Mann & Hummel Separator Elements

Diunggah oleh

steve@air-innovations.co.zaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mann & Hummel Separator Elements

Diunggah oleh

steve@air-innovations.co.zaHak Cipta:

Format Tersedia

Standard Wrap Element ...

Separation efficiency The residual oil content at nominal flow rate and at 7 bar (0.7 MPa) operating pressure is approximately 1 to 3 mg/m3 (1 to 3 ppm). Service life The rise in flow resistance and thus service life primarily depend on the cleanness of the oil and the quality of the air filter. A service life of several thousand hours can be achieved with a well-functioning system. Fitting advice Standard Wrap Elements are available in a variety of sizes. They will only function properly when there is no leakage between the wet and the dry sides. Air should be guided in such a way as to prevent the air oil stream impacting directly on the surface of the filter element.

Design and function This product is suitable for flow from the outside to the inside. It can be used for the entire range of current versions of screw-type and sliding vane compressors. The standard wrap elements are particularly insensitive to design variations and achieve optimal results with regard to separation efficiency and service life. Pressure drop The pressure drop at nominal flow rate and at 7 bar (0.7 MPa) operating pressure with a new element is 0.17 bar (17 KPa). If a higher resistance is permitted, the volumetric flow rate can be doubled without downgrading performance. Pressure resistance Air Oil Separators are designed for differential pressures of and upwards 5 bar (0.5 MPa).

Seals

Compressed air inlets for oil saturated air (3 inlet alternatives) to oil injection oil-free compressed air

Installation of Standard Wrap Element in pressure reservoir 8

... tried and tested thousand times

d2 d3

h1

h2 d1

Part No. Packaged model 49 49 49 49 49 49 49 49 49 49 49 49 49 49 49 49

1)

Flow rate1) [m3/min] 2 3.5 3.5 4.5 6.5 8 9 12 12 14 17 19 20 24 29 42

Dimensions in mm d1 135 135 170 170 170 275 220 275 220 300 300 300 275 300 300 475 d2 170 170 200 200 200 328 274 328 274 355 355 355 324 355 355 570 d3 88 88 123 123 123 220 165 220 165 245 245 245 220 245 245 400 h1 200 305 230 305 435 305 435 450 600 500 600 660 750 820 1 000 900 h2 12 12 12 12 12 12 12 12 12 12 12 12 12 12 12 20

000 000 000 000 000 000 000 000 000 000 000 000 000 000 000 000

51 51 51 51 51 51 51 51 51 51 51 51 51 51 51 51

531 411 201 121 111 101 171 321 131 191 181 221 521 481 541 581

Flow rate according to DIN 1945 at 7 bar (0.7 MPa) operating pressure. Specially adapted sizes are available on request.

Depth Separator Element ...

Design and function This product takes up very little space and is suitable for the entire range of current versions of screw-type and sliding vane compressors. In the depth separator element, oil flows from the outside to the inside. Pressure drop The pressure drop at nominal flow rate and at 7 bar (0.7 MPa) operating pressure with a new element is approx. 0.2 bar (20 KPa). If a higher resistance is permitted, the volumetric flow rate can be increased to 1.5 times the nominal flow rate without downgrading performance.

Pressure resistance Depth Separator Elements are designed for differential pressures of min. 5 bar (0.5 MPa).

Seals

Separation efficiency The residual oil content at nominal flow rate and at 7 bar (0.7 MPa) operating pressure is approx. 1 to 3 mg/m3 (1 to 3 ppm). Service life The rise in flow resistance and thus service life primarily depend on the cleanness of the oil and the quality of the air filter. A service life of several thousand hours can be achieved with a well-functioning system. Fitting advice Depth Separator Elements are available in a variety of sizes. They will only function properly when there is no leakage between the wet and the dry sides. Air should be guided in such a way as to prevent the air oil stream impacting directly on the surface of the filter element.

Compressed air inlets for oil saturated air (3 inlet alternatives) to oil injection oil-free compressed air

Installation of Depth Separator Element in pressure reservoir

10

... high performance in a confined space

d2 d3

d1

Part No. Packaged model 49 49 49 49 49 49 49 49 49

1)

Flow rate1) [m3/min] 4.5 6.5 9 16 20 22 28 33.5 39

Dimensions in mm d1 135 170 170 300 275 300 300 300 300 d2 170 200 200 355 328 355 355 355 355 d3 75 109 109 220 209 220 220 220 220 h 200 230 305 305 400 400 500 600 700

301 301 302 303 303 304 305 305 306

53 53 53 53 53 53 53 53 53

131 101 131 121 111 101 111 101 102

Flow rate according to DIN 1945 at 7 bar (0.7 MPa) operating pressure. Specially adapted sizes are available on request.

11

Anda mungkin juga menyukai

- Lubrication and Reliability HandbookDari EverandLubrication and Reliability HandbookPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Hertz HGO Series Compressed Air Filters Mai 2013Dokumen2 halamanHertz HGO Series Compressed Air Filters Mai 2013HP ServicesBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Sotras ManualDokumen24 halamanSotras ManualcivodulBelum ada peringkat

- Air Line AccessoriesDokumen4 halamanAir Line AccessoriesZeckBelum ada peringkat

- Aerzen Delta Hybrid Brochure Rev. 1-05-12Dokumen8 halamanAerzen Delta Hybrid Brochure Rev. 1-05-12carlangas77Belum ada peringkat

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDari EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementBelum ada peringkat

- Lubrication Equipment CatalogDokumen60 halamanLubrication Equipment Catalogjairo269Belum ada peringkat

- Comp AirDokumen6 halamanComp AirOliver CambelBelum ada peringkat

- MAN 946 E - 72dpi Precommissing Compressor ScrewDokumen16 halamanMAN 946 E - 72dpi Precommissing Compressor ScrewBalu Venkatesa PerumalBelum ada peringkat

- Summary of Positive Displacement CompressorDokumen8 halamanSummary of Positive Displacement CompressorKenn Carlo OningBelum ada peringkat

- ABAC Formula 5 5 22kWDokumen6 halamanABAC Formula 5 5 22kWsebastianBelum ada peringkat

- Hpa Series - en R01eoDokumen35 halamanHpa Series - en R01eoJorgeBelum ada peringkat

- Advantages of Oil-Free Screw CompressorsDokumen4 halamanAdvantages of Oil-Free Screw CompressorsMANIU RADU-GEORGIANBelum ada peringkat

- Air Filter Select PDFDokumen8 halamanAir Filter Select PDFMohamed ElnagdyBelum ada peringkat

- ScrollDokumen8 halamanScrolltrung2iBelum ada peringkat

- Compresoras de Tornillo KAISHAN Serie LGDokumen8 halamanCompresoras de Tornillo KAISHAN Serie LGcecoelsacBelum ada peringkat

- Advantages of Oil-Free Screw CompressorsDokumen4 halamanAdvantages of Oil-Free Screw CompressorsSelvaraji Muthu100% (1)

- Informacion Producto Martillo MX60Dokumen20 halamanInformacion Producto Martillo MX60ING MANTENIMIENTO CONINTEL S.ABelum ada peringkat

- Air Filter PDFDokumen4 halamanAir Filter PDFfherlixBelum ada peringkat

- Compair 2 PDFDokumen8 halamanCompair 2 PDFAveenBelum ada peringkat

- Filtro de AireDokumen7 halamanFiltro de AirejlfyBelum ada peringkat

- RA 90 221 Rexroth Environmentally Acceptable Hydraulic Fluids PDFDokumen8 halamanRA 90 221 Rexroth Environmentally Acceptable Hydraulic Fluids PDFeng13Belum ada peringkat

- MANN Filters For LiquidsDokumen48 halamanMANN Filters For LiquidsRoccinanteBelum ada peringkat

- Cast Aluminum BrochureDokumen2 halamanCast Aluminum BrochureRomanCHubaBelum ada peringkat

- Oil-Free Press-Gas Screw CompressorsDokumen16 halamanOil-Free Press-Gas Screw CompressorsMANIU RADU-GEORGIAN100% (1)

- Operating Manual SV 90-2Dokumen2 halamanOperating Manual SV 90-2alejovalles0% (1)

- Manual de Martelo Pneumático YT28Dokumen24 halamanManual de Martelo Pneumático YT28Luiz CarlosBelum ada peringkat

- Air CompressorsDokumen2 halamanAir Compressorsmike_bdnBelum ada peringkat

- 2020 2e6Dokumen6 halaman2020 2e6Jaikishan KumaraswamyBelum ada peringkat

- Fkr555.109.d4a 00apmt ManualDokumen12 halamanFkr555.109.d4a 00apmt ManualJavier FernándezBelum ada peringkat

- 3196xbulletin Read 06Dokumen20 halaman3196xbulletin Read 06bryandownBelum ada peringkat

- Operating Conditions and Standards in PneumaticsDokumen21 halamanOperating Conditions and Standards in PneumaticsKamalesh PgBelum ada peringkat

- LPG CompressorDokumen38 halamanLPG Compressorsizweh100% (1)

- Compressor Piston SealingDokumen7 halamanCompressor Piston SealingVarada Radjou CBelum ada peringkat

- Donaldson ultrafilter-DFTDokumen4 halamanDonaldson ultrafilter-DFTsyrinxBelum ada peringkat

- Partes y Piezas Compresor Schultz - MSI-2.6MLDokumen2 halamanPartes y Piezas Compresor Schultz - MSI-2.6MLWinca MantezBelum ada peringkat

- Rickmeier 34Dokumen12 halamanRickmeier 34carlosBelum ada peringkat

- Compressed Air Treatment, Drier and StorageDokumen24 halamanCompressed Air Treatment, Drier and StorageAna PrisacariuBelum ada peringkat

- Ge Dry Gas Seal RetrofitDokumen4 halamanGe Dry Gas Seal RetrofitlubangjarumBelum ada peringkat

- Liquid Ring Pump PDFDokumen66 halamanLiquid Ring Pump PDFphanindra100% (1)

- ABAC Formula 5.5 22kWDokumen6 halamanABAC Formula 5.5 22kW1976gt500Belum ada peringkat

- HYD. PumpDokumen40 halamanHYD. Pumprohitbhat2345Belum ada peringkat

- Micro FiltrationDokumen7 halamanMicro FiltrationEdwin CaleñoBelum ada peringkat

- Re 10223Dokumen26 halamanRe 10223medi38Belum ada peringkat

- Air Filter Regulator: Iat Industry LimitedDokumen7 halamanAir Filter Regulator: Iat Industry LimitedPetros IosifidisBelum ada peringkat

- Mitsubishi Centrifugal Compressor: MCO Web SiteDokumen3 halamanMitsubishi Centrifugal Compressor: MCO Web SitePoliana PolyBelum ada peringkat

- Man Turbo Oil Free PaperDokumen12 halamanMan Turbo Oil Free PaperSelvaraji MuthuBelum ada peringkat

- Bosch Gear PumpDokumen57 halamanBosch Gear PumpMaximus Maxis0% (1)

- Unique Single Seat Valve-Simply UniqueDokumen8 halamanUnique Single Seat Valve-Simply UniquelggomezupbBelum ada peringkat

- TG Filter Company Presentation - EN - 2015Dokumen36 halamanTG Filter Company Presentation - EN - 2015igor_sandulenkoBelum ada peringkat

- 04 Om049-1 MaintenanceDokumen34 halaman04 Om049-1 Maintenancegerman gualavisiBelum ada peringkat

- Maximizing Bearing PerformanceDokumen12 halamanMaximizing Bearing PerformanceJurun_Bidanshi100% (1)

- Compressed Air Filters PDFDokumen70 halamanCompressed Air Filters PDFdj22500Belum ada peringkat

- Customised Engineered Packages: Reciprocating Air CompressorsDokumen4 halamanCustomised Engineered Packages: Reciprocating Air Compressorsmogwai71Belum ada peringkat

- Model 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant ReliabilityDokumen74 halamanModel 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant Reliabilityscottt_84Belum ada peringkat

- HVAC Brochure Rev No 12Dokumen66 halamanHVAC Brochure Rev No 12steve@air-innovations.co.zaBelum ada peringkat

- Schorch Motors Metric PDFDokumen72 halamanSchorch Motors Metric PDFsteve@air-innovations.co.za100% (1)

- Schorch Motors Metric PDFDokumen72 halamanSchorch Motors Metric PDFsteve@air-innovations.co.zaBelum ada peringkat

- MSG TURBO-AIR 2000 Brochure A4Dokumen6 halamanMSG TURBO-AIR 2000 Brochure A4steve@air-innovations.co.zaBelum ada peringkat

- Operator Manual - CompAir L15,22 All Variations PDFDokumen72 halamanOperator Manual - CompAir L15,22 All Variations PDFsteve@air-innovations.co.zaBelum ada peringkat

- Inter Shop Displays: WWW - Intershopsa.co - ZaDokumen1 halamanInter Shop Displays: WWW - Intershopsa.co - Zasteve@air-innovations.co.zaBelum ada peringkat

- Cross - Referance - List-2017 PDFDokumen333 halamanCross - Referance - List-2017 PDFsteve@air-innovations.co.zaBelum ada peringkat

- 101 Mouthwatering Keto Chirstmas and Winter Recipes PDFDokumen134 halaman101 Mouthwatering Keto Chirstmas and Winter Recipes PDFMark Adrian Nathan100% (1)

- FEW Tapping Drill Sizes PDFDokumen1 halamanFEW Tapping Drill Sizes PDFsteve@air-innovations.co.zaBelum ada peringkat

- Sales Representatives TrainingDokumen27 halamanSales Representatives Trainingsteve@air-innovations.co.zaBelum ada peringkat

- Subaru Eh Engines Eh36 Eh41 ServiceDokumen74 halamanSubaru Eh Engines Eh36 Eh41 Servicesteve@air-innovations.co.za100% (1)

- Metmeister CatDokumen192 halamanMetmeister Catsteve@air-innovations.co.zaBelum ada peringkat

- Fabriekshandleiding Atlas Copco XAS 88 PDFDokumen134 halamanFabriekshandleiding Atlas Copco XAS 88 PDFsteve@air-innovations.co.zaBelum ada peringkat

- CECCATO Piston CatalogueDokumen10 halamanCECCATO Piston Cataloguesteve@air-innovations.co.zaBelum ada peringkat

- Airhorse Water Lubrication Oil Free Screw Air Compressor CatalogueDokumen4 halamanAirhorse Water Lubrication Oil Free Screw Air Compressor Cataloguesteve@air-innovations.co.zaBelum ada peringkat

- Habit Formation WorksheetDokumen6 halamanHabit Formation Worksheetsteve@air-innovations.co.za100% (1)

- Blades LocalDokumen7 halamanBlades Localsteve@air-innovations.co.zaBelum ada peringkat

- Ga22 VSDDokumen158 halamanGa22 VSDsteve@air-innovations.co.za100% (1)

- R160 Engineering Data Sheet V1297-99Dokumen2 halamanR160 Engineering Data Sheet V1297-99steve@air-innovations.co.za100% (1)

- LA Electric Linear ActuatorDokumen3 halamanLA Electric Linear Actuatorsteve@air-innovations.co.zaBelum ada peringkat

- Dominator Range Owners ManualDokumen9 halamanDominator Range Owners Manualsteve@air-innovations.co.zaBelum ada peringkat

- NE700 Valve PositionerDokumen9 halamanNE700 Valve Positionersteve@air-innovations.co.zaBelum ada peringkat

- Transeals O-Ring HandbookDokumen16 halamanTranseals O-Ring Handbooksteve@air-innovations.co.zaBelum ada peringkat

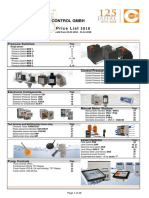

- Condor Price List 2018 Customer (Schwarz)Dokumen28 halamanCondor Price List 2018 Customer (Schwarz)steve@air-innovations.co.zaBelum ada peringkat

- AN125 Catálogo Completo InglêsDokumen71 halamanAN125 Catálogo Completo InglêsV_CABUSBelum ada peringkat

- ISO 3601 Metric Size O-Rings Quick Reference ChartDokumen6 halamanISO 3601 Metric Size O-Rings Quick Reference ChartHarryBelum ada peringkat

- Jumo Pressure TransmittersDokumen5 halamanJumo Pressure Transmitterssteve@air-innovations.co.zaBelum ada peringkat

- 2-xxx SizesDokumen9 halaman2-xxx SizesJonas PerezBelum ada peringkat

- E 50 Parts ManualDokumen13 halamanE 50 Parts Manualsteve@air-innovations.co.zaBelum ada peringkat

- Civil & Structural Designer'S Data Pack: Section 7: MasonryDokumen5 halamanCivil & Structural Designer'S Data Pack: Section 7: MasonryMirea Florentin0% (1)

- Job No. 25800: Quebrada Blanca Fase 2Dokumen1 halamanJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozBelum ada peringkat

- Configuration Diagrams: Group 80ADokumen24 halamanConfiguration Diagrams: Group 80ASaHdo AbdelHamid100% (1)

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDokumen3 halamanIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriBelum ada peringkat

- Heat ExchangerDokumen5 halamanHeat Exchangersara smithBelum ada peringkat

- G120D Getting Started 0418 en-USDokumen94 halamanG120D Getting Started 0418 en-USHamadi Ben SassiBelum ada peringkat

- BUCA IMSEF 2021 Jury Evaluation ScheduleDokumen7 halamanBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengBelum ada peringkat

- Trend Management How To Effectively Use Trend-Knowledge in Your Company (Jörg Blechschmidt)Dokumen121 halamanTrend Management How To Effectively Use Trend-Knowledge in Your Company (Jörg Blechschmidt)Antonio Gonzalez AriasBelum ada peringkat

- CV LeTranNguyen enDokumen4 halamanCV LeTranNguyen enLe Tran NguyenBelum ada peringkat

- Symptoms and DiseasesDokumen8 halamanSymptoms and Diseaseschristy maeBelum ada peringkat

- Wbuhs PG ThesisDokumen7 halamanWbuhs PG Thesisgbx272pg100% (2)

- Catholic Social TeachingsDokumen21 halamanCatholic Social TeachingsMark de GuzmanBelum ada peringkat

- NRP Grade 11 READING ENHANCEMENT March 1Dokumen3 halamanNRP Grade 11 READING ENHANCEMENT March 1LORELYN DELA CRUZBelum ada peringkat

- Makenna Resort: by Drucker ArchitectsDokumen12 halamanMakenna Resort: by Drucker ArchitectsArvinth muthuBelum ada peringkat

- Key Concepts: Adding and Subtracting FractionsDokumen7 halamanKey Concepts: Adding and Subtracting Fractionsnearurheart1Belum ada peringkat

- Executive Shirt CompanyDokumen6 halamanExecutive Shirt CompanyPramod kBelum ada peringkat

- Awb 4914934813Dokumen1 halamanAwb 4914934813Juandondr100% (1)

- Hydrology: Dua'a Telfah PH.D, Civil Engineering Department Jadara UniversityDokumen104 halamanHydrology: Dua'a Telfah PH.D, Civil Engineering Department Jadara UniversityFaris AlmomaniBelum ada peringkat

- PSY502 OLd PapersDokumen6 halamanPSY502 OLd Paperscs619finalproject.com100% (4)

- Heat Power Lab ManualDokumen68 halamanHeat Power Lab ManualRaghu KrishnanBelum ada peringkat

- Description: Super Thoroseal Is A Blend of PortlandDokumen2 halamanDescription: Super Thoroseal Is A Blend of Portlandqwerty_conan100% (1)

- Galaxy A8 User ManualDokumen193 halamanGalaxy A8 User ManualHüseyin ACARBelum ada peringkat

- Engineering Properties (Al O) : 94% Aluminum Oxide Mechanical Units of Measure SI/Metric (Imperial)Dokumen7 halamanEngineering Properties (Al O) : 94% Aluminum Oxide Mechanical Units of Measure SI/Metric (Imperial)Hendy SetiawanBelum ada peringkat

- Semantic SearchMonkeyDokumen39 halamanSemantic SearchMonkeyPaul TarjanBelum ada peringkat

- Evaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellDokumen6 halamanEvaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellTrần Hoàng ChươngBelum ada peringkat

- Dyn ST 70 Ser 2Dokumen12 halamanDyn ST 70 Ser 2alexgirard11735100% (1)

- KarcherDokumen21 halamanKarcherSIVARAMANJAGANATHANBelum ada peringkat

- Lock Maiolo Savonarola MachiavelliDokumen22 halamanLock Maiolo Savonarola MachiavelliHeliogabolusBelum ada peringkat

- JMPGuitars 18 Watt Tremolo TMB Reverb LayoutDokumen1 halamanJMPGuitars 18 Watt Tremolo TMB Reverb LayoutRenan Franzon GoettenBelum ada peringkat

- Inspection List For Electrical PortableDokumen25 halamanInspection List For Electrical PortableArif FuadiantoBelum ada peringkat

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDari EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuidePenilaian: 2 dari 5 bintang2/5 (1)

- Well Integrity for Workovers and RecompletionsDari EverandWell Integrity for Workovers and RecompletionsPenilaian: 5 dari 5 bintang5/5 (3)

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Asset Integrity Management for Offshore and Onshore StructuresDari EverandAsset Integrity Management for Offshore and Onshore StructuresBelum ada peringkat

- Advanced Production Decline Analysis and ApplicationDari EverandAdvanced Production Decline Analysis and ApplicationPenilaian: 3.5 dari 5 bintang3.5/5 (4)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDari EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesPenilaian: 4 dari 5 bintang4/5 (2)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDari EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsBelum ada peringkat

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsDari EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsBelum ada peringkat

- Casing and Liners for Drilling and Completion: Design and ApplicationDari EverandCasing and Liners for Drilling and Completion: Design and ApplicationPenilaian: 5 dari 5 bintang5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsDari EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsBelum ada peringkat

- Oil: An Overview of the Petroleum IndustryDari EverandOil: An Overview of the Petroleum IndustryPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsDari EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryDari EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryPenilaian: 5 dari 5 bintang5/5 (3)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationDari EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Certified Oil and Gas Project ManagerDari EverandThe Certified Oil and Gas Project ManagerPenilaian: 4 dari 5 bintang4/5 (2)

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)