Ground Earth Intigrity

Diunggah oleh

Krishan Kumar SharmaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ground Earth Intigrity

Diunggah oleh

Krishan Kumar SharmaHak Cipta:

Format Tersedia

Ground Grid Integrity

by Jeff Jowett Megger

Tech Tips

he testing of grounding electrodesgrids, meshes, and the likeis most

often considered in terms of a resistance test. That is to say, the resistance

carefully plotted point typically referred to as remote earth or infinite earth. The earth without exceeding the operating tolerances of any protected equipment

of the surrounding environment to current flow to some arbitrary or

ground grid is intended to serve the dual purpose of carrying currents into the while assuring that personnel in the vicinity are not exposed to electric shock as would result from excessive step or touch potentials. Resistance tests indicate the overall capability of the grid in this regard: its electrical relationship to its grid itself. environment. But there remains the question of the internal condition of the Out of sight, out of mind? Buried under ground, the grounding electrode doesnt call attention by mere visual inspection, which is the first step in most electrical maintenance. Though they may seem inert, grounding electrodes are subject to their own unique set of stresses, just like other electrical equipment. Fault clearance and lightning protection can severely damage a grid or mesh, separating individual elements, interrupting continuity, and introducing high resistance across bonds. But in the meantime, the electrode may have cleared the fault perfectly well, leaving no obvious indication that it has been compromised. A subsequent event may not be afforded the same level of protection. Furthermore, a less dramatic but more persistent force of deterioration is the incessant process of corrosion and weather. Freezing and expansion exert pressures that can break apart a grid. Ironically, the best grounding soils are also the most corrosive. Low resistivity soil that facilitates the flow of fault current also promotes electrolytic current that eats away at the metallic structure of a grounding electrode. Use of dissimilar metals hastens the process. Rods have been known to last as little as two years, with typically a risk of at least some corrosion effects being present after four.1 A standard ground resistance test just looks at voltage drop across the surrounding soil and gives no measure of the physical condition of the electrode itself.

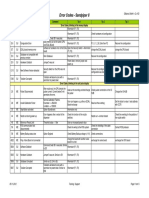

The grounding electrode typically is carrying only noise, but must be able to accommodate worst case conditions of high current flow when called on line during an event. Therefore, to test grid integrity, the tester must be able to produce high current. A grid tester works similarly to a ground tester in that it supplies current and measures voltage drop across the test item. In this case, the test item is the grid, whereas in a ground test, it includes the surrounding soil. It is dissimilar in that the grid tester typically employs an industry standard of 300 amperes, whereas a ground tester operates on the milliampere level. Rather than calculating and displaying resistance, the grid tester evaluates the change in current flow. Test equipment consists of a variable current source requiring on the order of a 10.5 kVA capability, operated from a 50 ampere, 240 Vac source. Test leads can range anywhere from 10 to 100 feet of 2/0 welding cable. A reference ground is first established, preferably a transformer neutral. The leads are connected, one to the test ground and the other to the reference ground below any bonding connections (Fig. 1). The tester is then energized and adjusted to pass 300 amperes via the reference ground through the grid under test for a duration of three minutes. Fall 2008 NETA WORLD

www.netaworld.org

A B

C D

Measurements after Test Hook-Up Figure 1

A clamp-on ammeter is then used to measure current at critical points around this system: through the reference ground above (A) and below (B) the attachment of the test lead and on the opposite side of the system through the test ground both above (C) and below (D) the lead connection. Current readings are recorded, and the tester indicates voltage drop across the system. Voltage drop of the leads themselves is also measured. This is done by disconnecting from the test item, shorting the leads together, and passing 300 amperes for three minutes, noting the voltage. This value is then subtracted from the voltage drop taken during the test to isolate voltage drop across the grid from the lead contribution. For an indication of acceptable continuity, a value of no more than 1.5 volts per 50 feet of straight line ground path should be measured. The straight line ground path is the distance between the two lead connections. Though valuable, this method is not rigorously precise, and so a redundant system of evaluation exists based on current return. For single driven electrodes, at least 200 amperes should return to the source via the ground path. For mats and grids, at least half of the current must return via the ground path. If not, it indicates a potentially bad connection and should be dug up for repair. What is the method that makes this procedure successful? What happened to Kirchhoff s laws? Kirchhoff s first law states that the sum of the currents flowing from a point in a circuit equals the current flowing to that point, i.e., current is a precisely measurable quantity that doesnt just disappear into thin air. Operation of the high-current grid tester is based on an application of Kirchhoff s first law to

account for all the current that is injected into the system. By injecting a substantial amount of current, it becomes comparatively easy to note its division along stress lines. It is expected that most of the current will follow the shortest, straightest path (least resistance) between the two test points. The ammeter readings indicate to what extent this is occurring. Discontinuity or high resistance connections anywhere between the test points will divert proportionate amounts of current through the rest of the system. Substations are multiply-bonded into a Faraday cage configuration, and other facilities with complex or extensive grids are also typically connected to the electrical system at multiple points. Therefore, it cannot be presumed that all current is flowing in a particular path. Current flowing from the tester must first be measured for any diversion into the system (point A, Fig. 1), and to determine the amount flowing into the grid (B). This value is then compared to the amount returning through the test ground (D), and that which is diverted through parallel paths into the rest of the system (C). To illustrate, an example of an acceptable test is shown in Fig. 2. Pretest conditions indicate typical values of current flowing on the system. The distance between the test connections is measured, and the voltage drop across the leads is taken from the tester. Performance of the test then indicates 270 amperes flowing into the grid, with some diversion through the reference ground back into the electrical system. The ground connection being measured then shows 280 amperes returning (test current enhanced by some noise on system). Since this is a grid, the industry standard calls for at least a 150 ampere return, so this is well exceeded. Voltage drop across the test was measured at 7.9, but as 7.5 of this was lead resistance, only 0.4 volt is across the tested path. This falls within the allowance for 1.5 volts per 50 feet (1.5/50 x 15 = 0.45). The tested ground path passes both criteria with acceptable values. A failed test is outlined in Fig. 3. Here, only a negligible amount of current returns through the tested ground connection, while 280 amperes flow through building structure via a parallel connection. Voltage drop calculates to 8.1 (15.6 7.5), which fails the requisite criterion (100 feet allows 2 x 1.5 = 3 volts). If the test setup were switched to the other leg of the structure, results would be essentially reversed, so the ground connection on the left would have to be dug up and inspected for a fault in continuity. Similarly, ground cables, clamps and ferrules can be tested prior to installation using the same equipment and parameters. Cable manufacturers specifications should provide proper voltage drop. For instance, 300 amperes on 100 feet of cable yields 30,000 ampere-feet. For 4/0 bare copper, the voltage drop should be 4.1 volts. For a 10 foot section, therefore, the voltage drop would be 0.41. If manufacturers guidelines are not available, the following www.netaworld.org

NETA WORLD Fall 2008

Measurements before Test Hook-Up Figure 2 1. 2. 3. 4. Current in transformer neutral (reference) = 82 amperes Current in the post ground wire = 6 amperes Distance between reference ground and post ground = 15 feet Voltage drop in test leads with 300 amperes = 7.5 volts Measurements before Test Hook-Up 1. 2. 3. 4.

Hook-Up and Connections Figure 3 Current in transformer neutral (reference) = 82 amperes Current in frame ground = none Distance between reference ground and frame ground = 100 feet Voltage drop of the test leads with 300 amperes = 7.5 volts Measurement before Test Hook-Up

1. 2. 3. 4. 5.

Measurements after Test Hook-Up and with 300 Amperes Flowing in the Test Circuit (i.e., test set meter reading) Current flow in reference ground to grid = 270 amperes Current flow in reference ground to T(X) = 50 amperes Current flow from grid to post ground = 280 amperes Current flow from the structure to post ground = 1 ampere Voltage reading at the test set meter = 7.9 volts

1. 2. 3. 4. 5.

Measurement after Test Hook-Up and with 300 Amperes Flowing in the Test Circuit (i.e., test set meter reading) Current flow in reference ground to grid = 270 amperes Current flow in reference ground to T(X) = 50 amperes Current in frame ground from grid = 2.5 amperes Current flow in frame ground from the structure = 280 amperes Voltage reading at the test set meter = 15.6 volts

formula can be used to get an approximation of voltage drop, bearing in mind that manufacturers specifications are always preferable: V = (2 x I x L x R)/1000 where, I = test current L = length R = resistance per 1000 feet Specific code requirements are not in effect, but standards exist that provide guidelines for grid testing. Notably, NFPA70E-1983, Part I, Chapter 2, Section F, Item 4 outlines low-impedance continuity, and Part III, Chapter I, Section B, Item 1 calls for continuous maintenance. OSHA has adopted this as a safety requirement, and IEEE 81 references testing of grid structure. By this method, each ground connection around a substation or other facility can be tested. Faults are not precisely pinpointed, but by isolating www.netaworld.org

a faulty current path, the work of excavation and repair is markedly reduced.

Lyncole XIT Grounding Electrical Equipment Testing and Maintenance, A. S. Gill, Prentice Hall

1

Jeffrey R. Jowett is Senior Applications Engineer for Megger in Valley Forge, Pennsylvania, serving the manufacturing lines of Biddle, Megger, and Multi-Amp for electrical test and measurement instrumentation. He holds a BS in Biology and Chemistry from Ursinus College. He was employed for 22 years with James G. Biddle Co. which became Biddle Instruments and is now Megger.

Fall 2008 NETA WORLD

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- CcaDokumen36 halamanCcaKrishan Kumar SharmaBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Bharat Ka Sanvidhan Part 8Dokumen20 halamanBharat Ka Sanvidhan Part 8Krishan Kumar SharmaBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Rajasthan Service Rules Cover Key ReformsDokumen381 halamanRajasthan Service Rules Cover Key ReformsKrishan Kumar SharmaBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- RERC SAFETY STANDARDSDokumen42 halamanRERC SAFETY STANDARDSKrishan Kumar SharmaBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Bharat Ka Sanvidhan Part 6Dokumen26 halamanBharat Ka Sanvidhan Part 6Krishan Kumar SharmaBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Bharat Ka Sanvidhan Part 9Dokumen24 halamanBharat Ka Sanvidhan Part 9Krishan Kumar SharmaBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Employee Service RegulationDokumen173 halamanEmployee Service RegulationKrishan Kumar Sharma50% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Political Philosophy of the Indian ConstitutionDokumen22 halamanPolitical Philosophy of the Indian ConstitutionKrishan Kumar SharmaBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Bharat Ka Sanvidhan Part 7Dokumen26 halamanBharat Ka Sanvidhan Part 7Krishan Kumar SharmaBelum ada peringkat

- Tnerc CodesDokumen84 halamanTnerc CodesBala SubramanianBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- CLRC 08-09 & 09-10Dokumen54 halamanCLRC 08-09 & 09-10Krishan Kumar SharmaBelum ada peringkat

- Power Cable Fault Location TrainingDokumen4 halamanPower Cable Fault Location TrainingKrishan Kumar SharmaBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Cable Fault Locators SPG40 Cable Fault Location Cable Fault LocatorsDokumen1 halamanCable Fault Locators SPG40 Cable Fault Location Cable Fault LocatorsKrishan Kumar SharmaBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Effectiveness of Sootblowers in Boilers Thermal Power StationDokumen7 halamanEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123Belum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Busway SpecificationDokumen6 halamanBusway SpecificationNATHANBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- FMC Product OverviewDokumen32 halamanFMC Product OverviewGustavoSilvinoSilvinoBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Water Wash Procedure For EconomizerDokumen3 halamanWater Wash Procedure For EconomizerRajendra100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Bel Ray BrochureDokumen20 halamanBel Ray BrochureaditBelum ada peringkat

- Kaise Batera Agm 12v 200ahDokumen2 halamanKaise Batera Agm 12v 200ahJOHN FREDY IBAÑEZ HERNANDEZBelum ada peringkat

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDokumen5 halamanTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- ONGC Ar201718Dokumen454 halamanONGC Ar201718Vrind JainBelum ada peringkat

- PotentiometryDokumen27 halamanPotentiometryShafique Ahmed100% (2)

- Pump Inlet Piping DesignDokumen2 halamanPump Inlet Piping DesignWayaya WaziwupyaBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Inter-Row Spacing Calculator by SeanwhiteDokumen22 halamanInter-Row Spacing Calculator by SeanwhiteAMIRBelum ada peringkat

- 30 International Cablemakers Federation Schroth PDFDokumen25 halaman30 International Cablemakers Federation Schroth PDFsajuaanalsaBelum ada peringkat

- Sabah TL 1Dokumen1 halamanSabah TL 1MT HazrieBelum ada peringkat

- Kia Picanto II Gen. (TA) EWD - Engine Control System (General Head Lamp Type)Dokumen9 halamanKia Picanto II Gen. (TA) EWD - Engine Control System (General Head Lamp Type)mutaz ahmed100% (4)

- Produktkatalog 2019 WebDokumen280 halamanProduktkatalog 2019 WebbagastcBelum ada peringkat

- Radiography Sai KripaDokumen4 halamanRadiography Sai KripaSarthak EnterprisesBelum ada peringkat

- An Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementDokumen15 halamanAn Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementMamta AgarwalBelum ada peringkat

- Practice HSC Papers General 2Dokumen47 halamanPractice HSC Papers General 2DarrenPurtillWrightBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Introduction To Batteries - BatteryDokumen17 halamanIntroduction To Batteries - BatteryJ dixojoBelum ada peringkat

- WASHING-Pearl GlobalDokumen8 halamanWASHING-Pearl Globalkanchanp93Belum ada peringkat

- Technical Specification TREO CF I48CA1Dokumen1 halamanTechnical Specification TREO CF I48CA1Razvan CorciuBelum ada peringkat

- Cutting Torch InstructionDokumen2 halamanCutting Torch Instructionfoxtrot mikeBelum ada peringkat

- Free Energy Devices Zero PDokumen8 halamanFree Energy Devices Zero PibeskosBelum ada peringkat

- Fundamental Laws of Chemistry Explained Atomic Theory DevelopmentDokumen10 halamanFundamental Laws of Chemistry Explained Atomic Theory DevelopmentDonni MaruliBelum ada peringkat

- ME1130 Mechanism of SolidificationDokumen15 halamanME1130 Mechanism of SolidificationShivam RajBelum ada peringkat

- Ship EducationDokumen34 halamanShip EducationBabu MuruganBelum ada peringkat

- IPL, Briggs, 14B907-0110-B1, 950 Series, EngineDokumen25 halamanIPL, Briggs, 14B907-0110-B1, 950 Series, EngineGiacomo DesideriBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Agenda Dynamics and Policy Subsystems Baumgartner1991Dokumen32 halamanAgenda Dynamics and Policy Subsystems Baumgartner1991Gustavo Decap AgüeroBelum ada peringkat

- Module 2: Diffusion: Lecture No. 5Dokumen2 halamanModule 2: Diffusion: Lecture No. 5Mehwish NoorBelum ada peringkat

- Effect of Clearance On Volumetric Efficiency in 2D Piston PumpsDokumen12 halamanEffect of Clearance On Volumetric Efficiency in 2D Piston PumpsSiddharth SinghBelum ada peringkat

- Build Your Own Electric Vehicle, Third EditionDari EverandBuild Your Own Electric Vehicle, Third EditionPenilaian: 4.5 dari 5 bintang4.5/5 (3)