Kuzay Inverter Welding Machine Operating Manual

Diunggah oleh

ercanbesliDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Kuzay Inverter Welding Machine Operating Manual

Diunggah oleh

ercanbesliHak Cipta:

Format Tersedia

KUZAY INVERTER WELDING MACHINE

KZY160 / KZY200 / KZY230 / KZY250 / KZY400 / KZY600 INVERTER WELDING MACHINE OPERATING MANUAL

1. Content 1. Contents 2. Electro-magnetic Compliance 3. Safety Rules 4. General info and Cautions 5. Main Features 6. Front and Rear Panel Controls 7. Technical Informations 8. How to Operate 9. Welding Method with Covered Electrode 10. Storage and Transportation Conditions 11. Maintenance and Repair 12. CE Certificate 13. ISO 9001:2008 Certificate 14. Warranty

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

2. Electro-Magnetic Compliance (EMC) Your machine is manufactured with complete compliance to the implementing regulations. Nevertheless, it may produce electro-magnetic fields which can interfere with other systems (Phones, Computers, T.V.s). To minimize these effects, please read this section carefully. This machine is designed to be used in industrial areas. If you use it in a house or office, please carry out the following precautions:

Check out the electro-magnetic immunity of, Input & output cables around the machines working space Phone and computer cables Radio and T.V. sets Computers and the devices run on computers Safety and control devices for industrial processes Calibration and measurement devices Medical equipment

User has to be sure of all the equipments compliancy in his working space. Otherwise extra safety precautions might be needed. The ideal measurements of a working space are determined by the construction of this area and other factors. To reduce the impact of the electro-magnetic waves produced by the machine:

Do the machines connection to the mains as explained in the manual. If any electro-magnetic interference occurs, some precautionary measures must be taken, such as filtering the mains. Output cables ( + /- tips ) should be as short as possible and kept together.

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

3. Safety Rules Caution: Keep children away from working space. People with cardiac pacemakers, should consult to their doctors before using the equipment. Electric shocks can cause injuries and death Electrode and the piece worked on are electrically active when the machine is on. Do not touch on these neither with naked hands, nor with wet clothes. To insulate your hands please wear dry, imperforate gloves. Light rays can be burning and dangerous To protect your eyes from flames and light rays, please use a protective mask with appropriate filter. Head mask and filtered glasses should conform to the ANSI Z87 standards. Gases and fumes can be suffocative and combustible During welding process, smokes and gases which are a detriment to health can occur. While welding, please keep your head out of the smoke and do not inhale the gases by ensuring there is enough ventilation in your working place. Welding sparks can cause fire and explosions If there are any elements that can start a fire in your working area, take them away. If that is not possible, cover them very well. Please keep in mind that; the welding sparks and hot particles come off the welding can pass through even the smallest spaces. Never weld around the hydraulic lines. Always keep a fire extinguisher nearby. The tube can explode when it is damaged Only use gas cylinders that inclusive protective gases suitable for the process and regulators that are designed for the chosen gas and the pressure. All the hoses, gears, and the components should be suited to the welding process and kept in good condition. Electric and Magnetic Fields (EMF) can be dangerous Electric current goes through a conductive material creates EMF. Welding current generates EMF around the welding machine and the cables. Being exposed to EMF can create some health issues. Therefore please take the advices below into consideration. Orientate the electrode and the chassis cables together.

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

Do not wrap the electrode and the chassis cables around your body. Attach the chassis cable onto the material being welded as close as possible. While welding stay as far as possible from the power units.

4. General Info and Cautions Do not install, use, or fix the welding machine before reading the manual. When taking a long break or after the job is finished, cut the machines electric connection off the mains. Do not make any changes in the machine, as it would change the machines technical and safety properties and also break the warranty agreement. During the work ambient temperature should be between -10 0C and +40 0C. Manufacturing firm reserves the right to change and modify the technical properties without notice.

5. Main Features In inverter technology, 50 Hz 60 Hz frequencies are converted in to 20 Khz by IGBT. And later by lowering down the voltage, alternating current transforms in to direct current. Because of this technologic revolution, welding machines dimensions got much smaller, became substantially lighter and also works % 40 more efficiently. KUZAY INVERTER WELDING MACHINE Has a feature which averts the Peak Flow coming from generator or mains. Due to its constant DC output current feature, it welds high quality. It can easily be converted into the Gas-Shielded Welding Machine by attaching a TIG Torch (Tube, Hose, Clamp ). With its ability to start at currents as low as 5amp, it enables you to weld really thin sheets. Igniting the electrode is easy because of its Hot Start feature. Can ignite the electrodes continuously at least 20 times in a row. If the electrode sticks to the material, the current lowers down automatically and the electrode comes off easily. Comparing to the transformer welding machines, it is much smaller and about %25 lighter. Consumes %35 to %40 less energy compared to the transformer welding machines. 160 V 230 V Electrode range: 1.6 mm 2.4 mm 3.25 mm ISO 9001 and CE certificates for safety and reliability 2 year warranty on parts and labor

5

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

6. Front & Rear Panel Controls

Welding Current Control Knob Thermal Protection Indicator Light Power Indicator Light Negative (-) Output Terminal

Positive (-) Output Terminal

ON / OFF Switch BUTTON Power Cable

Ventilation Duct

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

7. Technical Information

KZY 160A System Voltage Input Power Frequency Open Circuit Voltage Welding Current Range Protection Rating Electrode Diameter Fuse Value and Type Rated Outputs 230 V 1 Phase 3.6 KVA 50 / 60 Hz 55 V DC 5 A 160 A IP 21 1.6 2.5 3.25 mm 25 A Timedelay % 40 160 A % 60 140 A % 100 110 A 245 155 365 mm 5.5 kg

KZY 200A 230 V 1 Phase 4.4 KVA 50 / 60 Hz 56 V DC 5 A 200 A IP 21 1.6 2.5 3.25 4 mm 25 A Time-delay % 40 200 A % 60 160 A % 100 140 A 245 155 365 mm 6 kg

Dimensions ( H-W-L ) Weight

Input Voltage Input Power Frequency Rated Outputs

KZY 230A 280 V %15 V 1 phase 5 KVA 50/60 Hz (%40 250 A) (%60 210 A) (%100 180 A) 5 A 230 A 68 V DC 25 A ( Timedelay ) F 365 165 255 mm 8.4 kg

KZY 250A 280 V %15 2 phase 5 KVA 50/60 Hz (%40 250 A) (%60 220 A) (%100 190 A) 5A 250 A 68 V DC 25 A ( Time-delay )

7

Welding Current Range Max. Open Circuit Voltage Fuse Voltage & Type Protection Dimensions ( H-W-L ) Weight

F 365 165 255 mm 8.5 kg

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

KZY 400A 380 V %15 V 2 Phase 10 KVA 50/60 Hz (%40 390 A) (%60 320 A) (%100 280 A) Welding Current Range 20 A - 400 A Max Open Circuit Voltage 80 V DC Fuse Voltage & Type 32 A ( Time-delay ) Cooling 160 160 mm 220 V Fan 12 V 2 DC Fan Protection F Dimensions ( H-W-L ) 490 290 430 mm Weight 12 kg Input Voltage Input Power Frequency Rated Outputs 8. How to Operate

KZY 600A 380 V %15 V 2 Phase 15 KVA 50/60 Hz (%40 500 A) (%60 400 A) (%100 370 A) 20 A 500 A 85 V DC 40 A ( Time-delay ) 220 220 mm 220 V Fan 12 V 3 DC Fan F 490 290 560 mm 16 kg

Do not place or run the machine on a surface tilting level is more than 15. Always run the machine in a well ventilated environment. When machine is running do not cover it with anything. Dust and dirt might infiltrate into the machine. You should keep it at minimum level. The machine has IP 21 protection rating. Keep it as dry as possible. Never run the machine under direct sunlight or in a place there is water splash risqu. Run it away from radio controlled devices. Please read the Electro-magnetic Compliance section. Do not run the machine if the ambient temperature is outside the range of -10 and +40 0C and if the ambient air humidity is above %70. People who are not authorised with electrical equipment should not open the chassis cover and interfere with the workings of the machine. When the machine runs, its internal parts get heated. This machine is protected against overheating by means of Thermal protection. When this protection steps in, Temperature warning lamp switches on. When the temperature drop down to the safe working levels, the warning signal turns off. Stop running the machine if, insulation burnt is smelled or over-trembling is felt or flame and/or smoke are seen on it or loud noise is heard. Then make a detailed inspection.

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

If the current circuit gets locked or if voltage is noticed on the chassis, stop the machine and make a detailed inspection. Do not let connection contacts get over heated.

9. Welding Method with Covered Electrode Determine which one of the pole is suitable for the used electrode. You can find this info on the electrode box. Mount the electrode into the electrode holder. Attach the clamp pliers to a clean and rust-free part of the working piece. Plug in the power cable to the socket. Turn on the machine with on / off button. Adjust the suitable welding current value depends on the electrode diameter, type, position etc. Start welding by following the usual welding procedure.

10. Storage and Transportation Conditions

The machine should be stored in rooms which its ambient temperatures between -10 0C and +40 0C and the ambient air humidity is below %70. Ensure there is no burning, conductive gases or similar conditions in the room. Store the machine in its packaging. In long distance transportations, package the machine well against mechanical damages.

11. Maintenance and Repair Maintenance should be done only by the authorised staff. Check the connections and isolation of the power and energy lines. Change the loose connections. The dust accumulated inside the machine should be cleaned regularly by airpressure. This procedure can be practiced twice a month. If the machine is affected by the water and moister, it should be wicked and its isolation should be checked.

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

12. CE Certificate

10

10

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

13. ISO 9001:2008 Certificate

11

11

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

14. Warranty

12

12

Serkay Elektronik malat-Pazarlama San. ve Tic. Ltd. ti./ Talatpaa mah. Akl sok. 6/C Okmeydan ili/stanbul tel: +90 (212) 222 97 99 pbx:+90 (212) 222 72 07 | e-mail:m.besli@serkaynak.com

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

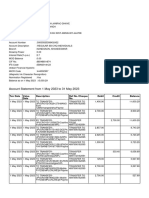

- Account Statement From 1 May 2023 To 31 May 2023: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDokumen10 halamanAccount Statement From 1 May 2023 To 31 May 2023: TXN Date Value Date Description Ref No./Cheque No. Debit Credit Balanceavinashdeshmukh7027Belum ada peringkat

- Mat1003 Discrete-Mathematical-Structures TH 3.0 6 Mat1003 Discrete-Mathematical-Structures TH 3.0 6 Mat 1003 Discrete Mathematical StructuresDokumen2 halamanMat1003 Discrete-Mathematical-Structures TH 3.0 6 Mat1003 Discrete-Mathematical-Structures TH 3.0 6 Mat 1003 Discrete Mathematical Structuresbalajichevuri8Belum ada peringkat

- Paper 13-Design of An Intelligent Combat Robot For War FieldDokumen7 halamanPaper 13-Design of An Intelligent Combat Robot For War FieldDhruv DalwadiBelum ada peringkat

- Fsuipc User GuideDokumen54 halamanFsuipc User GuideKAPTAN XBelum ada peringkat

- Computer Communication Networks CS-418: Lecture 8 - 1 Network Layer - Routing ProtocolsDokumen19 halamanComputer Communication Networks CS-418: Lecture 8 - 1 Network Layer - Routing ProtocolsAli MemonBelum ada peringkat

- Samsung Phones EnglishDokumen25 halamanSamsung Phones EnglishJAYAKUMAR PvBelum ada peringkat

- Mine Blast AlgorithmDokumen21 halamanMine Blast Algorithmnarottam jangirBelum ada peringkat

- Optimal Loan PorfolioDokumen11 halamanOptimal Loan PorfoliomohshiBelum ada peringkat

- Generations of Programming LanguageDokumen13 halamanGenerations of Programming LanguageMark Jerome AlbanoBelum ada peringkat

- Monitor Acer 7254E DELL E550Dokumen30 halamanMonitor Acer 7254E DELL E550José Luis Sánchez DíazBelum ada peringkat

- CAD Contest QuestionDokumen37 halamanCAD Contest QuestionFahad AbdullahtBelum ada peringkat

- Digital Platforms PI4 - Planning IntroductionDokumen40 halamanDigital Platforms PI4 - Planning IntroductionMANUEL ANTONIO AVALOS ROSASBelum ada peringkat

- Networking AssignmentDokumen53 halamanNetworking AssignmentManish SahBelum ada peringkat

- Common Core Grade 5 Math Printable WorksheetsDokumen3 halamanCommon Core Grade 5 Math Printable WorksheetsJessicaBelum ada peringkat

- DX DiagDokumen40 halamanDX DiagRadith FitriansyahBelum ada peringkat

- Parts of ComputerDokumen15 halamanParts of ComputerLarry Siga-an ConcepcionBelum ada peringkat

- Autocad Daywise - SyllabusDokumen1 halamanAutocad Daywise - SyllabusAmal_YaguBelum ada peringkat

- Bugreport 2015 08 22 22 55 05Dokumen4.142 halamanBugreport 2015 08 22 22 55 05Gelson Raizer AlvesBelum ada peringkat

- Project On A Population CalculatorDokumen42 halamanProject On A Population CalculatorNnamdi ChimaobiBelum ada peringkat

- DFo 3 1Dokumen44 halamanDFo 3 1Asfia SadrinaBelum ada peringkat

- RS900G DatasheetDokumen9 halamanRS900G DatasheetsamuelpemonBelum ada peringkat

- 2) VRP Basic ConfigurationDokumen37 halaman2) VRP Basic ConfigurationRandy DookheranBelum ada peringkat

- Manual of GDGS Transformer Tangent Delta TesterDokumen19 halamanManual of GDGS Transformer Tangent Delta TesterFernando Sanchez100% (1)

- De Thi Thu Vao THPT 2022 - Online 03.4.2022Dokumen5 halamanDe Thi Thu Vao THPT 2022 - Online 03.4.2022mai.nguyen.thi.phuongBelum ada peringkat

- Cross Tech Comm.Dokumen11 halamanCross Tech Comm.Tirth PatelBelum ada peringkat

- LG LCD CH La73a 47lc7df UbDokumen62 halamanLG LCD CH La73a 47lc7df UbvideosonBelum ada peringkat

- Unit1 - 2 - Unit1 - 3Dokumen9 halamanUnit1 - 2 - Unit1 - 3Tshepang RadingoanisBelum ada peringkat

- Format LeafletDokumen4 halamanFormat LeafletEllsrhmaBelum ada peringkat

- A Report On Gym Management SystemDokumen20 halamanA Report On Gym Management Systemdron upadhyayBelum ada peringkat

- Discrete MathDokumen1 halamanDiscrete MathAngelo John R. JavinezBelum ada peringkat