Honeywell 4219 Install Guide

Diunggah oleh

Alarm Grid Home Security and Alarm MonitoringDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Honeywell 4219 Install Guide

Diunggah oleh

Alarm Grid Home Security and Alarm MonitoringHak Cipta:

Format Tersedia

4219 Wired Zone Expander Module

INSTALLATION AND SETUP GUIDE

GENERAL INFORMATION

This module adds up to eight end-of-line resistor supervised zones to compatible control/communicators via the controls keypad wiring. The module may be mounted within the controls cabinet (if room permits), or remotely. If mounted remotely, there are provisions to tamper protect the unit. Communication to the module is supervised so that it cannot be disconnected from the keypad wiring without detection by the control. If the wiring is cut, a tamper alarm or signal will result, to indicate that this device (and possibly other similarly connected devices) has become inoperative. IMPORTANT: Some carbon monoxide detectors may not be compatible with the Honeywell 4219 hardwire zone expanders. When using carbon monoxide detectors in systems that support the 4219 zone expanders, install the detectors only on the basic hardwire zones of the system control panel, and NOT on the zone expanders.

CE

For CE installations ADEMCO N6361 EMI suppression bead is required. Refer to the N6361 installation guide for wire routing instructions.

INSTALLATION

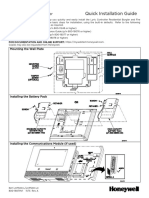

1. Power should be disconnected before proceeding. 2. Be sure to mount the 4219 before making any wire connections. When the module is mounted remotely, holes on the back of the modules housing permit it to be mounted horizontally or vertically. Wires can exit from the side or the breakout on the back of its housing. For tamper protection, attach the tamper magnet (provided) (Figure 1) to the module inside cover. Place DIP switch position #8 in the OFF position. Affix the connections label that accompanies the module to the inside of the modules cover. When the installation is complete, put the modules cover on. The magnet attached to the cover, positioned near the reed switch, will cause a tamper signal to be sent to the control if the cover is removed. When the module is to be mounted inside the controls cabinet, mount it horizontally to the raised tabs at the back of the cabinet. Insert self-tapping screws (provided) in two adjacent raised tabs at the back of the cabinet. Leave the heads projecting 1/8. Hang the module on the screw heads via two slotted holes on the back of the modules housing. When the module is installed in the controls cabinet, it need not be tamper protected. Affix the connections label that accompanies the module to the inside of the controls cover. See the controls installation and setup guide for additional information.

1. INSERT BOTTOM TABS FIRST. 2. ENGAGE TOP WITH CLIP.

4219-002-V0

Figure 1. Tamper Magnet Installation If a zone is not programmed, the resistor need not be used. The method of programming each zone for the type of alarm and reporting code to the central monitoring station varies with the control to which the module is connected. Refer to the Installation and Setup Guide for that control unit.

Set the DIP Switch to one of 31 addresses, as shown in Figure 3, so the control can identify the module and communicate with it properly. The address to be set is determined by the particular control to be used, and the controls installation instructions must be consulted. As shipped, the DIP Switch is set for an address of 0. Zone A can be set for fast response time of 10ms to an open circuit, if desired, by setting position 1 of the DIP Switch to OFF. As shipped, it is set to ON for a response time of 300ms, as shown in the table below. All other module protection zones have a nominal response time of 300ms. Connections to the controls keypad wiring points can be made via 4-terminal block TB2 or the 4-pin plug (wire color connections are the same).

SPECIFICATIONS

Physical Electrical Input Voltage: Current: 6-7/16W x 4-1/4H x 1-1/4 D (163mm x 108mm x 32mm) 12VDC (from controls remote keypad connection points) 30mA

CONNECTIONS AND SETTINGS

Make protection zone connections to the modules 12position terminal block TB1. Each zone that is used must have a 2K-ohm end-of-line resistor connected across the end of its loop, as shown in Figure 2.

DIP SWITCH FOR SETTING ADDRESS AND ZONE A RESPONSE 4-PIN CONSOLE PLUG CONNECTIONS SAME AS TB2 1

4219

2 3 4

NOTE FOR CE INSTALLATIONS A N6361EMI SUPPRESSION BEAD IS REQUIRED.

REED (TAMPER) SWITCH

TB2

4 3 2

TB1

GRN BLK RED YEL

DATA OUT TO CONTROL () GROUND (+) 12VDC DATA IN FROM CONTROL

10

11

12

ZONES

TERMINATE EACH PROGRAMMED ZONE WITH 2K OHM END-OF-LINE RESISTOR (EACH ZONE'S MAX. LOOP RESISTANCE: 300 OHMS + EOL)

4219-SOC-V1

Figure 2. Summary of Connections

EOLR value is 2K ohms.

UL

For UL installations, use 14-22AWG wire, and no more than one wire may be connected per terminal.

SWITCH NUMBER 0 1 2 3 4 5 6 7 8

OFF

1 2 3 4 5 6 7 8

ON

4219 ADDRESS SETTINGS ("" means "OFF") ON 22 23 24 25 26 27 28 ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON 15 16 17 18 19 20 21 ON ON ON ON ON ON ON ON ON ON ON 9 10 11 12 13 14 ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON 29 30 31 ON ON

4219-001-V0

2 3 4 5 6

DIP SWITCH: (WHITE AREAS DENOTE SWITCH HANDLES)

POSITION 8: DIP SWITCH POSITION #8: CASE TAMPER ON = DISABLED OFF= ENABLED POSITION 7: DIP SWITCH POSITION #7: NOT USED LEAVE ON POSITIONS 2-6: DETERMINE ZONE EXPANDER'S ADDRESS. CONSULT CONTROL'S INSTRUCTIONS FOR ADDRESS USE. SWITCH SETTING SHOWN SET FOR ADDRESS "0". POSITION 1: DETERMINES ZONE A's RESPONSE TIME: ON = NORMAL (300MS) RESPONSE, SHOWN (AS SHIPPED). OFF = FAST (10MS) RESPONSE TO AN OPEN.

NOTE: ADDRESSES 16-31 MAY NOT BE AVAILABLE; CONSULT THE HOST CONTROL PANEL INSTALLATION INSTRUCTIONS.

Figure 3. DIP Switch Settings

SEE THE CONTROL PANELS INSTALLATION AND SETUP GUIDE FOR COMPLETE INFORMATION REGARDING THE LIMITATIONS OF THE ENTIRE SECURITY SYSTEM.

Federal Communications Commission (FCC) Part 15 The user shall not make any changes or modifications to the equipment unless authorized by the Installation Instructions or User's Manual. Unauthorized changes or modifications could void the user's authority to operate the equipment. FCC CLASS B STATEMENT: This equipment has been tested to FCC requirements and has been found acceptable for use. The FCC requires the following statement for your information: This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with the limits for a Class B computing device in accordance with the specifications in Part 15 of FCC Rules, which are designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures: If using an indoor antenna, have a quality outdoor antenna installed. Reorient the receiving antenna until interference is reduced or eliminated. Move the radio or television receiver away from the receiver/control. Move the antenna leads away from any wire runs to the receiver/control. Plug the receiver/control into a different outlet so that it and the radio or television receiver are on different branch circuits. Consult the dealer or an experienced radio/TV technician for help. FCC/IC STATEMENT This Class B digital apparatus complies with Canadian ICES-003. Cet appareil numrique de la classe B est conforme la norme NMB-003 du Canada. This device complies with Part 15 of the FCC rules and RSS 210 of Industry Canada. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) This device must accept any interference received, including interference that may cause undesired operation. Cet appareil est conforme la partie 15 des rgles de la FCC & de RSS 210 des Industries Canada. Son fonctionnement est soumis aux conditions suivantes: (1) Cet appareil ne doit pas causer d' interferences nuisibles. (2) Cet appareil doit accepter toute interference reue y compris les interferences causant une reception indsirable.

N8924V3n

N8924V3 5/11 Rev. B

For the latest warranty information, please go to: http://www.security.honeywell.com/hsc/resources/wa

2 Corporate Center Drive, Suite 100 P.O. Box 9040, Melville, NY 11747

Copyright 2008 Honeywell International Inc.

Anda mungkin juga menyukai

- 1/16 Din Microbased Controller: Operators ManualDokumen69 halaman1/16 Din Microbased Controller: Operators ManualJosue Camacho100% (2)

- Asm 31 PDFDokumen87 halamanAsm 31 PDFrealiserBelum ada peringkat

- v570 57 t20b t40b J Instal GuideDokumen8 halamanv570 57 t20b t40b J Instal GuidecetadminBelum ada peringkat

- Character Certificate Format by Gazetted OfficerDokumen1 halamanCharacter Certificate Format by Gazetted Officerpratik_raj081050% (2)

- TURNITIN Student GuideDokumen10 halamanTURNITIN Student Guidemardak2953Belum ada peringkat

- Honeywell 5800C2W Installation ManualDokumen2 halamanHoneywell 5800C2W Installation ManualAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Inversor Abb 2 5kwDokumen2 halamanInversor Abb 2 5kwapi-290643326Belum ada peringkat

- Honeywell Vista 15p Honeywell Vista 20p Quick Install GuideDokumen2 halamanHoneywell Vista 15p Honeywell Vista 20p Quick Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Honeywell 5877 Installation Manual and Setup GuideDokumen2 halamanHoneywell 5877 Installation Manual and Setup GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Leviton VRCZ1 Installation Manual and Setup GuideDokumen2 halamanLeviton VRCZ1 Installation Manual and Setup GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- PLC m91 UnitromicsDokumen8 halamanPLC m91 UnitromicsJammil VenegasBelum ada peringkat

- HC900 Control Station Model Numbers 900CS10-00 and 900CS15-00 InstallationDokumen14 halamanHC900 Control Station Model Numbers 900CS10-00 and 900CS15-00 InstallationChiuda DanielBelum ada peringkat

- Notifier FMM 1 Monitor ModuleDokumen2 halamanNotifier FMM 1 Monitor Moduleghot334Belum ada peringkat

- Installation, Wiring, Operation Manua: One and Two Pen Circular Chart RecorderDokumen32 halamanInstallation, Wiring, Operation Manua: One and Two Pen Circular Chart RecorderkmpoulosBelum ada peringkat

- 310MV InstructionsDokumen29 halaman310MV InstructionsMIGUELBelum ada peringkat

- Federal Signal Corporation Installation and Service InstructionDokumen29 halamanFederal Signal Corporation Installation and Service InstructionTiagoBelum ada peringkat

- Manual Instalacion 900CRDokumen16 halamanManual Instalacion 900CRgeovanyhazellopezsixtosBelum ada peringkat

- Cd34install EnglishDokumen24 halamanCd34install EnglishZoltán VéberBelum ada peringkat

- Chromalox 3910 ControllerDokumen34 halamanChromalox 3910 ControllerkmpoulosBelum ada peringkat

- TW5201 Remote Control Unit - Operators ManualDokumen20 halamanTW5201 Remote Control Unit - Operators ManualAlexander J RokowetzBelum ada peringkat

- PC5108 V2.0 - Manual Instalare PDFDokumen2 halamanPC5108 V2.0 - Manual Instalare PDFDarie SilviuBelum ada peringkat

- Altronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)Dokumen36 halamanAltronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)francis_mouille_iiBelum ada peringkat

- PC5320 - Manual Instalare PDFDokumen2 halamanPC5320 - Manual Instalare PDFDarie SilviuBelum ada peringkat

- RT5201 Remote Control Unit - Operators ManualDokumen20 halamanRT5201 Remote Control Unit - Operators ManualAlexander J RokowetzBelum ada peringkat

- Dthoii 631355907Dokumen22 halamanDthoii 631355907Nigel RamkhalawanBelum ada peringkat

- Owners Manual and Installation Guide: Remote Control Automated SystemDokumen54 halamanOwners Manual and Installation Guide: Remote Control Automated SystemkelpiusBelum ada peringkat

- Manual de Instalacion PC5108Dokumen2 halamanManual de Instalacion PC5108Jairo Antonio Orellano ArbelaezBelum ada peringkat

- Inversor Abb 5kwDokumen2 halamanInversor Abb 5kwapi-290643326Belum ada peringkat

- MT6050i MT8050i: Installation InstructionDokumen2 halamanMT6050i MT8050i: Installation InstructionСања БанковићBelum ada peringkat

- Manual Technics 717Dokumen60 halamanManual Technics 717hsilvab0% (1)

- Manual Leviton-HCPRF All Code ReceiverDokumen2 halamanManual Leviton-HCPRF All Code ReceiverBenjamin DoverBelum ada peringkat

- Everspring Sm103 ManualDokumen4 halamanEverspring Sm103 ManualLokanatha ReddyBelum ada peringkat

- Linear WA105DBZ-1 - Z-Wave Siren Install GuideDokumen2 halamanLinear WA105DBZ-1 - Z-Wave Siren Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- PARTNER Contact Closure Adjunct: Installation InstructionsDokumen6 halamanPARTNER Contact Closure Adjunct: Installation InstructionslaurahotBelum ada peringkat

- Ni 9024Dokumen20 halamanNi 9024FraFraFra87Belum ada peringkat

- Honeywell l5100 Wifi Install GuideDokumen1 halamanHoneywell l5100 Wifi Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Numark CDN 22 S Owner ManualDokumen16 halamanNumark CDN 22 S Owner Manualnaupas007Belum ada peringkat

- SM Ami-208mc (E)Dokumen18 halamanSM Ami-208mc (E)DanielaCostaBelum ada peringkat

- Electronic Control Scada Input - OutputDokumen0 halamanElectronic Control Scada Input - OutputRonald Párraga AracenaBelum ada peringkat

- 1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00Dokumen71 halaman1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00kmpoulos100% (1)

- Industrial RF (Radio Frequency) Control: For Use With Model 8394053 SPIT-FIRE® MonitorDokumen11 halamanIndustrial RF (Radio Frequency) Control: For Use With Model 8394053 SPIT-FIRE® MonitortawfeeqsylanBelum ada peringkat

- Manual 1 Carrier Infinity TermostatoDokumen18 halamanManual 1 Carrier Infinity TermostatoJhonatan Sepulveda100% (1)

- MRC5000 CDokumen32 halamanMRC5000 CblueedemonBelum ada peringkat

- Instruction Manual: Model 7SL High/Low LimitrolDokumen48 halamanInstruction Manual: Model 7SL High/Low LimitrolkmpoulosBelum ada peringkat

- Haier HTAF21C Manual de Servicio PDFDokumen19 halamanHaier HTAF21C Manual de Servicio PDFPedro MoraBelum ada peringkat

- Dkg-205 Automatic Mains Failure UnitDokumen20 halamanDkg-205 Automatic Mains Failure UnitRafatBelum ada peringkat

- MDU2 CO Manual V2Dokumen10 halamanMDU2 CO Manual V2Ла БестиаBelum ada peringkat

- Ser Manual M20.04: Digital System ControllerDokumen22 halamanSer Manual M20.04: Digital System ControllerRiste Di MitrovBelum ada peringkat

- Installation Instructions: SpecificationsDokumen2 halamanInstallation Instructions: SpecificationsIvan FonsecaBelum ada peringkat

- Honeywell l5100 ZWAVE Install GuideDokumen1 halamanHoneywell l5100 ZWAVE Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- v350 35 Ta24 Instal GuideDokumen10 halamanv350 35 Ta24 Instal GuideDejan IlievBelum ada peringkat

- KDL42BX 320 420 AZ2 Uk ChassisDokumen34 halamanKDL42BX 320 420 AZ2 Uk ChassisDamon Brunger100% (1)

- ECX 400 SeriesDokumen16 halamanECX 400 SeriesGeneral Electronic Facility LandsideBelum ada peringkat

- DataKom 040 USERDokumen45 halamanDataKom 040 USERsebastianBelum ada peringkat

- DATAKOM DK40 Installation ManualDokumen45 halamanDATAKOM DK40 Installation ManualVykintas ImbrasasBelum ada peringkat

- Midas Venice ManualDokumen29 halamanMidas Venice Manualcb4pdfsBelum ada peringkat

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDari EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationBelum ada peringkat

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDari EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationBelum ada peringkat

- Total Connect 2.0 Integration - Total Connect Comfort WIFI ThermostatsDokumen4 halamanTotal Connect 2.0 Integration - Total Connect Comfort WIFI ThermostatsAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Lyric 3G Installation ManualDokumen2 halamanLyric 3G Installation ManualAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- L5210 Programming GuideDokumen32 halamanL5210 Programming GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- SiXPIR Quick Install GuideDokumen2 halamanSiXPIR Quick Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- SiXFOB Quick Install GuideDokumen2 halamanSiXFOB Quick Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- SiXSMOKE Installation GuideDokumen4 halamanSiXSMOKE Installation GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Lyric Controller Quick Install GuideDokumen4 halamanLyric Controller Quick Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Series: Photoelectric Smoke DetectorDokumen4 halamanSeries: Photoelectric Smoke DetectorRuben MoralesBelum ada peringkat

- Lyric Controller User GuideDokumen76 halamanLyric Controller User GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Honeywell Lyric Controller Installation and Setup GuideDokumen44 halamanHoneywell Lyric Controller Installation and Setup GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Call Letter For Online Phase Ii: Main Examination For Recruitment of Apprentice Development Officers (Applied Under Open Market Category)Dokumen3 halamanCall Letter For Online Phase Ii: Main Examination For Recruitment of Apprentice Development Officers (Applied Under Open Market Category)Abhishek KateBelum ada peringkat

- Oracle E-Business Suite Controls Application Security Best Practices TOCDokumen5 halamanOracle E-Business Suite Controls Application Security Best Practices TOCGreg LusinskiBelum ada peringkat

- Dremel 16" Scroll SawDokumen21 halamanDremel 16" Scroll SawTink EretteBelum ada peringkat

- Latest Passed Dump Citrix - 1Y0-A20Dokumen15 halamanLatest Passed Dump Citrix - 1Y0-A20Arunaigiri NmBelum ada peringkat

- Intel Lund 120502Dokumen30 halamanIntel Lund 120502RizkiBelum ada peringkat

- Email Tray Tool Using C# and Sharpdevelop (Part 2)Dokumen9 halamanEmail Tray Tool Using C# and Sharpdevelop (Part 2)JoeDabidBelum ada peringkat

- Resumen Normas en TablaDokumen1 halamanResumen Normas en TablaAne Mi KosteñlBelum ada peringkat

- MX-M356 315 265N Bro SDokumen4 halamanMX-M356 315 265N Bro Sanakraja11Belum ada peringkat

- RF03 Enrollment Data Issues 1Dokumen7 halamanRF03 Enrollment Data Issues 1SertnalBelum ada peringkat

- FA Registration AF JuridicalDokumen1 halamanFA Registration AF Juridicalgp_ph86100% (2)

- ACS Guide UserDokumen124 halamanACS Guide UserJose GomesBelum ada peringkat

- School Attendance Mangement SystemDokumen4 halamanSchool Attendance Mangement SystemCt ZaiBelum ada peringkat

- HRTC Print TicketDokumen2 halamanHRTC Print TicketVivek SinghBelum ada peringkat

- Malaysian Government Portal Website Assessment (MGPWA) 2011 CriteriaDokumen11 halamanMalaysian Government Portal Website Assessment (MGPWA) 2011 CriteriaKementerian Pertanian dan Industri Asas TaniBelum ada peringkat

- Cyber Security Basics: International Master's Programme (M. SC.)Dokumen1 halamanCyber Security Basics: International Master's Programme (M. SC.)sadyaakterBelum ada peringkat

- First Trainer 2Dokumen257 halamanFirst Trainer 2Chiara MeloniBelum ada peringkat

- End of Life Cisco SwitchDokumen2 halamanEnd of Life Cisco SwitchGustavo Marcelo Medina NarbonaBelum ada peringkat

- Please Affix Recent Passport Size Photo (Colour)Dokumen1 halamanPlease Affix Recent Passport Size Photo (Colour)SarabjeetSinghBelum ada peringkat

- OwnCloud Server Administration ManualDokumen295 halamanOwnCloud Server Administration ManualscobanxBelum ada peringkat

- Litmus TestsDokumen83 halamanLitmus TestsCucu BauBelum ada peringkat

- CIS Controls v8 v1.3-0522Dokumen2 halamanCIS Controls v8 v1.3-0522Ares ZathuraBelum ada peringkat

- Pre-Enlistment Form For Irregular Students (Coecsa)Dokumen1 halamanPre-Enlistment Form For Irregular Students (Coecsa)kangkongBelum ada peringkat

- TBANK Security Intellinx System V0.6 20160523Dokumen59 halamanTBANK Security Intellinx System V0.6 20160523Anonymous Qbc6mkp9GgBelum ada peringkat

- Quibell, Ramesseum 1896Dokumen126 halamanQuibell, Ramesseum 1896Fred Vink100% (1)

- Arquitetura e Crítica - MontanerDokumen155 halamanArquitetura e Crítica - MontanerIngryd BartholazziBelum ada peringkat

- Agha and Dardar IndictmentDokumen23 halamanAgha and Dardar Indictmentjonathan_skillingsBelum ada peringkat

- Room Clearing With GI JoeDokumen10 halamanRoom Clearing With GI JoeTerry Tmac McElwain100% (2)

- SAP Security Interview QuestionsDokumen11 halamanSAP Security Interview Questionsveena7570% (1)