Eprosys One Page Catalog

Diunggah oleh

ushashaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Eprosys One Page Catalog

Diunggah oleh

ushashaHak Cipta:

Format Tersedia

REPAIR

S

TESTING&

CALIBRATION

RETROFITTI

NG

ENGG & CONSULTANCY

SERVICES

PANEL

S

Eprosys Engineering Connsultants India Pvt.Ltd.

(Our motto is to provide quality services striving for ON TIME & ZERO ERROR execution of orders)

Eprosys, a professionally managed Engineering Services company, carries forward ten (10) years experience providing

specialised engineering services in the field of Electrical Power System Protection & Controls.

We offer technical excellence through experienced & trained personnel and use of state of art equipment.

EPROSYS offers a variety of Electrical engineering services for all sectors. These services include:

1. Electrical Power Systems:

I. Power System Protection Relays Working as Authorised Service Centre for

SEIL (earlier, AREVA /ALSTOM / English Electric)

- Repair & Modification of only SEIL/ AREVA /ALSTHOM /EE Relays.

- Testing & Calibration of relays & Protection System of any make.

- Retrofitting & refurbishing of old Technology relays & system of any make with

new technology products.

- Sale of Spare Relays.

- Protection coordination & other Application engineering services

- Training.

II. Other Testing & Commissioning Services:

- Primary injection testing.

- Testing of CTs, PTs, Transducers and Meters.

- Can undertake turnkey testing of substation equipment as a single point agency.

- Commissioning of protection system relays of all technologies for

Electromechanical to Numerical.

2. Power System Engineering & Consultancy:

- Design, Detailed Engineering for Electrical Power Distribution System.

- Provide Services for Selection, Supply, Erection, Testing & Commissioning of

Switchgear, Protection gear and Control gear, Transformer & other Electrical

Equipment.

- Consultancy services in Power Systems like Fault Analysis, Incident Investigation,

Protection Relay Coordination, T&D loss reduction.

3. Provide technical services related to SCADA systems.

4. Provide services for turnkey installation & supply of GIS Substation.

5. PANELS:

I. Design, Sizing, Detailed Engineering, manufacture(organization), Installation and

Commissioning of PCC, MCC Inter connection Panels and Control panels.

II. Design, Engineering & Supply of:

- DC System Panels (Battery Charging).

- Synchronising Panels.

- AMF Panels.

6. TRADING: We also do trading of Engineering Products.

OUR STRENGTHS

1. Flexibility and quick response time.

2. Repair & testing by skilled technicians trained at AREVA/SCHNEIDER using state of art

equipment duly calibrated.

3. Repair of SCHNEIDER/AREVA/EE make protection relays using genuine spare parts and

procedure & tools as used by AREVA including checking contact alignment and contact

pressure.

4. Facility to test by both primary injection and secondary injection method.

5. Can test any make & any type relay ie., Areva, ABB, Siemens, GE Multilin, Easun

Reyrolle, Schneider, C&S, Ashida etc.

6. We emphasise on thorough cleaning of relays for dust & moisture contamination

which is very important in our tropical climate.

7. We test relays over entire range & not at the settings only to ensure relay performs

correctly over the entire range.

8. Single point testing agency with capability to organize testing of complete Distribution

substation equipment.

9. Our engineers & Technicians pin point the correctness of settings & diagnose

accurately the faults.

10. Our retrofit solutions uses fitment methods and mounting plate arrangement such

that the time required at site is optimum and panel aesthetics are maintained.

11. We use software like ETAP for Power system analysis for study of power coordination,

short circuit analysis, load flow studies & providing protection settings.

12. We have expertise and rich experience in system design, detailed engineering and

execution of all types of LT control, Distribution, PLC & SCADA and instrumentation

panels.

13. Can be single point agency for supply of all items required for substation operation

under our TRADING activity & serve customers in totality for power system protection

& control needs.

PETPOuIT EOAYTIONE:

As the name suggests Retrofit involves replacing old technology systems with new technology

systems using the existing infrastructure.

What is Retrofit?

R Re-engineering

E Efficient in operation

R Technology at minimum cost

R Robust

O Optimization

Need for Retrofit?

A green field project can adopt all the latest process technologies and also the latest

protection relays in its substation. However, the expansion projects in the existing plant face

several criticalities.

The newly added plant will have the latest systems, also the latest technology protection

relays, whereas, the old plant continues to be straddled with the old protection relays.

Replacement of old panels with totally new panels entails heavy capital expenditure for which

budget allocation is not easy. It is here that our customized retrofit solutions fit in seamlessly.

In retrofit, only the relays & systems need to be upgraded or replaced in the existing panels

using latest microprocessor based relays.

This makes you FIT

to be in the

business.

Advantages of Retrofit Solutions:

At EPROSYS we have developed expertise to provide a very cost effective Retrofit Solution in

the field Power System Protection Relays.

- Simple & economic way of modernizing old panels without incurring large CAPEX

- No Need to change the panels at the same time, get the advantage of new technology

of multifunction, fault diagnosis, fault & event recording, measurement &

communication features in single relay as against host of electromechanical relays for

same functions.

The protection relays get integrated into CCMMS for continuous monitoring and

accessing real time information on the state of protection relay.

Thus there is saving inspace apart from achieving the basic features of selectivity,

sensitivity, reliability & flexibility using software.

- Retrofit solution does not call for changing the busbar & cable layout.

- Results in cutting down cost on maintaining inventory for large number of spare

electromechanical relays & their components.

- Reduced maintenance costs with reduction in variety of relays in plant & automation

of plant.

- Changing the old relays in stages will help the user develop confidence on new

technology relays.

Retrofit Activity Implementation:

Stage-1:

- Site visit for Collection of Data

- Preparation of Engineering

Drawings.

- Project plan for Activity

Schedule.

- Setting calculation for Relays.

Stage-2:

- Dismantling existing Relays.

- Mounting of front panel/plates if

required.

- Assemble of new Relays.

- Modification and re-wiring of

the existing schemes.

- Pre-commissioning and

commissioning with retrofitted

schemes.

- Training on relays.

.

Our Clientele for Retrofit Jobs include:

Our Expertise:

- With the knowledge & experience

gained in protection engineering, our

application / Service engineer will select

& recommend the most optimum new

technology (Microprocessor based)

relays & system for your requirements.

- With our in depth knowledge &

experience in panels, we work out the

detailed design, layout wiring and all

engineering details for smooth

execution.

- High calibre CAD engineers for preparing

the scheme & engineering

documentation for error free

implementation.

- We have developed special mechanical

hardware which preserves the aesthetics

of panels.

- Technically qualified & experienced in

assembly & wires for Retrofit.

- Thus, as a single agency we can take up

retrofitting jobs on a turnkey basis.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Class Prophecy 012Dokumen11 halamanClass Prophecy 012Mythical Persues100% (2)

- The Unseelie Prince Maze of Shadows Book 1 by Kathryn AnnDokumen267 halamanThe Unseelie Prince Maze of Shadows Book 1 by Kathryn Annanissa Hri50% (2)

- Pathophysiology of Cardiogenic Pulmonary EdemaDokumen8 halamanPathophysiology of Cardiogenic Pulmonary EdemaLili Fiorela CRBelum ada peringkat

- 797B Commissioning Guidebook 07 (Procesos)Dokumen65 halaman797B Commissioning Guidebook 07 (Procesos)wilmerBelum ada peringkat

- 2015 Nutrition Diagnosis Terminologi 2015Dokumen9 halaman2015 Nutrition Diagnosis Terminologi 2015Vivin Syamsul ArifinBelum ada peringkat

- ACCA P1 Governance, Risk, and Ethics - Revision QuestionsDokumen2 halamanACCA P1 Governance, Risk, and Ethics - Revision QuestionsChan Tsu ChongBelum ada peringkat

- PQ of Vial Washer Ensures Removal of ContaminantsDokumen25 halamanPQ of Vial Washer Ensures Removal of ContaminantsJuan DanielBelum ada peringkat

- Securifire 1000-ExtractedDokumen2 halamanSecurifire 1000-ExtractedWilkeey EstrellanesBelum ada peringkat

- Hydroponics SummaryDokumen4 halamanHydroponics SummaryJose NovoaBelum ada peringkat

- Optra - NubiraDokumen37 halamanOptra - NubiraDaniel Castillo PeñaBelum ada peringkat

- Pathophysiology of Uremic EncephalopathyDokumen5 halamanPathophysiology of Uremic EncephalopathyKristen Leigh Mariano100% (1)

- High Volume InstrumentDokumen15 halamanHigh Volume Instrumentcario galleryBelum ada peringkat

- JVW 110Dokumen2 halamanJVW 110Miguel Leon BustosBelum ada peringkat

- Coca Cola Live-ProjectDokumen20 halamanCoca Cola Live-ProjectKanchan SharmaBelum ada peringkat

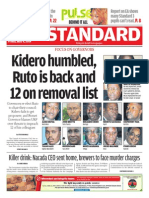

- The Standard 09.05.2014Dokumen96 halamanThe Standard 09.05.2014Zachary Monroe100% (1)

- M Audio bx10s Manuel Utilisateur en 27417Dokumen8 halamanM Audio bx10s Manuel Utilisateur en 27417TokioBelum ada peringkat

- Parts of A Computer With Their FunctionsDokumen19 halamanParts of A Computer With Their FunctionsJaried SumbaBelum ada peringkat

- Drug Delivery Technologies and Future DirectionsDokumen14 halamanDrug Delivery Technologies and Future Directionsraju1559405Belum ada peringkat

- Bylaw 16232 High Park RezoningDokumen9 halamanBylaw 16232 High Park RezoningJamie_PostBelum ada peringkat

- Mod. 34 Classic Compact T06Dokumen4 halamanMod. 34 Classic Compact T06Jaime Li AliBelum ada peringkat

- DesignWS P1 PDFDokumen673 halamanDesignWS P1 PDFcaubehamchoi6328Belum ada peringkat

- List of OperationsDokumen3 halamanList of OperationsGibs_9122100% (3)

- Sss PDFDokumen1 halamanSss PDFROVI ROSE MAILOMBelum ada peringkat

- Writing Lesson Plan LMDokumen6 halamanWriting Lesson Plan LMapi-457032696Belum ada peringkat

- ADD MATH ProjectDokumen13 halamanADD MATH Projectmegazat27Belum ada peringkat

- List of Psychotropic Drugs Under International ControlDokumen32 halamanList of Psychotropic Drugs Under International ControlRadhakrishana DuddellaBelum ada peringkat

- Introduction To South Korean History, Cultures, Traditions, & BeliefsDokumen8 halamanIntroduction To South Korean History, Cultures, Traditions, & BeliefsKatriceBelum ada peringkat

- CONTACT DETAILS HC JUDGES LIBRARIESDokumen4 halamanCONTACT DETAILS HC JUDGES LIBRARIESSHIVAM BHATTACHARYABelum ada peringkat

- FILM STUDIES CORE COURSE GUIDEDokumen230 halamanFILM STUDIES CORE COURSE GUIDEAmaldevvsBelum ada peringkat

- Chiller Carrier - 30gn-9siDokumen28 halamanChiller Carrier - 30gn-9siZJ Limited (ZJLimited)Belum ada peringkat