Geogrid Reinforcement

Diunggah oleh

philipyapDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Geogrid Reinforcement

Diunggah oleh

philipyapHak Cipta:

Format Tersedia

Saudi Aramco 2616-ENG (3/99)

OPERNS.

SAUDI ARAMCO OIL COMPANY

SECTION 02232 GEOGRID SOIL REINFORCEMENT PART I GENERAL 1.1 SUMMARY This section includes geogrid reinforcement for subgrade improvement in areas where Sabkha soils are encountered. Geogrid shall not be used in areas intended to be subject to further soil improvement by other methods. 1.2 RELATED SPECIFICATIONS SAES-A-l 14 Geotextiles (Filter Fabric)

1.3

REFERENCES Saudi Aramco Engineering Standards (SAES) Saudi Aramco Materials System (SAMS) American Society for Testing Materials (ASTM) Geosynthetic Research Institute (G RI) National Highway Institute (NIIl)

DISCIPLINE ENGINEER

__ ________ _ DATE: ________

1.4

DEFINITIONS Geogrid A biaxial polymeric grid formed by a regular network of internally connected tensile elements with apertures of sufficient size to allow interlocking with surrounding soil, rock, or earth to function primarily as reinforcement. Subgrade Improvement using geogrid Placement of a geogrid immediately over a soft subgrade soil in order to improve the bearing capacity and mitigate deformation of the subgrade soil. The goal of this application is to eliminate undercut of the Sabkha, improve construction efficiency, and provide a stiff working platform for embankment and pavement construction.

PROJECT ENGINEER

____________ DATE

CERTIFIED _ __________

DATE: ________

CONSTRUCTION AGENCY

________________ DATE:

OPERATIONS

______________ DATE:_________ REVISION CERTIFICATION EDSD VERIFICATION THIS INDICATES THAT REV. NO.________ OF THIS DRAWING IS COVERED, FOR ALL APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER BY DRAWING COMPLETION CERTIFICATE (DCC) NO.: __________________________ By:

1.5

SUBMITTALS A. Submit geogrid product sample approximately 300 mm by 300 mm or larger. Submit geogrid product data sheet and certification from the manufacturer that the geogrid product supplied meets the specified requirements. Submit manufacturers recommendations. installation instructions and general

SECTION 02232

DRAWING NO. SHT. NO. REV. NO.

CONSTRUCTION SPECIFICATIONS

KAUST TOWN CENTER RESIDENTIAL &

DWG. TYPE PLANT NO. INDEX

DOC

COMMUNITY SUPPORT BUILDINGS RABIGH SAUDI ARABIA

K55

JOB/EWO#

VE-417361 BI-25-00002

1 OF 5

00

14-Sep-07

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

REV. NO.

DATE JOB/EWO

DESCRIPTION

ENGG

CERT

PMT

Date:

Saudi Aramco 2616-ENG (3/99)

OPERNS.

SAUDI ARAMCO OIL COMPANY

ENGG

CERT

D.

Submit additional information as requested by the Engineer to fully evaluate the product. Submit calculations and construction details/shop drawings showing the improved bearing capacity/settlement properties of the soil (as a result of utilizing geogrid) and the composition of the geogrid / crushed stones layers (numbers and thickness) which are required to achieve the target improved bearing capacity. Design reinforced soil structure in conformance with the local codes and regulations or the design guidelines of NHI-00-043. Construction shall not proceed till the submittals are approved.

E.

1.6

QUALITY ASSURANCE A. Pre-Construction Conference Prior to installation of the geogrid, the Contractor shall arrange a meeting at the site with the geogrid material supplier. The Engineer will be notified at least three days in advance of the time of the meeting. A representative of the geogrid supplier shall be available on as needed basis during installation of the grid to provide guidance, advise and technical support. Manufacturer Qualifications: System components manufactured by licensees or by companies approved and authorized by the component supplier. Installer Qualifications: Firm with documented experience of at least five projects of similar construction and scope.

B.

DISCIPLINE ENGINEER

__ ________ _ DATE: ________

PROJECT ENGINEER

____________ DATE

C.

CERTIFIED _ __________

DATE: ________

1.7

STORAGE Geogrid shall be protected from deleterious materials, chemicals, sparks and flames, temperatures in access of 70 degrees C, and any other environmental conditions that may degrade the physical properties. If stored outdoors, the rolls shall be protected with an opaque waterproof cover.

CONSTRUCTION AGENCY

________________ DATE:

OPERATIONS

______________ DATE:_________ REVISION CERTIFICATION EDSD VERIFICATION THIS INDICATES THAT REV. NO.________ OF THIS DRAWING IS COVERED, FOR ALL APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER BY DRAWING COMPLETION CERTIFICATE (DCC) NO.: __________________________ By:

PART 2 PRODUCT 2.1 GEOGRID REINFORCEMENT Geogrid shall be a geosynthetic manufactured for reinforcement applications. The geogrid shall be a regular network of integrally connected polymer tensile elements with aperture geometry sufficient to permit significant mechanical interlock with the surrounding soil, aggregate, or other fill materials. The geogrid structure shall be dimensionally stable and able to retain its geometry under manufacture, transport and installation. The geogrid shall be manufactured with 100 percent virgin resin consisting of high density polyethylene (HDP), polypropylene (PP), polyester (PET), or other approved material.

CONSTRUCTION SPECIFICATIONS

KAUST TOWN CENTER RESIDENTIAL &

DWG. TYPE PLANT NO. INDEX DRAWING NO.

SECTION 02232

SHT. NO. REV. NO.

DOC

COMMUNITY SUPPORT BUILDINGS RABIGH SAUDI ARABIA

K55

JOB/EWO#

VE-417361 BI-25-00002

2 OF 5

00

14-Sep-07

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

REV. NO.

DATE JOB/EWO

DESCRIPTION

PMT

Date:

Saudi Aramco 2616-ENG (3/99)

OPERNS.

SAUDI ARAMCO OIL COMPANY

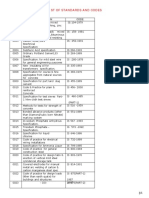

2.2 GEOGRID REINFORCEMENT PROPERTIES Geogrid shall be biaxial geogrid reinforcement with minimum tensile properties in both the machine and cross-machine direction not less than the following:

DESCRIPTION

Properties Aperture Dimensions Minimum Rib Thickness Tensile Strength @ 5% Stain (Ta) Ultimate Tensile Strength (Tult) Resistance to UV Degradation

Units mm mm kN/m kN/m %

Requirements 25 1.25 11 19 100

a.

DATE JOB/EWO

Allowable Tensile Strength (Ta) shall be defined as Tult I RF Where RF = RFCR x RFD x RFID. Reduction Factor for Creep (RFCR), Reduction Factor for Durability (RFD), and Reduction Factor for Installation Damage (RFID). Ultimate Tensile Strength (Tult) shall be the minimum average roll value (MARV) as tested per ASTM D 6637. Reduction Factor for Creep (RFCR) shall be based on 100-year design life determined in accordance with ASTM D 5262. Reduction Factor for Creep (RFCR) shall not be less than 1.60 for PET, 2.6 for HDPE, and 4.0 for PP in accordance with NHI-00043. Reduction Factor for Installation Damage (REID) shall be based on reinforced backfill type designated above or reinforced backfill gradation as indicated in the approved shop drawings or specifications. Installation damage testing and material sampling shall be in conformance with ASTM D 6637 and D 5818. Reduction Factor for Installation Damage (RFID) shall not be less than 1.05, regardless of test data. Reduction Factor for Durability (RFD) shall be based on polymer type used in manufacture of geogrid reinforcement. Polyester (PET) yarn shall have a molecular weight _25,000 glm per GRI-GG8 and a carboxyl end group (CEG) number _30 per GRI- GG7. High density polyethylene (HDPE) and polypropylene (PP) shall have a melt flow index ~J.4 g/10 mm as determined in accordance with ASTM D 1238 and retain a minimum of 70% tensile strength after 500 hours when tested in accordance with ASTM D 4355. Reduction Factor for Durability (RFD) shall not be less than 1.10, regardless of test data.

b.

c.

DISCIPLINE ENGINEER

__ ________ _ DATE: ________

PROJECT ENGINEER

____________ DATE

d.

CERTIFIED _ __________

DATE: ________

CONSTRUCTION AGENCY

________________ DATE:

e.

OPERATIONS

______________ DATE:_________ REVISION CERTIFICATION EDSD VERIFICATION THIS INDICATES THAT REV. NO.________ OF THIS DRAWING IS COVERED, FOR ALL APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER BY DRAWING COMPLETION CERTIFICATE (DCC) NO.: __________________________ By:

2.3

CRUSHED STONE FILL MATERIAL A well graded crushed stone aggregate material shall be used over the grid. The material shall meet the following gradation limits:

SECTION 02232

CONSTRUCTION SPECIFICATIONS

KAUST TOWN CENTER RESIDENTIAL &

DWG. TYPE PLANT NO. INDEX

DRAWING NO.

SHT. NO. REV. NO.

DOC

COMMUNITY SUPPORT BUILDINGS RABIGH SAUDI ARABIA

K55

JOB/EWO#

VE-417361 BI-25-00002

3 OF 5

00

14-Sep-07

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

REV. NO.

ENGG

CERT

PMT

Date:

Saudi Aramco 2616-ENG (3/99)

OPERNS.

SAUDI ARAMCO OIL COMPANY

CERT

Sieve Size 38.0 mm 19.0mm 4.75 mm 425 micrometers 150 micrometers 75 micrometers PART 3 EXECUTION 3.1 GENERAL

% Passing 100 50100 2550 10 20 5 - 15 less than 10

DATE JOB/EWO

Construct reinforced soil structure in accordance with the approved shop drawings and Construction and Quality Control Manual supplied by the manufacturer. 3.2 INSTALLATION Immediately prior to placement of the geogrid, the surface on which the geogrid will be placed shall be free of rock or other materials that damage the geogrid. Surface crust of the Sabkha shall not be disturbed or scarified. Clearing and grubbing of the Sabkha areas shall only include trimming the vegetation down to approximately 15 cm height. Geogrid shall be unrolled in the direction of fill placement. After a layer of geogrid has been placed, it will be pulled taut to remove slacks, held flat and in place by ties, staples, pins or sand bags until covered by crushed stone aggregate. Adjacent rolls of geogrid shall be overlapped and fastened as recommended by the manufacturer. Overlap shall not be less than one (1) meter in all directions. Adjacent embedment lengths of geogrid shall abut to provide 100% coverage at elevations requiring geogrid reinforcement, as indicated in the approved shop drawings. Fastener types and spacing shall be as recommended by the manufacturer and as approved by the Engineer. Metallic fasteners will not be allowed. Place crushed stone layers (in accordance with the following paragraph) Proved other layers of geogrid and crushed stones if calculations indicate the need to provide more than one layer to achieve the required bearing capacity.

Date:

DISCIPLINE ENGINEER

__ ________ _ DATE: ________

PROJECT ENGINEER

____________ DATE

CERTIFIED _ __________

DATE: ________

CONSTRUCTION AGENCY

________________ DATE:

OPERATIONS

______________ DATE:_________ REVISION CERTIFICATION EDSD VERIFICATION THIS INDICATES THAT REV. NO.________ OF THIS DRAWING IS COVERED, FOR ALL APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER BY DRAWING COMPLETION CERTIFICATE (DCC) NO.: __________________________ By:

SECTION 02232

CONSTRUCTION SPECIFICATIONS

KAUST TOWN CENTER RESIDENTIAL &

DWG. TYPE PLANT NO. INDEX

DRAWING NO.

SHT. NO. REV. NO.

DOC

COMMUNITY SUPPORT BUILDINGS RABIGH SAUDI ARABIA

K55

JOB/EWO#

VE-417361 BI-25-00002

4 OF 5

00

14-Sep-07

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

REV. NO.

DESCRIPTION

ENGG

PMT

Saudi Aramco 2616-ENG (3/99)

OPERNS.

SAUDI ARAMCO OIL COMPANY

3.3 CRUSHED STONE AGGREGATE PLACEMENT OVER GEOGRID Crushed stone aggregate fill material shall be placed in lifts and compacted as required by the design calculations. Crushed stone aggregate fill material shall be placed, spread, and compacted in such a manner that minimizes the development of wrinkles in the geogrid and/or movement of the geogrid. Initial layer of crushed stone aggregate shall be placed by end dump method such that the haul trucks are only backed up on the aggregate. Material hauling equipment shall not be allowed to operate on bare grid. The aggregate shall not be dropped onto the geogrid from height greater than one meter. Equipment placing cover aggregate shall not stop abruptly, make sharp turns, spin their wheels, or travel at speed exceeding 15 km/hour. 3.4 INSPECTION The Engineer may randomly inspect geogrid, before, during and after installation. Any defective work shall be repaired or replaced as directed by the Engineer. 3.5 TESTING Contractor shall employ an independent testing agency to conduct field testing. Verify that the completed work exhibits the required bearing capacity criteria by conducting field testing by means of plate load tests in accordance with ASTM D 1194-94.

DISCIPLINE ENGINEER

__ ________ _ DATE: ________

PROJECT ENGINEER

____________ DATE

CERTIFIED _ __________

DATE: ________

END OF SECTION 02232

CONSTRUCTION AGENCY

________________ DATE:

OPERATIONS

______________ DATE:_________ REVISION CERTIFICATION EDSD VERIFICATION THIS INDICATES THAT REV. NO.________ OF THIS DRAWING IS COVERED, FOR ALL APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER BY DRAWING COMPLETION CERTIFICATE (DCC) NO.: __________________________ By:

SECTION 02232

CONSTRUCTION SPECIFICATIONS

KAUST TOWN CENTER RESIDENTIAL &

DWG. TYPE PLANT NO. INDEX

DRAWING NO.

SHT. NO. REV. NO.

DOC

COMMUNITY SUPPORT BUILDINGS RABIGH SAUDI ARABIA

K55

JOB/EWO#

VE-417361 BI-25-00002

5 OF 5

00

14-Sep-07

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

REV. NO.

DATE JOB/EWO

DESCRIPTION

ENGG

CERT

PMT

Date:

Anda mungkin juga menyukai

- KDS 41 17 00 건축물 내진설계기준Dokumen131 halamanKDS 41 17 00 건축물 내진설계기준colt0Belum ada peringkat

- Pavement Thickness DesignDokumen28 halamanPavement Thickness DesignGuido OrtizBelum ada peringkat

- CEM Part VI Chap 5 Pt2Dokumen84 halamanCEM Part VI Chap 5 Pt2raly1Belum ada peringkat

- Geogrid Reinforcement of Flexible Pavements: A Practical PerspectiveDokumen15 halamanGeogrid Reinforcement of Flexible Pavements: A Practical PerspectiveMohammad TarawnehBelum ada peringkat

- Sub GradeDokumen6 halamanSub GradeIra AgcaoiliBelum ada peringkat

- Bailey Bridge 7Dokumen8 halamanBailey Bridge 7guillermoBelum ada peringkat

- Do 050 S2007-Mse SpecsDokumen12 halamanDo 050 S2007-Mse SpecsCarol SantosBelum ada peringkat

- Silt CurtainDokumen3 halamanSilt CurtainarvindkaushikBelum ada peringkat

- Guidelines For The Design of Sediment ContainmentDokumen10 halamanGuidelines For The Design of Sediment ContainmentBudi NadatamaBelum ada peringkat

- Types of PavementDokumen10 halamanTypes of Pavementmohsen.911.mkBelum ada peringkat

- Vibroreplacement PDFDokumen9 halamanVibroreplacement PDFthadikkaranBelum ada peringkat

- State of The Practice of Rigid Inclusions - 3-17-2021Dokumen11 halamanState of The Practice of Rigid Inclusions - 3-17-2021Tanju Tahir Ökten100% (1)

- Stone Pitching DetailDokumen1 halamanStone Pitching DetailTwahirwa JoelsonBelum ada peringkat

- Geogrid-Techgrid Technical LiteratureDokumen13 halamanGeogrid-Techgrid Technical Literaturesachindagrawal90440% (1)

- Profis Anchor 2.5.0 HILTIDokumen6 halamanProfis Anchor 2.5.0 HILTIALONSO GOMEZBelum ada peringkat

- Brochure ZA ProductGuideDokumen16 halamanBrochure ZA ProductGuideAli MasyhurBelum ada peringkat

- 751.24 LFD Retaining Walls Sept 2011 PDFDokumen94 halaman751.24 LFD Retaining Walls Sept 2011 PDFIjaz ShahBelum ada peringkat

- 12 M High Retaining Wall Design For Seismic LoadingDokumen27 halaman12 M High Retaining Wall Design For Seismic Loadingaminjoles0% (1)

- Steel Sheet Piling: Standard Specification ForDokumen2 halamanSteel Sheet Piling: Standard Specification ForGienelyn JulianoBelum ada peringkat

- Asphalt Specs ADMDokumen19 halamanAsphalt Specs ADMAbdul GhaniBelum ada peringkat

- Design of Mse WallsDokumen1 halamanDesign of Mse WallsAlan LumpkinBelum ada peringkat

- Ultimate Bearing Capacity of A SINGLE STONE COLUMNDokumen11 halamanUltimate Bearing Capacity of A SINGLE STONE COLUMNAnirudh Rathore100% (1)

- GW Byun Comparision Geotech Softwares PDFDokumen52 halamanGW Byun Comparision Geotech Softwares PDFManiBelum ada peringkat

- Ada 405009Dokumen253 halamanAda 405009ivantrax116Belum ada peringkat

- Polefdn - Pole Foundation Analysis ProgramDokumen10 halamanPolefdn - Pole Foundation Analysis ProgramANGEL .Belum ada peringkat

- USACE ShoreProtectionManual2 PDFDokumen652 halamanUSACE ShoreProtectionManual2 PDFPedro RipaceBelum ada peringkat

- MSE Wall 02Dokumen1 halamanMSE Wall 02Anonymous kBl0u3nBelum ada peringkat

- @ - Breakwater Foundation StabilityDokumen9 halaman@ - Breakwater Foundation Stabilityapi-3709579100% (1)

- RTGDokumen8 halamanRTGlnanescuBelum ada peringkat

- Use of Broms Charts For Evaluating Lateral LoadDokumen10 halamanUse of Broms Charts For Evaluating Lateral LoadGOPAL VERMABelum ada peringkat

- SDADokumen1 halamanSDAFrans van der MerweBelum ada peringkat

- Geological Society, London, Engineering Geology Special Publications, 16, 257-289, 1 January 1999Dokumen33 halamanGeological Society, London, Engineering Geology Special Publications, 16, 257-289, 1 January 1999akhila sBelum ada peringkat

- PVD SpecificationDokumen4 halamanPVD SpecificationAdy NugrahaBelum ada peringkat

- Geocell Design Reports at Different SectionsDokumen32 halamanGeocell Design Reports at Different SectionsPrakash Singh RawalBelum ada peringkat

- Numerical Modeling of Geogrid Reinforced Flexible Pave 2016 Construction andDokumen17 halamanNumerical Modeling of Geogrid Reinforced Flexible Pave 2016 Construction andHanamant HunashikattiBelum ada peringkat

- Barrier Design GuidelinesDokumen22 halamanBarrier Design GuidelineskonnariBelum ada peringkat

- Verdú GeneralDokumen36 halamanVerdú GeneralMiguel Belda DiezBelum ada peringkat

- Engineering Properties: Compression Consolidation Shear Strength PermeabilityDokumen19 halamanEngineering Properties: Compression Consolidation Shear Strength PermeabilityKiranmayi NethalaBelum ada peringkat

- JRCP - Parking Yard Calc R1Dokumen8 halamanJRCP - Parking Yard Calc R1Pieter HarryBelum ada peringkat

- Reduction of Overturning Effects at Soil-Foundation InterfaceDokumen2 halamanReduction of Overturning Effects at Soil-Foundation InterfaceClaudio ColettaBelum ada peringkat

- Flyer Ostraadt Concrete FleximatDokumen2 halamanFlyer Ostraadt Concrete FleximatChristian BarBelum ada peringkat

- CIVABTech81733Div A5rBrirAP - 11Dokumen6 halamanCIVABTech81733Div A5rBrirAP - 11Rohit VermaBelum ada peringkat

- Ground Improvement Using Soil-Cement ColumnsDokumen8 halamanGround Improvement Using Soil-Cement ColumnsCristina Andreea BitirBelum ada peringkat

- Subgrade ImprovementDokumen12 halamanSubgrade ImprovementknexpBelum ada peringkat

- Highways Agency DMRB 0-1 - 1Dokumen67 halamanHighways Agency DMRB 0-1 - 1Suraj De SilvaBelum ada peringkat

- 2000 CALTRANS Bridge Design SpecificationsDokumen14 halaman2000 CALTRANS Bridge Design Specificationsrhonald2000Belum ada peringkat

- Continuously Reinforced Concrete PavementDokumen34 halamanContinuously Reinforced Concrete PavementJorge Sobredo-Vega100% (1)

- Gis G 3112-2010Dokumen22 halamanGis G 3112-2010Tú TrầnBelum ada peringkat

- TENSAR-Guidlines For The Design and Construction of Embankments Over Stable Foundations Using Tensar GeogridsDokumen27 halamanTENSAR-Guidlines For The Design and Construction of Embankments Over Stable Foundations Using Tensar GeogridsCostinel CristescuBelum ada peringkat

- Depth of Fixity of Piles in Clay Under Dynamic Lateral Load PDFDokumen15 halamanDepth of Fixity of Piles in Clay Under Dynamic Lateral Load PDFRahulKumarSinghBelum ada peringkat

- Prefabricated Vertical DrainsDokumen25 halamanPrefabricated Vertical Drainsdory.azarhotmail.comBelum ada peringkat

- PCI DH-Loss of PrestressDokumen5 halamanPCI DH-Loss of PrestressCarlisle Flores-GarayBelum ada peringkat

- Semi-Empirical Procedures For Evaluating Liquefaction Potential, Idriss & Boulanger, 2004Dokumen26 halamanSemi-Empirical Procedures For Evaluating Liquefaction Potential, Idriss & Boulanger, 2004hugojameswoodBelum ada peringkat

- Slope Stability ImprovementDokumen43 halamanSlope Stability Improvementomar cBelum ada peringkat

- List Eurocode IBSTDokumen5 halamanList Eurocode IBSTLeed ENBelum ada peringkat

- Sealant and CaulkingDokumen8 halamanSealant and CaulkingphilipyapBelum ada peringkat

- Roof and Deck InsulationDokumen3 halamanRoof and Deck InsulationphilipyapBelum ada peringkat

- Bazaar Tent StructureDokumen5 halamanBazaar Tent StructurephilipyapBelum ada peringkat

- Sheet Membrance Water ProofingDokumen6 halamanSheet Membrance Water ProofingphilipyapBelum ada peringkat

- Finish CarpentryDokumen17 halamanFinish CarpentryphilipyapBelum ada peringkat

- Resilent FlooringDokumen7 halamanResilent FlooringphilipyapBelum ada peringkat

- Bazaar Tent StructureDokumen5 halamanBazaar Tent StructurephilipyapBelum ada peringkat

- Piping and Ducting SupportDokumen7 halamanPiping and Ducting SupportphilipyapBelum ada peringkat

- Saudi Aramco Oil Company: SECTION 16110 RacewaysDokumen10 halamanSaudi Aramco Oil Company: SECTION 16110 RacewaysphilipyapBelum ada peringkat

- Sealant and CaulkingDokumen8 halamanSealant and CaulkingphilipyapBelum ada peringkat

- Fire Protection SysytemDokumen5 halamanFire Protection SysytemphilipyapBelum ada peringkat

- DuctworksDokumen7 halamanDuctworksphilipyapBelum ada peringkat

- SignageDokumen4 halamanSignagephilipyapBelum ada peringkat

- Wire, Cable and Low VotageDokumen9 halamanWire, Cable and Low VotagephilipyapBelum ada peringkat

- Duct Works & AccessoriesDokumen5 halamanDuct Works & AccessoriesphilipyapBelum ada peringkat

- Metal FramesDokumen4 halamanMetal FramesphilipyapBelum ada peringkat

- Exterior LightingDokumen8 halamanExterior LightingphilipyapBelum ada peringkat

- Finish CarpentryDokumen17 halamanFinish CarpentryphilipyapBelum ada peringkat

- Chilled Water PumpDokumen6 halamanChilled Water PumpphilipyapBelum ada peringkat

- Floor MatsDokumen3 halamanFloor MatsphilipyapBelum ada peringkat

- Roof and Deck InsulationDokumen3 halamanRoof and Deck InsulationphilipyapBelum ada peringkat

- Plumbing SpecialitiesDokumen4 halamanPlumbing SpecialitiesphilipyapBelum ada peringkat

- Sheet Membrance Water ProofingDokumen6 halamanSheet Membrance Water ProofingphilipyapBelum ada peringkat

- Glass and GlazingDokumen8 halamanGlass and GlazingphilipyapBelum ada peringkat

- Control SystemDokumen21 halamanControl SystemphilipyapBelum ada peringkat

- Example 2 - Two Equal Spans: AbutmentDokumen94 halamanExample 2 - Two Equal Spans: AbutmentphilipyapBelum ada peringkat

- Handrail RailingDokumen11 halamanHandrail RailingphilipyapBelum ada peringkat

- Bridge Superstructure DesignDokumen108 halamanBridge Superstructure Designstefanotomasi123550% (2)

- GeotectilesDokumen2 halamanGeotectilesphilipyapBelum ada peringkat

- Concrete Curb, EdgingDokumen3 halamanConcrete Curb, EdgingphilipyapBelum ada peringkat

- Sap2000 Analysis Refer ManualDokumen467 halamanSap2000 Analysis Refer ManualphilipyapBelum ada peringkat

- Swimming PoolDokumen4 halamanSwimming PoolphilipyapBelum ada peringkat

- Example 2 - Option 2: Bent Columns On Capped Piles: AbutmentDokumen178 halamanExample 2 - Option 2: Bent Columns On Capped Piles: AbutmentphilipyapBelum ada peringkat

- 5) Manual SAP200 - Bridge Seismic Design (Pu)Dokumen71 halaman5) Manual SAP200 - Bridge Seismic Design (Pu)Alejandro AntezanaBelum ada peringkat

- Tables SaturationDokumen9 halamanTables SaturationGuilmar Moncayo PonceBelum ada peringkat

- Metal O-Ring PDFDokumen8 halamanMetal O-Ring PDFanon_481226617Belum ada peringkat

- Civil Engineering Final Year Project PDFDokumen76 halamanCivil Engineering Final Year Project PDFSaran KumarBelum ada peringkat

- Assembling Extension CordDokumen14 halamanAssembling Extension CordPaul Bulanadi Badiang67% (3)

- Bater SirtDokumen51 halamanBater Sirtsai projectBelum ada peringkat

- General: Title Design of Corbel Cl. No. Design Calculations ReferencesDokumen15 halamanGeneral: Title Design of Corbel Cl. No. Design Calculations ReferencesGovendan GopalakrishnanBelum ada peringkat

- Training ISO 50008Dokumen48 halamanTraining ISO 50008Ricardo AndresBelum ada peringkat

- Numerical Modelling of The Seismic Behaviour of Adobe BuildingsDokumen268 halamanNumerical Modelling of The Seismic Behaviour of Adobe BuildingsNicola Tarque100% (2)

- VRF Schedule Sample 3Dokumen10 halamanVRF Schedule Sample 3nazile_05Belum ada peringkat

- List of Standards and Codes For Power PlantDokumen3 halamanList of Standards and Codes For Power PlantS.KAMBANBelum ada peringkat

- Pratik Pawar Physics ProjectDokumen8 halamanPratik Pawar Physics ProjectaagneysuchitaBelum ada peringkat

- BQ 23-70a Bomba - ADokumen16 halamanBQ 23-70a Bomba - Asharifah atiqahBelum ada peringkat

- Non Return ValvesDokumen10 halamanNon Return ValvesDevendra Bangar100% (1)

- H GuruDokumen4 halamanH GuruAvneet MaanBelum ada peringkat

- Kebutuhan Mep Estimasi Harga No. Uraian Type Vol. SatDokumen8 halamanKebutuhan Mep Estimasi Harga No. Uraian Type Vol. SatKoplak MakmurBelum ada peringkat

- CAB Cable Rings and SaddlesDokumen5 halamanCAB Cable Rings and SaddlesgoyalmanojBelum ada peringkat

- Structural Report of Proposed Fencing and ExtensionDokumen21 halamanStructural Report of Proposed Fencing and ExtensionLester LazoBelum ada peringkat

- Components and Systems For Vehicle Construction and IndustryDokumen21 halamanComponents and Systems For Vehicle Construction and IndustryCarlos SantosBelum ada peringkat

- Boiler Operation On DcsDokumen4 halamanBoiler Operation On Dcsarif100% (2)

- Jain PE Piping System, p17 - Old PipesDokumen119 halamanJain PE Piping System, p17 - Old PipesVaios Anyfantis100% (1)

- Asme Section Ii A-2 Sa-985 Sa-985mDokumen22 halamanAsme Section Ii A-2 Sa-985 Sa-985mAnonymous GhPzn1xBelum ada peringkat

- Apollo Safety Valves Serie 19Dokumen5 halamanApollo Safety Valves Serie 19Daniel SanBelum ada peringkat

- Almasah Alamin Project - Post-Tensioned Method StatmentDokumen16 halamanAlmasah Alamin Project - Post-Tensioned Method StatmentMohamed AdelBelum ada peringkat

- Part Numbers / Dimensions: Seal RingsDokumen1 halamanPart Numbers / Dimensions: Seal RingsWong Chung MengBelum ada peringkat

- Code of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingDokumen1 halamanCode of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingtceterexBelum ada peringkat

- 64721B510BF11337E10000000AD5062ADokumen1 halaman64721B510BF11337E10000000AD5062AKailas NimbalkarBelum ada peringkat

- The Influence of Negative Skin Friction On Piles and Pile GroupsDokumen7 halamanThe Influence of Negative Skin Friction On Piles and Pile GroupsViet Anh PhamBelum ada peringkat

- Stress Analysis and Design of Bolted Flange Connections UnderDokumen11 halamanStress Analysis and Design of Bolted Flange Connections UndervijaygalaxyBelum ada peringkat

- Stress CorrosionDokumen13 halamanStress CorrosionAbhinav GuptaBelum ada peringkat

- Abdulpk@ciitsahiwal Edu PKDokumen8 halamanAbdulpk@ciitsahiwal Edu PKAhmadrazatahirBelum ada peringkat