Wilkerson

Diunggah oleh

mayurmachoDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Wilkerson

Diunggah oleh

mayurmachoHak Cipta:

Format Tersedia

IIM,INDORE

Wilkerson Company

MAC-2

Group 12 1/11/2012 Jagadeesh Putta, Mayur Macharla, Sarva Harish, Gali Stephen Stanley

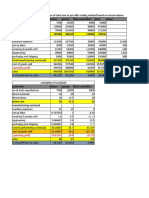

The cost pools and corresponding cost drivers are as follows: COST POOLS Machine-related expenses Setup labor cost Receiving and production control Engineering Packaging and shipment COST DRIVERS Machine hours Number of production runs Number of production runs Hours of engineering work Number of shipments

Machine Related Expenses For Machine hours 11,200

$336,000 $30/machinehour

Setup Labor For Production runs 160

$40,000 $250 / run

Receiving and Production Control For Production runs 160

$180,000 $1,125 / run

Engineering Hours of engineering work 1,250

$100,000 $80 / hour

Packaging and Shipment Number of shipments 300

$150,000 $500 / shipment

Existing cost system:- Currently Wilkerson implements volume-based full costing. Direct materials and labor costs are based on standard prices of materials and labor rates. Indirect cost (overhead) is allocated to cost objects (products) in proportion to direct labor cost at the rate of 300%.

VALVES PUMPS FLOW CONTROLLERS

machine Receiving and Packaging direct direct related Setup production and total per material labor expenses labor control Engineering shipping unit $16.00 $10.00 $15.00 $0.33 $1.50 $2.67 $0.67 $46.17 $20.00 $12.50 $15.00 $1.00 $4.50 $2.40 $2.80 $58.20

$22.00

$10.00

$9.00

$6.25

$28.13

$12.50

$27.50

$115.38

Table: ABC costing for assigning variables

Profitability analysis: volume based costing valves Standard unit costs Target selling price Planned gross margin (%) Actual selling price Actual gross margin (%) $56.00 $86.15 35% $86.00 34.90% pumps $70.00 $107.69 35% $87.00 19.50% flow controllers $62.00 $95.38 35% $105.00 41.00% valves $46.17 ABC costing flow pumps controllers $58.20 $115.38 $95.38 35% $105.00 -9.88%

$86.15 $107.69 35% $86.00 46.32% 35% $87.00 33.10%

Conclusions: Wilkerson can continue to decrease prices of commodity products (valves and pumps) since their margins are quite high, but need to react to negative profitability of flow controllers. Limitations of analysis is that our calculation of cost drivers and product cost doesnt allow revealing the difference between individual flow controllers, although we know that they are customized.

We recommend to move from traditional volume-based costing to activity-based costing because of the fact that high overheads were not showing the real picture regarding the cost of flow controllers. Having in mind the absence of price competition, customized nature of a product Wilkerson can change prices of individual flow controllers in order to secure healthy profit margin. Based on the ABC method of costing we conclude that Wilkerson can afford to decrease prices of pumps and valves to tackle price wars with competition and stop production of flow controllers.

Anda mungkin juga menyukai

- Solution Wilkerson CompanyDokumen10 halamanSolution Wilkerson CompanyHIMANSHU AGRAWAL67% (3)

- ABC Analysis Reveals Flow Controllers UnprofitableDokumen5 halamanABC Analysis Reveals Flow Controllers UnprofitableChinee Natividad100% (2)

- Wilkerson Company Analysis Using Activity Based CostingDokumen5 halamanWilkerson Company Analysis Using Activity Based CostingHardik Sanghavi100% (1)

- Wilkerson Case Costing AnalysisDokumen5 halamanWilkerson Case Costing AnalysisSwapan Kumar Saha100% (1)

- Outsourcing Manifold ProductionDokumen8 halamanOutsourcing Manifold Productionaliraza100% (2)

- Case Study WilkersonDokumen2 halamanCase Study WilkersonHIMANSHU AGRAWALBelum ada peringkat

- Wolfgang Merkel, Sascha Kneip - Democracy and Crisis-Springer International Publishing (2018) PDFDokumen369 halamanWolfgang Merkel, Sascha Kneip - Democracy and Crisis-Springer International Publishing (2018) PDFOtto Vazquez100% (2)

- WilkersonDokumen4 halamanWilkersonVarun Gogia67% (3)

- Wilkerson CompanyDokumen2 halamanWilkerson CompanyAnkit VermaBelum ada peringkat

- The Cannibalization of Jesus and The Persecution of The Jews.Dokumen193 halamanThe Cannibalization of Jesus and The Persecution of The Jews.DrChris JamesBelum ada peringkat

- Classic Pen CompanyDokumen4 halamanClassic Pen CompanyGaurav Kataria0% (1)

- WilkDokumen3 halamanWilkMohammed Maaz GabburBelum ada peringkat

- 05 Wilkerson Company Solution - StudentsDokumen9 halaman05 Wilkerson Company Solution - StudentsVinyabhooshan Bajpai PGP 2022-24 Batch100% (1)

- TV Socialism by Anikó ImreDokumen38 halamanTV Socialism by Anikó ImreDuke University Press100% (3)

- International Accounting Group Assignment WilkersonDokumen27 halamanInternational Accounting Group Assignment WilkersonToshimichi ItoBelum ada peringkat

- Wilkerson Company ABCDokumen4 halamanWilkerson Company ABCrajyalakshmiBelum ada peringkat

- Company CASE 4 Analyzes Activity-Based Costing to Improve Profit Margins/TITLEDokumen24 halamanCompany CASE 4 Analyzes Activity-Based Costing to Improve Profit Margins/TITLECik Beb Gojes100% (1)

- Group 8Dokumen20 halamanGroup 8nirajBelum ada peringkat

- Wilkerson Case Study Final1Dokumen5 halamanWilkerson Case Study Final1mayer_ofer95% (22)

- Sippican CorporationDokumen2 halamanSippican CorporationManikandan Swaminathan100% (3)

- EX 1 - WilkersonDokumen8 halamanEX 1 - WilkersonDror PazBelum ada peringkat

- Sippican A Case Study PDFDokumen9 halamanSippican A Case Study PDFAlex G. PichliavasBelum ada peringkat

- SiemensDokumen10 halamanSiemenssharadharjai100% (2)

- Harvard Business School Chemical Bank Allocation of profitsDokumen21 halamanHarvard Business School Chemical Bank Allocation of profitsMonisha SharmaBelum ada peringkat

- Wilkerson Company Full ReportDokumen9 halamanWilkerson Company Full ReportFatihahZainalLim100% (1)

- Wilkerson Case SubmissionDokumen5 halamanWilkerson Case Submissiongangster91100% (2)

- Dave BrothersDokumen6 halamanDave BrothersSangtani PareshBelum ada peringkat

- Old NCERT World History Ch12Dokumen208 halamanOld NCERT World History Ch12Aarti KumariBelum ada peringkat

- Wilkerson Case Study FinalDokumen5 halamanWilkerson Case Study Finalmayer_oferBelum ada peringkat

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesDari EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Color ScopeDokumen12 halamanColor Scopeprincemech2004100% (1)

- Wilkerson Company 3Dokumen2 halamanWilkerson Company 3Mohammad RakivBelum ada peringkat

- Wllkerson Company operating results valves pumps flow controllersDokumen2 halamanWllkerson Company operating results valves pumps flow controllersdp14Belum ada peringkat

- Tijuana Bronze MachiningDokumen19 halamanTijuana Bronze MachiningHari Haran43% (7)

- Seimens Electric Motor WorksDokumen5 halamanSeimens Electric Motor WorksShrey BhalaBelum ada peringkat

- Wilkerson Company case submission 4: Activity-based costing improves profitability analysisDokumen4 halamanWilkerson Company case submission 4: Activity-based costing improves profitability analysisishan.gandhi1Belum ada peringkat

- Siemens Electric Motor WorksAQ PDFDokumen3 halamanSiemens Electric Motor WorksAQ PDFHashirama SenjuBelum ada peringkat

- Destin BrassDokumen5 halamanDestin Brassdamanfromiran100% (1)

- Wilkerson ABC Costing Case StudyDokumen8 halamanWilkerson ABC Costing Case StudyParamjit Singh100% (4)

- Davey Brothers Watch Co. and Classic Pen Company Case AnalysisDokumen4 halamanDavey Brothers Watch Co. and Classic Pen Company Case Analysisabhishek pattanayakBelum ada peringkat

- Wilkerson CompanyDokumen26 halamanWilkerson CompanyChris Vincent50% (2)

- Dentin Brass Case Study3Dokumen13 halamanDentin Brass Case Study3Hosein Rahmati100% (2)

- Case AnalysisDokumen3 halamanCase AnalysisBadri100% (2)

- Management Accounting Wilkerson Company CasestudyDokumen3 halamanManagement Accounting Wilkerson Company CasestudysamacsterBelum ada peringkat

- SiemensDokumen7 halamanSiemensshshank pandeyBelum ada peringkat

- Wilkerson - Case Study1 PDFDokumen2 halamanWilkerson - Case Study1 PDFPavanBelum ada peringkat

- Appleby, Joyce. Republicanism in Old and New ContextsDokumen16 halamanAppleby, Joyce. Republicanism in Old and New ContextsMar R. CortésBelum ada peringkat

- University of South Africa Business Management TextbookDokumen153 halamanUniversity of South Africa Business Management TextbookKimmy PandayBelum ada peringkat

- Commodity Activism Cultural Resistance in Neoliberal Times by Roopali Mukherjee, Sarah Banet-WeiserDokumen316 halamanCommodity Activism Cultural Resistance in Neoliberal Times by Roopali Mukherjee, Sarah Banet-WeiserMarcela Rochetti100% (1)

- Davey Brothers Watch Co. SubmissionDokumen13 halamanDavey Brothers Watch Co. SubmissionEkta Derwal PGP 2022-24 BatchBelum ada peringkat

- Wilkerson Company ABC Cost System Exhibit 1.a Cost Pool Cost DriverDokumen2 halamanWilkerson Company ABC Cost System Exhibit 1.a Cost Pool Cost DriverLeonardoGomez100% (1)

- Wilkerson Case Assignment Questions Part 1Dokumen1 halamanWilkerson Case Assignment Questions Part 1gangster91Belum ada peringkat

- How Does Wilkerson's Existing Cost System Operate? Develop A Diagram To Show How Costs Flow From Factory Expense Accounts To ProductsDokumen4 halamanHow Does Wilkerson's Existing Cost System Operate? Develop A Diagram To Show How Costs Flow From Factory Expense Accounts To ProductsKunal DhageBelum ada peringkat

- Wilkerson CompanyDokumen4 halamanWilkerson Companyabab1990Belum ada peringkat

- Siemens CaseDokumen4 halamanSiemens Casespaw1108Belum ada peringkat

- MAC Davey Brothers - AkshatDokumen4 halamanMAC Davey Brothers - AkshatPRIKSHIT SAINI IPM 2019-24 BatchBelum ada peringkat

- Wilkerson CaseDokumen4 halamanWilkerson CaseChiara RibeiroBelum ada peringkat

- Costing Systems Reveal True Product MarginsDokumen1 halamanCosting Systems Reveal True Product Marginsfelipevwa100% (1)

- Bridgeton Industries Case Study Analysis of Overhead AllocationDokumen3 halamanBridgeton Industries Case Study Analysis of Overhead Allocationzxcv3214100% (1)

- Berkshire Toy CompanyDokumen25 halamanBerkshire Toy CompanyrodriguezlavBelum ada peringkat

- Classic Pen Company ScribdDokumen8 halamanClassic Pen Company ScribdMadhur BangurBelum ada peringkat

- Wilkerson Company Break Even Analysis for Multi-product SituationDokumen5 halamanWilkerson Company Break Even Analysis for Multi-product SituationYAKSH DODIABelum ada peringkat

- CitibankDokumen2 halamanCitibankNiks Srivastava100% (1)

- JHT's SuperMud Four Year System Project Financial AnalysisDokumen4 halamanJHT's SuperMud Four Year System Project Financial Analysisanup akasheBelum ada peringkat

- Wilkerson Company: Iim, IndoreDokumen4 halamanWilkerson Company: Iim, IndoreSwapan Kumar SahaBelum ada peringkat

- CompanyDokumen4 halamanCompanyKomalVatsaBelum ada peringkat

- Group 6 PPT CaseDokumen33 halamanGroup 6 PPT CaseRavNeet KaUr100% (1)

- Carnival Cruises Case Study For WebDokumen8 halamanCarnival Cruises Case Study For WebmayurmachoBelum ada peringkat

- Skin Care in IndiaDokumen15 halamanSkin Care in IndiamayurmachoBelum ada peringkat

- Analysis of Banking Industry PDFDokumen268 halamanAnalysis of Banking Industry PDFmayurmachoBelum ada peringkat

- Unit 8 Trade Mark Law in India: StructureDokumen11 halamanUnit 8 Trade Mark Law in India: StructuremayurmachoBelum ada peringkat

- Unit 8 Trade Mark Law in India: StructureDokumen11 halamanUnit 8 Trade Mark Law in India: StructuremayurmachoBelum ada peringkat

- Culinarian CookwareDokumen5 halamanCulinarian CookwaremayurmachoBelum ada peringkat

- MMBC Data Sheet: Barrels Needed To Recover Loss in ContributionDokumen5 halamanMMBC Data Sheet: Barrels Needed To Recover Loss in ContributionmayurmachoBelum ada peringkat

- SEBI (SAST) Regulations, 1997Dokumen75 halamanSEBI (SAST) Regulations, 1997tarun.mitra19854923Belum ada peringkat

- 27.mechanically Agitated Gas-Liquid ReactorsDokumen32 halaman27.mechanically Agitated Gas-Liquid Reactorsgauravraut1991Belum ada peringkat

- Karl Marx: Philosopher, Economist and Critic of CapitalismDokumen6 halamanKarl Marx: Philosopher, Economist and Critic of Capitalismlakshmi achayathBelum ada peringkat

- Hamacher - Guilt HistoryDokumen27 halamanHamacher - Guilt HistoryPaula KufferBelum ada peringkat

- Vietnam Case Study ReportDokumen10 halamanVietnam Case Study ReportBuğra BakanBelum ada peringkat

- Essay On The Profit Maximisation Theory of August Losch 1. Introduction To The Profit Maximization TheoryDokumen9 halamanEssay On The Profit Maximisation Theory of August Losch 1. Introduction To The Profit Maximization TheorySha Nkar JavleBelum ada peringkat

- FM FinalDokumen87 halamanFM FinalGaurav S JadhavBelum ada peringkat

- Islam, Nature and Accounting: Islamic Principles andDokumen21 halamanIslam, Nature and Accounting: Islamic Principles andkiedd_04100% (6)

- Missions of The BorderDokumen27 halamanMissions of The BorderrasrogerBelum ada peringkat

- Testing Marx With Input Output TablesDokumen27 halamanTesting Marx With Input Output TablesPaul CockshottBelum ada peringkat

- Political EconomyDokumen13 halamanPolitical EconomyRiyadBelum ada peringkat

- Southern Economic AssociationDokumen18 halamanSouthern Economic AssociationSyahms T. ThesaurusBelum ada peringkat

- Review. Colin HayDokumen24 halamanReview. Colin HayDCS Noé Hernández CortezBelum ada peringkat

- Lenin in Allah S CourtDokumen21 halamanLenin in Allah S CourtMuhammad Azam KhalidBelum ada peringkat

- Settler Colonial KDokumen12 halamanSettler Colonial KMason MitchellBelum ada peringkat

- Chapter 1 - The Changing Face of BusinessDokumen6 halamanChapter 1 - The Changing Face of BusinessArsalBelum ada peringkat

- Objective Political Science - 15 - Pol SC HelpDokumen440 halamanObjective Political Science - 15 - Pol SC Helpdrishtichhabra26Belum ada peringkat

- VELASCO SS198G Paper2Dokumen13 halamanVELASCO SS198G Paper2Vincent VelascoBelum ada peringkat

- Concepts and Indicators of DevelopmentDokumen56 halamanConcepts and Indicators of DevelopmentTyrick MinottBelum ada peringkat

- 3 1543985972 Ad1f545f2d PDFDokumen177 halaman3 1543985972 Ad1f545f2d PDFHaroon Rasheed100% (1)

- Colonialism in UgandaDokumen53 halamanColonialism in UgandaRUHANGABAHO RIDDICKSONBelum ada peringkat

- Topic 11: Industrialization and Urbanization in IndiaDokumen19 halamanTopic 11: Industrialization and Urbanization in Indiarishabkumarmp3Belum ada peringkat

- Dusanka Slijepcevic EngDokumen28 halamanDusanka Slijepcevic EngAnonymous NJbWAvnHTBelum ada peringkat

- Rice Magazine Fall 2005Dokumen56 halamanRice Magazine Fall 2005Rice UniversityBelum ada peringkat

- FanonDokumen4 halamanFanonPetronela Andreea Stoian100% (1)