Marine Ac Electrical Wiring Basics

Diunggah oleh

RENGANATHAN PDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Marine Ac Electrical Wiring Basics

Diunggah oleh

RENGANATHAN PHak Cipta:

Format Tersedia

http://www.practical-sailor.

com

While the principles of electric theory are the same whether on shore or afloat, the conductors and the methods of conductor installation...differ considerably from those used shoreside.

Marine AC: Electrical Wiring Basics

by Scoff Hen y If your boat can accommodate most household electrically-powered conveniences, it undoubtedly has two entirely separate electrical systems. The direct current (DC) electrical system derives its power from your boats storage battery or batteries. In addition to providing starting power for the engine, DC electrical power is used for bilge pumps, running lights, the water pressure pump, DC lighting and other related equipment. The source of power for your boats alternating current (AC) electrical system is either a shoreside connection or an on-board AC electrical generator. This system provides electricity for appliances and fixed AC electrical equipment aboard the boat. While the principles of electric theory are the same whether on shore or afloat, the conductors and the methods of conductor installation, as well as many of the appliances and AC electrical equipment used aboard boats, differ considerably from those used shoreside. Because of color coding and polarity requirements, working with your boats AC electrical system is really not complicated. A grounding conductor, or ground wire, in an AC system is always green. The neutral wire or grounded conductor is white. The ungrounded conductor, or hot wire, is identified by any color other than green or white and is usually black or red. ABYC (American Boat and Yacht Council) standards require that marine AC electrical systems be polarized. A polarized system is one in which the hot and neutral wires are connected in the same relation to all terminals on all devices in the circuit. For example, receptacles are connected so that the neutral wire attaches to the terminal identified by the letter s, normally a silver color. The hot wire should be attached to the brass or copper terminal. The green colored grounding wire is to be attached to the ground terminal on the receptacle. This procedure insures that the proper polarity is maintained and that the electricity will flow safely, without restriction, through each circuit. Terminal screws are usually color coded for easy identification. In all marine electrical applications, avoiding the entrance or accumulation of moisture is of prime importance. Junction boxes, receptacles, panelboards and other enclosures in which electrical connections are made should be weatherproof or installed in a protected location. All currentcarrying conductors should be routed as far away as practical from areas where water or moisture may accumulate. The conductors used in marine applications must be made of stranded copper wire. The black, white and green ground conductor in each cable or cord must each be of the stranded wire variety. Household conductors, on the other hand, have a single, solid core wire. The number of strands required in each conductor in marine applications is directly related to the conductors diameter and the degree to which the wire will be subjected to flexing through movement or vibration. The conductors proper size and diameter is also determined by the demand or amount of current the conductor must carry. Good household wiring often travels through the house in metallic tubing called conduit. The conduit supports and protects the wires within the walls and ceiling of your home. But on your boat, conductors are supported throughout their length by a self-draining loom or are secured every eighteen inches by straps or clamps. In areas other than the machinery compartments of your boat, nonmetallic straps or clamps are ideal for holding conductors firmly in place. Metal clamps lined with an insulating material to minimize damage from chafing are used in machinery areas. Another major difference between household wiring and the AC electrical wiring aboard your boat occurs when two conductors or wires are joined together, or a conductor is connected to a terminal on an appliance, receptacle or circuit breaker. A common practice in household wiring is to splice wire to wire by means of electrical tape or wire nuts. Wire nuts or twist-on connectors have no place aboard a boat. Joining conductor to conductor in marine appli-

cations is best accomplished through the use of insulated, solderless crimp-on connectors. The crimp-on connection may be covered with electrical tape, but under no circumstances should electrical tape be used to join two conductors together. Besides assuring continuity of current, crimp-on connectors prevent the conductors from being pulled apart when flexed. Working with a boats electrical system is something many boat owners refuse to do because they consider it mysterious. More than any other system on your boat, the AC electrical system is

standardized. By having the proper tools, following the safety tips outlined earlier and using only marine electrical equipment, wiring your boat for n AC current can be relatively simple. The aufhor, Scoff Hen y, is fhe sales manager for Marinco, a leading manufacturer of marine electrical systems and equipment fhaf is designed for ease of installation, for practicdify, and for a long service life in the marine environment. Marinco, 92 Hamilton Drive, Ignacio, CA 94947.

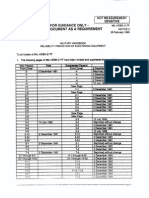

Pictured are some of the basic tools and supplies that make wiring aboard a boat an easy task. In addition to the items shown, you may have occasion to use an electric drill and a saber saw, particularly when youre adding another shore power cord or a new receptacle. A. Multipurpose Tool. This tool allows the insulation to be easily stripped from wires without damaging the wire conductors. The same tool is used to cut wire and to crimp the insulated, solderless connectors on to the wire. For optimum connections, the crimping tool should be compatible with the insulated connector (tool and connector from the same manufacturer). B. Wire Cutters. This form of pliers is strictly used for cutting wire conductors. Their shape and design makes them ideal for performing clean, even cuts of multi-stranded marine wire. C. Screwdrivers. Both Phillips head and straight slot screwdrivers. D. Tester. To check that all current is off before you begin to work on AC electrical items. E. Crimp-on Connectors. Available in a variety of wire and stud sizes, these connectors crimp on to multi-stranded wire and fasten securely to the terminal screws of receptacles and breakers. F. Cable Clamps and Support Clips. Available now in nylon or metal with rubber insulation, cable clamps are an effective way to support wiring. G. Electrical Tape. It is a good practice to apply electrical tape around the wire and the insulation of the crimp-on connector to prevent moisture fromentering the connection. Electrical tracer tape comes in a variety of colors and can be used to identify various circuits.

What You Need Before You Start

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Voice and Accent Training MaterialDokumen30 halamanVoice and Accent Training MaterialAnwar GaffBelum ada peringkat

- CM2880 Wiring Diagram enDokumen1 halamanCM2880 Wiring Diagram enAung Mh62% (21)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Marine Internal Combustion Diesel Egine I-SbrDokumen232 halamanMarine Internal Combustion Diesel Egine I-SbrRENGANATHAN P100% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Engine Room Systems and Layout PDFDokumen3 halamanEngine Room Systems and Layout PDFRENGANATHAN P33% (3)

- SM Me411 21 en 01Dokumen97 halamanSM Me411 21 en 01Sulay Avila Llanos100% (1)

- RIPS C869 Manual Service PDFDokumen791 halamanRIPS C869 Manual Service PDFcatalinni50% (8)

- Tyco HV Cable and Arresters Ans InsulatorDokumen104 halamanTyco HV Cable and Arresters Ans InsulatorRazvan MaresBelum ada peringkat

- TVSS (Transient Voltage Surge Suppression) What Is It and Why All of A Sudden Do We Need It?Dokumen12 halamanTVSS (Transient Voltage Surge Suppression) What Is It and Why All of A Sudden Do We Need It?Jecer Casipong NuruddinBelum ada peringkat

- 23 AuxiliaryMarineMachinery 000 PDFDokumen55 halaman23 AuxiliaryMarineMachinery 000 PDFLionel Richi100% (1)

- The Caliphate FilesDokumen7 halamanThe Caliphate FilesRENGANATHAN PBelum ada peringkat

- 6b Engine Rooms and Machinery Space Intertanko K Koo PDFDokumen4 halaman6b Engine Rooms and Machinery Space Intertanko K Koo PDFRENGANATHAN PBelum ada peringkat

- Engine Room Arrangement PDFDokumen1 halamanEngine Room Arrangement PDFRENGANATHAN PBelum ada peringkat

- The Mahabharata of 2019Dokumen7 halamanThe Mahabharata of 2019RENGANATHAN PBelum ada peringkat

- SWOT Analysis of AmulDokumen7 halamanSWOT Analysis of AmulRENGANATHAN PBelum ada peringkat

- Machinery EquipmentDokumen2 halamanMachinery EquipmentFrano BokoBelum ada peringkat

- Fire-Fighting Guidance Notes - E-Feb15Dokumen161 halamanFire-Fighting Guidance Notes - E-Feb15Moe LattBelum ada peringkat

- Physics - I PDFDokumen179 halamanPhysics - I PDFRENGANATHAN PBelum ada peringkat

- Academic Brochure 2016-17 PDFDokumen52 halamanAcademic Brochure 2016-17 PDFRENGANATHAN P0% (1)

- Chanakya's Management Lessons From Ancient India - Sanskriti - Indian CultureDokumen4 halamanChanakya's Management Lessons From Ancient India - Sanskriti - Indian CultureRENGANATHAN PBelum ada peringkat

- ARM Microprocessor PracticeDokumen1 halamanARM Microprocessor PracticeRENGANATHAN PBelum ada peringkat

- Optimum Nutrition For Vigour and Vitality: Your Food Shall Be Your Medicine. - HippocratesDokumen22 halamanOptimum Nutrition For Vigour and Vitality: Your Food Shall Be Your Medicine. - HippocratesRENGANATHAN PBelum ada peringkat

- Cet June 2016 Results Ug 8jun16 PDFDokumen436 halamanCet June 2016 Results Ug 8jun16 PDFRENGANATHAN PBelum ada peringkat

- What Hindus Must Do Series 2 WHMD IIDokumen22 halamanWhat Hindus Must Do Series 2 WHMD IIRENGANATHAN PBelum ada peringkat

- What Hindus Must DoDokumen9 halamanWhat Hindus Must DoNaliniBelum ada peringkat

- Intact Stability Code msc-267-85 08Dokumen94 halamanIntact Stability Code msc-267-85 08sugram100% (1)

- What Hindus Must Do Series 3 Whmd-IiiDokumen5 halamanWhat Hindus Must Do Series 3 Whmd-IiiNaliniBelum ada peringkat

- Lesson 1 - Master MindDokumen0 halamanLesson 1 - Master MindRENGANATHAN P100% (1)

- Kerala Government Holidays 2014Dokumen5 halamanKerala Government Holidays 2014RENGANATHAN PBelum ada peringkat

- Chip Formation and Tool LifeDokumen37 halamanChip Formation and Tool LifeSquakx BescilBelum ada peringkat

- White Paper Shipbuilding - EnglDokumen19 halamanWhite Paper Shipbuilding - EnglRENGANATHAN PBelum ada peringkat

- BASEL2Dokumen7 halamanBASEL2RENGANATHAN PBelum ada peringkat

- Basel III For Global Banks: Third Time's The Charm?Dokumen9 halamanBasel III For Global Banks: Third Time's The Charm?RENGANATHAN PBelum ada peringkat

- Draft Regulations On Tech and Prof EduDokumen28 halamanDraft Regulations On Tech and Prof EduRENGANATHAN PBelum ada peringkat

- Basel III-ADokumen12 halamanBasel III-ARENGANATHAN PBelum ada peringkat

- Basel I Is The Round of Deliberations by Central Bankers From Around TheDokumen2 halamanBasel I Is The Round of Deliberations by Central Bankers From Around TheRENGANATHAN PBelum ada peringkat

- H5000BF Series User's Manual: 1. PrefaceDokumen19 halamanH5000BF Series User's Manual: 1. PrefaceRashed alganmBelum ada peringkat

- Military HandbookDokumen80 halamanMilitary HandbookLuthfyatma HardyBelum ada peringkat

- EM Synchronous GeneratorDokumen22 halamanEM Synchronous GeneratorDeepanshu SehgalBelum ada peringkat

- Service KlimaDokumen50 halamanService Klimaspirittotti100% (1)

- Xii Holiday Homework 2022-23Dokumen4 halamanXii Holiday Homework 2022-23Tarun JainBelum ada peringkat

- At Command Set For Nokia GSM and WCDMA Products v1 2 enDokumen111 halamanAt Command Set For Nokia GSM and WCDMA Products v1 2 endhwanil_k8031Belum ada peringkat

- Ide&Sdcc C CompilerDokumen24 halamanIde&Sdcc C Compileriik MubarakBelum ada peringkat

- Akai P42l6a-T1 (SM)Dokumen49 halamanAkai P42l6a-T1 (SM)ricardoBelum ada peringkat

- BZX55CV24Dokumen4 halamanBZX55CV24kcraussBelum ada peringkat

- Catalogue: EnglishDokumen44 halamanCatalogue: EnglishEman AdhamBelum ada peringkat

- SolderDokumen13 halamanSolderBalaji N MuthuramanBelum ada peringkat

- Migrating Panelview Enhanced Terminal Applications: Quick StartDokumen160 halamanMigrating Panelview Enhanced Terminal Applications: Quick StartAguirre Castillo Jose de JesusBelum ada peringkat

- DMR-UBT1GL-K Operating InstructionsDokumen96 halamanDMR-UBT1GL-K Operating InstructionsZakaria ZebbicheBelum ada peringkat

- SW Driver User Manual For Marvell Serial ATA Host AdaptersDokumen116 halamanSW Driver User Manual For Marvell Serial ATA Host Adapterstosser12Belum ada peringkat

- User's Manual For Thermal PrinterDokumen17 halamanUser's Manual For Thermal PrinterAbu Muhammad ZaidBelum ada peringkat

- For Clean Gases With Optional Integral Display: FMA1700A/1800A SeriesDokumen2 halamanFor Clean Gases With Optional Integral Display: FMA1700A/1800A SeriesIvette Desales SotoBelum ada peringkat

- Ricoh MP2852 PDFDokumen93 halamanRicoh MP2852 PDFJohn JuquenBelum ada peringkat

- Cat Eeg9100Dokumen8 halamanCat Eeg9100Juan Carlos Barrios Granados0% (1)

- MuramasaDokumen4 halamanMuramasaThomson AffendyBelum ada peringkat

- ProductSheet HeadEnd HttvStream HBBTVDokumen2 halamanProductSheet HeadEnd HttvStream HBBTVlikebossBelum ada peringkat

- JPX202 MDF User Manual V3.0Dokumen130 halamanJPX202 MDF User Manual V3.0SamuelBelum ada peringkat

- Yeskawa vs-606 PC3 InstructionsDokumen210 halamanYeskawa vs-606 PC3 InstructionsRASHID Ansari100% (1)

- Artificial Intelligence Project IdeasDokumen2 halamanArtificial Intelligence Project IdeasRahul PatraBelum ada peringkat

- VSAT Agilis Transreceivers 20w To 60wpdfDokumen2 halamanVSAT Agilis Transreceivers 20w To 60wpdfnyanhtunBelum ada peringkat

- Telsen Radiomag No.1Dokumen36 halamanTelsen Radiomag No.1Rick MendelezBelum ada peringkat