Supply Chain

Diunggah oleh

nilayjDeskripsi Asli:

Hak Cipta

Format Tersedia

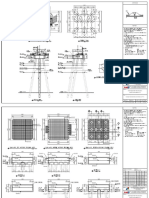

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Supply Chain

Diunggah oleh

nilayjHak Cipta:

Format Tersedia

upply Chain - Petroleum Presentation Transcript

1. Presented by: Sowmya A. (PRN 006) Arun Chaudhary (PRN 025) Amitabh Jasuja (PRN 049) Swati Kanade (PRN 052) Srimoyee Panda (073) 2. INTRODUCTION The petroleum industry plays an important role in the economic development of the country Performance of its supply chain has become very important 3. INTRODUCTION (contd.) The petroleum industry traditionally had prices decided by the Government of India. Effective from August 1, 2004, the Government put in a revised methodology allowing oil companies to revise the prices of motor spirit and High Speed Diesel (HSD). The total investment estimated in the petroleum sector from 1995 till 2010, is expected to be Rs. 4,32,000 cr (US$120 bn), out of which Rs. 2,58,000 cr (US$80 bn), are for the upstream sector alone Petrochemical industry in India employs around 40,000 people directly and around 4 lakh indirectly 4. OBJECTIVES Understanding the importance of supply chain management in the petroleum industry. Identifying distinguishing features of the petroleum industry supply chain vis--vis discrete manufacturing supply chains. Discussing the petroleum supply chain in India. Identifying non-value added activities in the petroleum supply chain. Discussing the role of information technology in revamping the petroleum industry supply chain. 5. SUPPLY CHAIN IN PETROLEUM INDUSTRY Supply Planning Crude Crude Crude Purchase Transptn. Refining Storage (Tanker/PL) Distribution Planning Retailing / Mktg Product Product Consumer Storage Transptn/Distribution (Demand Centre) (Terminal/ Depot/ Port) (Tanker/PL/Rail/Road) 6. DIFFERENT STAGES IN PETROLEUM SUPPLY CHAIN Exploration Production Refining Marketing Consumer Exploration: Seismic, geophysical and geological operations Production: Drilling, reservoir, production and facilities engineering. Refining : complex operation and its output is the input to marketing. Marketing : The retail sale of gasoline, engine oil and other refined products. 7. IMPORTANCE OF SUPPLY CHAIN IN PETROLEUM INDUSTRY Petroleum industry is highly asset intensive Like other chemical companies supply chain can account for upto 70% of overall cost . Highly specialized business processes encourages fragmentation. Chemical supply chains are typically non-linear in nature Supply chain optimization at a strategic and operational level is a value creating opportunity for chemical companies and a potential source of competitive advantage 8. Petroleum Supply Chain In India Ministry of Petroleum & Natural Gas Upstream Downstream Industry Bodies Exploration & Production Refining & Marketing Petroleum IndianOil Bharat Planning & ONGC Analysis Cell Petroleum Centre for High Technology OVL CPCL, BRPL NRL PCRA PetroFed Reliance Hindustan Oil Industry Safety Oil India Industries Directorate Petroleum Petroleum India Limited Ltd. International MRPL Engineers India Limited Pvt E&P Director General Cos. of Hydrocarbon 9. UPSTREAM SUPPLY CHAIN Acquisition of crude oil. Operations Exploration ,Forecasting , Production . Logistics management - Delivering crude oil from remotely located oil wells to refineries 10. DOWN STREAM SUPPLY CHAIN Refinery- The crude oil is manufactured into the consumable products that are the specialty of refineries and petrochemical

companies. Processes - forecasting, production, and the logistics management of delivering the crude oil derivatives to customers around the globe. 11. PETROLEUM FINISHED PRODUCTS IN INDIA 12. OBJECTIVES OF A SUCCESSFUL SUPPLY CHAIN IN PETROLEUM Minimization of material procurement Maximization of manufacturing capacity and sales Meet demand numbers Respond quickly to market opportunity by purchasing the production shortfall from other players Objective of each production unit would be to maximize the throughput and its margin Procurement would purchase the feedstock with not the best yields at lowest cost 13. SUPPLY CHAIN STRATEGIES Planning Which feed stock to buy Where to process How much to buy readymade and how much to make What to make and where How to transport 14. SUPPLY CHAIN STRATEGIES CONTD. Scheduling When and in what order feedstock should arrive at manufacturing facility When and in what sequence or modes to run the equipments Which orders to meet and what dates to promise 15. SUPPLY CHAIN STRATEGIES CONTD. Demand planning: For demand forecasting and aggregation of the final demand numbers based on requirements of supply chain Integrated Planning: Planning for the complete supply chain of the customer based on demand numbers Distribution Planning: Generating operational plans for distribution Production Planning: Generating operational plans for production. These modules are supported by various enablers that facilitate planning activity that include: (1) Supply Chain Database (SCD) (2) Geographical Information System (GIS) (3)Data Interfaces 16. SUPPLY CHAIN PLANNING SOLUTION The demand numbers are fed to an integrated planning module that contains representation of supply, production and distribution facilities The production and the Supply and Distribution (S&D) structure forms the basis on which the optimised plan for the entire organisation is generated This corporate plan is communicated to distribution modules and the production planning modules to generate operational plans The optimised plan for the entire corporation is also used as a basis for feedstock selection runs. GIS can be used to obtain the distances between locations, which are used as a basis for freight calculation 17. UNIQUE FEATURES OF THE PETROLEUM INDUSTRY SUPPLY CHAIN Raw Material Supplies: Process industry has limited choice of suppliers for raw material Supplies in petroleum industry are dominated by cartels It is a sellers market wrt supply of raw material Raw Material Prices: Raw material prices are highly unstable and fluctuating on weekly or even daily basis Fluctuating prices directly affect the supply chain costs and prices of final product 18. UNIQUE FEATURES OF THE PETROLEUM INDUSTRY SUPPLY CHAIN Reverse Production Flow: The production flow is reversed in petroleum industry. In downstream petroleum companies, inventory starts from one product, i.e., crude and creates many products like petrol, diesel, naphtha, bitumen, etc High Transportation Costs : Transportation costs about 20% of the production cost. Length of Supply Chain: Very Complex and lengthy supply chain 19. UNIQUE FEATURES OF THE PETROLEUM INDUSTRY SUPPLY CHAIN Integration of Supply Chain Partners : Integration of suppliers as well as customers and distributors is difficult Cost pressures are the driving force in the supply chain. Flexibility : Supply chains are highly inflexible both in terms of volumes handled and in terms of product variation/customization.

20. FUNCTIONS OF SUPPLY CHAIN DB SCD provides distribution related inputs to both Integrated Planning and Distribution Planning models and has these following functions: Temporal integration: Data for yearly and quarterly models available in one place and can be rolled up or down as per requirement. Hierarchical integration: Aggregation for integrated model is done based on detailed data available for operational distribution models Calculations: Final linkage costs are calculated using tax logic, current prices, distances and freight rates. 21. NON-VALUE ADDED ACTIVITIES IN THE PETROLEUM SUPPLY CHAIN Waiting: Crude oil is often imported. Cargo ships have to often wait at the harbour before they can unload the crude. Waiting leads to increase in inventory holding within the supply chain. Occur while finished product is sent to storage installations by rail Additional Quality Checks: Adulteration usually happens in case of petroleum products like petrol and diesel Adulteration is also possible in transit from storage installation to the retail outlet Use of common pipeline for transporting different products leads to a small portion of product being quot;degraded. Testing of the product is required at various times. 22. NON-VALUE ADDED ACTIVITIES IN THE PETROLEUM SUPPLY CHAIN Holding of Huge Inventories: Product is made to stock and mammoth inventories are being kept at refineries and at storage installations In Transit inventories Information on demand and supply is not very clear and there is lack of visibility that adds up to increased safety stock requirements both for raw material and finished product Over Production: continuous process plants continuous supply of feed stock, resulting in the production of several downstream products inflexibility in capacity, as these plants have to run continuously all the time This increases inventories of finished product and results in inefficient use of capital. 23. ROLE OF INFORMATION TECHNOLOGY IN THE PETROLEUM INDUSTRY Timely flow of accurate information can affect performance of the supply chain to a large extent. Integration of demand chain information Hence process optimization is the key task for the Information Technologies function of process industries and currently seems to be a huge challenge It is a method that unites the modelling, designing and monitoring of engineering assets with scheduling, supply chain, trading a fulfilment via multiple flows of information between stages in life cycle of products, bringing huge efficiencies Customer-segmentation strategies and effective demand management, will lead to increased top line revenues and reduced cost of sales. 24. SUGGESTIONS Raw Material Supplies: Formulating a long term agreement with some of the oil producing nations and in order to take care of price fluctuations Government should allow the petroleum companies to use hedging for finalizing deals involving purchase of crude oil. Transportation Costs: Use of Pipeline transportation Length of Supply Chain: Facilities at the ports should be improved and their capacity to be increased so that more tankers could berth at the harbour 25. SUGGESTIONS (Contd.) Inventory Carrying Costs: Use of a reliable transportation system and quick information exchange can reduce carrying costs Government should aim at reducing the minimum safety stock, which oil companies are supposed to keep Integration of Supply Chain Partners: Oil companies should aggressively use information technology to integrate suppliers and customers. Effective use of ERP can help in this regard.

Anda mungkin juga menyukai

- Balanced Scorecard: Submitted byDokumen9 halamanBalanced Scorecard: Submitted bynilayjBelum ada peringkat

- Project Management Tutorial: BY: Abhishek Kumar PGP-11 School of Petroleum ManagementDokumen82 halamanProject Management Tutorial: BY: Abhishek Kumar PGP-11 School of Petroleum ManagementnilayjBelum ada peringkat

- HR PresentationDokumen4 halamanHR PresentationnilayjBelum ada peringkat

- Computron Inc - Wac ReportDokumen10 halamanComputron Inc - Wac ReportnilayjBelum ada peringkat

- SCNEWDokumen1 halamanSCNEWnilayjBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- National Data Repository launched to boost oil explorationDokumen10 halamanNational Data Repository launched to boost oil explorationbrahm DuttBelum ada peringkat

- Supply Chain Management in Petroleum Industry - General ViewDokumen3 halamanSupply Chain Management in Petroleum Industry - General Viewpearlinwhite100% (2)

- Overview Malaysia Oil and Gas IndustryDokumen3 halamanOverview Malaysia Oil and Gas IndustryNik NajmiBelum ada peringkat

- Basics of LWD: Zeyad Ramadan EEG LWD Domain ChampionDokumen21 halamanBasics of LWD: Zeyad Ramadan EEG LWD Domain ChampionMohammed Zubair AhmedBelum ada peringkat

- How Shell Uses Big Data in PracticeDokumen18 halamanHow Shell Uses Big Data in Practicetaran singhBelum ada peringkat

- History ONGCDokumen5 halamanHistory ONGCManojKumarBelum ada peringkat

- Hubbert's Peak TheoryDokumen15 halamanHubbert's Peak TheoryHrishikesh ChappadiBelum ada peringkat

- Mooring & Breasting Jetty IIDokumen12 halamanMooring & Breasting Jetty IIDwiki AdriyantoBelum ada peringkat

- FPSO Projects Worldwide 2019 - 1549865522Dokumen1 halamanFPSO Projects Worldwide 2019 - 1549865522Puix Ozil TherPanzer100% (1)

- GSR April 2022Dokumen32 halamanGSR April 2022Abhi PasupulatiBelum ada peringkat

- Tanzania'S Oil and Gas Contract Regime, Investments and MarketsDokumen45 halamanTanzania'S Oil and Gas Contract Regime, Investments and Marketssamwel danielBelum ada peringkat

- Pngstat 1Dokumen232 halamanPngstat 1Sandra GilbertBelum ada peringkat

- Oil & Gas Industry in KuwaitDokumen17 halamanOil & Gas Industry in KuwaitSuleiman Baruni100% (1)

- Daftar Pustaka AfegaDokumen3 halamanDaftar Pustaka Afeganendry11Belum ada peringkat

- Major Oil & Gas Operators in ColombiaDokumen23 halamanMajor Oil & Gas Operators in ColombiaWilliam Alexander OrtizBelum ada peringkat

- Top 50 Oil Companies Nov 2013Dokumen6 halamanTop 50 Oil Companies Nov 2013renatogeo14Belum ada peringkat

- Weekly HSE Statistic & Manhours September 2023 - FlaDokumen5 halamanWeekly HSE Statistic & Manhours September 2023 - Flasafety.fighterBelum ada peringkat

- Why Brent Crude Oil Price Is Higher Than WTIDokumen4 halamanWhy Brent Crude Oil Price Is Higher Than WTIVerrsha TollasariyaBelum ada peringkat

- Libia EiaDokumen12 halamanLibia EiaFreedom BreezeBelum ada peringkat

- QC Form for Dung Quat Refinery Hydrotest PackageDokumen1 halamanQC Form for Dung Quat Refinery Hydrotest Packageminhnn75% (4)

- Trinidad and Tobago's Shift to Natural Gas DependenceDokumen22 halamanTrinidad and Tobago's Shift to Natural Gas DependenceRich Ian100% (1)

- Deepwater HorizonDokumen1 halamanDeepwater HorizonFilipe BarretoBelum ada peringkat

- India DGH - Maps of E&P Areas - Active (All Blocks) and Reliquinshed (Offshore)Dokumen1 halamanIndia DGH - Maps of E&P Areas - Active (All Blocks) and Reliquinshed (Offshore)masoninman1Belum ada peringkat

- API GravityDokumen3 halamanAPI GravityKamilah HarumasariBelum ada peringkat

- Northsea Oil Gas Map 2013Dokumen1 halamanNorthsea Oil Gas Map 2013Free_Beating_HeartBelum ada peringkat

- PWC Oil Gas Guide 2019 PDFDokumen148 halamanPWC Oil Gas Guide 2019 PDFRafael DamarBelum ada peringkat

- FPSODokumen7 halamanFPSOjohn_tigerBelum ada peringkat

- Asia-Pacific - Arab Gulf Marketscan - Refined - 01112021Dokumen25 halamanAsia-Pacific - Arab Gulf Marketscan - Refined - 01112021Đức Vũ NguyễnBelum ada peringkat

- Ae472 QPDokumen2 halamanAe472 QPMegha G KrishnanBelum ada peringkat