Corrosion Rate Conversion Guide

Diunggah oleh

m_alodat6144Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Corrosion Rate Conversion Guide

Diunggah oleh

m_alodat6144Hak Cipta:

Format Tersedia

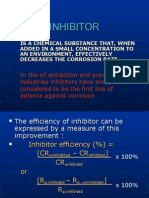

Corrosion Rate Conversion The most used expression for Corrosion Rate in the US is the mpy (Mils per

year). To convert corrosion rate (corrosion rate conversion) between the mpy and the equivalent in metric unit mm/y (millimeter per year): 1 mpy = 0.0254 mm/y = 25.4 microm/y To calculate the corrosion rate from metal loss: mm /y = 87.6 x (W / DAT)

where: W = weight loss in milligrams D = metal density in g /cm3 A = area of sample in cm2 T = time of exposure of the metal sample in hours

Anodic protection is a method used to prevent corrosion. This method is most often used in highly corrosive environments to protect metal immersed in a solution with uncommonly acidic or basic qualities. Anodic protection is different from cathodic protection, another technique used to prevent corrosion in metal devices and structures. In anodic protection, electric current is used to create a protective oxidized layer on the base protected material, often known as the substrate. This process is most frequently employed in industrial production.

Usually, anodic protection is used to protect metal in environments too corrosive for other methods of protection like cathodic protection to be effective. Cathodic protection differs from anodic techniques because cathodic protection uses a metal rod called a sacrificial cathode to corrode in place of the protected metal. This technique is usually used in water, while anodic methods of protection are used in more corrosive environments.

Commonly used to protect metal in solutions with unusually high or low potential hydrogen (pH) levels, which indicate the acidic or basic nature of a solution, anodic protection is most frequently used for steel. This technique can usually be found in factories that work with high or low pH

solutions, particularly sulfuric acid, phosphoric acid, or chromic acid. Other lesser-used substrate materials that can benefit from anodic protection include magnesium, titanium, and zinc.

Anodic protection is a method used to prevent corrosion. This method is most often used in highly corrosive environments to protect metal immersed in a solution with uncommonly acidic or basic qualities. Anodic protection is different from cathodic protection, another technique used to prevent corrosion in metal devices and structures. In anodic protection, electric current is used to create a protective oxidized layer on the base protected material, often known as the substrate. This process is most frequently employed in industrial production. Usually, anodic protection is used to protect metal in environments too corrosive for other methods of protection like cathodic protection to be effective. Cathodic protection differs from anodic techniques because cathodic protection uses a metal rod called a sacrificial cathode to corrode in place of the protected metal. This technique is usually used in water, while anodic methods of protection are used in more corrosive environments. Commonly used to protect metal in solutions with unusually high or low potential hydrogen (pH) levels, which indicate the acidic or basic nature of a solution, anodic protection is most frequently used for steel. This technique can usually be found in factories that work with high or low pH solutions, particularly sulfuric acid, phosphoric acid, or chromic acid. Other lesser-used substrate materials that can benefit from anodic protection include magnesium, titanium, and zinc.

Anda mungkin juga menyukai

- Anodic Protection - Eng. Onel IsraelDokumen11 halamanAnodic Protection - Eng. Onel IsraelOnel Israel Badro100% (2)

- Corrosion Prevention by Use of InhibitorsDokumen19 halamanCorrosion Prevention by Use of InhibitorsSai PradeepBelum ada peringkat

- تقرير تأكل (Anodic Protection)Dokumen10 halamanتقرير تأكل (Anodic Protection)ياسر نوفل ورد100% (1)

- Method To Prevent CorrosionDokumen4 halamanMethod To Prevent CorrosionFaradilah Binti Ajma'inBelum ada peringkat

- Corrosion PreventionDokumen10 halamanCorrosion Preventionওয়াসিমBelum ada peringkat

- C51 PDFDokumen29 halamanC51 PDFAbdulsalam MaaBelum ada peringkat

- Selection of MaterialDokumen16 halamanSelection of MaterialRiyaBelum ada peringkat

- Corrosion Control MethodsDokumen4 halamanCorrosion Control MethodsYousuf MemonBelum ada peringkat

- Two Corrosion Protection MethodsDokumen5 halamanTwo Corrosion Protection MethodsShukry AmiryBelum ada peringkat

- Coating Inhibitors MonitoringDokumen23 halamanCoating Inhibitors Monitoringdip_maan100% (1)

- Corrosion Doctors OrgDokumen1 halamanCorrosion Doctors OrgSuryatejaDaidiBelum ada peringkat

- FALLSEM2015 16 CP3624 24 Aug 2015 RM01 Module 5 CoordinatorDokumen43 halamanFALLSEM2015 16 CP3624 24 Aug 2015 RM01 Module 5 CoordinatorPlaya 5Belum ada peringkat

- Corrosion Management StrategiesDokumen6 halamanCorrosion Management StrategiesPrasadBelum ada peringkat

- Corrosion Prevention For MetalsDokumen17 halamanCorrosion Prevention For Metalsabdul100% (1)

- Corrosion InhibitorsDokumen38 halamanCorrosion Inhibitors20pcha122 20pcha122Belum ada peringkat

- CorrosionDokumen10 halamanCorrosionshivamBelum ada peringkat

- Corrosion Minimizing ProceduresDokumen5 halamanCorrosion Minimizing ProceduresCh. Muhammad UsamaBelum ada peringkat

- Corrosion Protection WebDokumen2 halamanCorrosion Protection Webjmab13Belum ada peringkat

- Corrosion ProtectionDokumen37 halamanCorrosion Protectionmaaz siddiqueBelum ada peringkat

- Corrosion Inhibitors and Protective CoatingsDokumen27 halamanCorrosion Inhibitors and Protective CoatingsVeviet pomata100% (1)

- Anodic Protection: Liquid Environment: Name: Muhammad Emir Rafiansyah Akbar NPM: 2006489193Dokumen30 halamanAnodic Protection: Liquid Environment: Name: Muhammad Emir Rafiansyah Akbar NPM: 2006489193emir akbarBelum ada peringkat

- Anti-Corrosion Coatings For Different Service Exposures: Shivananda PrabhuDokumen10 halamanAnti-Corrosion Coatings For Different Service Exposures: Shivananda Prabhurohit yadavBelum ada peringkat

- Inhibitor CorrosionDokumen21 halamanInhibitor CorrosionDiego Pabon100% (2)

- Corrosion and RustDokumen9 halamanCorrosion and RustahmedBelum ada peringkat

- Durability, Oxidation, Corrosion and Degradation: - Laura García - Juan Triviño - Andrés Salazar - Cristian ÁlvarezDokumen39 halamanDurability, Oxidation, Corrosion and Degradation: - Laura García - Juan Triviño - Andrés Salazar - Cristian Álvarezestefania0696Belum ada peringkat

- InhibitorDokumen33 halamanInhibitorMohd SyazwanBelum ada peringkat

- Corrosion Part 2Dokumen23 halamanCorrosion Part 2ronnie1992Belum ada peringkat

- Anodic Protection Lecture23 PDFDokumen5 halamanAnodic Protection Lecture23 PDFKantilal MalwaniaBelum ada peringkat

- Corrosion Protection: Short Overview and SummaryDokumen39 halamanCorrosion Protection: Short Overview and SummarydangminhBelum ada peringkat

- Anodic ProtectionDokumen30 halamanAnodic ProtectionChintoo GeeBelum ada peringkat

- Improving Piston Ring Wear Resistance Through Coated SurfacesDokumen47 halamanImproving Piston Ring Wear Resistance Through Coated SurfaceseshuBelum ada peringkat

- Control of CorrosionDokumen12 halamanControl of CorrosionSyed ShahbazBelum ada peringkat

- Chemistry Project: Problems in Daily Life and Its SolutionDokumen32 halamanChemistry Project: Problems in Daily Life and Its Solutionanurag prernaBelum ada peringkat

- Unit 5 Corrosion ControlDokumen36 halamanUnit 5 Corrosion ControlMohammad KhBelum ada peringkat

- Project Proposal: 1. AbstractDokumen4 halamanProject Proposal: 1. Abstractgilberto herreraBelum ada peringkat

- Anodic Protection Taufiq, AqilDokumen13 halamanAnodic Protection Taufiq, AqilnazirulhakimBelum ada peringkat

- Submitted By:: Priyabrat Prasad MahapatraDokumen13 halamanSubmitted By:: Priyabrat Prasad MahapatraPriyabrat PrasadBelum ada peringkat

- Corrosion and Methods To Avoide ItDokumen8 halamanCorrosion and Methods To Avoide ItYogeshwari RaoljiBelum ada peringkat

- Ways To Control CorrosionDokumen37 halamanWays To Control CorrosionKyle DugayoBelum ada peringkat

- Circuits Assignment 1Dokumen5 halamanCircuits Assignment 1LykaShanineGabrielMendozaBelum ada peringkat

- FALLSEM2019-20 CHY1701 ETH VL2019201007055 Reference Material I 06-Sep-2019 Revised Module 4Dokumen73 halamanFALLSEM2019-20 CHY1701 ETH VL2019201007055 Reference Material I 06-Sep-2019 Revised Module 4yuvanBelum ada peringkat

- CORROSION RATE ANALYSIS ,, Assignment 1Dokumen4 halamanCORROSION RATE ANALYSIS ,, Assignment 1Muhammad MustafaBelum ada peringkat

- Cathodic Protection PDFDokumen24 halamanCathodic Protection PDFJorge Luis Clavijo Iturri50% (2)

- Seminar On Oxidation Resistant CoatingDokumen18 halamanSeminar On Oxidation Resistant CoatingManoj IyengarBelum ada peringkat

- A Seminar On Cathodic Protection TechniquesDokumen9 halamanA Seminar On Cathodic Protection TechniquesDevashish JoshiBelum ada peringkat

- Sacrificial Anode: Computer Application in Pipeleine Cathodic Protection DesignDokumen13 halamanSacrificial Anode: Computer Application in Pipeleine Cathodic Protection DesignboypardedeBelum ada peringkat

- Everything You Need to Know About Corrosion ResistanceDokumen12 halamanEverything You Need to Know About Corrosion ResistanceTal PeraltaBelum ada peringkat

- Cathodic Protection: The BasicsDokumen8 halamanCathodic Protection: The BasicsbookbumBelum ada peringkat

- Corrosion Control Methods Solar Case StudiesDokumen7 halamanCorrosion Control Methods Solar Case StudiesAshwin AnilBelum ada peringkat

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionDari EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionBelum ada peringkat

- Hot-Dip Galvanizing of Steel StructuresDari EverandHot-Dip Galvanizing of Steel StructuresPenilaian: 5 dari 5 bintang5/5 (3)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesDari EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesBelum ada peringkat

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksDari EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksBelum ada peringkat

- Corrosion: Corrosion ControlDari EverandCorrosion: Corrosion ControlL L ShreirPenilaian: 5 dari 5 bintang5/5 (1)

- Oil and Gas Corrosion Prevention: From Surface Facilities to RefineriesDari EverandOil and Gas Corrosion Prevention: From Surface Facilities to RefineriesPenilaian: 5 dari 5 bintang5/5 (6)

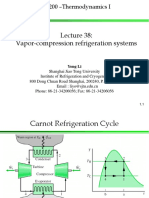

- Vapor Compression Cycle ImprovementsDokumen12 halamanVapor Compression Cycle Improvementsm_alodat6144Belum ada peringkat

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDokumen13 halamanLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloBelum ada peringkat

- Chapter 6-Multiple Evaporator and CompressorDokumen27 halamanChapter 6-Multiple Evaporator and Compressorm_alodat6144Belum ada peringkat

- Advanced Fluid Mechanics Inclined Plane FlowDokumen33 halamanAdvanced Fluid Mechanics Inclined Plane Flowm_alodat6144Belum ada peringkat

- Steady Conduction Heat TransferDokumen14 halamanSteady Conduction Heat TransferAmirBelum ada peringkat

- Boundary Layer ThoryDokumen120 halamanBoundary Layer ThoryTSIGE ABERABelum ada peringkat

- 0 C3 01Dokumen24 halaman0 C3 01danytiger132Belum ada peringkat

- Compound Vapor Refrigeration System ExamplesDokumen65 halamanCompound Vapor Refrigeration System Examplesm_alodat6144100% (1)

- Flow of Viscous Fluids and Boundary Layer Flow-SetDokumen18 halamanFlow of Viscous Fluids and Boundary Layer Flow-Setm_alodat6144Belum ada peringkat

- Flow of Viscous Fluids and Boundary Layer Flow-SetDokumen18 halamanFlow of Viscous Fluids and Boundary Layer Flow-Setm_alodat6144Belum ada peringkat

- Unsteady Heat ConductionDokumen8 halamanUnsteady Heat ConductionRamesh KonakallaBelum ada peringkat

- Chapter 5-Compounded Vapor Compression CycleDokumen40 halamanChapter 5-Compounded Vapor Compression Cyclem_alodat6144100% (1)

- Fluid Flow EquationsDokumen24 halamanFluid Flow Equationsm_alodat6144Belum ada peringkat

- Fundamentals of Mass Transfer in Multi-Component SystemsDokumen8 halamanFundamentals of Mass Transfer in Multi-Component SystemsWs LimBelum ada peringkat

- Capítulo 5 - IncroperaDokumen7 halamanCapítulo 5 - IncroperaCaio Muniz100% (2)

- Rev BraytonDokumen7 halamanRev BraytonAnil Kumar RoutBelum ada peringkat

- Vapor Compression Refrigeration SystemDokumen11 halamanVapor Compression Refrigeration Systemm_alodat6144Belum ada peringkat

- Refrigeration and Air Conditioning Chapter8Dokumen51 halamanRefrigeration and Air Conditioning Chapter8Richard Weimer100% (2)

- Refrigeration and Heat Pump SystemsDokumen26 halamanRefrigeration and Heat Pump SystemsJojolasBelum ada peringkat

- Vapor-Compression Refrigeration SystemsDokumen28 halamanVapor-Compression Refrigeration Systemsm_alodat6144Belum ada peringkat

- 620 28 PDFDokumen28 halaman620 28 PDFwaraBelum ada peringkat

- Vapor Compression Refrigeration SystemDokumen11 halamanVapor Compression Refrigeration Systemm_alodat6144Belum ada peringkat

- MCE 407 Refrigeration and Air Conditioning CourseDokumen100 halamanMCE 407 Refrigeration and Air Conditioning Coursem_alodat6144Belum ada peringkat

- Types of Vapour Compression CyclesDokumen9 halamanTypes of Vapour Compression CyclesFully YoursBelum ada peringkat

- CHE 311 Transport I Course NotesDokumen234 halamanCHE 311 Transport I Course Notesm_alodat6144Belum ada peringkat

- CH 4 Flowing Fluids and Pressure Variation Compatibility Mode PDFDokumen93 halamanCH 4 Flowing Fluids and Pressure Variation Compatibility Mode PDFm_alodat6144Belum ada peringkat

- Innovative Refrigeration Systems: Sameer KhandekarDokumen16 halamanInnovative Refrigeration Systems: Sameer Khandekarm_alodat6144Belum ada peringkat

- Chapter 4-Simple Vapour Compression Refrigeration SystemDokumen40 halamanChapter 4-Simple Vapour Compression Refrigeration Systemm_alodat614450% (2)

- Dimensional Analysis for Similarity Between Models and PrototypesDokumen50 halamanDimensional Analysis for Similarity Between Models and Prototypesm_alodat6144Belum ada peringkat

- Dimensional Analysis for Similarity Between Models and PrototypesDokumen50 halamanDimensional Analysis for Similarity Between Models and Prototypesm_alodat6144Belum ada peringkat

- List of RelaysDokumen26 halamanList of RelaysadhyarthaBelum ada peringkat

- 7.1 (149 Marks) : MarkschemeDokumen51 halaman7.1 (149 Marks) : MarkschemeSemwezi Enock100% (1)

- A Psychologist Explains Why Everyone Is Suddenly On TiktokDokumen3 halamanA Psychologist Explains Why Everyone Is Suddenly On TiktokImen ImenBelum ada peringkat

- Underpinning Methods, Procedure and ApplicationsDokumen10 halamanUnderpinning Methods, Procedure and ApplicationsShivaun Seecharan0% (1)

- Orgin of Life and Organic EvolutionDokumen74 halamanOrgin of Life and Organic Evolutionasha.s.k100% (5)

- Grid Infrastructure Installation and Upgrade Guide Ibm Aix Power Systems 64 BitDokumen284 halamanGrid Infrastructure Installation and Upgrade Guide Ibm Aix Power Systems 64 BitAntonioBelum ada peringkat

- L10: Factors that Affect a Pendulum's PeriodDokumen9 halamanL10: Factors that Affect a Pendulum's PeriodHeide CarrionBelum ada peringkat

- Vandergrift - Listening, Modern Theory & PracticeDokumen6 halamanVandergrift - Listening, Modern Theory & PracticeKarolina CiBelum ada peringkat

- Module 3 - Subsequent To AcquisitionDokumen8 halamanModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTREROBelum ada peringkat

- Eslit-Vinea-LA 03 Task #1-4Dokumen11 halamanEslit-Vinea-LA 03 Task #1-4darkBelum ada peringkat

- Syllabus: Android Training Course: 1. JAVA ConceptsDokumen6 halamanSyllabus: Android Training Course: 1. JAVA ConceptsVenkata Rao GudeBelum ada peringkat

- Gec220 Assignment 2Dokumen5 halamanGec220 Assignment 2precious omokhaiyeBelum ada peringkat

- CourseLab 2 4 PDFDokumen252 halamanCourseLab 2 4 PDFLiliana StanescuBelum ada peringkat

- 2021.01 - Key-Findings - Green Bond Premium - ENDokumen6 halaman2021.01 - Key-Findings - Green Bond Premium - ENlypozBelum ada peringkat

- CompReg 13SEPTEMBER2023Dokumen2.725 halamanCompReg 13SEPTEMBER2023syed pashaBelum ada peringkat

- MF Formula Sheet - FullDokumen10 halamanMF Formula Sheet - FullublehkogeniusBelum ada peringkat

- SITXWHS001 Participate in Safe Work Practices - Training ManualDokumen82 halamanSITXWHS001 Participate in Safe Work Practices - Training ManualIsuru AbhimanBelum ada peringkat

- SC WD 1 WashHandsFlyerFormatted JacobHahn Report 1Dokumen3 halamanSC WD 1 WashHandsFlyerFormatted JacobHahn Report 1jackson leeBelum ada peringkat

- Rajani Panchal Phone: - 0279642567Dokumen4 halamanRajani Panchal Phone: - 0279642567Phillip JohnsonBelum ada peringkat

- Drift Punch: Product Features ProfilesDokumen3 halamanDrift Punch: Product Features ProfilesPutra KurniaBelum ada peringkat

- Grand Central Terminal Mep Handbook 180323Dokumen84 halamanGrand Central Terminal Mep Handbook 180323Pete A100% (1)

- CH 9 - Spontaneity, Entropy, and Free EnergyDokumen65 halamanCH 9 - Spontaneity, Entropy, and Free EnergyCharbel RahmeBelum ada peringkat

- Quick Healthcare Stencil: SketchDokumen2 halamanQuick Healthcare Stencil: SketchNafiz Hannan NabilBelum ada peringkat

- Boosting BARMM Infrastructure for Socio-Economic GrowthDokumen46 halamanBoosting BARMM Infrastructure for Socio-Economic GrowthEduardo LongakitBelum ada peringkat

- Alpacon Degreaser BIO GENDokumen2 halamanAlpacon Degreaser BIO GENFahmi Ali100% (1)

- Online Dispute ResolutionDokumen18 halamanOnline Dispute ResolutionMak YabuBelum ada peringkat

- VNL-Essar Field Trial: Nairobi-KenyaDokumen13 halamanVNL-Essar Field Trial: Nairobi-Kenyapoppy tooBelum ada peringkat

- Corporate Citizenship, Social Responsibility, Responsiveness, and PerformanceDokumen27 halamanCorporate Citizenship, Social Responsibility, Responsiveness, and Performanceguru2k9100% (1)

- Adoption ApplicationDokumen3 halamanAdoption ApplicationwriterhildBelum ada peringkat

- Conflict Analysis Tools PDFDokumen12 halamanConflict Analysis Tools PDFApeuDerrop0% (1)