Plant Tissue Culture Lab

Diunggah oleh

Norhisham DaudDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Plant Tissue Culture Lab

Diunggah oleh

Norhisham DaudHak Cipta:

Format Tersedia

Plant Tissue Culture Lab

We have a modern, well equipped state of the art production facility with an annual capacity of 10 million plants per annum. The laboratory is having 2137.12 Sq. Mtr build up area for the operations and it comprises of two main sections sterile area and non-sterile area. Sterile areas (Bio clean) is having a sterility level of class 10,000. Non sterile area is having media preparation, plant washing, grading and packing area. We also have state of the art plant hardening facility in 16571 Sq. Mtr. area. Washing room:

We have a separate area for washing, drying and storing of glassware. We have a bottle washing machine which takes care of quality washing process. Contaminated culture bottles are kept separately and washed thoroughly.Overall cleanliness is maintained during the entire process so that there is no trace of used media.After washing with normal water , the containers are rinsed with deionized water and dried. Media Preparation Facility:

Our media Preparation facility (Lab Associates LA-50/V18) is equipped with dispensing system, with a capacity of 720 liters media preparation per day.Automatic media preparation specially designed unit for mixing and sterilizing media.Improved user programming capabilities, sterile steam generator, Process control unit, heating control unit and sterile air supply has made this unit a unique plant tissue culture laboratory. Our media room is well equipped with basic equipments like pH meter, weighing balance (electronic) , conductivity meter , distillation unit, RO water facility, etc. Autoclaving:

Our high capacity sterilizers are with Microprocessor based automatic process sequence control system. In addition to the standard use of steam at higher temperature as the sterilizing agent, this unit also employs the vacuum system for added advantage in the sterilization process. After autoclaving the media, it is stored for 2-3 days to check microbial contamination before use. Quality control:

In order to maintain disease free culture, we have separate room for quality check. Every culture is checked before processing to the next stage. Our highly experienced and qualified team members do in process quality check (IPQC).

Virus Indexing:

Virus indexing for all the varieties of crop ensure elimination of affected plant before micro-propagation. Virus testing is done from the established and government accredited laboratory. Plant Inoculation Room:

The activity of segregating and transferring cultured plant material is being done in our Plant Inoculation room. Five fully controlled and sophisticated plant inoculation rooms with total 43 laminar flow benches with a seating capacity of 86 operators. Class 10000 is maintained by fumigating the room periodically with sterilant and regular monitoring of air borne microbes. Highly skilled, trained and efficient operators handle the cultures by strictly following SOP. Growth Room:

The growth room is designed to grow cultures with controlled light. Humidity and temperature.We have seven State of the art growth rooms with best accuracy and reliability. Total culture holding capacity is of 65.00 lacs cultures at a time. Growth rooms are equipped with highly modern Air Handling Units and Screw Chiller. Culture racks are fitted with the fluorescent tube lights to ensure optimum availability of light for proper growth of the cultures. The rooms are fumigated periodically to keep the contamination under control. Each growth room has capacity to maintain different temperatures. Growth room area sterility is also maintained to control contamination. Greenhouse:

We have climate controlled greenhouses in an area of 1800 sq mt for the primary hardening of 15.00 lacs plants/cycle.Green houses are maintained at desired temperature and humidity with the help of latest control panels.Plants are monitored regularly for their growth and presence of any disease or pest. Periodical and timely spraying of suitable chemicals are carried out with proper recording and reference. Shade house:

We have 13500 sq mt of the shade house area equipped with foggers and misters for the secondary hardening of the plants at Hirapur, Ahmedabad. We have in total of 70000 sq mt areas for plant hardening in the states of Gujarat, Maharashtra, UP, Karnataka and Tamil Nadu. Pan India hardening facility assures timely delivery of the plants through out the country in time. Utmost care is taken for selection of proper tray, potting mixture, during washing of plants, waterfor irrigation. All records pertaining to transfer of plants is maintained for tracking of movement of plants.

http://www.cadilapharma.com/agro/index.php/plant-tissue-culture-lab

Anda mungkin juga menyukai

- Tissue Culture Lab PDFDokumen13 halamanTissue Culture Lab PDFTimothy Dalingay Jr.100% (2)

- Department of Biotechnology N.C.College of Engineering, Israna (Panipat)Dokumen33 halamanDepartment of Biotechnology N.C.College of Engineering, Israna (Panipat)Aashishkatyaal100% (1)

- Wild Edible Mushrooms of Northern Odisha, IndiaDokumen22 halamanWild Edible Mushrooms of Northern Odisha, IndiaSimo IboBelum ada peringkat

- Basic Plant Tissue CultureDokumen6 halamanBasic Plant Tissue Culturealphabetagama713085100% (1)

- CSS451-Plant Tissue Culture (2010)Dokumen45 halamanCSS451-Plant Tissue Culture (2010)adawiyah_sariman100% (1)

- Food IcpmsDokumen82 halamanFood IcpmsJose GarciaBelum ada peringkat

- Enzyme InhibitorsDokumen10 halamanEnzyme InhibitorsVijendra KavatalkarBelum ada peringkat

- MushroomsGB NLDokumen16 halamanMushroomsGB NLkalvinchaw100% (1)

- Micropropagation of Anthurium AnthuriumDokumen7 halamanMicropropagation of Anthurium AnthuriumRockyBelum ada peringkat

- Mushroom Farming: Department of ArchitectureDokumen7 halamanMushroom Farming: Department of ArchitectureHritika GurungBelum ada peringkat

- Cell and Tissue Culture Laboratory Manua PDFDokumen142 halamanCell and Tissue Culture Laboratory Manua PDFsampathdt100% (1)

- Plant - Tissue Culture - and - ApplicationsDokumen24 halamanPlant - Tissue Culture - and - Applications1balamanianBelum ada peringkat

- Plant Tissue Culture Practical Note BookDokumen22 halamanPlant Tissue Culture Practical Note BookNasir Hussain Faraz90% (10)

- In Vitro Propagation Reviews of OrchidDokumen7 halamanIn Vitro Propagation Reviews of OrchidInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Asymbiotic in Vitro Seed Germination and Regeneration of Vanda Coerulea Giff. Ex. Lindl., An Endangered Orchid From Northeast IndiaDokumen5 halamanAsymbiotic in Vitro Seed Germination and Regeneration of Vanda Coerulea Giff. Ex. Lindl., An Endangered Orchid From Northeast IndiaBự BụngBelum ada peringkat

- Haploid CultureDokumen35 halamanHaploid CultureSpark is within me89% (18)

- URBAN FARMING Case Study - 23.11.19Dokumen5 halamanURBAN FARMING Case Study - 23.11.19gaurav dhoreBelum ada peringkat

- Micro-Farming of Greens A Viable Enterprise For Enhancing Economic, Food and Nutritional Security of FarmersDokumen7 halamanMicro-Farming of Greens A Viable Enterprise For Enhancing Economic, Food and Nutritional Security of FarmerskoriatsuBelum ada peringkat

- Botanical NameDokumen25 halamanBotanical NameOdubanjo Kingsley Shegun100% (1)

- Generation System of Seed ProductionDokumen2 halamanGeneration System of Seed ProductionamitlapatraBelum ada peringkat

- Plant Tissue CultureDokumen17 halamanPlant Tissue CultureVenkateswarlu Yadavalli100% (1)

- OrchidsDokumen11 halamanOrchidsAnduk Guemera100% (1)

- Plant Tissue CultureDokumen8 halamanPlant Tissue CultureHong Yee YongBelum ada peringkat

- Plant Tissue Culture Rajesh BhammarDokumen51 halamanPlant Tissue Culture Rajesh BhammarRajesh Bhammar67% (3)

- Strawberry Cultivation - High DensityDokumen20 halamanStrawberry Cultivation - High DensityAnonymous EAineTizBelum ada peringkat

- Full Thesis PDFDokumen165 halamanFull Thesis PDFlengyianchua206Belum ada peringkat

- Micología Tropical - MicromycetesDokumen218 halamanMicología Tropical - MicromycetesSergio L.100% (1)

- Manual On Vegetable Seed Production in BangladeshDokumen125 halamanManual On Vegetable Seed Production in BangladeshAravind Kanth100% (3)

- 3.1 Nursery Production Lecture NoteDokumen11 halaman3.1 Nursery Production Lecture Note21981100% (1)

- Theory: Micropropagation Plant TissueDokumen17 halamanTheory: Micropropagation Plant TissuekzrdurBelum ada peringkat

- Cactus Tissue CultureDokumen8 halamanCactus Tissue CultureHüseyin Avni TokgözBelum ada peringkat

- Economic BotanyDokumen27 halamanEconomic BotanyAnanth Kulkarni0% (1)

- Hibiscus Rosa SinensisDokumen5 halamanHibiscus Rosa SinensisYuliana PravitasariBelum ada peringkat

- E Book How To Set Up A Low Tech Mushroom FarmDokumen29 halamanE Book How To Set Up A Low Tech Mushroom FarmcjBelum ada peringkat

- Microbial EcologyDokumen6 halamanMicrobial Ecologyakifuji913Belum ada peringkat

- Mushroom GuideDokumen285 halamanMushroom GuidejakeBelum ada peringkat

- Practocal Manual On Plant Tissue CultureDokumen130 halamanPractocal Manual On Plant Tissue CultureĐương Anh CaoBelum ada peringkat

- Biology Paper Plant Tissue Culture Aulia Putri KusumaDokumen9 halamanBiology Paper Plant Tissue Culture Aulia Putri KusumaAulia Putri KusumaBelum ada peringkat

- Plant Tissue Culture MediaDokumen34 halamanPlant Tissue Culture MediavijendBelum ada peringkat

- Plant Tissue Culture PDFDokumen38 halamanPlant Tissue Culture PDFSheryl JoseBelum ada peringkat

- Arditti Hist Orchid Prop 2010Dokumen4 halamanArditti Hist Orchid Prop 2010Joseph ArdittiBelum ada peringkat

- Mushroom Cultivation in Odisha: Challenges and OpportunitiesDokumen8 halamanMushroom Cultivation in Odisha: Challenges and OpportunitiesSudha BiharyBelum ada peringkat

- Plant Tissue Culture LabDokumen9 halamanPlant Tissue Culture LabannjoyceajajBelum ada peringkat

- Propagation of Rose (Rosa Hybrida L.) Under Tissue Culture TechniqueDokumen5 halamanPropagation of Rose (Rosa Hybrida L.) Under Tissue Culture TechniqueEmilia NatashaBelum ada peringkat

- AGRO ORGANICS - Product List 2021Dokumen16 halamanAGRO ORGANICS - Product List 2021AnddrixBelum ada peringkat

- Mushroom ProcessingDokumen7 halamanMushroom ProcessingMahadeoBelum ada peringkat

- Mushroom CultivationDokumen16 halamanMushroom CultivationKanwarpreet Kaur100% (1)

- Tropical, Subtropical and Temperate Fruit Crop ListDokumen1 halamanTropical, Subtropical and Temperate Fruit Crop ListSuraj vishwakarma100% (1)

- Economic Botany PresentationDokumen16 halamanEconomic Botany Presentationjames allenBelum ada peringkat

- Myceliated Grain Tek1.3Dokumen84 halamanMyceliated Grain Tek1.3Tyrex: Psychedelics & Self-improvementBelum ada peringkat

- Successful Commercial Polycultures Tomas Remiarz ORFC2017Dokumen3 halamanSuccessful Commercial Polycultures Tomas Remiarz ORFC2017Igor ZBelum ada peringkat

- Mushroom Production and Processing Teach PDFDokumen35 halamanMushroom Production and Processing Teach PDFA-em Jaime AlbertusBelum ada peringkat

- Handbook of Plant Tissue CultureDokumen300 halamanHandbook of Plant Tissue Culturedoclozmak86% (7)

- 4x Plant Tissue Culture Media & ChemicalsDokumen14 halaman4x Plant Tissue Culture Media & Chemicalsxxx_pic2531Belum ada peringkat

- Anther CultureDokumen78 halamanAnther CultureDhanya Krishnan50% (2)

- Basic Principles and Protocol in Plant Tissue CultureDokumen17 halamanBasic Principles and Protocol in Plant Tissue CultureHelenChungBelum ada peringkat

- Terra GardenDokumen3 halamanTerra GardenNorhisham DaudBelum ada peringkat

- Review of Domestic Broiler Market: Issues Paper: 16 July 2012Dokumen45 halamanReview of Domestic Broiler Market: Issues Paper: 16 July 2012Norhisham DaudBelum ada peringkat

- 4x Plant Tissue Culture Media & ChemicalsDokumen14 halaman4x Plant Tissue Culture Media & Chemicalsxxx_pic2531Belum ada peringkat

- Biotechnology To Benefit Small-Scale Banana Producers in KenyaDokumen24 halamanBiotechnology To Benefit Small-Scale Banana Producers in KenyaNorhisham DaudBelum ada peringkat

- Plant Tissue Culture MediaDokumen17 halamanPlant Tissue Culture MediaNorhisham DaudBelum ada peringkat

- Plant Tissue Culture Software-FarmERP BiotechDokumen10 halamanPlant Tissue Culture Software-FarmERP BiotechNorhisham DaudBelum ada peringkat

- Financial Projection Template - NewDokumen5 halamanFinancial Projection Template - NewNorhisham DaudBelum ada peringkat

- Tissue Culture Media-CompositionDokumen7 halamanTissue Culture Media-CompositionMani RaoBelum ada peringkat

- 18-1039 Draft Report (Nuberg Engg.) Complete PDFDokumen73 halaman18-1039 Draft Report (Nuberg Engg.) Complete PDFYatendra TyagiBelum ada peringkat

- F-7052X Cellpack DCL PDFDokumen9 halamanF-7052X Cellpack DCL PDFKadek Ayang Cendana PrahayuBelum ada peringkat

- Landforms in Relation To StructureDokumen12 halamanLandforms in Relation To StructureAnagha mohanBelum ada peringkat

- MLC PDFDokumen84 halamanMLC PDFAlem LoajnerBelum ada peringkat

- Corrosion of Steel in ConcreteDokumen2 halamanCorrosion of Steel in ConcreteaaBelum ada peringkat

- 2 Statoil Innovate Whats Your Idea - An Introduction To Innovate Stat Oil Com and Statoil Subsea Technology Gaps Dag Oxnevad StatoilDokumen21 halaman2 Statoil Innovate Whats Your Idea - An Introduction To Innovate Stat Oil Com and Statoil Subsea Technology Gaps Dag Oxnevad StatoilgdvngkrishnaBelum ada peringkat

- ZIMSEC O Level Geography Notes PDFDokumen63 halamanZIMSEC O Level Geography Notes PDFMaster T86% (7)

- Inspection Report: 4.40 Junction at 11 o Clock, Dia 100 MMDokumen5 halamanInspection Report: 4.40 Junction at 11 o Clock, Dia 100 MMPraveen NairBelum ada peringkat

- Busan George Fixed Link Canal Basics of TunnelDokumen31 halamanBusan George Fixed Link Canal Basics of TunnelbhargavipulivarthiBelum ada peringkat

- What's Happening in The World of AquaponicsDokumen6 halamanWhat's Happening in The World of AquaponicsLindaM857Belum ada peringkat

- Alok NandanDokumen41 halamanAlok NandanSean Curnow100% (1)

- 1169 BOK Apr-Dec-2017 Final-011117 PDFDokumen9 halaman1169 BOK Apr-Dec-2017 Final-011117 PDFUnni CyriacBelum ada peringkat

- Outline Construction Method StatementDokumen15 halamanOutline Construction Method Statementtsuak100% (2)

- ĐỀ ÔN NGHI LỘC ĐỀ 6Dokumen5 halamanĐỀ ÔN NGHI LỘC ĐỀ 6Dũng HoàngBelum ada peringkat

- Yapım Aşamaları Ve Çölde Karşılaşılan ZorluklarDokumen6 halamanYapım Aşamaları Ve Çölde Karşılaşılan ZorluklarefeahBelum ada peringkat

- Diver Tech Manual PDFDokumen246 halamanDiver Tech Manual PDFChowdhury FatemaBelum ada peringkat

- Grand Rapids Fluoridation Study-Results Pertaining The Eleventh of FluoridationDokumen7 halamanGrand Rapids Fluoridation Study-Results Pertaining The Eleventh of FluoridationpambleBelum ada peringkat

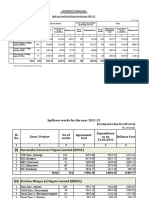

- Spill-Over and Fresh Works For The Year 2021-22: Rs. in CroresDokumen4 halamanSpill-Over and Fresh Works For The Year 2021-22: Rs. in Croreshoney honeyBelum ada peringkat

- YORK Marine Screw Chiller Units: Type MCSH-SDokumen2 halamanYORK Marine Screw Chiller Units: Type MCSH-SMike ErftmierBelum ada peringkat

- Bridge 070 Passage PlanningDokumen4 halamanBridge 070 Passage PlanningMiha MihaelaBelum ada peringkat

- Respiratory System NotesDokumen4 halamanRespiratory System NotesFlare FlareonBelum ada peringkat

- Costa Cálida Chronicle's Monthly Magazine October 2016Dokumen104 halamanCosta Cálida Chronicle's Monthly Magazine October 2016costacalidachronicleBelum ada peringkat

- Method of Statement For Honeycomb RepairDokumen10 halamanMethod of Statement For Honeycomb RepairHansika RajapakshaBelum ada peringkat

- Practice 8Dokumen5 halamanPractice 8Nguyễn Tuấn ĐịnhBelum ada peringkat

- Pre Treatment PresentationDokumen183 halamanPre Treatment PresentationHamza RaoBelum ada peringkat

- Compressed Air Treatment EquipmentDokumen12 halamanCompressed Air Treatment EquipmentSAUL OSPINOBelum ada peringkat

- Absorption Refrigeration: Kevin D. Rafferty, P.E. Geo-Heat CenterDokumen4 halamanAbsorption Refrigeration: Kevin D. Rafferty, P.E. Geo-Heat CenterRichard WeimerBelum ada peringkat

- Precis & Drafting Question Paper 2018Dokumen4 halamanPrecis & Drafting Question Paper 2018Sunil Teron A 2 ZBelum ada peringkat

- Chapter 11 - Dryland Strategies - A Permaculture Design Course HandbookDokumen8 halamanChapter 11 - Dryland Strategies - A Permaculture Design Course Handbookikhlas65Belum ada peringkat

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDari EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsPenilaian: 4 dari 5 bintang4/5 (146)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDari EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincPenilaian: 3.5 dari 5 bintang3.5/5 (137)

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDari EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifePenilaian: 5 dari 5 bintang5/5 (4)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDari EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolBelum ada peringkat

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDari EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilPenilaian: 5 dari 5 bintang5/5 (1)

- Advanced Modelling Techniques in Structural DesignDari EverandAdvanced Modelling Techniques in Structural DesignPenilaian: 5 dari 5 bintang5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDari EverandChemistry for Breakfast: The Amazing Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (90)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDari EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresPenilaian: 1 dari 5 bintang1/5 (2)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDari EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifePenilaian: 4 dari 5 bintang4/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Marine Structural Design CalculationsDari EverandMarine Structural Design CalculationsPenilaian: 4.5 dari 5 bintang4.5/5 (13)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableDari EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TablePenilaian: 3.5 dari 5 bintang3.5/5 (22)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDari EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookBelum ada peringkat

- Taste: Surprising Stories and Science About Why Food Tastes GoodDari EverandTaste: Surprising Stories and Science About Why Food Tastes GoodPenilaian: 3 dari 5 bintang3/5 (20)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireDari EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesirePenilaian: 4 dari 5 bintang4/5 (129)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideDari EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideBelum ada peringkat

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDari EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsPenilaian: 5 dari 5 bintang5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeDari EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifePenilaian: 5 dari 5 bintang5/5 (1)

- Bioplastics: A Home Inventors HandbookDari EverandBioplastics: A Home Inventors HandbookPenilaian: 4 dari 5 bintang4/5 (2)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsDari EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsBelum ada peringkat

- Tribology: Friction and Wear of Engineering MaterialsDari EverandTribology: Friction and Wear of Engineering MaterialsPenilaian: 5 dari 5 bintang5/5 (1)