple cathode erosion model. J. Appl. Phys., vol. 66, no. 9, p.4095- 4103. [7] Mamalis, A.G., Vosniakos, G.C.,

Vaxevanidis, N.M. (1987). Macroscopic phenomena of electro-discharge machined steel surface: an experimental investigation. J. Mech. Work. Technol., vol. 15, p. 335-356. [8] Boujelbene, M., Bayraktar, E., Tebni, W., Ben Salem, S. (2009). Influence of machining parameters on the surface integrity in electrical discharge machining. Arch. Mater. Sci. Eng., vol. 37, p. 110-116. [9] Rebelo, J.C., Dias Morao, A., Kremer, D., Lebrun, J.L. (1998). Influence of EDM pulse

Influence of input parameters on characteristics of EDM process

Strojniki vestnik - Journal of Mechanical Engineering Volume(Year)No, StartPage-EndPage

energy on the surface integrity of martensitic steel. J. Mater. Process. Technol., vol. 84 p. 90-96. [10] Bhler edelstahl.at [11] Fischer, U., Heinzle, M., Nher, F., Paetzold, H., Gomeringer, R., Kilgus, R., Oesterle, S., Stephan, A. (2008). Tabellenbuch Metall. Verlag Europa-Lehrmittel, Nourney, Vollmer GmbH & Co. KG, 42781 Haan-Gruiten. [12] Lee, H.T. Tai, T.Y. (2003). Relationship between EDM parameters and surface crack formation. J. Mater. Process. Technol., vol. 142, p. 676-683. [13] Hascalyk, Experimental A. Caydas, study of U. wire (2004). electrical Edelstahl, http://www.bohler-

discharge machining of AISI D5 tool steel. J. Mater. Process. Technol., vol. 148, p. 362367. [14] Kansal, H.K., Singh, S., Kumar, P. (2008). Numerical simulation of powder mixed electric discharge machining (PMEDM) using finite element method, Mathematical and Computer Modeling. vol. 47 , p.12171237. [15] Shuvra Das, Mathias Klotz, F. Klocke, (2003). EDM simulation: finite elementbased calculation of deformation,

microstructure and residual stresses, Journal of Materials Processing Technology, vol. 142, p.434-451.

M.R. Shabgard, M. Seyedzavvar, S. Nadimi Bavil Oliaei

Anda mungkin juga menyukai

- American AccentDokumen40 halamanAmerican AccentTimir Naha67% (3)

- Reverse Engineering in Rapid PrototypeDokumen15 halamanReverse Engineering in Rapid PrototypeChaubey Ajay67% (3)

- Effect of Current On EDMDokumen58 halamanEffect of Current On EDMAli M. ElghawailBelum ada peringkat

- P394 WindActions PDFDokumen32 halamanP394 WindActions PDFzhiyiseowBelum ada peringkat

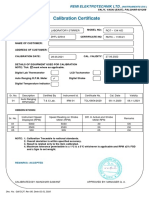

- Calibration CertificateDokumen1 halamanCalibration CertificateSales GoldClassBelum ada peringkat

- FIRE FIGHTING ROBOT (Mini Project)Dokumen21 halamanFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- 09 WA500-3 Shop ManualDokumen1.335 halaman09 WA500-3 Shop ManualCristhian Gutierrez Tamayo93% (14)

- Hydrodynamic Machining (HDM)Dokumen5 halamanHydrodynamic Machining (HDM)Anonymous V7NIJYd8Belum ada peringkat

- Electrical Discharge Machine (Edm) PDFDokumen65 halamanElectrical Discharge Machine (Edm) PDFsujayan2005100% (3)

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Dokumen14 halamanTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- Daraman vs. DENRDokumen2 halamanDaraman vs. DENRJeng GacalBelum ada peringkat

- 171 382 1 SM PDFDokumen8 halaman171 382 1 SM PDFsujayan2005Belum ada peringkat

- Metallurgical Alterations in The Surface of Steel Cavities Machined by EDMDokumen8 halamanMetallurgical Alterations in The Surface of Steel Cavities Machined by EDMDeak Ferenc-JozsefBelum ada peringkat

- A Study of Electrical Discharge Grinding Using A Rotary Disk ElectrodeDokumen9 halamanA Study of Electrical Discharge Grinding Using A Rotary Disk ElectrodeSarath ChandraBelum ada peringkat

- Effect of Process Parameters On The Surface Integrity of Micro-Holes of Ti6Al4V Obtained by Micro-EdmDokumen8 halamanEffect of Process Parameters On The Surface Integrity of Micro-Holes of Ti6Al4V Obtained by Micro-EdmTJPRC PublicationsBelum ada peringkat

- Investigation On Electro Discharge Machining of H13Dokumen10 halamanInvestigation On Electro Discharge Machining of H13Nguyễn Hữu PhấnBelum ada peringkat

- Parametric Optimization of Electrochemical Machining Using Signal-To-Noise (S/N) RatioDokumen8 halamanParametric Optimization of Electrochemical Machining Using Signal-To-Noise (S/N) RatioIJMERBelum ada peringkat

- AFM Surface Imaging of AISI D2 Tool Steel Machined by The EDM ProcessDokumen6 halamanAFM Surface Imaging of AISI D2 Tool Steel Machined by The EDM Processالسيد ابراهيم عبدالعزيز عبداللهBelum ada peringkat

- Ijmet: ©iaemeDokumen9 halamanIjmet: ©iaemeIAEME PublicationBelum ada peringkat

- Edm Exp 6,7,9Dokumen19 halamanEdm Exp 6,7,9Ali RazaBelum ada peringkat

- Materials Processing Technology: ElsevierDokumen7 halamanMaterials Processing Technology: ElsevierNguyễn Hữu PhấnBelum ada peringkat

- A Review On Recent Developments in Machining Methods Based On Electrical Discharge PhenomenaDokumen18 halamanA Review On Recent Developments in Machining Methods Based On Electrical Discharge PhenomenachristianBelum ada peringkat

- Edm3 PDFDokumen2 halamanEdm3 PDFAbhishek PandeyBelum ada peringkat

- Ijmet: ©iaemeDokumen8 halamanIjmet: ©iaemeIAEME PublicationBelum ada peringkat

- IMECS2009 pp1803-1808Dokumen6 halamanIMECS2009 pp1803-1808neerajBelum ada peringkat

- Lec5 - Machining Equipment - PRE 314 - NewDokumen38 halamanLec5 - Machining Equipment - PRE 314 - NewMahmoud EldesoukiBelum ada peringkat

- Electrochemical Grinding of Titanium-Containing MaterialsDokumen8 halamanElectrochemical Grinding of Titanium-Containing MaterialsAkhil CenaBelum ada peringkat

- IMECS2009 pp1803-1808Dokumen6 halamanIMECS2009 pp1803-1808Ratan KumarBelum ada peringkat

- HW 8 Non Traditional Machining Ch26Dokumen2 halamanHW 8 Non Traditional Machining Ch26BobBelum ada peringkat

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDokumen8 halamanStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelAngga Pamilu PutraBelum ada peringkat

- CNC Wire-Cut Parameter Optimized Determination of The Stair Shape WorkpieceDokumen6 halamanCNC Wire-Cut Parameter Optimized Determination of The Stair Shape Workpiecegargsumit107Belum ada peringkat

- Studying The Affect of Current On (MRR) and (EW) in Electrical Discharge Machining (EDM)Dokumen15 halamanStudying The Affect of Current On (MRR) and (EW) in Electrical Discharge Machining (EDM)Mostafa AdilBelum ada peringkat

- Optimization of Process Parameters in Die Sinking EDM - A REVIEWDokumen6 halamanOptimization of Process Parameters in Die Sinking EDM - A REVIEWIJSTEBelum ada peringkat

- International Journal of Engineering Research and Development (IJERD)Dokumen6 halamanInternational Journal of Engineering Research and Development (IJERD)IJERDBelum ada peringkat

- Comparative Performance of Wet and Near-Dry Edm Process For Machining of Oil Hardned Non Sinking Steel MaterialDokumen10 halamanComparative Performance of Wet and Near-Dry Edm Process For Machining of Oil Hardned Non Sinking Steel MaterialIAEME PublicationBelum ada peringkat

- Kung2009 Article MaterialRemovalRateAndElectrod PDFDokumen10 halamanKung2009 Article MaterialRemovalRateAndElectrod PDFAkasapu SaisreeharshaBelum ada peringkat

- Kerf WidthDokumen6 halamanKerf WidthlarryBelum ada peringkat

- 2 MankovaDokumen4 halaman2 MankovaBehailu FelekeBelum ada peringkat

- An Investigation To Achieve A Good Surface IntegriDokumen23 halamanAn Investigation To Achieve A Good Surface IntegriashadoitBelum ada peringkat

- Lec3 - Machining Equipment - PRE 314 - NewDokumen18 halamanLec3 - Machining Equipment - PRE 314 - NewMahmoud EldesoukiBelum ada peringkat

- A Brief Review of Die Sinking Electrical Discharging Machining Process Towards AutomationDokumen7 halamanA Brief Review of Die Sinking Electrical Discharging Machining Process Towards AutomationMayank Rajesh Kumar ShrivastavaBelum ada peringkat

- EdmDokumen29 halamanEdmGaurav SinghBelum ada peringkat

- Electrical Discharge Machining (Edm) : Process PrinciplesDokumen11 halamanElectrical Discharge Machining (Edm) : Process PrinciplesPrasad ChikkamBelum ada peringkat

- Materials 15 00513 v2Dokumen14 halamanMaterials 15 00513 v2Abraham GutierrezBelum ada peringkat

- Determination of Material Removal Rate in Electro Discharge Machining Through Copper ElectrodeDokumen7 halamanDetermination of Material Removal Rate in Electro Discharge Machining Through Copper ElectrodeIJRASETPublicationsBelum ada peringkat

- NTM Module 3Dokumen12 halamanNTM Module 3RishiJpBelum ada peringkat

- Investigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachDokumen6 halamanInvestigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachPujara ManishBelum ada peringkat

- Modeling and Analysis of The Effects of Machining Parameters On The Performance Characteristics in The Edm Process of Al O +tic Mixed CeramicDokumen11 halamanModeling and Analysis of The Effects of Machining Parameters On The Performance Characteristics in The Edm Process of Al O +tic Mixed CeramicusbkitsBelum ada peringkat

- Experimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum AlloyDokumen7 halamanExperimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum AlloyÐɤ Suman ChatterjeeBelum ada peringkat

- Optimization of Various Machining Parameters of Electrical Discharge Machining (EDM) Process On AISI D2 Tool Steel Using Hybrid Optimization MethodDokumen9 halamanOptimization of Various Machining Parameters of Electrical Discharge Machining (EDM) Process On AISI D2 Tool Steel Using Hybrid Optimization MethodInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Ch-12 Unconventional MachiningDokumen188 halamanCh-12 Unconventional MachiningAbhishek AroraBelum ada peringkat

- Arshad Paper - EDMDokumen6 halamanArshad Paper - EDMVENKATA KRISHNAIAH BACHUBelum ada peringkat

- Materials Today: Proceedings: M. Subrahmanyam, T. NancharaiahDokumen5 halamanMaterials Today: Proceedings: M. Subrahmanyam, T. NancharaiahakashBelum ada peringkat

- Materials Today: Proceedings: M. Subrahmanyam, T. NancharaiahDokumen5 halamanMaterials Today: Proceedings: M. Subrahmanyam, T. NancharaiahakashBelum ada peringkat

- 67 Ijmperdaug201867Dokumen6 halaman67 Ijmperdaug201867TJPRC PublicationsBelum ada peringkat

- Amm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMDokumen12 halamanAmm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMErin BarryBelum ada peringkat

- Machining of Shape Memory Alloys by Using WEDMDokumen5 halamanMachining of Shape Memory Alloys by Using WEDMIJIRSTBelum ada peringkat

- LESSON 4 (B)Dokumen12 halamanLESSON 4 (B)learntomindyourownbusinessokayBelum ada peringkat

- Ch-12 Unconventional MachiningDokumen135 halamanCh-12 Unconventional MachiningSaumil ShahBelum ada peringkat

- Comparative Study of White Layer Characteristics For StaticDokumen12 halamanComparative Study of White Layer Characteristics For StaticShahid MehmoodBelum ada peringkat

- Wedm: Influence of Machine Feed Rate in Machining Titanium Ti-6Al-4V Using Brass Wire and Constant Current (4A)Dokumen6 halamanWedm: Influence of Machine Feed Rate in Machining Titanium Ti-6Al-4V Using Brass Wire and Constant Current (4A)Gopinath GangadhariBelum ada peringkat

- EDM With ECM PDFDokumen8 halamanEDM With ECM PDFlogeshboy007Belum ada peringkat

- A Review of Electrochemical Macro-To Micro-Hole Drilling ProcessesDokumen16 halamanA Review of Electrochemical Macro-To Micro-Hole Drilling ProcessesMaitry DaveBelum ada peringkat

- Metallurgical Characterization of Electrical Discharge Textured Roll SurfaceDokumen8 halamanMetallurgical Characterization of Electrical Discharge Textured Roll Surfacevishalbhojak vishalbhojakBelum ada peringkat

- ETJ - Volume 40 - Issue 1 - Pages 181-188Dokumen8 halamanETJ - Volume 40 - Issue 1 - Pages 181-188Jabbar AljanabyBelum ada peringkat

- Review of State of Art and Process Parameter Influence in EDM TechnologyDokumen9 halamanReview of State of Art and Process Parameter Influence in EDM TechnologyNguyễn Hữu PhấnBelum ada peringkat

- Dike Calculation Sheet eDokumen2 halamanDike Calculation Sheet eSaravanan Ganesan100% (1)

- A Novel Adoption of LSTM in Customer Touchpoint Prediction Problems Presentation 1Dokumen73 halamanA Novel Adoption of LSTM in Customer Touchpoint Prediction Problems Presentation 1Os MBelum ada peringkat

- Rating SheetDokumen3 halamanRating SheetShirwin OliverioBelum ada peringkat

- 2.1 Components and General Features of Financial Statements (3114AFE)Dokumen19 halaman2.1 Components and General Features of Financial Statements (3114AFE)WilsonBelum ada peringkat

- Vinera Ewc1201Dokumen16 halamanVinera Ewc1201josue1965Belum ada peringkat

- Interruptions - 02.03.2023Dokumen2 halamanInterruptions - 02.03.2023Jeff JeffBelum ada peringkat

- Expectation Vs Reality: Job Order and Contract of ServiceDokumen10 halamanExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolBelum ada peringkat

- As 60068.5.2-2003 Environmental Testing - Guide To Drafting of Test Methods - Terms and DefinitionsDokumen8 halamanAs 60068.5.2-2003 Environmental Testing - Guide To Drafting of Test Methods - Terms and DefinitionsSAI Global - APACBelum ada peringkat

- Electricity 10thDokumen45 halamanElectricity 10thSuryank sharmaBelum ada peringkat

- Online Learning Interactions During The Level I Covid-19 Pandemic Community Activity Restriction: What Are The Important Determinants and Complaints?Dokumen16 halamanOnline Learning Interactions During The Level I Covid-19 Pandemic Community Activity Restriction: What Are The Important Determinants and Complaints?Maulana Adhi Setyo NugrohoBelum ada peringkat

- SBL - The Event - QuestionDokumen9 halamanSBL - The Event - QuestionLucio Indiana WalazaBelum ada peringkat

- 1SXP210003C0201Dokumen122 halaman1SXP210003C0201Ferenc SzabóBelum ada peringkat

- Level 3 Repair: 8-1. Block DiagramDokumen30 halamanLevel 3 Repair: 8-1. Block DiagramPaulo HenriqueBelum ada peringkat

- Jerome4 Sample Chap08Dokumen58 halamanJerome4 Sample Chap08Basil Babym100% (7)

- Brochure Ref 670Dokumen4 halamanBrochure Ref 670veerabossBelum ada peringkat

- The Rise of Populism and The Crisis of Globalization: Brexit, Trump and BeyondDokumen11 halamanThe Rise of Populism and The Crisis of Globalization: Brexit, Trump and Beyondalpha fiveBelum ada peringkat

- Aisladores 34.5 KV Marca Gamma PDFDokumen8 halamanAisladores 34.5 KV Marca Gamma PDFRicardo MotiñoBelum ada peringkat

- Basics: Define The Task of Having Braking System in A VehicleDokumen27 halamanBasics: Define The Task of Having Braking System in A VehiclearupBelum ada peringkat

- Building Program Template AY02Dokumen14 halamanBuilding Program Template AY02Amy JaneBelum ada peringkat

- Financial Derivatives: Prof. Scott JoslinDokumen44 halamanFinancial Derivatives: Prof. Scott JoslinarnavBelum ada peringkat

- Avalon LF GB CTP MachineDokumen2 halamanAvalon LF GB CTP Machinekojo0% (1)

- Lactobacillus Acidophilus - Wikipedia, The Free EncyclopediaDokumen5 halamanLactobacillus Acidophilus - Wikipedia, The Free Encyclopediahlkjhlkjhlhkj100% (1)