Technical Specification For Bridge

Diunggah oleh

Richard WestonyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Technical Specification For Bridge

Diunggah oleh

Richard WestonyHak Cipta:

Format Tersedia

SPECIFICATIONS

1.07 Structural Concrete

a)

General This section covers the manufacture, transport, placing and testing of concrete in the works where plain or reinforced concrete is specified.

b)

Concrete Mixes Concrete mixes required for various parts of the works are indicated on the drawings and are designated by their characteristic strengths in N/mm2 (MPa) in accordance with the provisions of BS 5328. The table below gives details of the prescribed concrete mixes that may be used on the works. Weights of cement and total dry aggregate in kg to produce approximately one cubic metre of fully compacted concrete, together with the percentage by weight of fine aggregate in total dry aggregates are shown.

STANDARD CONCRETE MIXES

Grade

Quality

30 25 20 15 10

1:1:2 1:11/2:3 1:2:4 1:3:6 1:4:8 1:10

Max size of Max water coarse cement Min. crushing strength of aggregate ratio by works Test Cubes weight kg/cm2) 7 days 28 days 20 mm 0.50 210 315 20 mm 0.55 175 262 20 mm 0.60 140 210 25 mm 0.60 84 140 40 mm 0.60 65 100 All in aggregate -

Unless otherwise directed the Contractor shall comply with the relevant provisions of BS 5328 for proportioning, whether by mass or by volume, and mixing concrete. c) Placing The Contractor shall give the Engineer a minimum or 24 hours notice of his intention to place concrete. The supervision employed should be such as to ensure the required standard of control of materials and workmanship. The Engineer should be afforded all reasonable opportunity and facility to inspect the materials and the manufacture of concrete and to take any samples or to make any tests. All such inspection, sampling and testing should be carried out with the minimum of interference with the process of manufacture and delivery. All concrete shall be transported in a manner to avoid any segregation of materials and placed as rapidly as possible after mixing and before initial set takes place. It shall be deposited as nearly as possible in its final position in small quantities, so as to avoid re-handling or flowing. In no case is concrete to be dropped from a height of

more than 1.5 metres except when prior approval has been obtained from the Engineer. Care shall be taken to ensure that the reinforcement is not displaced from its correct position and that the concrete entirely surrounds the rods. Once placed in position the concrete is to be left undisturbed and protected from vibration, loading, excessive temperature variations and rapid drying out. In walls, the concrete shall be placed in horizontal layers about 150 mm thick. Construction joints shall be avoided as far as possible. Where they are necessary, the surface of the old concrete shall be roughened and all laitance and scum shall be removed immediately before placing the fresh concrete, the joint face shall be wetted and coated with a thin layer of neat cement paste. After concrete has been placed, appropriate measures must be taken, as approved by the Engineer, to prevent the concrete drying out too rapidly. All finished concrete must be sound, and the Engineer may reject any that is honeycombed or is in any other way defective. In such cases it is to be broken out and replaced at the Contractor's expenses. c) Weather Condition Hot weather presents problems in the mixing, placing and curing of concrete. If the temperature of the concrete at the time of placing exceeds 32 C the Engineer may instruct the Contractor to either suspend concreting or, alternatively the Contractor may cool the constituent materials of the concrete. During hot weather, all exposed concrete surfaces, which have recently been cast, shall be suitably screened from the sun in an approved manner. Arrangements shall be made to the satisfaction of the Engineer to prevent or minimize the harmful effects of rain during placing of concrete. e) Testing Where considered necessary by the Engineer he shall require tests to be carried out to evaluate the consistency and strength of the concrete. All testing shall be carried out at the Contractor's expense. i) Slump Test When required, while concreting is in progress, the consistency of the mixture shall be ascertained by carrying out a slump test in the form and manner described in BS S3. 1881. The results of the test shall be within the following limits: 25 mm - 75 mm slump. ii) Test Cubes

The Contractor shall at his own expense cast concrete cubes 150 mm x 150 mm x 150 mm from concrete, as deposited in the work, as often as directed by the Engineer. Such cubes must be cast in the presence of the Engineer and in the form and manner described in B.S.

The cubes are to be cast in groups of two, three or four and are to be tested as directed. They shall normally be taken from each 20 cubic metre of concrete or from each continuous pour of less than 20 cubic metres. They shall be marked with a distinguishing sign, which shall be entered in Concrete Cubes Log Book with origin of each cube and date of casting also entered. iii) Acceptance Criteria Compliance with the following characteristic strength shall be assumed if when tested at 28 days. the average crushing strength determined from the first 2, or the first 3 consecutive test results, or from consecutive but non-overlapping, groups of 4 test results complied with the appropriate limits in column A of the table below, and any individual test result complies with the appropriate limits in column B of the table below:

COMPREHENSIVE STRENGTH COMPLIANCE REQUIREMENTS

Concrete Class

Test Results

Average of test results exceeds the specified characteristic strength by at least 0 N/mm2 1 N/mm2 2 N/mm2 1 N/mm2 2 N/mm2 3 N/mm2

7.5 to 15

20 and above

First 2 First 3 Consecutive 4 First 2 First 3 Consecutive 4

Any individual test result is not less than the specified characteristic strength minus 2 N/mm2 2 N/mm2 2 N/mm2 3 N/mm2 3 N/mm2 3 N/mm2

Sampling, compacting and curing of test specimens shall conform to B.S 1881. Cubes must be despatched packed in damp sand in good time to arrive for testing. Storage, packing and despatching to the laboratory shall be at the expenses of the Contractor.

f)

Formwork Forms shall conform to the shapes, lines, levels and dimensions of the concrete as shown on the drawings. The centring, shuttering and casing of the concrete work shall be true, rigid and properly braced and sufficiently strong to resist without bulging or distorting, loads and shock. All joints shall be sufficiently tight to prevent leakage.

If in the opinion of the Engineer, the formwork is at any time insufficiently rigid or in any way defective, then the Contractor shall strengthen and improve such formwork in such manner, as the Engineer shall direct. No formwork shall be removed without the permission of the Engine, and unless otherwise instructed by the Engineer, is shall be left in position before easing and removal for three days. The Contractor shall be responsible for any injury to the work and any consequent damage cussed by or arising from the removal or striking of moulds, centring and supports, and supports, and any advise, permission or approval given by the Engineer relative to the removal and striking of moulds, centring and supports shall not relieve the Contractor from the responsibility herein defined. g) Reinforcement Bends in bars shall be cold formed on an approved manually motor operated machine in which the power is applied smoothly and evenly and at such a speed so as to cause no fracture or damage in the reinforcement. Reinforcement damaged in any way shall be removed from the site. Before being placed in position, the rods shall be thoroughly cleaned of all grease, dirt, bituminous material, scale and loose rust. Great care must be taken in placing the rods and mesh in their correct positions as shown on the drawings and in retaining them during the placing of the concrete. When the ends of bars are to be formed into a U-hook, they must be bent to a semicircular hook, the internal diameter of which is to be not less than twice the diameter of which is to be not less than twice the diameter of the rod, with a straight end beyond the semicircular portion having a length of not less than four times the diameter of the rod. Unless otherwise shown on the drawings, all joints in reinforcing rods are to be lapped 24 times the diameter of the rod for compression laps and 30 times the diameter of the rod for tension laps. The laps must be securely tied With 16 or 18 S.W.G annealed iron wire. Rods crossing one another are to be bound at every intersection, unless otherwise directed with 16 or 18 S.W.G annealed iron wire. All stirrups are to be properly fastened to the main reinforcement so as to retain their position during the placing of the concrete. Welding will not be permitted in any rods. The Contractor shall notify the Engineer when any section is ready for concreting and no concrete shall be placed in position until the steel work has been inspected and approved by the Engineer. The concrete cover to the main reinforcement shall be 50 mm or as stated on the drawings. b) Measurement

i)

Concrete The unit of measurement for cast-in-situ concrete is the cubic metre measured in accordance with the dimensions given in the drawings.

ii)

Reinforcement The unit of measurement for bar reinforcement is the kilogram. The total mass of bar reinforcement will be calculated from the total length indicated on the drawings multiplied by the effective cross sectional area and the nominal density. The unit of measurement for mesh reinforcement is the square metre. The total area of mesh will be calculated from the net plan area of reinforcement.

i)

Payment i) The rate for each cubic metre of concrete will include full compensation for the execution of the following operations and for all work incidental and necessary thereto: supply of all materials, excluding steel reinforcement; provision, placing and removal of formwork; mixing, transporting, placing and vibrating the concrete. forming construction joints and shrinkage joints. the provision of unformed surfaces. curing and protection of completed concrete work.

ii)

Reinforcement The rate per kilogram for bar reinforcement will include full compensation for supply and delivery, cutting, bending, placing and fixing and for all work incidental and necessary thereto.

iii)

Formwork There will be no separate payment for formwork and the Contractor must allow for this item in his rate for concrete.

Anda mungkin juga menyukai

- Publication PDFDokumen202 halamanPublication PDFYoucefChaabnaBelum ada peringkat

- Methodology of CHBDokumen15 halamanMethodology of CHBLevy Jane DobleBelum ada peringkat

- Wms - Concrete Repairing Works (Pedestals)Dokumen4 halamanWms - Concrete Repairing Works (Pedestals)krmchari100% (1)

- Steel Design - Tradeoff On Structural SystemDokumen71 halamanSteel Design - Tradeoff On Structural SystemEmmanuel Lazo100% (1)

- Laboratory Testing Manual (2000) PDFDokumen330 halamanLaboratory Testing Manual (2000) PDFandressaoliveira2301100% (8)

- Technical Specification For Micropile ConstructionDokumen9 halamanTechnical Specification For Micropile ConstructionFFerideKochanBelum ada peringkat

- Methodology For Convreting WorksDokumen7 halamanMethodology For Convreting WorksLokesh SaranBelum ada peringkat

- Sample Geaotech CapstoneDokumen160 halamanSample Geaotech CapstoneGiemhel GeleraBelum ada peringkat

- Cracking Moment (Prestressed Design)Dokumen11 halamanCracking Moment (Prestressed Design)kimberly buenaaguaBelum ada peringkat

- Pipeline Design-Third EditionDokumen130 halamanPipeline Design-Third EditionRichard Westony100% (2)

- 425-Chp7-Bond Development Length SplicesDokumen41 halaman425-Chp7-Bond Development Length SplicesAhsan BuriroBelum ada peringkat

- CHB ReinforcementDokumen16 halamanCHB ReinforcementMack Salazar0% (1)

- 1 Functional Specification TemplateDokumen9 halaman1 Functional Specification TemplatestomilsonBelum ada peringkat

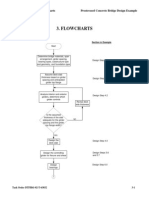

- Design Flowcharts for Prestressed Concrete BridgeDokumen30 halamanDesign Flowcharts for Prestressed Concrete BridgeNamelezz ShadowwBelum ada peringkat

- 1413 Excavation Written ReportDokumen7 halaman1413 Excavation Written ReportVirgilio F. Abundo Jr.100% (1)

- Ultimate Strength Design (Usd) - Analysis: (2010/2015 NSCP)Dokumen9 halamanUltimate Strength Design (Usd) - Analysis: (2010/2015 NSCP)James Kyle Apa-apBelum ada peringkat

- The NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsDokumen33 halamanThe NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsFritze Hansteen OngBelum ada peringkat

- Technical Specifications (Building)Dokumen51 halamanTechnical Specifications (Building)Richard WestonyBelum ada peringkat

- Method Statement for Concrete WorksDokumen7 halamanMethod Statement for Concrete WorksArthur Ruhinda100% (1)

- Methods of Reinforced Concrete ConstructionDokumen25 halamanMethods of Reinforced Concrete ConstructionIra MejiaBelum ada peringkat

- Technical Specification (Roads)Dokumen8 halamanTechnical Specification (Roads)Richard Westony100% (1)

- Prestressed Concrete Design: A. Reference: NSCP 2015 and AASHTO 2007 (SI Edition) Philosophy of Prestressed ConcreteDokumen15 halamanPrestressed Concrete Design: A. Reference: NSCP 2015 and AASHTO 2007 (SI Edition) Philosophy of Prestressed ConcreteJon SnowBelum ada peringkat

- Ce 421: Theory of Structures 2Dokumen5 halamanCe 421: Theory of Structures 2VOJBelum ada peringkat

- NSCP structural design code summaryDokumen78 halamanNSCP structural design code summaryanon_716820639Belum ada peringkat

- Build Block WallsDokumen11 halamanBuild Block Wallsjmhike_1050% (2)

- Method Statement - Structural ConcreteDokumen7 halamanMethod Statement - Structural Concretearif_rubinBelum ada peringkat

- Materials Engineer Examination With Answers SET1 PDFDokumen24 halamanMaterials Engineer Examination With Answers SET1 PDFArmie May Rico100% (1)

- Lower Ceiling Estimation MaterialsDokumen8 halamanLower Ceiling Estimation MaterialsMyla Riza Sintones NepomucenoBelum ada peringkat

- Concrete Mix SpecsDokumen5 halamanConcrete Mix SpecsKent XyrellBelum ada peringkat

- General Notes For ConstructionDokumen7 halamanGeneral Notes For Constructionjonilyn florentino100% (1)

- Steel ReinforcementDokumen16 halamanSteel ReinforcementVannah Elyssa AustriaBelum ada peringkat

- Structural Design Questions and AnswersDokumen24 halamanStructural Design Questions and AnswersJohn Kervin Rodriguez100% (1)

- Masonry Works: HEO Architects Technical SpecificationDokumen6 halamanMasonry Works: HEO Architects Technical SpecificationDk MariBelum ada peringkat

- Standards for CHBs in the PhilippinesDokumen6 halamanStandards for CHBs in the Philippineskharlj3604Belum ada peringkat

- QAUDokumen90 halamanQAUakclams77Belum ada peringkat

- Measurement Beng. 010-1Dokumen56 halamanMeasurement Beng. 010-1Richard WestonyBelum ada peringkat

- Civil Engineering Practice (Section 1)Dokumen10 halamanCivil Engineering Practice (Section 1)Kurt Laurhon Cabahug100% (1)

- Review of Related LiteratureDokumen14 halamanReview of Related LiteratureDennis LundayBelum ada peringkat

- Selection of Civil EngineerDokumen3 halamanSelection of Civil EngineerMJ JessaBelum ada peringkat

- Megawide Precast PlantDokumen21 halamanMegawide Precast PlantPaolo ManansalaBelum ada peringkat

- Assignment 8 - Ra544 ReflectionDokumen3 halamanAssignment 8 - Ra544 ReflectionLuke MoraledaBelum ada peringkat

- Chapter Two, Tension Members PDFDokumen10 halamanChapter Two, Tension Members PDFZeleke TaimuBelum ada peringkat

- CONCRETE ESTIMATION MODULEDokumen5 halamanCONCRETE ESTIMATION MODULEMac KYBelum ada peringkat

- 5 Design of Surfaces and GuidewaysDokumen90 halaman5 Design of Surfaces and GuidewaysRenalyn Andrade0% (1)

- Rebar Cutting List SlabDokumen4 halamanRebar Cutting List SlabMaria Fe MercadoBelum ada peringkat

- Truck PCT and Directional PCT in AASHTO LRFD 2014Dokumen2 halamanTruck PCT and Directional PCT in AASHTO LRFD 2014dapinmin0% (1)

- Activity Report 2 (Soil Sampling) Fajardo Bsce3aDokumen6 halamanActivity Report 2 (Soil Sampling) Fajardo Bsce3aGuilbert FajardoBelum ada peringkat

- Ce Laws, Contracts, Specifications and ProfessionalDokumen31 halamanCe Laws, Contracts, Specifications and ProfessionalKatharosJane100% (1)

- OJT RQMT MonitoringDokumen4 halamanOJT RQMT MonitoringJerico VeranoBelum ada peringkat

- Faculty Marked Assignment NO. 11Dokumen15 halamanFaculty Marked Assignment NO. 11Vince GapasinBelum ada peringkat

- Bar Chart PDM Drainage Construction 1 - ModelDokumen1 halamanBar Chart PDM Drainage Construction 1 - ModelMae AromazBelum ada peringkat

- Notes Ce Laws, Contracts and ObligationsDokumen5 halamanNotes Ce Laws, Contracts and ObligationsWilliam LimBelum ada peringkat

- Steel HandbbokDokumen420 halamanSteel HandbbokMJ100% (1)

- A Proposed Bridge Widening Project in Matina CrossingDokumen9 halamanA Proposed Bridge Widening Project in Matina CrossingRGDayananBelum ada peringkat

- Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, IDokumen4 halamanTable 2-1. Allowable Stress On Fasteners, Mpa: G V E, ILouie Jay CabunocBelum ada peringkat

- Pre1 1Dokumen43 halamanPre1 1Tooty FrootyBelum ada peringkat

- NSCP 2015 minimum concrete coverDokumen2 halamanNSCP 2015 minimum concrete coverAllyson DulfoBelum ada peringkat

- Steel Design Chapter 3.3 Staggered ConnectionsDokumen5 halamanSteel Design Chapter 3.3 Staggered ConnectionsJonathan YambaoBelum ada peringkat

- Materials Engineer REVIEWER 2Dokumen2 halamanMaterials Engineer REVIEWER 2Jimuel Gonzales100% (1)

- 4 Storey With DeckDokumen9 halaman4 Storey With DeckFaye HidalgoBelum ada peringkat

- Rebar Cutting ListDokumen20 halamanRebar Cutting Listleo dumapiBelum ada peringkat

- Plate No.5 - Autor, Joy - STEELDokumen10 halamanPlate No.5 - Autor, Joy - STEELJoy lauria100% (1)

- An Example Problem On Wind Load Calculation According To NSCP 2010 )Dokumen32 halamanAn Example Problem On Wind Load Calculation According To NSCP 2010 )joshua humirangBelum ada peringkat

- Saint Mary's UniversityDokumen2 halamanSaint Mary's Universityjun junBelum ada peringkat

- Bill of Materials: EarthworksDokumen11 halamanBill of Materials: EarthworksJef Junio AlvarezBelum ada peringkat

- Module 2 PDFDokumen32 halamanModule 2 PDFDhanendra TMGBelum ada peringkat

- Electrical DrawingsDokumen1 halamanElectrical DrawingsRichard WestonyBelum ada peringkat

- Electrical Drawings 2Dokumen1 halamanElectrical Drawings 2Richard WestonyBelum ada peringkat

- Substation Layout and FoundationDokumen2 halamanSubstation Layout and FoundationRichard WestonyBelum ada peringkat

- Electrical DrawingsDokumen1 halamanElectrical DrawingsRichard WestonyBelum ada peringkat

- Architectural Drawings For A Simple BuildingDokumen1 halamanArchitectural Drawings For A Simple BuildingRichard WestonyBelum ada peringkat

- Nyerere SSDokumen15 halamanNyerere SSRichard WestonyBelum ada peringkat

- Cement StabilizationDokumen11 halamanCement StabilizationRichard WestonyBelum ada peringkat

- Lecture 2 ReservoirDokumen17 halamanLecture 2 ReservoirRichard WestonyBelum ada peringkat

- CHAPTER 5 PUMPS-Third EditionDokumen127 halamanCHAPTER 5 PUMPS-Third EditionRichard WestonyBelum ada peringkat

- Design of Raft FoundationDokumen9 halamanDesign of Raft FoundationRichard WestonyBelum ada peringkat

- Chapter 7 Reporting-Third EditionDokumen12 halamanChapter 7 Reporting-Third EditionRichard WestonyBelum ada peringkat

- Chapter Six IndexDokumen18 halamanChapter Six IndexRichard WestonyBelum ada peringkat

- Chapter 7 ReportingDokumen12 halamanChapter 7 ReportingRichard WestonyBelum ada peringkat

- Chapter 2 Water ResourcesDokumen52 halamanChapter 2 Water ResourcesRichard WestonyBelum ada peringkat

- Assignment 1 - RCCDokumen7 halamanAssignment 1 - RCCRichard WestonyBelum ada peringkat

- EPANET 2 Users ManualDokumen200 halamanEPANET 2 Users ManualFelicia MichaelBelum ada peringkat

- Rock CharacterizationDokumen26 halamanRock CharacterizationRichard WestonyBelum ada peringkat

- How Sedimentary Rock Is FormedDokumen25 halamanHow Sedimentary Rock Is FormedRichard WestonyBelum ada peringkat

- Research ProblemsDokumen21 halamanResearch ProblemsRichard Westony100% (1)

- Assignment 1 - RCCDokumen7 halamanAssignment 1 - RCCRichard WestonyBelum ada peringkat

- Safety and Occupational Health.Dokumen12 halamanSafety and Occupational Health.Richard WestonyBelum ada peringkat

- Engineering Geology Assignment 29.11.12Dokumen4 halamanEngineering Geology Assignment 29.11.12Richard WestonyBelum ada peringkat

- CJ Blossom Park Lab of the Year Award Winner 2018Dokumen3 halamanCJ Blossom Park Lab of the Year Award Winner 2018petiepanBelum ada peringkat

- Tajeshwar SinghDokumen2 halamanTajeshwar SinghTajeshwar SinghBelum ada peringkat

- Controllogix Power Supplies: Installation InstructionsDokumen14 halamanControllogix Power Supplies: Installation InstructionsneoflashBelum ada peringkat

- 117 Weldox 420 Uk DatasheetDokumen2 halaman117 Weldox 420 Uk DatasheetAndrewFranciscoBelum ada peringkat

- Bang Head Here PDFDokumen12 halamanBang Head Here PDFhalackBelum ada peringkat

- Strength of Materials IiDokumen48 halamanStrength of Materials IiARUNRAJH.V.GBelum ada peringkat

- CW 50 Building Connections Architect Catalogue EN PDFDokumen62 halamanCW 50 Building Connections Architect Catalogue EN PDFJaimasaBelum ada peringkat

- Mapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringDokumen43 halamanMapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringCha RobinBelum ada peringkat

- PMDokumen32 halamanPMRaif AhmedBelum ada peringkat

- Principles of Object Oriented Systems: Software Engineering DepartmentDokumen34 halamanPrinciples of Object Oriented Systems: Software Engineering DepartmentQuynh KhuongBelum ada peringkat

- Pearl River Tower Fire Protection StrategiesDokumen7 halamanPearl River Tower Fire Protection StrategiesDorin DavidBelum ada peringkat

- North Territory Occupation ListDokumen7 halamanNorth Territory Occupation ListHariza Jaya MuhammadBelum ada peringkat

- Machine Elements MidtermDokumen1 halamanMachine Elements MidtermSmajo BorovićBelum ada peringkat

- Static Load Test Service DetailsDokumen2 halamanStatic Load Test Service DetailsMarcelo MotaBelum ada peringkat

- Iec60079 0Dokumen7 halamanIec60079 0Aleksandar GrkicBelum ada peringkat

- Limitless Innovation With Limited Space: Parking Simpli EdDokumen7 halamanLimitless Innovation With Limited Space: Parking Simpli EdAbudo PaixaoBelum ada peringkat

- PID ScrollbarDokumen10 halamanPID Scrollbargogo2021Belum ada peringkat

- Declaration: Approved and Guided byDokumen12 halamanDeclaration: Approved and Guided byRashmiBelum ada peringkat

- AocvDokumen5 halamanAocvgowripBelum ada peringkat

- NIT Warangal MBA Finance CVDokumen2 halamanNIT Warangal MBA Finance CVV Arvind KumarBelum ada peringkat

- t220 Building Drawing n3 QP Aug 2014Dokumen8 halamant220 Building Drawing n3 QP Aug 2014Balungile0% (1)

- Chemical EngineeringDokumen4 halamanChemical EngineeringSanni Tajudeen OlugbengaBelum ada peringkat

- Role of The Structural Engineer in DemolitionDokumen6 halamanRole of The Structural Engineer in DemolitionJames EllisBelum ada peringkat

- It WorkshopDokumen51 halamanIt WorkshopSarthak DugarBelum ada peringkat

- 2019 2020 Degree Checklist BEng SpaceDokumen2 halaman2019 2020 Degree Checklist BEng Spacetysonlit27Belum ada peringkat

- Mechanical 3Rd Sem Class Teacher-Ms. ROSHNI KUNWARE CRDokumen6 halamanMechanical 3Rd Sem Class Teacher-Ms. ROSHNI KUNWARE CRSudeep MazumdarBelum ada peringkat