Project Assignment - 3

Diunggah oleh

Derek MartinDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Project Assignment - 3

Diunggah oleh

Derek MartinHak Cipta:

Format Tersedia

Martin0

SAMPLING AND OPERATIONAL PROCEDURES & SAMPLING FOR WASTE WATER TREATMENT FACILITY

Written by Derek A. Martin Fall2011-EVR1190 10/24/11 Environmental Samplg-350653 Project Assignment #3

JEA W/WWRT-South Grid

10828 Hampton Road Jacksonville, Florida 32257 Contact: Prentiss Garraway Phone: 904-665-8125 Email: garrpm@jea.com

Martin1

Sampling and Operational Procedures for W/WWT Facility

I selected to write a report on JEAs Mandarin Waste Water Treatment Facility. I figured that this would be a fantastic topic to discuss and write about, due to the fact that it is outside of my knowledge base. I had a phone call interview with a gentleman from JEA and a site visit to the Water/Waste Water Treatment Facility or W/WWT facility. I will attempt to explain what I saw and the questions and answers I received while walking through this facility. There are many tests done at the facility in an ongoing basis as well as offsite test to monitor progress as well as any error in what is being discharged at any given time. Of course, being in the site work and underground utility business for years I understood that the underground force main and lift stations we were installing were for the purpose of pushing wastewater to these types of facilities for treatment and introduction back into the environment. I did not know how the material was necessarily cleaned or treated and did not understand the methods. When pulling into this facility in the Mandarin area, I was greeted by a great big automated gate. There was an intercom system used for access. Once I was identified the gates opened and I entered. Upon entering I noticed huge pipes made of ductile iron they had to have been at least 24-30 maybe even larger, extending from the ground upward into a building facility. I couldnt even imagine the type of force it would take to fill those pipes and send material upward into the start of this process. I parked my car and went to meet a man by the name of Prentiss Garraway. As I sat in his office I noticed maps of the serviced area which was all of mandarin. Later in the interview I had asked and he said that they also received wastewater from as far as Saint Johns County. I asked Prentiss his position and all the questions regarding his background in this field. His

Martin2

position in JEA is W/WW RT Operations Coordinator, Water/Waste Water & Reuse Treatment South Grid. He has been working with JEA for the past 10 years and in the WWT business for an overall time period of 32 years. We discussed where the sampling was done which he answered at the facility and also upstream from their discharge points as well as downstream. Some of these test samples are performed quarterly and some are done semi-annually whether they are governed by the state or federal government. I specifically asked what type of testing they performed at the facility and he explained that it is a mixture of composite testing and also grab tests. Automated computer testing is a regular thing at these facilities and is a 24 hr. process. Workers perform grab test using what he called dipoles. These were made from plastic materials and ranged in size, I guess depending on where the sample needed to be taken. All these sample were permit requirements. The automated systems used were performing test on the reuse or reclaimed water. These test were performed daily or every 24 hrs. JEA has its own lab governed by JEA and also the DEP. This lab has to be certified every year. Outside labs are used from time to time. He said that they are used for special testing that may require a shorter suspense after a significant event. There are many things that the facility is looking for on a daily basis. When asked what the tests were for, he gave me a list consisting of Nitrogen limits to the river, mercury, cyanide and carbon to name a few. When performing the grab samples they have to make an effort to get samples to the lab ASAP. These are fecal samples that have a hold time of 6 hours. These fecal tests are done to make sure that the natural enzymes are doing their job and ingesting the fecal matter. Its also to make sure that the system is limiting that matter it lets pass onto the next level of treatment. All tests are put together in a BNR Report which stands for a Biological Nutrient Removal report. This allows overseeing permitting agencies that the system is operating in the most sufficient manner. The other report is

Martin3

a DMR report which stands for Discharge Monitoring Report. This report is used for wastewater facility permitting. However, on a routine basis, self-monitoring information consist of daily, weekly, and monthly effluent quality data. This information is generally reported on either a monthly or quarterly Discharge Monitoring Report (DMR) which is issued to the permitted wastewater facility. All operation money comes from revenue by way of your JEA bill. No money comes from the state or federal government. It takes at least a year to start and finish one of these facilities, and they are grand. This particular facility is considered an A plant which means it takes a high rate of flow coming in and handles a lot of wastewater material. This material come through those large effluent pipes into the first facility called the grit system where particles are filtered and hydrogen sulfide is monitored. The sludge material goes through a secondary chamber where they are filtered one more time before being sent to the aeration chambers. Within these chambers which are at least twenty feet deep and have pumps that constantly turn the materials to keep the buildup of foam from getting too high. Mr. Prentiss called this area of the system the scum system. The materials in these chambers look like sludgy chocolate; however, dont be fooled, its someones dinner from yesterday with tampons for skewers. Not a pretty site or a good smell either I might add. Throughout this entire system are these huge 40+ grey ductile iron pipes called the Biomass Reduction System, it is in place specifically for odors. If this system wasnt in place it would stink even worse. In the last aeration chamber there are pipe all slotted with pressured air that bubbles the material like a hot soup, allowing the breakdown of particulates to be achieved. This was really unpleasant! When the material or what he called Mixed Liquor leaves this area it is sent to the primary clarifier, some of the material is sent back through the system from

Martin4

secondary pump systems to start the process all over again. The remainder that is sent to the primary clarifiers is now in a process that nature usually does, its just sped up a lot! The solids settle out and the water then skims over and sent to another stage where it is then forced pumped or syphoned up and sent through a sand filter. Half of this material is sent through as Reuse or Reclaimed water and the other is sent through and discharged back into the Saint Johns River. Here in Jacksonville, JEAs plants collect the solids once they have gone through a large UV system. This system sterilizes the viruses in the sludge therefore it doesnt allow them to grow or multiply and they die. It is then processed with polymers to bind the material and is hauled to a facility downtown where it compost and they make pellets which are used by agriculture industries as fertilizer. The name of the game is to have the lowest amount of nutrients enter back into the environment, whether its through reuse lines or the Saint Johns River. This facility was top notch and everyone I met knew there information. They were a tight knit group. I found out that this particular facility has a track record of removing 95.6% of material waste and nutrients from the water they allow to be introduced back into the system. Even though this facility has millions of gallons a day, they do their job and are compliant with local, state, and federal regulations. I had a fantastic time learning about these facilities and hope that we continue to find ways that help clean our environment for a better tomorrow.

Martin5

Sources

JEA Contact: Prentiss Garraway Phone: 904-665-8125 Email: garrpm@jea.com

Anda mungkin juga menyukai

- Maintaining Your Septic System-A Guide For Homeowners: What's Inside..Dokumen8 halamanMaintaining Your Septic System-A Guide For Homeowners: What's Inside..Fitri ArdhianBelum ada peringkat

- Managua Waste Water Treatment Plant WootDokumen5 halamanManagua Waste Water Treatment Plant WootpablolanzasBelum ada peringkat

- 331 204 PDFDokumen118 halaman331 204 PDFjose03Belum ada peringkat

- Report On The Water Treatment Process-MonaDokumen9 halamanReport On The Water Treatment Process-MonaBrandeice BarrettBelum ada peringkat

- Instructions: Watch The Video MaterialsDokumen4 halamanInstructions: Watch The Video MaterialslkjhsldBelum ada peringkat

- San Jose-Santa Clara Treatment ProcessDokumen2 halamanSan Jose-Santa Clara Treatment ProcessLishan ZhuBelum ada peringkat

- How Water Gets from Treatment Plants to Toilet BowlsDari EverandHow Water Gets from Treatment Plants to Toilet BowlsBelum ada peringkat

- TFG SARA CHARCO INIESTA ADokumen231 halamanTFG SARA CHARCO INIESTA AGowtham SinghBelum ada peringkat

- Water Supply and Distribution in The Philippines PDFDokumen3 halamanWater Supply and Distribution in The Philippines PDFJea May CallejoBelum ada peringkat

- Ae892 PDFDokumen32 halamanAe892 PDFSyafmi KarotBelum ada peringkat

- Wastewater Treatment ActivityDokumen4 halamanWastewater Treatment Activityapi-330185541Belum ada peringkat

- V2 I 304Dokumen6 halamanV2 I 304tariq76Belum ada peringkat

- Waste Water Treatment PlantDokumen51 halamanWaste Water Treatment PlantenockelisantemsangiBelum ada peringkat

- BEC710 Field Report - 2006001699Dokumen15 halamanBEC710 Field Report - 2006001699DeepakRavindraPrasadBelum ada peringkat

- Honest Information About Your Septic System - YOU Make The Decision!Dokumen4 halamanHonest Information About Your Septic System - YOU Make The Decision!Tally AnuBelum ada peringkat

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDokumen10 halamanName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentNicoleZhangBelum ada peringkat

- Homeowner Guide LongDokumen19 halamanHomeowner Guide LongAdrian MillerBelum ada peringkat

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDokumen10 halamanName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentNicoleZhangBelum ada peringkat

- Dissertation On Waste Water TreatmentDokumen5 halamanDissertation On Waste Water TreatmentGhostWriterForCollegePapersFargo100% (1)

- Installation GuideDokumen7 halamanInstallation GuideJake SmithBelum ada peringkat

- Sewerage System PDFDokumen2 halamanSewerage System PDFJatteah Suib CalulongBelum ada peringkat

- 04DEC9RD Research DigestDokumen12 halaman04DEC9RD Research DigestDeveshDharDwivediBelum ada peringkat

- Groundwater Recharge Info Fact SheetDokumen6 halamanGroundwater Recharge Info Fact SheetStukineBelum ada peringkat

- Salmon Creek Water Conservation: Residential Self-Survey For Efficient Water Use in Coastal California CommunitiesDokumen15 halamanSalmon Creek Water Conservation: Residential Self-Survey For Efficient Water Use in Coastal California CommunitiesSalmon Creek Watershed CouncilBelum ada peringkat

- Comparison of Methods of Sewage PurificationDari EverandComparison of Methods of Sewage PurificationBelum ada peringkat

- OM Extended Aeration PDFDokumen25 halamanOM Extended Aeration PDFHendra SusantoBelum ada peringkat

- Assessment of Grease Interceptor Performance PDFDokumen128 halamanAssessment of Grease Interceptor Performance PDFvacomanoBelum ada peringkat

- CASTRO ChEA 2203 Group 1 Midterm ExamDokumen3 halamanCASTRO ChEA 2203 Group 1 Midterm ExamRoyce Matthew CastroBelum ada peringkat

- N E W S: IrrigationDokumen2 halamanN E W S: IrrigationKings River Conservation DistrictBelum ada peringkat

- Automated Water Level Controller For Overhead Water Storage.Dokumen60 halamanAutomated Water Level Controller For Overhead Water Storage.samueljerryjajaBelum ada peringkat

- EPRI Evaluation of Coal Combustion Product Damage CasesDokumen178 halamanEPRI Evaluation of Coal Combustion Product Damage CasesPenjual AirBelum ada peringkat

- Reconsidering Rotating Biological ContactorsDokumen11 halamanReconsidering Rotating Biological ContactorsJohn WellardBelum ada peringkat

- 2012-Jan-26 Epa Notifies Bia Leachfield A Failing Pine View Estates SewerDokumen1 halaman2012-Jan-26 Epa Notifies Bia Leachfield A Failing Pine View Estates Sewertsmith-6Belum ada peringkat

- Treatment Options - LeafletDokumen2 halamanTreatment Options - LeafletdeephamsconsultationBelum ada peringkat

- Banks DIH Field Trip ReportDokumen10 halamanBanks DIH Field Trip ReportTakchandra JaikeshanBelum ada peringkat

- Major Project Part-1Dokumen22 halamanMajor Project Part-1api-387022302100% (2)

- Greywater ResearchDokumen37 halamanGreywater ResearchJanine MasayonBelum ada peringkat

- In Search of Better Water Quality Through Continuous MonitoringDokumen7 halamanIn Search of Better Water Quality Through Continuous MonitoringRaúl RivasBelum ada peringkat

- Active Sludge PDFDokumen8 halamanActive Sludge PDFDark_KiroBelum ada peringkat

- Visit ReportDokumen9 halamanVisit Reportrohit Sharma100% (1)

- Pollution in California's Drinking Water Pollution in California's Drinking WaterDokumen14 halamanPollution in California's Drinking Water Pollution in California's Drinking Waterapi-549042757Belum ada peringkat

- T FoskettDokumen18 halamanT FoskettkuaBelum ada peringkat

- May - June 2005 Irrigation Newsletter, Kings River Conservation District NewsletterDokumen2 halamanMay - June 2005 Irrigation Newsletter, Kings River Conservation District NewsletterKings River Conservation DistrictBelum ada peringkat

- Term PaperDokumen34 halamanTerm PaperGourav GuptaBelum ada peringkat

- Wiley Journal (American Water Works Association)Dokumen7 halamanWiley Journal (American Water Works Association)kudzaiishe musonaBelum ada peringkat

- Buildings and Facilities, Plant LocationDokumen9 halamanBuildings and Facilities, Plant LocationJames Carl GarsulaBelum ada peringkat

- Types of Water Treatment Plants and Their ApplicationsDokumen5 halamanTypes of Water Treatment Plants and Their Applicationsvishal kashyapBelum ada peringkat

- Waste and Wastewater Trip ReportDokumen15 halamanWaste and Wastewater Trip ReportAira Ariana100% (4)

- Waste Water TreatmentDokumen7 halamanWaste Water TreatmentBusi_SeleshoBelum ada peringkat

- History of Nano FiltrationDokumen42 halamanHistory of Nano FiltrationKieran Sexton100% (2)

- Chapter 2Dokumen7 halamanChapter 2Edita O PanuncioBelum ada peringkat

- Optimisation - of - Water Treatment SystemDokumen49 halamanOptimisation - of - Water Treatment SystemChijioke ObiBelum ada peringkat

- Epa Tank Resuspension PDFDokumen101 halamanEpa Tank Resuspension PDFZeroRecoBelum ada peringkat

- Management of Onsite Sewage Disposal Systems in Jefferson CountyDokumen3 halamanManagement of Onsite Sewage Disposal Systems in Jefferson CountyMuhammad Suko Adi PratamaBelum ada peringkat

- God Reproducing Himself in UsDokumen6 halamanGod Reproducing Himself in UsLisa100% (1)

- The Philippine GovernmentDokumen21 halamanThe Philippine GovernmentChristel ChuchipBelum ada peringkat

- Random Questions From Various IIM InterviewsDokumen4 halamanRandom Questions From Various IIM InterviewsPrachi GuptaBelum ada peringkat

- Derivation Bragg's Snell Law PDFDokumen4 halamanDerivation Bragg's Snell Law PDFVaswati BiswasBelum ada peringkat

- University of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSDokumen3 halamanUniversity of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSPhilip Pearce-PearsonBelum ada peringkat

- VTB Datasheet PDFDokumen24 halamanVTB Datasheet PDFNikola DulgiarovBelum ada peringkat

- ING C1 CO JUN2016 CorrectorDokumen6 halamanING C1 CO JUN2016 CorrectoraciameBelum ada peringkat

- Unit-5 Harmonics & FiltersDokumen25 halamanUnit-5 Harmonics & FiltersBhanu100% (1)

- Kingroon ConfiguracoesDokumen3 halamanKingroon ConfiguracoesanafrancaBelum ada peringkat

- Speaking RubricDokumen1 halamanSpeaking RubricxespejoBelum ada peringkat

- Chudamani Women Expecting ChangeDokumen55 halamanChudamani Women Expecting ChangeMr AnantBelum ada peringkat

- Using Your Digital Assets On Q-GlobalDokumen3 halamanUsing Your Digital Assets On Q-GlobalRemik BuczekBelum ada peringkat

- Materials Management - 1 - Dr. VP - 2017-18Dokumen33 halamanMaterials Management - 1 - Dr. VP - 2017-18Vrushabh ShelkarBelum ada peringkat

- A Method For Prediction of Gas/Gas Ejector PerformanceDokumen6 halamanA Method For Prediction of Gas/Gas Ejector PerformancedhavaleshBelum ada peringkat

- Essay On Stem CellsDokumen4 halamanEssay On Stem CellsAdrien G. S. WaldBelum ada peringkat

- Collins Ks3 Science Homework Book 3Dokumen5 halamanCollins Ks3 Science Homework Book 3g3pz0n5h100% (1)

- MSDS Leadframe (16 Items)Dokumen8 halamanMSDS Leadframe (16 Items)bennisg8Belum ada peringkat

- MCC333E - Film Review - Myat Thu - 32813747Dokumen8 halamanMCC333E - Film Review - Myat Thu - 32813747Myat ThuBelum ada peringkat

- Iso 22301 2019 en PDFDokumen11 halamanIso 22301 2019 en PDFImam Saleh100% (3)

- Data Mining in IoTDokumen29 halamanData Mining in IoTRohit Mukherjee100% (1)

- Sub-Wings of YuvanjaliDokumen2 halamanSub-Wings of Yuvanjalin_tapovan987100% (1)

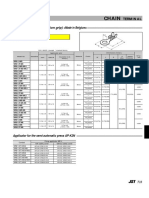

- Chain: SRB Series (With Insulation Grip)Dokumen1 halamanChain: SRB Series (With Insulation Grip)shankarBelum ada peringkat

- 2023 2024 Syllabus PDFDokumen23 halaman2023 2024 Syllabus PDFRika DianaBelum ada peringkat

- Pipe Freezing StudyDokumen8 halamanPipe Freezing StudymirekwaznyBelum ada peringkat

- What Is Urban PlanningDokumen33 halamanWhat Is Urban PlanningDivine Grace FernandoBelum ada peringkat

- TESP12201R0Dokumen20 halamanTESP12201R0Muhammad AliBelum ada peringkat

- EDAG0007Dokumen5 halamanEDAG0007krunalBelum ada peringkat

- Circuit Construction: Assignment 3Dokumen45 halamanCircuit Construction: Assignment 3ali morisyBelum ada peringkat

- Action Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorDokumen1 halamanAction Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorEdelmar BenosaBelum ada peringkat

- UpdateJul2007 3julDokumen10 halamanUpdateJul2007 3julAnshul SinghBelum ada peringkat