Design of Internal & External Water Supply

Diunggah oleh

Atish KumarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Design of Internal & External Water Supply

Diunggah oleh

Atish KumarHak Cipta:

Format Tersedia

E2-E3/Civil

Rev date: 01-04-11

E2-E3: CIVIL

CHAPTER-5 DESIGN OF INTERNAL & EXTERNAL WATER SUPPLY SYSTEM

BSNL India

For Internal Circulation Only

Page: 1

E2-E3/Civil

Rev date: 01-04-11

Design of Internal & external Water supply System

Quality Of Water 1.0 Absolute pure water is never found in nature. Water found in nature contains a number of impurities in varying amount in the form of salts, gases, bacteria algae etc. 1.10 Onl y potable water is to be supplied in a water suppl y scheme. A potable water is one that is safe to drink, pleasant to the taste, and usable for domestic purpose. Cont aminated water is one that contains micro-organisms, chemicals, industrial or other waters, or sewage so that it is unfit for its intended use. 1.20 The following are the standards of water to be used for domestic purposes. Physical Temperature Odour Colour Turbidit y Taste Chemical Total Solids Hardness - 10 0 c to 15.6 0 c - 0 to 4 P 0 value - 10 to 20 (platinum cobalt scale) - 5 to 10 ppm (Silica scale) - no objectionable taste - upto 500 p.p.m. - 75 p.p.m. to 115 p.p.m. (hardness expressed as caco3 equivalent) - upto 250 p.p.m. - upto 0.3 p.p.m. - 6.5 to 8 - 0.1 p.p.m. - upto 250 p.p.m. - upto 120 p.p.m. - 5 to 6 p.p.m. - Nil - No B- coil in 100 ml. - One Number in 100 ml.

Chlorides Iron and Manganese PH Value Lead Arsenic Sulphate Carbonate Alkanit y Dissolved Ox ygen B.O.D. Biological B- coil Most Probable Number (M.P.N) Radiological emitters emitters

- 1 c/liter - 10 c/liter

BSNL India

For Internal Circulation Only

Page: 2

E2-E3/Civil

Rev date: 01-04-11

1.30 Regular periodical chemical, physical and bacteriological tests of water samples shall be got it done through approved laboratory. Remedial measures based on test results shall be taken. 2.0 Treatment Process The treatment process depends on the impurities present in water. For removing various t ypes of impurities, the following treatment processes are used. --------------------------------------------------------- -------------------------Impurity Process used for removal --------------------------------------------------------- -------------------------1. Floating matters as leaves, Screening Dead animals etc. 2. Suspended impurities as silt clay, Sand etc. Fine suspended matter Plain Sedimentation

3.

Sedimentation with coagulation Filtration

4.

Micro-organism and Colloidal matters Dissolved gases, tastes and odours Softening

5.

Aeration and chemical treatment Permutit method

6.

7. Pathogenic bacteria Disinfections --------------------------------------------------- -------------------------------We in our department generall y use e ither Municipal water or ground water. Water received from above sources are usuall y clear and may require onl y disinfect ion, chemical treatment softening etc. Therefore discussion is onl y restricted to the disinfection of water. 2.2 Methods of Disinfe ction The disinfection of water can be done by the following common methods. a) By the boiling of water. b) By ultra-violet rays. c) By the use of ozone. d) By treatment with silver or electro -Katadyn process. e) By the use of Iodine and Bromine. f) By the use of excess lime. g) By using potassium permanganate. h) By the use of chlori ne.

BSNL India For Internal Circulation Only

Page: 3

E2-E3/Civil

Rev date: 01-04-11

Methods a.b.c.d. & e are effective bu t very costl y. Therefore these methods can be used at individual level and cannot be used in water works. 2.2.1 Disinfection by Chlorine Disinfection by Chlorine is very useful to kill the various Micro Organisms present in the water. When Chlorine is dissolved in water, it hydrol ysis immediatel y as : Cl 2 + H 2 O HOC L + H + + Cl ( Hypochlorous Acid)

After some time Hypochlorous Acid further ionizes as HOC L H + + OC L ( Hypochlorite Ions)

Two prevailing species HOCL (Hypochlorous Acid) and OC L (Hypochlorite Ion) are called Free Available Chlorine and are responsible for the disinfection of water. 2.2.1.1 Forms of Chlorine Chlorine is generall y available in the following forms a) In the forms of Liquid Chlorine. b) In the forms of gaseous Chlorine. c) In the form of Chlorine dioxide. d) In the form Chloramines. e) In the form of Bleaching Powde r. Form of Chlorine (a ) to (d) require treatment plants and are used in big water works. For small colonies we commonl y use Bleaching Powder as a source of Chlorine for disinfection. When Bleaching Powder (Calcium Hypochlorite) is added to the water , following chemical reaction takes place. Ca (ocl) 2 (Calcium Hypochlorite) ----Ca + + + 2OCL (Hypochlorite Ions)

Hypochlorite ions obtained further combine with Hydrogen ions present in water and form hypochlorous Acid as follows OCl - + H + HOC L (Hypochlorous Acid) Hypochlorous Acid and Hypochlorite Ions so formed kills the bacteria present in the water.

BSNL India For Internal Circulation Only

Page: 4

E2-E3/Civil

Rev date: 01-04-11

2.2.1.2 Dosage of Chlorine In normal waters that are pre treated with settling and filtration, a chlorine of about 0.2 to 1 ppm (Particle Per Million) may be required to obtain the desired results. The commercial bleaching powder normall y contains low values of chlorine which vary 25-30%. The value of chlorine content continuously decreases if the powder is exposed to the atmosphere; therefore it should be stored in air tight container. The dose of Bleaching Powder should be calculated properly. If the dose is less, it will not be effective to kill the Bacteria and if it is more, odour and taste of water wi ll be objectionable and will not be potable. 3.0 Example Given Data Population of Colony Demand of water Availabilit y of Chlorine in Bleaching Powder = 30% Required dosage of Chlorine in water at Water works. = 0.3 p.p.m. = 1,000 = 200 litre/Capita/day

Calculate the Quantity of Chlorine & Bleaching Powder required Per day? Solution Water requirement of The colony = = Chlorine dose required For disinfection = 200 x 1,000 2 x 100000 litre

0.3 p.p.m.

= Quantit y of Chlorine Required = = Quantit y of Bleaching Powder

BSNL India

0.3 mg/lit re 0.3 x 2 x 10 5 mg 60 gm/day 60 x 100 30 Page: 5

For Internal Circulation Only

E2-E3/Civil

Rev date: 01-04-11

= 200 gm. Demand Requirement and General Principles 1.0 The demand load of water suppl y system in a building is not exactl y determinable. The number of sanitary fitting varies not onl y for different classes of buildings but also in same class of buildings but depending upon the habits of people. The minimum flow that will be satisfactory for any part of premises wi ll greatl y depend upon consumer, his standard of living, his professional needs, the size of famil y and other ancillary requirements such as gardening air conditioning etc. The total daily requirement of the buildings is calculated on the basis of the popu lation to be served and per capita rate of supply. Calculate the population on the basis of the five members per famil y, and number of dwelling units in the building. The per capita rate may be taken as 200 lit/head/day as residences are to be provided with full flushing system. In case of non -residential buildings the dail y consumption per day in liters shall be given table B and the population to be provided for, shall be as per actual requirements in the building or as given in table A. 1.1 Requirement of water for Buildings 1. The total expected population of the building should first be worked out with reference to area of the building by using table A. The total requirement of water per day of this population should be calculated on the basis of table B. This would give the figure for storage of general water suppl y. Fire Fighting Requirements For buildings not greater than 15 m in height, no separate provision is to be made for firefighting purposes. For buildings greater than 15m, dema nd of water should be worked out as per Table E. General Guide lines for Underground and Over Head Tank

1.2

2.0

Where underground tanks are used for the storage of water for domestic purposes, the following requirements should be compiled with. 1. The tank should project at least 30 cm above the highest flood level. Where this is not possible the manhole cover should be raised 30 cm above the highest flood level of the localit y or ground level whichever is higher. 2. The design of the tank should be such that w ater should not be allowed to collect round the tank.

BSNL India

For Internal Circulation Only

Page: 6

E2-E3/Civil

Rev date: 01-04-11

3. The tank should be perfectl y water tight. 4. The inner surface of tank should be rendered smooth as for as possible. 5. The top of tank should be so leveled to prevent water from accumulating on it. 6. The tank must be covered by R.C.C. slab leaving a manhole opening provided with iron cover fitted with leak proof cast iron frame . Where tank is of large size, Adequate number of manholes should be provided. 7. No gap should be allowed around the suction pipe. 8. The overflow pipe or vent shafts if provided shall have a wire gauge cover of 1.5 mm mesh properl y screwed tightl y to the opening. 9. The tall building fittings should not be subjected to pressure greater than 30 Mt. Head. This can be achieved by provision of intermediate cisterns and pumps or by use of pressure release values. 2.1 In case of an individual building like telephone exchange. Post office, or administrative building, the overhead water storage should be provided over the terrace of the building. For spread out complexes like the residential colonies, training centers, workshop complexes , overhead tank and underground tanks should be located at a high ground and at the center of the demand. The height of staging of overhead tank should be such that the residual water pressure at consumers tap after allowing for all losses is not less than 3.5 m head or 0.35 kg/cm 2 . 2.2 The underground and overhead tank with independent staging should be designed and constructed for the ultimate requirements of th e building or complex to meet the needs of further expansion. Whenever temporary overhead water storage tanks are located over the terrace of a building with a provision for future vertical extension, such tanks should be designed for 1/3rd dail y requirem ent of existing phase onl y. However the underground tank should be designed for 2/3rd of ultimate dail y requirement of the building after further expansion. 3.0 Supply to High Rise Buildings

3.1 General In the case of high rise or multistoried buildi ngs, the down take system may be one or a combination of the following systems;

BSNL India For Internal Circulation Only

Page: 7

E2-E3/Civil

Rev date: 01-04-11

i) Overhead storage system ii) Break pressure tank system i) The Overhead Storage System In this system the tanks are provided on the terrace of the building. A main fold down take pipe may be taken out from the storage tanks which should be designed for peak load demand. A pressure reducing value shall be provided in the down takes to limit the head to a maximum of 25 m head in easil y accessible places like ducts, cat walks, etc. ii) Break Pressure Tank System In this system, the entire building is to be convenientl y divided into suitable zones of 5 to 8 stories each. For each such zone there shall be a break pressure tank, the capacit y of which should be such that it holds 10 to 15 minutes suppl y of the floors it feeds below and shall be not less than 2KL each for flushing and other domestic purposes separatel y. The down take from the master - overhead tank feeds into the pressure tank. The capacit y of the pump should be such as t o cope up with the peak demand. Normall y 3 pumps called the lead pump; the supplementary pump and the stand by pump respectively are provided. The last pump is preferabl y diesel driven to serve where there is a power failure. 4.0 Principles and General Gu idelines for Planning of External Water Supply System. 4.1 Distribution 4.1.1 Pipe Work a) There should be no inter - connection or cross connection whatsoever between pipe or fitting for conveying or containing whole some water and a pipe or fitting for containing impure water, water liable to contamination or uncertain qualit y or water which has been used for any purpose. b) The design of the pipe work should be such that there is no possibilit y of back siphonage or otherwise. Valves cannot be relied on to prevent such back flow.

BSNL India

For Internal Circulation Only

Page: 8

E2-E3/Civil

Rev date: 01-04-11

c) All pipe work should be so designed, laid or fixed and maintained as to be and to remain completel y water t ight, there by avoiding waste of water, damage to propert y and the risk of contamination of the wate r conveyed. d) No piping should be laid in or through any sewer or drain or any manhole or chamber connected herewith, nor in ground contaminat ed by sewage farm yards, stable yards and proximit y of cesspools should be avoided. In designing and planni ng the layout of the pipe work, due attention should be given to maximum rate or discharge required , econom y in labour & material, accessibilit y, protection against damage, corrosion and avoidance of airlocks noise in transmission and unsightl y arrangem ent. e) To reduce frictional losses, the piping should be as smooth as possible internall y. Methods of jointing should be such as to avoid internal roughness and projections at joints whether of the jointing materials or otherwise. f) Change in diameter and direction should preferabl y be gradual rather than abrupt to avoid undue loss of head. g) Underground piping should be laid at such a depth that is unlikel y to be damaged by traffic loads, or frost and vibrations. Where piping has to be laid in any g round liable to subsidence then special consideration should be given to the t ype of joint to be adopted in order to minimize risk of damage due to settlement. Where the piping has to be laid across recentl y disturbed ground, continuous longitudinal suppor t should be provided and not merel y supporting piers at inter vals. 4.1.2 a. b. Water Supply Mains Mains should be divided into sections by provisions of sluice valves (or stop valves if the main is of 50mm bore or less). Air valves should be provided at summi ts and washouts at low points between on summits unless adequate provision is made for the discharge of air and water by pressure of service connection and fire hydrants. Washouts should not be discharged into drain or sewer or into a main hall or chamber connected there to. Where a washout discharges into a natural water, the discharge should at all times be well above the highest possible water level in the water course.

c.

BSNL India

For Internal Circulation Only

Page: 9

E2-E3/Civil

Rev date: 01-04-11

d.

e. f.

Mains need not be laid at unvarying gradients but may follow the general contour of t he ground. They should however as for as possible, fall continuousl y towards the washouts and rise continuousl y towards the air valves. They should not rise above the hydraulic gradient that is to say there should always be positive presser greater than at mospheric, at every point under working condition. Provisions should be made at every bend, branch and dead end in a main to resist the hydraulic thrust. Mains should be designed for a rate of flow sufficient to certified the combined the maximum demand of all the services to be supplied. All maximum demand of the separate service may not occur simultaneousl y and the actual combined maximum demand may be proportion sum of the separate maximum demands , which will be determined by the number and character of services.

4.1.3

General Principles for Arrangements of External Water Supply Pipe The distribution pipes consist of suppl y mains, branches and laterals. They are normall y laid sloping from high level to low level areas to secure maximum advantage of head available due to gravity. Sluice valves are placed at intervals on straight runs, at junctions and at branching of points to control the flow of water in different sections. Drain valves are placed at low spots in the system to drain off the pipes for carry out any repairs. 5.0 Layout of Distribution System 5.1 Dead End System Since the distribution pipes are to be laid under the roads in towns, their layout gets guided by the layout of the roads. Where the roads are not properl y planned, the water suppl y mains have to follow main roads and branches are taken off from these at different junction which usuall y terminate at a number of dead ends. Each system has also to be followed in the ribbon development which usuall y takes place along the main roads to longer towns, and cities. This system requires less number of valves to control the flow in the system and also shorter pipe lengths so that it is cheap and simple but since water can be reached to any place by onl y one route, any damage and subseq uent repair to the pipe line result in shutting downs the suppl y of a large area ahead. Further the dead ends in the system cause the water in pipe to remain stagnant which results in the degradation of its quality.

BSNL India

For Internal Circulation Only

Page: 10

E2-E3/Civil

Rev date: 01-04-11

5.2 Grid Iron System Where the roads arranged in grid iron pattern the pipe lines are laid similarl y in the form of net work with number of interconnections. Water reaches different places through more than one route. Hence the amounts to be carried frictional losses, and the sizes of th e pipe get reduced. However the system requires more length of pipes and number of sluice valves to control it. It is also difficult to design and costlier to construct. But it eliminates all dead ends and because of its different interconnections the wat er remains in constant circulation. If repairs are to be carried out to any pipe, onl y a small portion in the vicinit y gets affected, since water can be supplied ahead by some other route.

5.3 The Ring Main System The capacit y of grid iron can be en hanced and the pressure can be improved by running a looped feeder around the high demand section and arranging grid over it.

BSNL India

For Internal Circulation Only

Page: 11

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 12

E2-E3/Civil

Rev date: 01-04-11

Table - A

The assessment of (clause 6.2.1. part clause 7,5 or part code of India 1970 S No. i) the population in occupancies based on plinth area IX Plumbing services section I. Water suppl y and IV fire protection as given in * National Building *) Population Assume a famil y of 5 person per quarter or an area of 12.5m 2 /person whichever is more. 10.00m 2 /person

Type of Building Staff Quarters & residence

ii)

iii)

Technical buildings such as Telephone Exchange Buildings, Telecom Buildings, Factories and workshop. Post offices and Administrative Buildings Dormitories Assembl y without seating facilities including Tiffin rooms,dining rooms canteen etc. Day Schools, Boarding schools and Hostels Communit y halls Institutional Stores

10.00m 2 /person 7.50m 2 /person 1.5m 2 /person (*) 4.00m 2 /person 1.5 m 2 /person (*) 15.00m 2 /person (**) 30.00m 2 /person

iv) v)

vi) vii) viii) ix)

Notes : *The plinth area shall include, in addition to the main assembl y room or space, any occupied connecting room o r space in the same story or in the storey above or below, where entrance is common to such rooms and spaces and they are available for use by the occupants of the assembl y place. No deductions shall be made is the plinth area for corridors, closets or o ther sub divisions; the area shall include all space serving the particular assembl y occupancy. **Occupant load in dormitory portions where sleeping accommodation is provided, shall be calculated at not less than 7.5m2 plinth area per person.

BSNL India

For Internal Circulation Only

Page: 13

E2-E3/Civil

Rev date: 01-04-11

Table B

S. No. i) ii) Building Staff Quarters & residence Technical buildings such as Telephone Exchange Buildings, Telecom, Buildings, factories And workshops. Post offices and Administrative Buildings Dormitories Assembl y without seating facilities including Tiffin rooms, dining rooms canteen etc. School a) Day Schools, b) Boarding Schools and Hostels. Institutions Communit y halls Stores Demand of Water 200 Liters/ head/ day (Para 5.1.N.B.C. 1983) 45 liters/ head/ day (Para 3.2 IS -1172-1971)

iii) iv ) v)

45 liters/ head/ day (Para 3.2 IS -1172/ 1971) 135 liters/ head/ day (para 3.2 IS -1172-1971) 70 liters/ seat/ day (Para 3.2 Is. 1172 1971)

vi)

45 liters/ head/ day 135 liters/head/day 45 liters/ head/ day 15 liter/seat/d ay 45 liters/ head/ day

vii) viii) ix)

BSNL India

For Internal Circulation Only

Page: 14

E2-E3/Civil

Rev date: 01-04-11

Design of Water Distribution System 1.0Till date no direct methods are available for design of distribution pipes. While doing the design, diameter of pipes are assumed. Terminal pressure is calculated, aft er allowing the losses of head, when full peak flow discharge is flowing. The Hazen s williams formula is widely used for determining the velocit y through pipes. 0.85 CH.R 0 . 6 3 . Velocit y m/Sec. Slope of the Energy Line. Hydraulic Mean Depth A/P = = (Cross section Area/ Perimeter) S0.54

V = V = S = R = R = CH

Coefficient of Hydraulic Capacit y.

For circular conduits, expression becomes V = 4.567 X 10 - 3 .CH.d 0 . 6 3 .S 0 . 5 4

Discharge Q = 3.1 X 10 - 4 X CH. d 2 . 6 3 . S 0 . 5 4

In the above said expression Q = d = Discharge in K.L Per day Dia of pipe in mm Slope of Hydraulic Gradient = Coefficient of Hydraulic Capacit y.

S = CH

BSNL India

For Internal Circulation Only

Page: 15

E2-E3/Civil 1.1 Value of CH for Different Pipes

Rev date: 01-04-11

(Hazens Williams Coefficient) The value of CH for new conduit materials are as follows: ----------------------------------------------------------------------------------Sl. Conduit Value CH for Recommended Value of CH No. Material New Material for design purpose --------------------------------------------------------------------------- -------1. Cast Iron 130 100 2. G.I. for more than 50mm dia G.I. for less than 50mm Steel rivetted joints Steel, welded joints with cement or bitumen enamel Steel, welded joints Concrete A.C.

120 120 110

100 55 95

3. 4. 5.

140 140 140 150

110 100 110 120

6. 7. 8.

9. P.V.C. 150 120 ----------------------------------------------------------------------------------1.2 Head Losses due to Friction Head loss due friction can be determined by the formula Q 1 L 1.85 HL = -----------------------X --------------X 0.094 CH D4.97 HL L = = Head loss due to friction in M Length of pipe in M.

Head loss in assumed pipe diameter is determined by above formula. After deduction head loss, the terminal pressure is determined.

BSNL India

For Internal Circulation Only

Page: 16

E2-E3/Civil

Rev date: 01-04-11

2.0 2.1

General Design Guide Lines Design Period It is generall y taken 30 years for new distribution system. Peak Factor Capacit y of distribution system should be sufficient to meet the maximum hourl y flow which can be computed by multipl ying the average hourl y flow the following peak factors. For Towns having Population i) ii) iii) iv) Up to 50,00 From 50,000 to 2 lac Above 2 lac For Industrial demand = = 3.0 = 2.0 =

2.2

2.5 1.0

2.3

Rate of Water Supply As discussed earlier , generall y we may assume 200 lit/capit a/day for staff quarters. Terminal Pressure Distribution system should be designed for following minimum terminal pressure i) ii) iii) Single Stroyed Building = Double Stroyed Building = Three Stroyed Building = 7.0m 12.0m 17.0m

2.4

2.5

Permissible Velocity The permissibl e velocit y is kept as per follows --------------------------------------------------------------------------Diameter of pipe approximate value of the velocit y (Internal in cm) meter/second ------------------------------------------------------- -------------------10 0.9 15 1.2 25 1.5 40 1.8 ---------------------------------------------------------------------------

2.0 Design of pipe Network Since the design of network involves the method of trial and error by assuming various diameters of the pipes, it is very tedious and cumbersome job.

BSNL India

For Internal Circulation Only

Page: 17

E2-E3/Civil

Rev date: 01-04-11

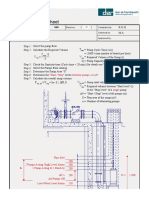

To reduce the tedious calculations, the Hazens Williams Nomogram is used Hazen s Williams chart for various materials of pipe are available in Public Health Engineering departments of the state Govt. For using the Nomogram, a straight edge is placed on any two known values, such as discharge and velocit y, and the value of the two other unknowns such loss of head per thousand meter and the diameter of pipe can be directl y read out. If the termin al pressure in any particular zone is found to be more or less than the minimum permissible, than size of pipe can be suitabl y decreased or increased. The process is continued on trial till the terminal pressures are obtained. 4.0 Example Design a water s uppl y scheme. shown in plan as Annexure A. Average requirement of water = Reduced Level of O.H.T. = R.L. of Point ------do-------------do-------------do-------Length of pipe ------do-------------do-------Peak Factor Minimum terminal pressure A B C D AB BC CD = = = = = = = = =

Various zone and population

200lit/ capita/ day 120 m 100m 98m 96m 93m 700m 500m 600m 3 17.00m

________________________

BSNL India

For Internal Circulation Only

Page: 18

E2-E3/Civil

Rev date: 01-04-11

Annexure A

200

200

500

200

500

A

O.H. T.

500 300 200 300 300 200 400 400

BSNL India

For Internal Circulation Only

Page: 19

E2-E3/Civil

Rev date: 01-04-11

400

500

700

A

O.H. T.

D 500

600

300

300

900

BSNL India

For Internal Circulation Only

Page: 20

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 21

E2-E3/Civil

Rev date: 01-04-11

S. N

Lin e

Population Served

Maximum Demand 3x200xP 24x60x60 Lit./secon d

Proposed dia meter of pipe in mm

Loss of head

Hydra ulic level in M

Groun d level in M

Termi nal Head in M

Previou s

Local

Total

1 1. 2. 3.

2 CD BC AB

3 ----2100 2900

4 2100 800 1300

5 2100 2900 4200

6 14.58 20.14 29.17

7 150 200 250

Rate per 1000 M 8 8.0 4.0 3.0

Lengt h of pipe in M 9 600 500 700

Loss in pipe in M 10 4.8 2.0 2.1

11 D = 111.1 C = 115.9 B = 117.9 A = 120

12 D = 93 C = 96 B = 98 A = 100

13 18.1 O.K 19.0 O.K 19.9 O.K 20

BSNL India

For Internal Circulation Only

Page: 22

E2-E3/Civil

Rev date: 01-04-11

Internal Water Supply 1.0 Principle and General Guide for Planning of Internal Water Supply System The maximum rate of demand for water in premises should be estimated based on number, nature and use of the fittings provided. If no storage or onl y small storage for water is provided in the premises, the service pipe should be capable of discharging at the rate of maximum demand. Service pipes larger than necessary to furnish the required suppl y should not be installed, exc ept where it is desirable to make provision for future expansion. The pressure of the water in service pipe will depend upon the head of water in main, or upon the elevation of the over head tank or upon pumping plant if any, and the appropriate class or grade of piping of suitable strength should be chosen in accordance therewith. As far as practicable, the underground service pipe should be laid at right angles to the main and in approximatel y strength lines to facilities location for repairs. A stop valve should be provided in the service pipe in an accessible position inside the building, as near as practicable to the point of entry of pipe, so that the suppl y may be readil y shut off in case of trouble and for repairs. a draining tap should be provided just above the stop valve to enable the service piping in the building to be emptied of water when the stop valve is shut. Where building is divided into flats or other separatel y occupied parts which are supplied from common service pipe, there should be a stop valve to control the suppl y of each part, fixed inside so as to be under the sole control of the occupiers. The service pipe should be so arranged that if does not pass through any such part of the building on its way to a suppl y elsewhere, but if it does so pass through, then instead of stop valve on the service pipe where it enters there should be stop valve on every branch pipe of the service pipe in the said part and in addition there should the building, in a place accessible to all occupie s of the building. Where water is supplied to flats or other separatel y occupied parts of a building through a common distributing pipe from

1.1

1.2

1.3

1.4

BSNL India

For Internal Circulation Only

Page: 23

E2-E3/Civil

Rev date: 01-04-11

1.5

storage cistern, distributing pipe should be arranged and stop valves fixed as described above for a common servic e pipe. Where practicable, water for drinking should not pass through cistern, and there, taps suppl ying water for these purposes should be supplied directl y from service pipe. A service pipe should not be connected (into any distributing pipe. Such connections might permit the backflow in certain circumstances of water from a cistern into service pipe with consequent danger of contamination. It might also result in pipes and fitting being subjected to a pressure higher than that for which they were design ed and in flooding from overflowing system. The services should be designed and installed so as to avoid airlocks and so that piping and fittings can be drained off water for prevention of damages by frost and to facilitate repairs. There should be draini ng taps or draw off taps at low points from which the piping should rise continuously to draw off taps, ball valves cisterns or vents at high points. In a building which is divided into flats or other separatel y occupied parts, it should be possible to drain off the water in any such without interfering with suppl y to any other part. Service should be designed and installed so as to reduce the production and transmission of noise as much as, possible. High velocit y of water in piping and fittings should be avoided. Piping should be confined as far as possible to rooms where appliances are fixed. Noise may be reduced by the use of thick walled piping and choice of pipe material. Piping should be so located that it is not undul y exposed to accidental damage, and fixed so as to avoid accumulations of dirt and facilitate cleaning.

1.6

1.7

1.8

1.9

All pipe work should be planned so that the piping is accessible for inspection, replacement and repair. To avoid its being unsightl y, it is usuall y possible to arrange it in or ad jacent to cupboards, recesses etc. provided that there is a sufficient space to work on the piping with usual tools. Piping should not be buried in walls solid floors. In suitable cases, piping may be buried for short distances provided that adequate prot ection is given against damage by frost, corrosion on expansion and that no joints are buried. If the piping is laid in ducts or

BSNL India For Internal Circulation Only

Page: 24

E2-E3/Civil

Rev date: 01-04-11

chases these should be room y enough to facilitate repairs. Covers to ducts and chases or floors boards covering piping should b e so fixed as to be readil y removable.

BSNL India

For Internal Circulation Only

Page: 25

E2-E3/Civil

Rev date: 01-04-11

1.10 Number of Connections Fed from a Main DIA OF DELIVERY PIPE 100mm 90mm 80mm 65mm 50mm 40mm 32mm 25mm 20mm 100 1 90 1 1 80 2 1 1 DIAMETER OF BRANCH PIPE (MM) 65 3 2 2 1 50 6 4 6 2 1 40 10 8 6 3 2 1 32 17 13 10 6 3 2 1 25 32 25 18 11 6 3 2 1 20 53 43 32 19 10 6 3 2 1 15 113 88 66 39 20 12 7 4 2

BSNL India

For Internal Circulation Only

Page: 26

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 27

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 28

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 29

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 30

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 31

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 32

E2-E3/Civil

Rev date: 01-04-11

BSNL India

For Internal Circulation Only

Page: 33

E2-E3/Civil

Rev date: 01-04-11

Questions:1. What are the different standards of Potable Water? 2. What are the different processes for removal of various impurities in water? 3. What are the various methods of disinfection of water? 4. What is Free Available Chlorine and which compound is responsible for killing the bacteria of water in Chlorination? 5. What are the various forms of Chlorine? 6. Which is the cheap and best source of Chlorine? 7. What is the range of dosage of Chlorine for disinfection of water? 8. What are the parameters for assessment of population in occupancies based on plinth area in case of Staff Quarters and Telephone Exchange Buildings? 9. What is the daily requirement of water for designing water supply system in case of Staff Quarters and Telephone Exchange Buildings? 10. What are the merits and demerits of Dead End System, Grid Iron System and Ring Main System? 11. Which empirical formula is used for calculating the head losses in the pipe network?

BSNL India

For Internal Circulation Only

Page: 34

Anda mungkin juga menyukai

- EM 1110-2-3104 Design of Pump StationsDokumen72 halamanEM 1110-2-3104 Design of Pump Stationsomar_lozano_26Belum ada peringkat

- Residential and Commercial High StrengthDokumen36 halamanResidential and Commercial High StrengthNiong DavidBelum ada peringkat

- AWDM 10 CH04 Water - Consumption PDFDokumen49 halamanAWDM 10 CH04 Water - Consumption PDFEdward BeleñoBelum ada peringkat

- Population Equivalance and WSPDokumen5 halamanPopulation Equivalance and WSPWong Kuan SengBelum ada peringkat

- Design Criteria 2019 PDFDokumen64 halamanDesign Criteria 2019 PDFngronau124545Belum ada peringkat

- Activated Sludge Waste Water Treatment Calculations - S.I. UnitsDokumen2 halamanActivated Sludge Waste Water Treatment Calculations - S.I. Unitsnsr2t100% (1)

- Pump Calcs PreDokumen3 halamanPump Calcs PreaberraBelum ada peringkat

- Projectile MotionDokumen11 halamanProjectile MotionRamachandran VenkateshBelum ada peringkat

- Min Pattern: Icrc/Wathab Demand Analysis 10/19/2017Dokumen3 halamanMin Pattern: Icrc/Wathab Demand Analysis 10/19/2017GJ CCBelum ada peringkat

- Permeate Line Pressure Drop CalculationsDokumen2 halamanPermeate Line Pressure Drop Calculationsask.kulkarni KulkarniBelum ada peringkat

- Electrical Load Data Sheet: Facility Name: Date: Address: City/State/Zip: Directions or Nearest Intersecting StreetDokumen1 halamanElectrical Load Data Sheet: Facility Name: Date: Address: City/State/Zip: Directions or Nearest Intersecting Streetgag aaBelum ada peringkat

- 4 Hydraulic Design: (For Design Storm Volume of Storm Sewer See Section 3.2 On Page 22)Dokumen15 halaman4 Hydraulic Design: (For Design Storm Volume of Storm Sewer See Section 3.2 On Page 22)Syazwan AbhBelum ada peringkat

- Design of Vertical Drop Fall: Surface FlowDokumen3 halamanDesign of Vertical Drop Fall: Surface FlowMohammedBelum ada peringkat

- Is Reinforcement Needed in Precast Concrete Manhole UnitsDokumen1 halamanIs Reinforcement Needed in Precast Concrete Manhole UnitsPanji Ginaya TaufikBelum ada peringkat

- Lec 5 Fire Demand & Variation in Water Consumption PDFDokumen19 halamanLec 5 Fire Demand & Variation in Water Consumption PDFchyousuf75% (4)

- Damping Dissipation AbsorbtionDokumen3 halamanDamping Dissipation AbsorbtionLia MatiasBelum ada peringkat

- Population Forecasting MethodsDokumen40 halamanPopulation Forecasting MethodsViralo MeBelum ada peringkat

- Water DemandDokumen9 halamanWater Demandraveena athiBelum ada peringkat

- Growth and Capacity Evaluation Warrenton 05072015Dokumen16 halamanGrowth and Capacity Evaluation Warrenton 05072015Fauquier NowBelum ada peringkat

- Pumping Stations Design Lecture 2 PDFDokumen25 halamanPumping Stations Design Lecture 2 PDFabuzaidcoBelum ada peringkat

- Water Demand CalculationDokumen6 halamanWater Demand CalculationValium MorphineBelum ada peringkat

- Hydraulic Jump Length Calculator 111205Dokumen2 halamanHydraulic Jump Length Calculator 111205abhishek5810Belum ada peringkat

- 4.2 Design of The Pump According To The Installation Baseplated Pumps AdvantagesDokumen3 halaman4.2 Design of The Pump According To The Installation Baseplated Pumps AdvantagesSandi AslanBelum ada peringkat

- Sewer Pipes and Flows in SewersDokumen28 halamanSewer Pipes and Flows in SewersBalanlan PenalesBelum ada peringkat

- Side Wall of Screen Chamber & Grit Chamber DataDokumen5 halamanSide Wall of Screen Chamber & Grit Chamber DataShankarappa NBelum ada peringkat

- Design calculation sheet: V V n−1) - ΔH. SDokumen8 halamanDesign calculation sheet: V V n−1) - ΔH. SMoh Amm0% (2)

- Design Calculation For Overflow Pipeing System and Overfllow Lagoon at Unit IIIDokumen10 halamanDesign Calculation For Overflow Pipeing System and Overfllow Lagoon at Unit IIIAnonymous 3kDy7eBelum ada peringkat

- 5 A Surface Irrigation System PDFDokumen65 halaman5 A Surface Irrigation System PDFsewmehon amareBelum ada peringkat

- Volume of Water Required, Distance, Flow Rate and Pressure. Water Reticulation System Should BeDokumen2 halamanVolume of Water Required, Distance, Flow Rate and Pressure. Water Reticulation System Should BeMae Gillain Maquilan MilanaBelum ada peringkat

- Percolation - Tank DesignDokumen25 halamanPercolation - Tank DesignSanthosh Kumar Baswa100% (1)

- Muhammad Jazil L13-5775 B: LPCD Liters Per Capita in One DayDokumen5 halamanMuhammad Jazil L13-5775 B: LPCD Liters Per Capita in One DaySikandar MalikBelum ada peringkat

- Epa SWMM TutorialDokumen16 halamanEpa SWMM TutorialHassan Abib BasalBelum ada peringkat

- Design of Outlets - JaboriDokumen7 halamanDesign of Outlets - JaboriHaji Ahmad BhattiBelum ada peringkat

- Water Tank CLPMDokumen3 halamanWater Tank CLPMkiran raghukiranBelum ada peringkat

- 15 Gravity Sewer SpreadsheetDokumen3 halaman15 Gravity Sewer SpreadsheetShashank YadavBelum ada peringkat

- Hydraulic Grade LineDokumen0 halamanHydraulic Grade LinemuazeemKBelum ada peringkat

- Zimbabwe - Urgent Water Supply and Sanitation Rehabilitation Project - Phase 2 - Appraisal ReportDokumen28 halamanZimbabwe - Urgent Water Supply and Sanitation Rehabilitation Project - Phase 2 - Appraisal ReportTrevor T Paraziva100% (1)

- Biogas Production Fromuasb Technology: A Review Onfunctioning and Suitability Ofuasb Based Sewage Treatment Plant Atraipur Kalan, ChandigarhDokumen7 halamanBiogas Production Fromuasb Technology: A Review Onfunctioning and Suitability Ofuasb Based Sewage Treatment Plant Atraipur Kalan, ChandigarhIOSRjournalBelum ada peringkat

- Traverse CalculationsDokumen6 halamanTraverse CalculationsAngelie LapeBelum ada peringkat

- Sediment Basin Design Example PDFDokumen8 halamanSediment Basin Design Example PDFAgus FirdausBelum ada peringkat

- Roughing Filter For Water Pre-Treatment TechnologyDokumen10 halamanRoughing Filter For Water Pre-Treatment TechnologyFauzan AffifBelum ada peringkat

- 14Dokumen4 halaman14dpkBelum ada peringkat

- HDPE Pipe Line Sizes & RatingsDokumen10 halamanHDPE Pipe Line Sizes & RatingsSreenubabu KandruBelum ada peringkat

- Design of Pipe Line Source: HW FormulaeDokumen8 halamanDesign of Pipe Line Source: HW FormulaeyadavBelum ada peringkat

- Head Losses CalculationDokumen3 halamanHead Losses Calculationmeisam100% (1)

- Lec 7-Week 4 - (Design of Pumping Station)Dokumen17 halamanLec 7-Week 4 - (Design of Pumping Station)jahanzaibchBelum ada peringkat

- Lab Waste WaterDokumen10 halamanLab Waste WaterAriffBelum ada peringkat

- Hydrology ManualDokumen10 halamanHydrology ManualCivil Engineer Hub100% (1)

- Water Supply Engineering Tutorials 4 To 7Dokumen5 halamanWater Supply Engineering Tutorials 4 To 7Dr. Akepati Sivarami ReddyBelum ada peringkat

- Pressure Loss in Schedule 40 Steel PipesDokumen11 halamanPressure Loss in Schedule 40 Steel PipesAnonymous qrSsYuxyoYBelum ada peringkat

- Trikling FiltersDokumen16 halamanTrikling Filtersmosaad khadrBelum ada peringkat

- CLSRP Guiedelines PDFDokumen7 halamanCLSRP Guiedelines PDFbirajajenaBelum ada peringkat

- Complete Syllabus Mechanical-MinDokumen191 halamanComplete Syllabus Mechanical-MinSalman Mohd HBelum ada peringkat

- Commercial Banks Behavior and Effect On Profitability in UaeDokumen16 halamanCommercial Banks Behavior and Effect On Profitability in UaeAbdelghani RemramBelum ada peringkat

- TOPIC 1bi Units For Quantities & Concentrations - Molarity, Normality & StoichiometryDokumen26 halamanTOPIC 1bi Units For Quantities & Concentrations - Molarity, Normality & StoichiometrySyahirah FazialBelum ada peringkat

- Fluid2015 Lecture Ch3-2 PDFDokumen33 halamanFluid2015 Lecture Ch3-2 PDFBolWolBelum ada peringkat

- Activated SludgeDokumen17 halamanActivated SludgeAquasoul Co100% (1)

- Kasba Packaged Drinking WaterDokumen5 halamanKasba Packaged Drinking Watersenhill007Belum ada peringkat

- Problems: Water Supply For ResidencesDokumen16 halamanProblems: Water Supply For ResidencesShilpi Sethi100% (1)

- WHO EmergencyDokumen64 halamanWHO EmergencysandeepanchoudhuryBelum ada peringkat

- Basement Floor PlanDokumen1 halamanBasement Floor PlanAtish KumarBelum ada peringkat

- Footing Calculation L B HT Cuboid (L+B) Thickness Nos Strap F1 Feets 5 5 2 50 10 1 6 5 5 6 3 90 11 1 5 5.5Dokumen2 halamanFooting Calculation L B HT Cuboid (L+B) Thickness Nos Strap F1 Feets 5 5 2 50 10 1 6 5 5 6 3 90 11 1 5 5.5Atish KumarBelum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- E RTN FAQDokumen10 halamanE RTN FAQtalsur2002Belum ada peringkat

- India WikipediaDokumen929 halamanIndia WikipediaAtish KumarBelum ada peringkat

- IELTS Writing Master v1 2Dokumen33 halamanIELTS Writing Master v1 2IELTSguruBelum ada peringkat

- IELTS Speaking TopicsDokumen2 halamanIELTS Speaking Topicsim.alirazaBelum ada peringkat

- Quality Assurance in Buillding WorksDokumen8 halamanQuality Assurance in Buillding WorksAtish KumarBelum ada peringkat

- Structural Components Design in RCC BuildingsDokumen72 halamanStructural Components Design in RCC BuildingsVedha NayaghiBelum ada peringkat

- IELTS Writing Topics2Dokumen4 halamanIELTS Writing Topics2Atish KumarBelum ada peringkat

- TH', U L: Fo' I TuDokumen5 halamanTH', U L: Fo' I TuAtish KumarBelum ada peringkat

- Ielts Preparation - SpeakingDokumen8 halamanIelts Preparation - Speakingarvindappadoo4243256Belum ada peringkat

- Chapter02.Structural Design Using STAAD PRODokumen22 halamanChapter02.Structural Design Using STAAD PROSiddharth Chetia100% (3)

- RAIN WATER HARVESTING in INDIA POLICYDokumen69 halamanRAIN WATER HARVESTING in INDIA POLICYAtish Kumar100% (1)

- Types of Railway SleepersDokumen4 halamanTypes of Railway SleepersAtish KumarBelum ada peringkat

- CBR TestDokumen4 halamanCBR TestAtish Kumar100% (1)

- Bhakra Dam Term PaperDokumen18 halamanBhakra Dam Term PaperAtish Kumar100% (2)

- Hydrology Final PPTX - GRP.5 PDFDokumen55 halamanHydrology Final PPTX - GRP.5 PDFAlvin DeliroBelum ada peringkat

- Site Engineering Design Checklist SampleDokumen12 halamanSite Engineering Design Checklist SampleRhio CruzBelum ada peringkat

- Turbidity Lab ReportDokumen3 halamanTurbidity Lab ReportKate Borja67% (6)

- Sanitation Standard Operating ProcedureDokumen5 halamanSanitation Standard Operating Proceduresjmpak100% (3)

- Abu Dhabi Sew, SWD Irr Specsc Design CriteriaDokumen30 halamanAbu Dhabi Sew, SWD Irr Specsc Design Criteriamalgendy0Belum ada peringkat

- Appendix A1Dokumen270 halamanAppendix A1Javier Alejandro Rodriguez MelgozaBelum ada peringkat

- Flare PackageDokumen42 halamanFlare PackageMandar Kardekar100% (3)

- Methane Capture: Options For Greenhouse Gas Emission ReductionDokumen24 halamanMethane Capture: Options For Greenhouse Gas Emission ReductionMhackSahuBelum ada peringkat

- MC Mehta Vs Union of India (Taj Trapezium Case)Dokumen9 halamanMC Mehta Vs Union of India (Taj Trapezium Case)Chaitanya JethaniBelum ada peringkat

- Check Burner Air To Fuel Ratios PDFDokumen2 halamanCheck Burner Air To Fuel Ratios PDFLuz SmithBelum ada peringkat

- 21Dokumen672 halaman21WellfroBelum ada peringkat

- Sewergems Product Data SheetDokumen2 halamanSewergems Product Data Sheetal_ig_ro3Belum ada peringkat

- LEEDS Existing BLDG ChecklistDokumen5 halamanLEEDS Existing BLDG ChecklistMedz MedinaBelum ada peringkat

- 268 658 1 PBDokumen14 halaman268 658 1 PBRaghav DhootBelum ada peringkat

- World Energy Outlook 2018: The Gold Standard of Energy AnalysisDokumen10 halamanWorld Energy Outlook 2018: The Gold Standard of Energy AnalysisCristhianRebazaBelum ada peringkat

- Centrifugal DecantersDokumen24 halamanCentrifugal DecantersNaik Larka100% (4)

- Office Health HazardsDokumen4 halamanOffice Health HazardsPlinio CabreraBelum ada peringkat

- GO Envi IssueDokumen1 halamanGO Envi IssueMohd Nazrul AkmalBelum ada peringkat

- Certi FicateDokumen3 halamanCerti FicateSahil AnujBelum ada peringkat

- Global Climate ChangeDokumen28 halamanGlobal Climate Changeতথাগত চক্রবর্তীBelum ada peringkat

- 3.table of ContentsDokumen11 halaman3.table of ContentsRaquel Paleyan CalawenBelum ada peringkat

- EV Car Report On SDGsDokumen1 halamanEV Car Report On SDGsAnas ur RehmanBelum ada peringkat

- DPCC Guidelines HotelsDokumen3 halamanDPCC Guidelines Hotelsjohntylee1969Belum ada peringkat

- Hudson River Shoreline Restoration Alternatives AnalysisDokumen135 halamanHudson River Shoreline Restoration Alternatives AnalysisHRNERRBelum ada peringkat

- GroundwaterDokumen81 halamanGroundwaterCésar Augusto Niño CastroBelum ada peringkat

- 6 Activated Sludge Process PDFDokumen61 halaman6 Activated Sludge Process PDFVineet ChaudharyBelum ada peringkat

- Rain Water Harvesting For Residential Project Daulat Heights in SaswadDokumen4 halamanRain Water Harvesting For Residential Project Daulat Heights in SaswadJournalNX - a Multidisciplinary Peer Reviewed JournalBelum ada peringkat

- Sea Turtles Endangered by PollutionDokumen4 halamanSea Turtles Endangered by Pollutionbianca_3010100% (1)

- Techniques For Waste Water TreatmentDokumen50 halamanTechniques For Waste Water TreatmentManu JainBelum ada peringkat

- Environmental Health Issues in ElderlyDokumen26 halamanEnvironmental Health Issues in ElderlyGraham Anassah MorganBelum ada peringkat