Post Weld

Diunggah oleh

danemsalDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Post Weld

Diunggah oleh

danemsalHak Cipta:

Format Tersedia

TM

SM

Why Postweld Heat Treat?

Tempers Carbon and Low-Alloy Steels

electrode coatings, fluxes, base metal contamination, or the atmosphere greatly increases the possibility of HAZ and/or weld metal cracking, particularly in hardenable steels.

Alters Hardness and Residual Stresses

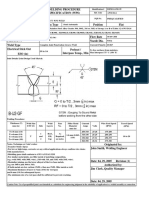

Cross-Sectional View

Typical Postheat (stress relief ) Setup

Weld Center Line

COOPERKNIT high-temperature silicabased knitted fabric offers excellent thermal insulation using non-respirable fibers. Thermocouple putty

Flexible Ceramic Pad (FCP) Heaters (28 watts/inch sq.) connected to a micro-processor control unit. Type K thermocouple connected to microprocessor for accurate temperature control monitoring and documentation.

Weld Properties Improved

Cooperheat-MQS postweld heat treatment (PWHT) can help improve weld integrity, minimize the need for rework, and alter both hardness and residual stress, thereby reducing the potential for cracking. PWHT typically lowers the tensile and yield strength of carbon steel and alloy steel weld metals because the materials soften during the PWHT process. The resulting material is formed more readily and resists impact loading. PWHT also increases hydrogen diffusion, removing the potentially-damaging element from the weld.

Axial Temperature Gradient Gradient Control Band (GCB) Heated Band (HB) Soak Band (SB)

Heat Loss

Heat Loss

(Minimum recommended heat bank 2Rt beyond soak band. R=inside radius of pipe or vessel t=thickness)

Soak Band (SB). The volume of metal that must be heated to and held within the required temperature range for a specified time. It should consist of the weld metal, heat-affected zone (HAZ) and sufficient base metal adjacent to the weld. Heated Band (HB). The surface area over which the heat source is applied to achieve the required temperature in the soak band and limited induced stresses in the vicinity of the weld. It should consist of the soak band plus adjacent base metal necessary to control the temperature within the soak band and limit induced stress.

Gradient Control Band (GCB). The surface area over which insulation and/or additional heat source(s) are placed. It should encompass the soak band, heated bank, and sufficient adjacent base metal such that the maximum axial temperature gradient is not exceeded. Axial Temperature Gradient. The reduction in temperature moving away from the soak band in a direction parallel to the axis of the pipe or pressure vessel. It is frequently specified as a minimum distance, L, over which the temperature may drop to a percentage of that at the edge of the soak band.

Cooperheat-MQS: A Trusted Resource

Common Causes of Weld Failure

Weld failures can result from the presence of residual stresses, poor material properties, or hydrogen. Stress-corrosion cracking and caustic embrittlement Cracked welds pose danger. can occur when exposed to This weld joint in low-alloy steel certain environments, such cracked because it did not cool as hydroxides, nitrates, and properly. hydrogen sulfides. Carbon steel weldments (weld metal, heat-affected zone [HAZ], and adjacent base metal) may be vulnerable to cracking because of environmental conditions, especially wet H2S, amine, and other caustic substances. Certain forms of weld cracking are specifically caused by high hardness (in the weld metal or HAZ) and/or tensile residual stress. Hydrogen introduced into the weld from

Because Cooperheat-MQS has extensive experience in PWHT technologies, we can also help you meet the postweld heat treatment requirements recommended by the American Society of Mechanical Engineers (ASME), American Welding Society (AWS), American Institute of Steel Construction (AISC), and other organizations that provide input or regulation to the welding industry.

Improved Machining Stability

Complex fabrications can result in locked-in stresses. If the stresses remain unrelieved, distortion after machining can result because the metal helping to balance BEFORE MOLTEN WELDMETAL CONTRACTS the tension and compression forces is removed. Sometimes, intermediate UNRESTRAINED CONTRACTION FORCES heating is conducted as the weldment is fabricated, thus reducing excessive build-up of stresses. A final postweld enables the weldment to be machined after welding, without distortion.

(continued on page 4)

TM

SM

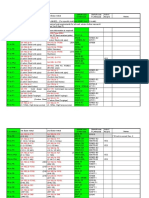

Postweld Heat Treatment Requirements for ASME B31.1 1998 Edition, Updated to 1999 Addenda Process Piping Table 132

Important Note: For information only. Always refer to the actual code.

P-No. Gr. Nos.

1 1,2,3 3 1,2 4 1, 2 5 1, 2 6 1,2,3 7 1, 2 8 1, 2, 3 9A 1 9B 1 10H 1 10I 1

Notes:

1

Holding Temperature Range, oF (oC)

1100 (600) to 1200 (650) 1100 (600) to 1200 (650) 1300 (700) to 1375 (750) 1300 (700) to 1400 (760) 1400 (760) to 1475 (800) 1350 (730) to 1425 (775) None1 1100 (600) to 1200 (650) 1100 (600) to 1175 (630) None1 1350 (730) to 1500 (815)

Holding Time Based On Nominal Thickness Up to 2 in. (50 mm)

1 hr/in. (25 mm) 15 min. minimum 1 hr/in. (25 mm) 15 min. minimum 1 hr/in. (25 mm) 15 min. minimum 1 hr/in. (25 mm) 15 min. minimum 1 hr/in. (25 mm) 15 min. minimum 1 hr/in. (25 mm) 15 min. minimum None1 1 hr/in. (25 mm) 15 min. minimum 1 hr/in (25 mm) 15 min. minimum None1 1 hr/in. (25 mm) 15 min. minimum

Over 2 in. (50 mm)

2 hr plus 15 min. for each additional inch over 2 in. (50 mm) 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) None1 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) 2 hr plus 15 min. for each additional inch over 2 in. (50 mm) None1 1 hr/in. (25 mm)

Postweld heat treatment is neither required nor prohibited. SEE ACTUAL CODE FOR NOTES AND EXEMPTIONS.

TM

SM

Postweld Heat Treatment Requirements for ASME B31.3 1999 Edition, Updated to 2000 Addenda Process Piping Table 331.1.1

Important Note: For information only. Always refer to the actual code. Base Weld Metal Metal Analysis P-No. or S-No. A-Number [Note (1)] [Note (2)] Base Metal Group

1 3 1 2, 11 Carbon Steel Alloy steels Cr 1/2% Alloy steels, 1/2%< Cr 2%

Nominal Wall Thickness in.

3/4 >3/4 3/4 >3/4 All 1/2 >1/2 All

Specified Min. Tensile Strength, Base Metal ksi

All All 71 All >71 71 All >71 All All All All All All All All All All >71 All >71 All All All All All All

Holding Time Metal Temperature Range Nominal Wall [Note (3)] Min. Time, hr/in. hr

1 1 1 1 1 1 1 1 2 2 225 225 225 225

mm

19 >19 19 >19 All 12.7 >12.7 All 13 13 All All All All All 19 >19 All 19 >19 All All All 51 51 >51 All

MPa

All All 490 All >490 490 All >490 All All All All All All All All All All >490 All >490 All All All All All All

F

None 1100-1200 None 1100-1325 1100-1325 None 1300-1375 1300-1375 None 1300-1400 1300-1400 1350-1450 1150-1225 None None None 1100-1175 1400-1500 [Note (5)] None 1100-1300 1100-1300 [Note (7)] 1225-1300 [Note (6)] None 1025-1085 [Note (8)]

C

None 593-649 None 593-718 593-718 None 704-746 704-746 None 704-760 704-760 732-788 621-663 None None None 593-635 760-816 [Note (5)] None 593-704 593-704 [Note (7)] 663-704 [Note (6)] None 552-585 [Note (8)]

Brinell Hardness [Note (4)] Max.

4(10)

5A(10) 5B(10) 5C(10) 6

4, 5

Alloy steels, (2 1/4% Cr 10%) 3% Cr and 0.15% C 1/2 3% Cr and 0.15% C 1/2 >3% Cr or >0.15% C All High alloy steels martensitic A 240 Gr. 429 High alloy steels, ferritic High alloy steels, austenitic Nickel alloy steels Cr-Cu steel Mn-V steel All All All All 3/4 >3/4 All 3/4 >3/4 All All All 2 2 >2 All

1 1 1 1

2 2 2 2

241 241 241 241

7 8 9A, 9B 10 10A

7 8, 9 10

1/2 1/2

1 1/2

1 1 1/2 1

1 1 1/2 1

225 225

10H 10I 11A SG1 11A SG2 62

Duplex stainless steel 27Cr steel 8 Ni, 9Ni steel

1 1 Note [Note (9)]

1 1 1

5Ni steel Zr R60705

1025-10855 552-5855 [Note (8)] [Note (8)] 1000-1100 [Note (9)] 538-593 [Note (9)]

Notes:

P-Number or S-Number from BPV Code, Section IX, QW/QB-422 A-Number from Section IX, QW-442 For holding time in U.S. units, use hr/in. thickness; for SI metric units use min/mm (minutes per mm thickness). Where a hardness limit is specified in Table 331.1.1, at least 10% of welds, hot bends, and hot formed components in each furnace heat treated batch# and 1200% of those locally heat treated shall be tested. When dissimilar metals are joined by welding, the hardness limits specified for the base and welding materials in Table 331.1.1 shall be met for each material. 5. Cool as rapidly as possible after the hold period. 6. Cooling rate to 1200F (649C) shall be less than 100F (56C)/hr; thereafter the cooling rate shall be fast enough to prevent embrittlement. 7. Postweld heat treatment is neither required nor prohibited, but any heat treatment applied shall be as required in the material specification. 8. Cooling rate shall be >300F (167C)/hr to 600F (316C). 9. Heat treat within 14 days after welding. Hold time shall be increased by 1/2 for each 1 in. (25mm) over 25 mm thickness. Cool to 800F (427C) at a rate 500F (278C)/hr, per 1 in. (25mm) nominal thickness, 500F (278C)/hr max. Cool in still air from 800F (427C). 10. Heat treatment temperatures listed for some P-No. 4 and P-No.5 materials may be higher than the minimum tempering temperatures specified in the ASTM specifications for the base material. For higher-strength normalized and tempered materials, there is consequently a possibility of reducing tensile properties of the base material, particularly if long holding times at the higher temperatures are used.

1. 2. 3. 4.

TM

'S OYD REGI LL

SM

QUALI ER T ST

ACCREDITED

ANSI RAB

QMS

SURANCE AS

IS O

9002

Examples of Tensile Stress

CAST WELD METAL PLATE

Documentation for Quality Assurance

Regulatory agencies, as well as many in-house quality assurance departments, often require permanent records of PWHT. All thermocouples and recorders used or supplied by Cooperheat-MQS have certificates of conformance or calibration, respectively, traceable to the National Institute of Standards and Technology (NIST).

The case weld metal is the same length as the plates when hot, but tries to contract as it cools.

PLATE

If this weld metal could be separated from the plates, the cold weld would be shorter than the plate.

HOT COLD

Common Postweld Heat Treatment Cycles

PWHT for carbon and low-alloy steels will fall into one of three categories: 1 Subcritical PWHT, the most common, is typically completed between 1,100oF and 1,400oF and at lower temperatures for hydrogen removal. 2 Supercritical PWHT, although less common, is used to anneal, normalize, harden, and remove hydrogen. It is typically performed between 1,500oF and 1,700oF. 3 Intercritical PWHT is generally not desirable because of partial material transformation. When small areas are treated, subcritical PWHT is used in order to avoid creating partially transformed material.

The weld metal is rigidly attached to the plates and, after cooling must remain the same length. It is, therefore, stretched by the plates and subject to tensile stress. The plates develop a corresponding compressive stress.

Benefits of Tempering

Tempering (softening) helps improve resistance to brittle fracture by producing a more ductile and tougher weld metal and heataffected zone (HAZ). Softening also helps minimize the risk of hydrogen sulfide stress cracking and other failures created by FCP heating pads are typically used for postweld heating. Our exposure to potentially crews have the experience to damaging service environhelp achieve optimum results. ments.

Practical Options

Cooperheat-MQS offers experience and expertise in PWHT technologies, electrical resistance and combustion. Our experienced, and highly trained technicians will carefully assess your needs, and then implement a cost-effective program to achieve the desired results. You have various options for meeting your PWHT requirements including complete, on-site service. Or if you prefer, you can purchase postweld heat treatment equipment from Cooperheat-MQS with assurance that the equipment you select will be the finest available

Serving industries throughout North America with on-site and lab services

Corporate Headquarters 5858 Westheimer road, Suite 625 Houston, Texas 77057 Phone: 800-526-4233 or 713-735-6900 Fax: 713-735-6901 E-mail: cooperheat-mqs@2isi.com

For the location of the facility nearest you, visit our website. www.coopherheat-mqs.com

Anda mungkin juga menyukai

- Post Weld Heat TreatmentDokumen10 halamanPost Weld Heat Treatmentcristian291011Belum ada peringkat

- PWHT, HT, Igc, MawpDokumen40 halamanPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- Preheat and Interpass TempDokumen2 halamanPreheat and Interpass TempUche UrchBelum ada peringkat

- PWHT of P91Dokumen7 halamanPWHT of P91Howo4Die100% (4)

- Duplex Stainless Steel - Part 2 - TWIDokumen6 halamanDuplex Stainless Steel - Part 2 - TWItuanBelum ada peringkat

- WPSASMEDokumen76 halamanWPSASMERama TamaBelum ada peringkat

- Concept of Post Weld Heat Treatment PDFDokumen2 halamanConcept of Post Weld Heat Treatment PDFsridharchebrolu100% (2)

- Metrode Dissimilar Consumable SelectorDokumen7 halamanMetrode Dissimilar Consumable SelectorClaudia MmsBelum ada peringkat

- Review of Type IV Cracking of Weldments in 9Dokumen64 halamanReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajBelum ada peringkat

- Welding PreheatDokumen2 halamanWelding PreheatsjmudaBelum ada peringkat

- Welding of P91Dokumen11 halamanWelding of P91mahmoud_allam3100% (1)

- WPS API1104 A516 GR 70Dokumen1 halamanWPS API1104 A516 GR 70Erick HoganBelum ada peringkat

- Electrodes EnglishDokumen139 halamanElectrodes Englishcostelino72Belum ada peringkat

- WPS 316 L PDFDokumen4 halamanWPS 316 L PDFIrinaBelum ada peringkat

- PWTH RequirementDokumen2 halamanPWTH Requirementveeru290683_20976731Belum ada peringkat

- P91 Repair With NiCrDokumen76 halamanP91 Repair With NiCrElias KapaBelum ada peringkat

- Duplex Ss Welding PDF FreeDokumen8 halamanDuplex Ss Welding PDF Freeel_sharkawy2011Belum ada peringkat

- Metrode P92TP Welding ConsumablesDokumen23 halamanMetrode P92TP Welding Consumablespipedown456Belum ada peringkat

- Equivalent ASME en MaterialsDokumen3 halamanEquivalent ASME en MaterialsChee WeiBelum ada peringkat

- PWHTDokumen79 halamanPWHTnguyenBelum ada peringkat

- Filler Metal SelecionDokumen1 halamanFiller Metal SelecionMurugananthamParamasivam100% (1)

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Dokumen9 halamanJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- Presentation On PWHT & Stress RelievingDokumen23 halamanPresentation On PWHT & Stress Relievingedu_canete88% (16)

- Materials For Reformer Furnace Tubes History of EvolutionDokumen7 halamanMaterials For Reformer Furnace Tubes History of EvolutionAPI100% (1)

- Metrode - P92 WPS PDFDokumen3 halamanMetrode - P92 WPS PDFXing ChenBelum ada peringkat

- PWHT of Dissimilar: Metal WeldsDokumen48 halamanPWHT of Dissimilar: Metal WeldswchavezbBelum ada peringkat

- Duplex Stainless Steel Welding - Best PracticesDokumen4 halamanDuplex Stainless Steel Welding - Best PracticesjosemiguelzuBelum ada peringkat

- CR Mo Issues of Concern 6Dokumen33 halamanCR Mo Issues of Concern 6Asad Bin Ala Qatari100% (1)

- Super Duplex Stainless SteelDokumen1 halamanSuper Duplex Stainless SteelUma Shankar100% (1)

- Gmaw Complete Aws d1.6Dokumen1 halamanGmaw Complete Aws d1.6Silvia CardenasBelum ada peringkat

- P 91 - Welding WPSDokumen2 halamanP 91 - Welding WPSSuhailshah123475% (4)

- WPS - EngineerDokumen20 halamanWPS - Engineerhunghoanglong100% (1)

- All Material and Filler & PWHTDokumen20 halamanAll Material and Filler & PWHTMOHANBelum ada peringkat

- PWHTDokumen57 halamanPWHTssBelum ada peringkat

- Ferrite Weld Test Procedure-1Dokumen5 halamanFerrite Weld Test Procedure-1tedmer1Belum ada peringkat

- PWHT ReqDokumen13 halamanPWHT ReqAbhay KarandeBelum ada peringkat

- PWHTDokumen9 halamanPWHTshervinyBelum ada peringkat

- Bohler Welding Thermalpower - ENGDokumen24 halamanBohler Welding Thermalpower - ENGghostinshellBelum ada peringkat

- Welding of Cast IronDokumen35 halamanWelding of Cast IronincaurcoBelum ada peringkat

- P 91 Piping WeldingDokumen81 halamanP 91 Piping Weldingneelapu mahesh reddy100% (1)

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDokumen4 halamanDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamBelum ada peringkat

- Welding Heat TreatmentDokumen33 halamanWelding Heat TreatmentWan HafiyBelum ada peringkat

- Dillimax 690 eDokumen4 halamanDillimax 690 ePrabhakar TiwariBelum ada peringkat

- Cswip - Section 20-Heat TreatmentDokumen9 halamanCswip - Section 20-Heat TreatmentNsidibe Michael Etim100% (1)

- Welding Recommendation TS890Dokumen2 halamanWelding Recommendation TS890max_powerBelum ada peringkat

- As Rolled, Hot Rolled, Hot Finished: Applied ToDokumen8 halamanAs Rolled, Hot Rolled, Hot Finished: Applied ToAlaaBelum ada peringkat

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDokumen12 halaman02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical Applicationsivanmatijevic100% (1)

- Duplex Stainless SteelsDokumen6 halamanDuplex Stainless SteelsFaisal NaeemBelum ada peringkat

- Duplex Stainless Steel - Welding-TwiDokumen4 halamanDuplex Stainless Steel - Welding-TwiNatrajj SivakumarBelum ada peringkat

- Recom. de Soldadura XARDokumen4 halamanRecom. de Soldadura XARelias667Belum ada peringkat

- Fabrication of Heavy Wall Reactors Kesselbautag 2003Dokumen8 halamanFabrication of Heavy Wall Reactors Kesselbautag 2003faiz oeBelum ada peringkat

- Cor-Ten - Weather & Corrosion Resistant SteelDokumen5 halamanCor-Ten - Weather & Corrosion Resistant SteelAnjan DeyBelum ada peringkat

- Welding Domex SteelsDokumen16 halamanWelding Domex Steelspozolab100% (1)

- WI Contoh JawapanDokumen5 halamanWI Contoh JawapanMuhammad ZariqBelum ada peringkat

- Thyssenkrupp Materials International: Material Data SheetDokumen4 halamanThyssenkrupp Materials International: Material Data SheetjaseerkannothBelum ada peringkat

- Balancing Wear, StrengthDokumen4 halamanBalancing Wear, StrengthStephen MontelepreBelum ada peringkat

- Alloy Data Sheet 6082Dokumen1 halamanAlloy Data Sheet 6082Prashant MalveBelum ada peringkat

- Cold Formed Steel Members and SheetingDokumen14 halamanCold Formed Steel Members and SheetingMihai MariusBelum ada peringkat

- Post Weld Heat TreatmentDokumen2 halamanPost Weld Heat TreatmentgullenariBelum ada peringkat

- Psrao Welding DefectsDokumen35 halamanPsrao Welding DefectsdanemsalBelum ada peringkat

- Παρουσίαση EC3 Connections Και ΙNSTANT Steel 2012Dokumen28 halamanΠαρουσίαση EC3 Connections Και ΙNSTANT Steel 2012danemsalBelum ada peringkat

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDokumen7 halamanWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalBelum ada peringkat

- Buried PipeDokumen83 halamanBuried PipePlalvarezcelis100% (3)

- A - SeriesDokumen18 halamanA - SeriesdanemsalBelum ada peringkat

- Welding Defects During Fabrication of PipesDokumen12 halamanWelding Defects During Fabrication of PipesDeepak GuptaBelum ada peringkat

- Psrao Welding DefectsDokumen35 halamanPsrao Welding DefectsdanemsalBelum ada peringkat

- RT Formulas For CalculationsDokumen4 halamanRT Formulas For CalculationsdanemsalBelum ada peringkat

- Welding Processes: Basic Ideas, Terminology, Properties of The Welding ArcDokumen38 halamanWelding Processes: Basic Ideas, Terminology, Properties of The Welding ArcdanemsalBelum ada peringkat

- A - SeriesDokumen18 halamanA - SeriesdanemsalBelum ada peringkat

- Isostud Isostud: 08 1213-CPD-4454 EN 13967Dokumen1 halamanIsostud Isostud: 08 1213-CPD-4454 EN 13967Alexandru PelinBelum ada peringkat

- Unit 5 - Week 2 - Crystallography II + Structure of Solids IDokumen4 halamanUnit 5 - Week 2 - Crystallography II + Structure of Solids IAnonymous OYXHZSksBelum ada peringkat

- Astm f1554Dokumen1 halamanAstm f1554Reyuni doankBelum ada peringkat

- Navy Welding ManualDokumen194 halamanNavy Welding Manualeugenemic100% (1)

- 776 Dayton's Engineered Clearance-WebDokumen6 halaman776 Dayton's Engineered Clearance-WebNaukowyDrpBelum ada peringkat

- Lecture 03 Design of RC Members For Flexure and Axial Loads Color VersionDokumen82 halamanLecture 03 Design of RC Members For Flexure and Axial Loads Color VersionawaishahmadBelum ada peringkat

- Rheology Unit 2Dokumen69 halamanRheology Unit 2Shivani SinghBelum ada peringkat

- Introduction To Fracture MechanicsDokumen63 halamanIntroduction To Fracture MechanicsSaAhRaBelum ada peringkat

- Steel Properties, Limit State Design and Introduction To EurocodesDokumen51 halamanSteel Properties, Limit State Design and Introduction To EurocodesLilyBelum ada peringkat

- 90mm 316l Peeled and PolishedDokumen1 halaman90mm 316l Peeled and PolishedB.M Industrial WorksBelum ada peringkat

- Ch2 3rded ExtendedDokumen81 halamanCh2 3rded ExtendedReza SadeghiBelum ada peringkat

- ThermoplasticsDokumen3 halamanThermoplasticsMadhuShakthiBelum ada peringkat

- Lesson 1 and 2Dokumen22 halamanLesson 1 and 2Mark MarkBelum ada peringkat

- Effects of Asphalt Mix Design Properties On Pavement Performance A Mechanistic ApproachDokumen8 halamanEffects of Asphalt Mix Design Properties On Pavement Performance A Mechanistic ApproachAmul ShresthaBelum ada peringkat

- ENR202 Mechanics of Materials Lecture 1B Slides and Notes: Slide 1Dokumen29 halamanENR202 Mechanics of Materials Lecture 1B Slides and Notes: Slide 1jimyBelum ada peringkat

- CMG Advances in Polymer Modelling TS2018Dokumen28 halamanCMG Advances in Polymer Modelling TS2018lvt2906Belum ada peringkat

- Solid Solution HardeningDokumen5 halamanSolid Solution HardeningVasantha SudasinghaBelum ada peringkat

- Three Dimensional Finite ElemeDokumen16 halamanThree Dimensional Finite ElemeSajjad AnwarBelum ada peringkat

- Explain ASD Vs LRFD To A Dumb ME - Structural Engineering Other Technical Topics - Eng-TipsDokumen12 halamanExplain ASD Vs LRFD To A Dumb ME - Structural Engineering Other Technical Topics - Eng-TipscblerBelum ada peringkat

- Nanomaterials - Wikipedia, The Free EncyclopediaDokumen6 halamanNanomaterials - Wikipedia, The Free EncyclopediaGurunath AeroBelum ada peringkat

- Bendin Moment ClaculationDokumen1 halamanBendin Moment ClaculationMoher NeerajBelum ada peringkat

- Section 6Dokumen133 halamanSection 6ILAYAPERUMAL K100% (2)

- Material Data Center - Datasheet Teldene® R40MLTDokumen2 halamanMaterial Data Center - Datasheet Teldene® R40MLTAndy KayBelum ada peringkat

- Composites: Part B: Ali Nazari, Shadi RiahiDokumen9 halamanComposites: Part B: Ali Nazari, Shadi RiahitrawsBelum ada peringkat

- DelrinDokumen65 halamanDelrind-fbuser-98630126100% (1)

- Effect of Thermomechanical Treatment On The Intergranular Corrosion of Al-Mg-Si-Type Alloy BarsDokumen8 halamanEffect of Thermomechanical Treatment On The Intergranular Corrosion of Al-Mg-Si-Type Alloy BarsbharatBelum ada peringkat

- PV 6702 EnglischDokumen13 halamanPV 6702 Englischjopster84Belum ada peringkat

- UNIT 3 ThermodynamicsDokumen40 halamanUNIT 3 ThermodynamicsHimadhar SaduBelum ada peringkat

- Surface & Coatings Technology: SciencedirectDokumen8 halamanSurface & Coatings Technology: SciencedirectVikrant Saumitra mm20d401Belum ada peringkat

- Casting DefectsDokumen2 halamanCasting DefectskoushikraoBelum ada peringkat