Certainteed

Diunggah oleh

Dxtr MedinaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Certainteed

Diunggah oleh

Dxtr MedinaHak Cipta:

Format Tersedia

Submittal Form

Insulation Residential Products

Submitted to: Job Name: Submitted by: Date:

This Submittal Form is provided to assist you in specifying and selecting the proper CertainTeed Insulation product. Basic product descriptions and performance data are included. For further information or technical assistance, contact your local CertainTeed representative.

CertainTeed Corporation, P.O. Box 860, Valley Forge, PA 19482

1-800-233-8990

Visit our web site at: http://www.certainteed.com Fax-on-Demand service: 1-800-947-0057 Customer Service 1-800-441-9850 Fax 1-800-799-2381

CertainTeed was the first fiber glass insulation manufacturer to have all its manufacturing plants, R&D center and corporate headquarters registered to ISO 9001:2000 standards.

Product

Description

Thermal Nominal Resistance* Thickness

Applicable Standards

Complies with ASTM C665, Type I. Is noncombustible, meeting test criteria of ASTM E136. Thermal performance determined by ASTM C653 and C518.

Unfaced Building Insulation

Manufactured in widths to permit pressure fit installation. Used with a separate vapor retarder or where no vapor retarder is required or recommended.

R-38 / 12" R-38C / 1014" (Cathedral Ceiling Batt) R-30 / 10" R-30C / 814" (Cathedral Ceiling Batt) R-25 / 8" R-22 / 612" R-21 / 512" R-19 / 614" R-15 / 312" R-13 / 312" R-11 / 312"

Kraft Faced Building Insulation

Manufactured with a kraft paper facing with a vapor permeance rating of 1.0 or less. Includes stapling flanges.

R-38 / 12" R-38C / 1014" (Cathedral Ceiling Batt) R-30 / 10" R-30C / 812" (Cathedral Ceiling Batt) R-26 / 838" R-25 / 8" R-22 / 612" R-21 / 512" R-19 / 614" R-15 / 312" R-13 / 312" R-11 / 312"

Complies with ASTM C665, Type II, Class C, Category 1. Thermal performance determined by ASTM C653 and C518.

SpeedyR Kraft Faced Building Insulation EZR Building Insulation

Manufactured with a kraft paper facing with a vapor permeance rating of 1.0 or less. No stapling required. Manufactured with a kraft paper facing with a vapor retarder permeance rating of 1.0 or less and a non-woven tissue adhered to the fiber glass surface. No stapling required.

R-21 / 512" R-19 / 614" R-13 / 312"

Complies with ASTM C665, Type II, Class C, Category 1. Thermal performance determined by ASTM C653 and C518. Complies with ASTM C665, Type II, Class C, Category 1. Thermal performance determined by ASTM C653 and C518.

R-13 / 312"

CertaSound Products

Sound Attenuation Batts

Description

Thermal Nominal Resistance* Thickness

Applicable Standards

Complies with ASTM C665, Type I. Is noncombustible, meeting test criteria of ASTM E136. Thermal performance determined by ASTM C653 and C518. Complies with ASTM C665, Type I (unfaced), Type II, Class C, Category 1, (faced). Thermal performance determined by ASTM C653 and C518. Complies with ASTM C665, Type II, Class C, Category 2. Thermal performance determined by ASTM C653 and C518.

Unfaced batts manufactured in widths to permit pressure fit installation in steel stud systems.

R-11 / 312" R-8 / 212"

Acoustical Ceiling Batts

24" x 48" batts either unfaced or with tabless kraft paper facing. For use in suspended ceiling systems.

R-19 / 614" R-11 / 312"

NoiseReducer Batts are available with a white kraft facing for easy positive attachment to interior wood stud framing.

R-11 / 312"

*R means resistance to heat flow. The higher the R-Value, the greater the insulating power.

Product

Description

Thermal Nominal Resistance* Thickness

Applicable Standards

Complies with ASTM C665, Type I. Is noncombustible, meeting test criteria of ASTM E136. Thermal performance determined by ASTM C653 and C518.

Masonry Wall Batts

Unfaced batts designed for use behind paneling in masonrytype construction where cavity depth is limited by the furring strips. Used with a separate vapor retarder or where no vapor retarder is required or recommended.

R-6 / 134" R-3 / 34"

Basement Wall Insulation

Available with perforated white flame resistant polypropylene or foil facings. Used to insulate walls of unfinished basements. Flame spread rating is 25 or less. Available in 48" and 72" widths.

R-11 / 318"

Complies with ASTM C665, Type II, Class A, Category 1 and 2. Thermal performance determined by ASTM C653 and C518.

MemBrain

Vapor retarder sheeting intended for use with unfaced, vapor permeable mass insulation (fiber glass and mineral wool) in wall and ceiling cavities. MemBrain is a polyamide film that changes its permeability with ambient humidity conditions.

2 mil

Water vapor permeance values are determined by ASTM E96. < 1.0 perm (57 ng/Pasm2) (ASTM E96, Standard Desiccant method) > 10 perms (Membrain S/B 570/Pasm2) (ASTM E96, Standard Water method)

DryRight

DryRight batt insulation is intended for use in either residential or commercial construction as thermal and acoustical insulation in wood wall assemblies.

R-13 / 312" R-19 / 614"

Complies with ASTM C665, Section 7.4, Water-Vapor Permeance Complies with ASTM E96 Water vapor permeance values are determined by ASTM E96. < 1.0 perm (57 ng/Pasm2) (ASTM E96, Desiccant method) Dry Cup Mean, Relative Humidity=25% > 8 perms (1,144ng/Pasm2) (ASTM E96, Water method) Wet Cup Mean, Relative Humidity=75%

CertaPro Products

CertaPro Thermal Foil Faced Batts

Description

Thermal Nominal Resistance* Thickness

Applicable Standards

Complies with ASTM C553, Type I & ASTM C665, Type III, Class B, Category 1. Thermal performance determined by ASTM C653 and ASTM C518.

Manufactured with a flanged foil/kraft vapor retarder providing a perm rating of 0.05 or less. Has a flame spread rating of 75 or less. Manufactured with a flanged flame resistant foil-scrim-kraft facing. Used where a flame spread rating of 25 or less is required for insulation facings. The facing has a perm rating of 0.02 or less.

R-38 R-30 R-19 R-13 R-11 R-38 R-30 R-19 R-13 R-11

/ / / / / / / / / /

12" 10" 614" 312" 312" 12" 10" 614" 1 2" 312"

CertaPro Thermal FSK-25 Faced Batts

Complies with ASTM C553, Type I & ASTM C665, Type III, Class A, Category 1. Thermal performance determined by ASTM C653 and ASTM C518.

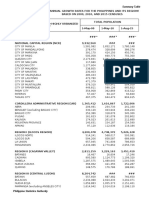

Premium Description Blowing Wool Products

Thermal Resistance R-Value

60 49 44 38 30 22 19 13

Bags per 1,000 sq. ft.

31.4 25.2 22.4 19.1 14.9 10.8 9.3 6.2

Minimum Weight Min. Installed Pounds per sq. ft. Settled Thickness

0.972 0.780 0.695 0.591 0.462 0.334 0.289 0.192 22.00" 18.50" 16.75" 14.50" 11.75" 8.75" 7.75" 5.25"

Applicable Standards

InsulSafe SP

Fiber glass blowing insulation for pneumatic application in open attics or closed cavities.

Complies with ASTM C764, Type I. Thermal performance is determined by ASTM C687 and ASTM C518.

OPTIMA System

System including OPTIMA premium fiber glass blowing insulation and OPTIMA non-woven fabric or equivalent.

56 47 39 30 23 15

71.0 60.3 49.6 38.8 29.5 18.8

1.988 1.688 1.388 1.088 0.825 0.525

13.25" 11.25" 9.25" 7.25" 5.50" 3.50"

(2 (2 (2 (2 (2 (2

x x x x x x

14) 12) 10) 8) 6) 4)

Complies with ASTM C764, Type I. Thermal performance is determined by ASTM C687 and ASTM C518.

System 5

System including System 5 premium fiber glass blowing insulation, System 5 insulation blowing machine and System 5 insulation blowing hose.

49 44 38 30 22 19 13

29.6 26.3 22.5 17.4 12.5 10.8 7.3

0.83 0.736 0.629 0.487 0.351 0.303 0.21

19.25" 17.50" 15.25" 12.25" 9.25" 8.00" 5.50"

Complies with ASTM C764, Type I. Thermal performance is determined by ASTM C687 and ASTM C518.

Standard Blowing Wool

Description R-Value

Fiber glass insulation material processed for pneumatic application. 49 44 38 30 22 19 13

Thermal Resistance Bags per 1,000 sq. ft.

42.2 37.6 32.6 25.5 18.6 16.1 11.0

Minimum Weight Min. Installed Pounds per sq. ft. Settled Thickness

1.056 0.941 0.815 0.638 0.466 0.402 0.276 20.25" 18.25" 16.00" 12.75" 9.50" 8.25" 5.75"

Applicable Standards

UltraTherm

Complies with ASTM C764, Type I. Is noncombustible, meeting criteria of ASTM E136. Thermal performance is determined by ASTM C687.

Spray Foam Products

CertaSpray Open Cell Foam

Description

Thermal Nominal Resistance* Thickness

A two-component water blown spray foam applied as a spray insulation. The foam provides thermal insulation for the interior of buildings and reduces air infiltration through the building envelope

R-3.6 / 1" R-5.3 / 112" R-7.0 / 2" R-8.8 / 212" R-10.5 / 3" R-12.3 / 312" R-14.0 / 4" R-15.8 / 412" R-17.5 / 5" R-19.3 / 512" R-21 / 6"

Spray Foam Products

CertaSpray Closed Cell Foam

Description

Thermal Nominal Resistance* Thickness

A two-component HFC blown spray foam applied as a spray insulation. The foam provides thermal insulation for the interior of buildings and reduces air infiltration through the building envelope

R-5.4 / 1" R-8.1 / 112" R-10.8 / 2" R-13.5 / 212" R-16.2 / 3" R-18.9 / 312" R-21.6 / 4" R-24.3 / 412" R-27 / 5" R-29.7 / 512" R-32.4 / 6"

Product Characteristics

Sound Transmission Loss CertainTeeds Fiber Glass products can reduce sound transmission when properly installed in construction assemblies and can add from 3 to 12 points to the STC rating depending on the type of assembly. The actual rating is dependent on the workmanship, mass of total material, thickness of insulation, and the air tightness of the construction. In wood stud assemblies, separation of the wall surfaces plus the addition of insulation in stud cavities are the most effective means of reducing sound transmission. This may be accomplished by installing resilient channels on one side of the partition, or with staggered or double wall constructions. The table on the following page lists some typical sound rated partition assemblies.

Surface Burning Characteristics

These products have the following maximum flame spread and smoke developed ratings when tested per ASTM E84: Product Unfaced Building Insulation UltraTherm InsulSafe SP OPTIMA System 5 FSK-25 Building Insulation Basement Wall Insulation Standard Foil Building Insulation MemBrain DryRight CertaSpray Open Cell Foam CertaSpray Closed Cell Foam Flame Spread 5 5 5 5 5 25 25 75 20 <25 <25 <25 Smoke Developed 0 0 5 5 5 50 50 150 55 <50 <450 <450

FSK-25, Basement Wall and standard foil-faced insulation products have a critical radiant flux flame propagation resistance equal to or greater than 0.12 w/cm 2

Fire Safety

CertainTeed Unfaced Fiber Glass Building Insulation, OPTIMA, InsulSafe SP, System 5 and UltraTherm are noncombustible per ASTM E136 test criteria. Many building codes require that foam plastic insulation be covered with an approved 15-minute thermal barrier. Consult local building code officials to ensure the application meets local building codes and regulations.

Approximate STC Ratings

Wood Frame Partitions With Gypsum Wallboard Facings (1/2" & 5/8") Single studs/single layer facings Single studs/resilient channel Staggered studs/single layer facings Double stud walls/single layer facings 312" of CertainTeed Fiber Glass Insulation (batts or blown) 5/8" 35 40 43 45 1/2" 39 46 50 57 5/8" 38 50 51 57

No Insulation 1/2" 34 39 39 46

Steel Stud Partitions With Gypsum Wallboard Facings (1/2" & 5/8")

1

No Insulation 2 2" Studs 1/2" 5/8" 358" Studs 1/2" 5/8" 36 42 50 39 47 52

312" of CertainTeed Fiber Glass Insulation (batts or blown) 212" Studs 1/2" 5/8" 45 50 54 47 52 57 358" Studs 1/2" 5/8" 47 52 56 50 55 58

Single layer facings Double layer one side, single layer other side Double layer each side

36 39 45

39 44 48

Guide Specifications for CertainTeed Fiber Glass Thermal and Acoustical Insulations

Note to the specifier: Provide information as required; delete inappropriate items and fill in where indicated. This guide specification applies to thermal and acoustical insulation in walls, ceilings and floors. It follows Construction Specifications Institute (CSI) format. Part 1 General 1.01 Work Included State type of insulation and where it is to be installed. 1.02 Related Work State if separate vapor retarder and/or air barrier is to be installed. 1.03 References Include appropriate insulation standards. Part 2 Products 2.01 Acceptable Manufacturers CertainTeed Corporation 2.02 Materials Thermal Insulation Insulation for (ceilings) (walls) (floors) shall be CertainTeed _____________ inches thick with R-Value of ___________ or Insulation for (ceilings) (or other approved location) shall be CertainTeed installed at minimum of ________ inches thick, with _________ bags/1,000 sq. ft. for R-Value of ________ . Sound Control Insulation Insulation for (ceilings) (walls) (floors) shall be CertainTeed Acoustical Ceiling Batts Insulation over suspended ceilings shall be CertainTeed kraft-faced (312" R-11) (614" R-19) Acoustical Ceiling Batts Part 3 Execution 3.01 Preparation Verify that mechanical and electrical services in (ceilings) (walls) (floors) have been installed and tested and, if appropriate, verify that adjacent materials are dry and ready to receive insulation. 3.02 Installation Installation shall be in accordance with CertainTeeds instructions.

ASK ABOUT OUR OTHER CERTAINTEED PRODUCTS AND SYSTEMS:

E X T E R I O R : R O O F I N G S I D I N G W I N D O W S F E N C E R A I L I N G T R I M D E C K I N G F O U N D AT I O N S P I P E I N T E R I O R : I N S U L AT I O N G Y P S U M C E I L I N G S

CertainTeed Corporation P.O. Box 860 Valley Forge, PA 19482

3/08 CertainTeed Corporation, Printed in U.S.A.

Professional: 800-233-8990 Consumer: 800-782-8777 www.certainteed.com

Code: 30-21-890/Residential Products Submittal Sheet

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Rules For Pipes P1Dokumen10 halamanRules For Pipes P1asif712Belum ada peringkat

- 2.06 SIPOC DiagramDokumen4 halaman2.06 SIPOC DiagramJoao LuisBelum ada peringkat

- OTA Customer Solution PDFDokumen5 halamanOTA Customer Solution PDFDxtr MedinaBelum ada peringkat

- Markov ProcessDokumen93 halamanMarkov ProcessDxtr MedinaBelum ada peringkat

- Work PracticeDokumen3 halamanWork PracticeDxtr MedinaBelum ada peringkat

- Costing Life CycleDokumen8 halamanCosting Life CycleDxtr MedinaBelum ada peringkat

- 2015 Population Counts Summary - 0Dokumen12 halaman2015 Population Counts Summary - 0Krystallane ManansalaBelum ada peringkat

- Small Big Data: Using Multiple Data-Sets To Explore Unfolding Social and Economic ChangeDokumen6 halamanSmall Big Data: Using Multiple Data-Sets To Explore Unfolding Social and Economic ChangeDxtr MedinaBelum ada peringkat

- 1764 PDFDokumen288 halaman1764 PDFDxtr MedinaBelum ada peringkat

- Box IPO Financial ModelDokumen42 halamanBox IPO Financial ModelVinBelum ada peringkat

- 13Dokumen5 halaman13Dxtr MedinaBelum ada peringkat

- Nancy A. Mathiowetz, Charlie Brown, and John BoundDokumen38 halamanNancy A. Mathiowetz, Charlie Brown, and John BoundDxtr MedinaBelum ada peringkat

- Early Childhood EducDokumen13 halamanEarly Childhood EducWarren Amante MabaoBelum ada peringkat

- Quasi-Empirical Scenario Analysis and Its Application To Big Data QualityDokumen21 halamanQuasi-Empirical Scenario Analysis and Its Application To Big Data QualityDxtr MedinaBelum ada peringkat

- Analysis of Studies On Applications and Challenges in Implementation of Big Data in The Public AdministrationDokumen9 halamanAnalysis of Studies On Applications and Challenges in Implementation of Big Data in The Public AdministrationEditor IJRITCCBelum ada peringkat

- The Complete Guide To Referencing and Avoiding Plagiarism: Colin NevilleDokumen2 halamanThe Complete Guide To Referencing and Avoiding Plagiarism: Colin NevilleDxtr MedinaBelum ada peringkat

- C - B D A - A S C R F D: Loud Based IG ATA Nalytics Urvey of Urrent Esearch and Uture IrectionsDokumen12 halamanC - B D A - A S C R F D: Loud Based IG ATA Nalytics Urvey of Urrent Esearch and Uture Irectionsprayas jhariyaBelum ada peringkat

- Very Fast Estimation For Result and Accuracy of Big Data Analytics: The EARL SystemDokumen4 halamanVery Fast Estimation For Result and Accuracy of Big Data Analytics: The EARL SystemDxtr MedinaBelum ada peringkat

- Measuring Income and Poverty Using Proxy Means TestsDokumen5 halamanMeasuring Income and Poverty Using Proxy Means TestsDxtr MedinaBelum ada peringkat

- DF 23Dokumen23 halamanDF 23Dxtr MedinaBelum ada peringkat

- 06Dokumen28 halaman06Dxtr MedinaBelum ada peringkat

- Proxy Means Testing: An Alternative Method For Poverty AssessmentDokumen6 halamanProxy Means Testing: An Alternative Method For Poverty AssessmentDxtr MedinaBelum ada peringkat

- Ar Promise Peril of Big DataDokumen41 halamanAr Promise Peril of Big DataDxtr MedinaBelum ada peringkat

- Egov For Dev CountriesDokumen24 halamanEgov For Dev CountriesmadagalynBelum ada peringkat

- Big Data, Machine Learning Shape Performance-Monitoring DevelopmentsDokumen5 halamanBig Data, Machine Learning Shape Performance-Monitoring DevelopmentsDxtr MedinaBelum ada peringkat

- 02Dokumen10 halaman02Dxtr MedinaBelum ada peringkat

- 04 Education Technology WestDokumen24 halaman04 Education Technology WestDxtr MedinaBelum ada peringkat

- 1Dokumen1 halaman1Dxtr MedinaBelum ada peringkat

- Big Data For Education: Data Mining, Data Analytics, and Web DashboardsDokumen11 halamanBig Data For Education: Data Mining, Data Analytics, and Web DashboardsDxtr MedinaBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Landscape ArchitectureDokumen9 halamanLandscape Architecturelisan2053Belum ada peringkat

- Air Blower ManualDokumen16 halamanAir Blower ManualshaiknayeemabbasBelum ada peringkat

- Acceptable Use Policy 08 19 13 Tia HadleyDokumen2 halamanAcceptable Use Policy 08 19 13 Tia Hadleyapi-238178689Belum ada peringkat

- Ode To The West WindDokumen4 halamanOde To The West WindCharis Mae DimaculanganBelum ada peringkat

- Forensic IR-UV-ALS Directional Reflected Photography Light Source Lab Equipment OR-GZP1000Dokumen3 halamanForensic IR-UV-ALS Directional Reflected Photography Light Source Lab Equipment OR-GZP1000Zhou JoyceBelum ada peringkat

- 4039-Texto Del Artículo-12948-3-10-20211123Dokumen14 halaman4039-Texto Del Artículo-12948-3-10-20211123Ricardo ApazaBelum ada peringkat

- Quotation - 1Dokumen4 halamanQuotation - 1haszirul ameerBelum ada peringkat

- Documentos de ExportaçãoDokumen17 halamanDocumentos de ExportaçãoZineBelum ada peringkat

- SPFL Monitoring ToolDokumen3 halamanSPFL Monitoring ToolAnalyn EnriquezBelum ada peringkat

- Diesel Engines For Vehicles D2066 D2676Dokumen6 halamanDiesel Engines For Vehicles D2066 D2676Branislava Savic63% (16)

- Index: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsDokumen5 halamanIndex: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsZidi BoyBelum ada peringkat

- This Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiDokumen7 halamanThis Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiIvo BogoevskiBelum ada peringkat

- Land CrabDokumen8 halamanLand CrabGisela Tuk'uchBelum ada peringkat

- Parrot Mk6100 Userguide Zone1Dokumen100 halamanParrot Mk6100 Userguide Zone1Maria MartinBelum ada peringkat

- Kortz Center GTA Wiki FandomDokumen1 halamanKortz Center GTA Wiki FandomsamBelum ada peringkat

- PM 50 Service ManualDokumen60 halamanPM 50 Service ManualLeoni AnjosBelum ada peringkat

- TransistorsDokumen21 halamanTransistorsAhmad AzriBelum ada peringkat

- Caroline Coady: EducationDokumen3 halamanCaroline Coady: Educationapi-491896852Belum ada peringkat

- French Cuisine RecipeDokumen6 halamanFrench Cuisine RecipeJimmy AchasBelum ada peringkat

- Visi RuleDokumen6 halamanVisi RuleBruce HerreraBelum ada peringkat

- Post Renaissance Architecture in EuropeDokumen10 halamanPost Renaissance Architecture in Europekali_007Belum ada peringkat

- Institutions and StrategyDokumen28 halamanInstitutions and StrategyFatin Fatin Atiqah100% (1)

- Linux ProgramDokumen131 halamanLinux ProgramsivashaBelum ada peringkat

- Stratum CorneumDokumen4 halamanStratum CorneumMuh Firdaus Ar-RappanyBelum ada peringkat

- Extraction of Mangiferin From Mangifera Indica L. LeavesDokumen7 halamanExtraction of Mangiferin From Mangifera Indica L. LeavesDaniel BartoloBelum ada peringkat

- DHA - Jebel Ali Emergency Centre + RevisedDokumen5 halamanDHA - Jebel Ali Emergency Centre + RevisedJam EsBelum ada peringkat

- Measuring Road Roughness by Static Level Method: Standard Test Method ForDokumen6 halamanMeasuring Road Roughness by Static Level Method: Standard Test Method ForDannyChaconBelum ada peringkat

- CBSE 10th ResultsDokumen1 halamanCBSE 10th ResultsAkshit SinghBelum ada peringkat

- Unit 1 Bearer PlantsDokumen2 halamanUnit 1 Bearer PlantsEmzBelum ada peringkat

- Learning English Through The Educational Games of Wordwall Website For Elementary Students by Group 1 (R4E)Dokumen6 halamanLearning English Through The Educational Games of Wordwall Website For Elementary Students by Group 1 (R4E)NurulBelum ada peringkat