Zinc Clad III

Diunggah oleh

Scott Van PeltHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Zinc Clad III

Diunggah oleh

Scott Van PeltHak Cipta:

Format Tersedia

Protective & Marine Coatings

Revised 2/11

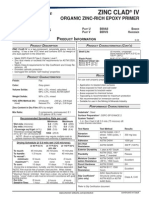

ZINC CLAD III HS

ORGANIC ZINC-RICH EPOXY PRIMER

PART A PART B PART F B69A100 B69V100 B69D11 BASE HARDENER ZINC DUST

6.07

PRODUCT DESCRIPTION

ZINC CLAD III HS is a three-component, polyamide epoxy, zinc-rich coating. It has a low VOC level and contains 90.5% by weight of zinc dust pigment in its dried lm. Meets Class B requirements for Slip Coefcient and Creep Resistance Provides cathodic protection Damaged lm exhibits "self-healing" properties Fast Recoat Time Outstanding application properties

RECOMMENDED USES

For use over properly prepared blasted steel. Fabrication Shops Bridge and Highway Structures Stadiums and Sports Complexes Drilling Rigs Piping Reneries Barges and Ships Wind Towers - onshore and offshore Shop or Field Applications Not recommended for immersion service

PRODUCT CHARACTERISTICS

Finish: Color: Volume Solids: Weight Solids: VOC (EPA Method 24): Flat Gray-green 60% 2%, mixed 90% 2%, mixed

Unreduced: <340 g/L; 2.80 lb/gal mixed Reduced 5%: <360 g/L; 3.00 lb/gal

PERFORMANCE CHARACTERISTICS

Substrate*: Steel Surface Preparation*: SSPC-SP10/NACE 2 System Tested*: 1 ct. Zinc Clad III HS @ 5.0 mils (125 microns) dft 1 ct. Macropoxy 646 @ 5.0-10.0 mils (125-250 microns) dft 1 ct. Acrolon 218 HS @ 5.0 mils (125 microns) dft

*unless otherwise noted below

Zinc Content in Dry Film: 90.5% by weight Mix Ratio: 3 components, premeasured 3.25 gallons (12.3L) total

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L) Minimum 5.0 (125) 3.0 (75) 190 (4.6) Maximum 8.0 (200) 5.0 (125) 320 (7.8)

Test Name Adhesion Corrosion Weathering Dry Heat Resistance (zinc only) Moisture Condensation Resistance Pencil Hardness (zinc only) Salt Fog Resistance

Test Method ASTM D4541 ASTM D5894, 13 cycles, 2016 hours ASTM D2485 ASTM D4585, 100F (38C), 4000 hours ASTM D3363 ASTM B117, 4500 hours AISC Specications for Structural Joints using ASTM A325 or ASTM A490 Bolts AISC Specication for Structural Joints using ASTM A325 or ASTM A490 Bolts

Theoretical coverage sq ft/gal 960 (23.5) (m2/L) @ 1 mil / 25 microns dft NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Results 975 psi Rating 10 per ASTM D610 for rusting; Rating 10 per ASTM D714 for blistering 300F (149C) Rating 10 per ASTM D610 for rusting; Rating 10 per ASTM D714 for blistering 2H Rating 10 per ASTM D610 for rusting; Rating 10 per ASTM D714 for blistering Class B, 0.52

Drying Schedule @ 5.0 mils wet (125 microns):

@ 35F/1.7C @ 77F/25C 50% RH @ 120F/49C

To touch: To handle: To recoat*: minimum: **maximum: To cure:

45 minutes 2 hours 4 hours none 10 days

30 minutes 1 hour 2 hours none 7 days

10 minutes 30 minutes 1 hour none 7 days

Drying time is temperature, humidity, and lm thickness dependent. *NOTE: Film must be free of solvent, hard and rm. When rubbed with the face of a coin or knife the lm should polish but not ake or chip. **Maximum Recoat: Unlimited. Must have a clean, dry surface for topcoating. "Loose" chalk or salts must be removed in accordance with good painting practice. Paint temperature must be at least 40F (4.5C) minimum.

Slip Coefcient (zinc only)

Pot Life: Sweat-in-Time: Shelf Life:

6 hours 1 hour

Slip Coefcient1

Passes Class B, 0.58

4 hours 30 minutes

2 hours 15 minutes

Flash Point: Reducer/Clean Up: Below 80F (27C): Above 80F (27C):

Part A: 18 months, unopened Parts B & F: 24 months, unopened Part F: 24 months, unopened Store indoors at 40F (4.5C) to 100F (38C) 58F (14C) Seta Flash, mixed Reducer #58 (R7K58) or MEK, R6K10 Reducer #58 (R7K58) or R7K104

Meets SSPC Paint Spec 20 - 1ct. Zinc @ 5 mils (125 microns) dft Complies with ISO 12944-5 C5I and C5M requirements. Footnotes: 1 1 ct. Zinc Clad III HS @ 3.0-5.0 mils (75-125 microns) dft 1 ct. Steel Spec Epoxy Primer @ 4.0-6.0 mils (100-150 microns) dft

www.sherwin-williams.com/protective

continued on back

Protective & Marine Coatings

RECOMMENDED SYSTEMS

ZINC CLAD III HS

ORGANIC ZINC-RICH EPOXY PRIMER

PART A PART B PART F B69A100 B69V100 B69D11 BASE HARDENER ZINC DUST

6.07

PRODUCT INFORMATION

SURFACE PREPARATION

Dry Film Thickness / ct. Mils (Microns) Steel, polyurethane topcoat: 1 ct. Zinc Clad III HS 1-2 cts. Acrolon 218 HS Steel, catalyzed epoxy topcoat: 1 ct. Zinc Clad III HS 1-2 cts. Macropoxy 646 Steel, catalyzed epoxy topcoat: 1 ct. Zinc Clad III HS 1-2 cts. Tile-Clad HS Steel, acrylic topcoat: 1 ct. Zinc Clad III HS 2 cts. DTM Acrylic Coating or 1 ct. Fast Clad HB Acrylic Steel, water based epoxy topcoat: 1 ct. Zinc Clad III HS 2 cts. Waterbased Tile-Clad Epoxy Steel, water-based urethane topcoat: 1 ct. Zinc Clad III HS 1 ct. Waterbased Tile-Clad Epoxy 1-2 cts. Hydrogloss Steel, Class B Compliant System: 1 ct. Zinc Clad III HS 1 ct. Steel Spec Epoxy Primer (red) ISO 12944 C5M System: 1 ct. Zinc Clad III HS 1 ct. Fast Clad Urethane or 1 ct. Zinc Clad III HS 1 ct. Tower Guard Epoxy 1 ct. Acrolon 218 HS 3.0-5.0 (75-125) 3.0-6.0 (75-150)

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Refer to product Application Bulletin for detailed surface preparation information. Minimum recommended surface preparation: Iron & Steel: SSPC-SP6/NACE 3, 2 mil (50 micron) prole Galvanizing: SSPC-SP7 Weathered Zinc Rich Primer: Clean, dry, sound

Surface Preparation Standards

Condition of Surface White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Rusted Pitted & Power Tool Cleaning Rusted Rusted Pitted & ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

3.0-5.0 (75-125) 5.0-10.0 (125-250)

3.0-5.0 (75-125) 2.5-4.0 (63-100)

3.0-5.0 (75-125) 2.5-4.0 (63-100) 5.0-8.0 (125-200)

TINTING

3.0-5.0 (75-125) 2.0-4.0 (50-100) Do not tint.

APPLICATION CONDITIONS

3.0-5.0 (75-125) 2.0-4.0 (50-100) 2.0-4.0 (50-100) Temperature: 35F (1.7C) minimum, 120F (49C) maximum (air and surface) 40F (4.5C) minimum, 120F (49C) maximum (material) At least 5F (2.8C) above dew point 85% maximum

Relative humidity: 3.0-5.0 (75-125) 4.0-6.0 (100-150)

Refer to product Application Bulletin for detailed application information.

ORDERING INFORMATION

Packaging: Part A Part B Part F Weight: 3.25 gallons (12.3L) mixed 1 gallon (3.78L) 1 gallon (3.78L) 73 lb (33.1 Kg) Zinc Dust 27.63 0.2 lb/gal ; 3.31 Kg/L, mixed

3.0-5.0 (75-125) 6.0-9.0 (150-225) 3.0-5.0 (75-125) 5.0-11.5 (125-287.5) 3.0-6.0 (75-150)

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

The systems listed above are representative of the product's use, other systems may be appropriate.

WARRANTY DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin. The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

Protective & Marine Coatings

Revised 2/11

ZINC CLAD III HS

ORGANIC ZINC-RICH EPOXY PRIMER

PART A PART B PART F B69A100 B69V100 B69D11 BASE HARDENER ZINC DUST

6.07

APPLICATION BULLETIN

SURFACE PREPARATIONS APPLICATION CONDITIONS

Temperature:

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Zinc rich coatings require direct contact between the zinc pigment in the coating and the metal substrate for optimum performance. Iron & Steel (atmospheric service) Remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. Minimum surface preparation is Commercial Blast Cleaning per SSPC-SP6/NACE 3. For better performance, use Near White Metal Blast Cleaning per SSPC-SP10/NACE 2. Blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (2 mils / 50 microns). Coat any bare steel the same day as it is cleaned or before ash rusting occurs. Galvanized Steel Allow to weather a minimum of six months prior to coating. Solvent Clean per SSPC-SP1 (recommended solvent is VM&P Naphtha). When weathering is not possible, or the surface has been treated with chromates or silicates, rst Solvent Clean per SSPC-SP1 and apply a test patch. Allow paint to dry at least one week before testing adhesion. If adhesion is poor, brush blasting per SSPC-SP7 is necessary to remove these treatments. Rusty galvanizing requires a minimum of Hand Tool Cleaning per SSPC-SP2, prime the area the same day as cleaned or before ash rusting occurs. Weathered Zinc-Rich Primer Remove zinc salts by either high pressure water washing and scrubbing with stiff bristle brush or sweep blast followed by water ush. Allow to dry. Note: If blast cleaning with steel media is used, an appropriate amount of steel grit blast media may be incorporated into the work mix to render a dense, angular 1.5-2.0 mil (38-50 micron) surface prole. This method may result in improved adhesion and performance.

35F (1.7C) minimum, 120F (49C) maximum (air and surface) 40F (4.5C) minimum, 120F (49C) maximum (material) At least 5F (2.8C) above dew point 85% maximum

Relative humidity:

APPLICATION EQUIPMENT

The following is a guide. Changes in pressures and tip sizes may be needed for proper spray characteristics. Always purge spray equipment before use with listed reducer. Any reduction must be compliant with existing VOC regulations and compatible with the existing environmental and application conditions. Reducer/Clean Up Below 80F ....................Reducer #58, R7K58 or MEK, R6K10 Above 80F ....................Reducer #58, R7K58 or R7K104 Airless Spray (use Teon packings and continuous agitation) Pressure.........................2000 - 2300 psi Hose...............................3/8" ID Tip ...................................019" Filter ...............................none Reduction .......................As needed up to 5% by volume Conventional Spray (continuous agitation required) Gun ................................Binks 95 Fluid Nozzle ...................68 Air Nozzle.......................68P Atomization Pressure .....50 psi Fluid Pressure ................10 - 20 psi Reduction .......................As needed up to 5% by volume Keep pressure pot at level of applicator to avoid blocking of uid line due to weight of material. Blow back coating in uid line at intermittent shutdowns, but continue agitation at pressure pot. Brush Brush..............................Small areas only; natural bristle Reduction .......................Not recommended

Surface Preparation Standards

ISO 8501-1 BS7079:A1 White Metal Sa 3 Near White Metal Sa 2.5 Commercial Blast Sa 2 Brush-Off Blast Sa 1 Rusted Hand Tool Cleaning Pitted & Rusted C St 2 D St 2 Power Tool Cleaning Rusted Rusted C St 3 Pitted & D St 3 Condition of Surface Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

If specic application equipment is not listed above, equivalent equipment may be substituted.

www.sherwin-williams.com/protective

continued on back

Protective & Marine Coatings

APPLICATION PROCEDURES

ZINC CLAD III HS

ORGANIC ZINC-RICH EPOXY PRIMER

PART A PART B PART F B69A100 B69V100 B69D11 BASE HARDENER ZINC DUST

6.07

APPLICATION BULLETIN

PERFORMANCE TIPS

Surface preparation must be completed as indicated. Zinc Clad III HS comes in 3 premeasured containers which when mixed provides 3.25 gallons (12.3L) of ready-to-apply material. Mixing Instructions: Mix contents of component A and B thoroughly with low speed power agitator. Make certain no pigment remains on the bottom of the can. Then combine 1 part by volume of Part A with 1 part by volume of Part B, then add Part F (73 lb zinc dust). Thoroughly agitate the mixture with power agitation. After mixing, pour through a 30-60 mesh screen. Allow the material to sweat-in as indicated. Re-stir before using. If reducer solvent is used, add only after components have been thoroughly mixed, after sweat-in. Continuous agitation of mixture during application is required, otherwise zinc dust will quickly settle out.

Stripe coat all crevices, welds, and sharp angles to prevent early failure in these areas. When using spray application, use a 50% overlap with each pass of the gun to avoid holidays, bare areas, and pinholes. If necessary, cross spray at a right angle. Spreading rates are calculated on volume solids and do not include an application loss factor due to surface prole, roughness or porosity of the surface, skill and technique of the applicator, method of application, various surface irregularities, material lost during mixing, spillage, overthinning, climatic conditions, and excessive lm build.

Excessive reduction of material can affect lm build, appearance, Apply paint at the recommended lm thickness and spreading and performance. rate as indicated below:

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L) Minimum 5.0 (125) 3.0 (75) 190 (4.6) Maximum 8.0 (200) 5.0 (125) 320 (7.8)

Do not mix previously catalyzed material with new. Do not apply the material beyond recommended pot life. In order to avoid blockage of spray equipment, clean equipment before use or before periods of extended downtime with MEK, R6K10. Keep pressure pot at level of applicator to avoid blocking of uid line due to weight of material. Blow back coating in uid line at intermittent shutdowns, but continue agitation at pressure pot. Application above recommended lm thickness may result in mud cracking.

Theoretical coverage sq ft/gal 960 (23.5) (m2/L) @ 1 mil / 25 microns dft NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Drying Schedule @ 5.0 mils wet (125 microns):

@ 35F/1.7C @ 77F/25C 50% RH @ 120F/49C

To touch: To handle: To recoat*: minimum: **maximum: To cure:

45 minutes 2 hours 4 hours none 10 days

30 minutes 1 hour 2 hours none 7 days

10 minutes 30 minutes 1 hour none 7 days

Drying time is temperature, humidity, and lm thickness dependent. *NOTE: Film must be free of solvent, hard and rm. When rubbed with the face of a coin or knife the lm should polish but not ake or chip. **Maximum Recoat: Unlimited. Must have a clean, dry surface for topcoating. "Loose" chalk or salts must be removed in accordance with good painting practice. Paint temperature must be at least 40F (4.5C) minimum.

Refer to Product Information sheet for additional performance characteristics and properties.

Pot Life: 6 hours 4 hours 2 hours Sweat-in-Time: 1 hour 30 minutes 15 minutes Application of coating above maximum or below minimum recommended spreading rate may adversely affect coating performance.

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

CLEAN UP INSTRUCTIONS

Clean spills and spatters immediately with MEK, R6K10. Clean tools immediately after use with MEK, R6K10. Follow manufacturer's safety recommendations when using any solvent.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

www.sherwin-williams.com/protective

Anda mungkin juga menyukai

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyDari EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinBelum ada peringkat

- Zinc Clad IVDokumen4 halamanZinc Clad IVvitrolaBelum ada peringkat

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDari EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášBelum ada peringkat

- Fast Clad Urethane Spec SheetDokumen4 halamanFast Clad Urethane Spec SheetScott Van PeltBelum ada peringkat

- Advances in Ceramic Armor XIDari EverandAdvances in Ceramic Armor XIJerry C. LaSalviaBelum ada peringkat

- Acrolon 218 HSDokumen4 halamanAcrolon 218 HSAndres MoralesBelum ada peringkat

- Advances in Solid Oxide Fuel Cells XDari EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffBelum ada peringkat

- Coal Tar PDFDokumen4 halamanCoal Tar PDFMohammadreza AsheghBelum ada peringkat

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014Dari Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramBelum ada peringkat

- ZRC GALVILITE Galvanizing Repair CompoundDokumen2 halamanZRC GALVILITE Galvanizing Repair CompoundRaymond LalumiereBelum ada peringkat

- Modern Glass CharacterizationDari EverandModern Glass CharacterizationMario AffatigatoBelum ada peringkat

- ZRC 3 07Dokumen2 halamanZRC 3 07groelzjBelum ada peringkat

- Advances in Ceramic Armor XDari EverandAdvances in Ceramic Armor XJerry C. LaSalviaBelum ada peringkat

- Duraplate Uhs EnglishDokumen4 halamanDuraplate Uhs EnglishLuis JaraBelum ada peringkat

- DP B58W00610Dokumen4 halamanDP B58W00610tangouzeBelum ada peringkat

- Carboguard 890 PDSDokumen2 halamanCarboguard 890 PDSLinnie McleodBelum ada peringkat

- 7) PPG Amercoat 385 - Pds - AiDokumen4 halaman7) PPG Amercoat 385 - Pds - AididbeauBelum ada peringkat

- Carbomastic 15 PDS 2013Dokumen2 halamanCarbomastic 15 PDS 20134508366279Belum ada peringkat

- ZRC Zero VocDokumen2 halamanZRC Zero Vochksn77Belum ada peringkat

- Carbo Guard 893 SGDokumen2 halamanCarbo Guard 893 SGsuzilamatsallehBelum ada peringkat

- Carboguard 89dfsfs0 PDSDokumen2 halamanCarboguard 89dfsfs0 PDSMayur PatelBelum ada peringkat

- Alpha SP Range: DescriptionDokumen3 halamanAlpha SP Range: Descriptionvicky kBelum ada peringkat

- Product Data Sheet SP-8888Dokumen7 halamanProduct Data Sheet SP-8888pablo gonzalezBelum ada peringkat

- 323 Data Sheet and Application GuideDokumen4 halaman323 Data Sheet and Application Guidejast111Belum ada peringkat

- Loctite 222MS™: Technical Data SheetDokumen4 halamanLoctite 222MS™: Technical Data SheetbabshuagBelum ada peringkat

- Loctite 243™: Technical Data SheetDokumen4 halamanLoctite 243™: Technical Data SheetRadu_ISBelum ada peringkat

- Solder Paste SC Blf03: Lead-FreeDokumen2 halamanSolder Paste SC Blf03: Lead-FreeluismcmcBelum ada peringkat

- Product Data Sheet SP-6888Dokumen5 halamanProduct Data Sheet SP-6888rmfpereiraBelum ada peringkat

- Pds Psx700 Jan 2008Dokumen3 halamanPds Psx700 Jan 2008mjayhawk28Belum ada peringkat

- QC SkillDokumen31 halamanQC SkillJagdish100% (1)

- Surface PreparationDokumen8 halamanSurface PreparationimyparkarBelum ada peringkat

- SB Drill CollarDokumen51 halamanSB Drill CollarJeff ZhangBelum ada peringkat

- 8.hyspin AWS - VNDokumen2 halaman8.hyspin AWS - VNThắng Phạm NguyênBelum ada peringkat

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Dokumen3 halamanMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsBelum ada peringkat

- Carbo Zinc 11 HsDokumen2 halamanCarbo Zinc 11 Hstyto_rmzBelum ada peringkat

- Never-Seez® India Call +91-891-6666482Dokumen2 halamanNever-Seez® India Call +91-891-6666482Project Sales CorpBelum ada peringkat

- Carboguard 635 Thinned 50% - Sealer PDSDokumen5 halamanCarboguard 635 Thinned 50% - Sealer PDSjakeBelum ada peringkat

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDokumen7 halamanAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheBelum ada peringkat

- Description Packaging Product Data SheetDokumen2 halamanDescription Packaging Product Data SheetRonald Fernandez ManubuluBelum ada peringkat

- Acrolon 890 EN 20130206Dokumen2 halamanAcrolon 890 EN 20130206hainguyenbkvhv0% (1)

- Amercoat 370Dokumen3 halamanAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Surface Preparation EssentialsDokumen18 halamanSurface Preparation EssentialsVincent LecoursBelum ada peringkat

- Hyspin ZZ Range: DescriptionDokumen2 halamanHyspin ZZ Range: DescriptionDaniel VuletaBelum ada peringkat

- SigmaCover 280Dokumen5 halamanSigmaCover 280ajuhaseenBelum ada peringkat

- Carbothane+134+HG+PDS+3 11Dokumen2 halamanCarbothane+134+HG+PDS+3 11James Everett AbdulBelum ada peringkat

- Carboguard 888 PDSDokumen3 halamanCarboguard 888 PDSsalamrefighBelum ada peringkat

- 3M2216Dokumen8 halaman3M2216pat_kunal1601Belum ada peringkat

- Dura-Plate UHS Epoxy - JSP PDFDokumen4 halamanDura-Plate UHS Epoxy - JSP PDFNageswara Rao BavisettyBelum ada peringkat

- Ficha Técnica SpotcheckDokumen5 halamanFicha Técnica SpotcheckJuan PazBelum ada peringkat

- 105 Ta D411-350Dokumen3 halaman105 Ta D411-350isaacalvareztejanoBelum ada peringkat

- Roadsaver Silicone SLDokumen2 halamanRoadsaver Silicone SLTeddy TPBelum ada peringkat

- Data Sheet FBEDokumen4 halamanData Sheet FBEAnonymous Xaf2033Belum ada peringkat

- Alphasyn HG RangeDokumen2 halamanAlphasyn HG RangecarmaBelum ada peringkat

- Dacromet Coating: World Class Corrosion ProtectionDokumen6 halamanDacromet Coating: World Class Corrosion Protectionmarcelogf74Belum ada peringkat

- Especificaciones RECUBRIMIENTO PAM RevisadaDokumen59 halamanEspecificaciones RECUBRIMIENTO PAM RevisadaToapanta FredyBelum ada peringkat

- Surface Prep GuideDokumen8 halamanSurface Prep GuideDamen YardBelum ada peringkat

- Loctite 243Dokumen4 halamanLoctite 243ablemathew173974Belum ada peringkat

- Never-Seez High Temperature Stainless NSSBT 8Dokumen2 halamanNever-Seez High Temperature Stainless NSSBT 8Project Sales CorpBelum ada peringkat

- SSPC SP8Dokumen2 halamanSSPC SP8longlong3003100% (2)

- PROTECTIVE-COATINGS-SURFACEDokumen5 halamanPROTECTIVE-COATINGS-SURFACEkhor_albertBelum ada peringkat

- F WW Grooving PlanesDokumen5 halamanF WW Grooving PlanesKaren Rathbun100% (1)

- American Girl Dollhouse - Fits 18 Dolls Ana WhiteDokumen1 halamanAmerican Girl Dollhouse - Fits 18 Dolls Ana WhiteSchindler JoanieBelum ada peringkat

- My Last DuchessDokumen13 halamanMy Last DuchessixmawelBelum ada peringkat

- Senior KG CBSE Courseware and Stationery List For AY 2020-21Dokumen1 halamanSenior KG CBSE Courseware and Stationery List For AY 2020-21harshkumar patelBelum ada peringkat

- Rimas, Thea Stephanie D. Art Analysis Lavanderas by Fernando AmorsoloDokumen2 halamanRimas, Thea Stephanie D. Art Analysis Lavanderas by Fernando Amorsoloeyo rimas0% (1)

- Knitscene Fall 2015Dokumen100 halamanKnitscene Fall 2015Carla Fartouse Dias100% (13)

- Annotated BibliographyDokumen5 halamanAnnotated BibliographyvnkommuBelum ada peringkat

- Marketing Strategy of Berger PaintDokumen113 halamanMarketing Strategy of Berger PaintShashank Srivastava91% (11)

- Bois. Guy Brett. October 2021Dokumen67 halamanBois. Guy Brett. October 2021Roberta PlantBelum ada peringkat

- The Real Gaze Film Theory After LacanDokumen267 halamanThe Real Gaze Film Theory After LacanCizic Woat100% (14)

- Vilas County News-Review, Nov. 30, 2011 - SECTION BDokumen12 halamanVilas County News-Review, Nov. 30, 2011 - SECTION BNews-ReviewBelum ada peringkat

- Making The Violin ManualDokumen73 halamanMaking The Violin ManualThanasis KyrgiazoglouBelum ada peringkat

- Fashionable Accessories and Their OriginsDokumen12 halamanFashionable Accessories and Their OriginsAdonis GaleosBelum ada peringkat

- Floor DeckDokumen184 halamanFloor DeckAbelbelachewBelum ada peringkat

- The Impact of Moorish Rule in Spain - Aman RaiDokumen15 halamanThe Impact of Moorish Rule in Spain - Aman RaiAman RaiBelum ada peringkat

- Grade 7Dokumen32 halamanGrade 7judy ann neri100% (1)

- Powderhorn Art Fair 2010Dokumen12 halamanPowderhorn Art Fair 2010Powderhorn Art FairBelum ada peringkat

- LitDokumen3 halamanLitMarella Ria MonteronaBelum ada peringkat

- Cave Art Dating Technique Reveals Works Took 20,000 YearsDokumen8 halamanCave Art Dating Technique Reveals Works Took 20,000 Years12D1.04 .Nguyễn Doãn Ngân HàBelum ada peringkat

- Women - A Pictorial Archive From Nineteenth-Century Sources (PDFDrive)Dokumen130 halamanWomen - A Pictorial Archive From Nineteenth-Century Sources (PDFDrive)Torque100% (2)

- Early Christian Sarcophagus From Rome Lost and FoundDokumen8 halamanEarly Christian Sarcophagus From Rome Lost and FoundLuiz Fernando Pina SampaioBelum ada peringkat

- How To Build Better AircraftDokumen23 halamanHow To Build Better Aircraftmichael Dodd100% (2)

- Surface Area Practice ProblemsDokumen4 halamanSurface Area Practice ProblemsNoonTeachathanyakulBelum ada peringkat

- Lucrare de Atestat La Limba EnglezaDokumen34 halamanLucrare de Atestat La Limba EnglezaAlexandraMariaGheorgheBelum ada peringkat

- Midterm Examination Ge-Art AppDokumen8 halamanMidterm Examination Ge-Art Appbalot eggBelum ada peringkat

- Photoshop PDFDokumen26 halamanPhotoshop PDFblob232Belum ada peringkat

- Spiti - Tabo Mud MonasteryDokumen4 halamanSpiti - Tabo Mud MonasteryMonidipa DeyBelum ada peringkat

- Woodsmith Magazine 219Dokumen68 halamanWoodsmith Magazine 219chrix100% (3)

- Twenty To MakeDokumen6 halamanTwenty To MakeInterweave50% (2)

- Concise for English Exam DocumentDokumen4 halamanConcise for English Exam DocumentPutri_MawilianaBelum ada peringkat