Centrifugal Pump

Diunggah oleh

samuad59Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Centrifugal Pump

Diunggah oleh

samuad59Hak Cipta:

Format Tersedia

241

Root Cause Analysis on a Multistage Centrifugal Pump in a Power Plant due to Shaft Crack Based on ODS and FEA

27th International Pump Users Symposium George R. Brown Convention Center Houston, TX September 12 - 15, 2011

By: Maki Onari Mechanical Solutions, Inc. Whippany, NJ 07981 USA Tel: (973) 326-9920 www.mechsol.com

242

Introduction

Two multistage barrel type pumps for each 1200 MW Unit were installed in 1986 in a large power plant. The 11 stage centrifugal pumps were designated as Pump(s) 1A/B and Pump(s) 2A/B. All impellers were designed with 6 vanes and 8 diffuser vanes. The pumps are driven by 600 HP four-pole induction motors (1,770 rpm or 29.5 Hz) through a gear increaser (output speed of 4,860 rpm or 81 Hz). Rated capacity: 350 GPM and 2,516 ft of TDH Normal capacity: 150 GPM (43% BEP).

243

Introduction

Barrel Type - 11 stage Pump Outline Drawing

244

Introduction

Barrel Type - 11 stage Pump

245

Background History

Three pump shaft failures (cracks) have been detected since Pump 1B installation (MTBF=7.7 years). In 1989, the first failure took place, but the failure analysis was not properly documented and the failed shaft was not saved. In 1999, a crack was found at the rear end of the 9th stage hub. In December 2007, the last failure was discovered under the 11th stage impeller hub with evidence of fretting. A circumferential crack was found at the keyway with 132 degrees arc. The vibration level of the pump had been always considered low and adequate.

246

Background History

2007 Failure after 8 years of operation. Crack detected under 11th stage impeller hub.

247

Background History

2007 Failure after 8 years of operation. Crack detected under 11th stage impeller hub with the origin away from the keyway.

248

Specialized Testing

Experimental Modal Analysis (EMA) test to determine the natural frequencies of the impeller, pump structure, and the rotor system with their mode shapes. Monitoring test during transient and steady operation to monitor the vibration amplitude and natural frequencies. Dynamic pressure transducer data from suction, discharge, and balance line. Operating Deflection Shape (ODS) testing during steady operation.

249

11th Stage Impeller EMA Testing

250

Vibration EMA Test

11th Stage Impeller Modal Impact Test

251

Vibration EMA Test

11th Stage Impeller Modal Impact Test

Impeller Model FRF Wet

252

Vibration EMA Test

11th Stage Impeller Modal Impact Test

2 Nodal Diameter / 0 Nodal Circle at 2620 Hz

253

Vibration EMA Test

11th Stage Impeller Modal Impact Test (Wet)

Interference Diagram 11th Stage of 2 1/2 RLIJ Pacific Pump (Wet Impeller) 6 Rotating Vanes and 8 Diffuser Vanes

5000

4000

Frequency (Hz)

3000

2000

1x VPF 1x Diff VPF 2x Diff VPF 1x V_Dir_Exc

1000

1x V_Dif _Exc 2x V_Dir_Exc 0NC

0 0 1 2 3 Nodal Diameter 4 5 6

Interference Diagram

254

Specialized Field Testing

255

Vibration Monitoring

Pump 1B Typical Spectrum OBB in the Vertical Direction

[g] 1 Autospectrum(Signal 5) - Mark 1 (Magnitude) Working : ODS2 : Input : FFT Analyzer

[g] 1

Pump 2B Typical Spectrum OBB in the Vertical Direction

Autospectrum(Signal 1) - Mark 1(Magnitu de) Working : 2 B Linear Average : Input : FFT Analyzer

0.15 in/s peak @ 1x rpm

300m 100m

0.16 in/s peak @ 4x motor rpm

0.06 in/s peak @ 1x rpm

300m

0.06 in/s peak @ 4x motor rpm

100m

30m 10m

30m 10m

3m 1m

3m 1m

300u 100u 0 100 200 300 400 [Hz] 500 600 700 800

300u 100u 0 100 200 300 400 [Hz] 500 600 700 800

Pump Operating at 145 GPM

Pump Operating at 160 GPM

256

Vibration Monitoring

Pump 1B Axial Proximity Probe FFT at OBB

[mil] 1 Autospectrum(Signal 12) - Mark 1 (Magnitude) Working : 1B Linear Ave at 100 GPM : Input : FFT Analyzer

[mil] 600m

Pump 1B Axial Proximity Probe Time Signature at OBB

Time(Signal 1 - Mark 1 2) Working : 1B Linear Ave at 100 GPM : Input : FFT Analyzer

0.46 mils pk-pk @ ~30 Hz

100m

400m

29.5 Hz 28.3 Hz

200m

10m

0

1m

- 200m

100u

- 400m

10u 0 100 200 300 400 [Hz] 500 600 700 800

- 600m 0 100m 200m 300m 400m 500m [s] 600m 700m 800m 900m

257

Vibration Monitoring

Pump 2B Axial Proximity Probe FFT at OBB

[mil] 300m Autospectrum(Signal 12) - Mark 1 (Magnitude) Working : 2 B Linear Average : Input : FFT Analyzer

[mil] 600m

Pump 2B Axial Proximity Probe Time Signature at OBB

Time(Signal 1 - Input 2) Working : Input : Input : FFT Analyzer

0.4 mils pk-pk @ 81 Hz

100m

400m

81 Hz

30m 10m

0.04 mils pk-pk @ ~30 Hz

200m

3m 1m

- 200m

300u

- 400m

100u

- 600m

100

200

300

400 [Hz]

500

600

700

800

40m

80m

120m

160m

200m 240m 280m 320m 360m 400m 440m 480m [s]

258

Pump Rotor Modal Impact Testing During Operation

259

Experimental Modal Analysis Bump Test

Pump 1B Axial Proximity Probe FRF

[mil/lbf] 3m Frequency Response(Signal 1 2,Signal 17) - Mark 1(Magnitude) Working : Axial Hits Channel 1 Axial Prox Probe 100 GPM : Inp ut : Enhanced 2

Pump 2B Axial Proximity Probe FRF

[mil/lbf] 10m Frequency Response(Signal 1 2,Signal 17) - Input (Magnitude) Working : Input : Input : Enhanced

29.5 Hz (1x motor speed)

1m

81 Hz (1x pump speed)

121.2 Hz

3m

300u

1m

118.2 Hz (4x motor speed)

100u

300u

30u

100u

10u

OBB natural frequency

30u

OBB natural frequency

0 100 200 300 400 [Hz] 500 600 700 800

10u

100

200

300

400 [Hz]

500

600

700

800

Pump operating at 160 GPM

260

Operating Deflection Shape (ODS)

261

Operating Deflection Shape

Natural excitation signature of the pump train structure. Over 700 vibration measurements. Data base of amplitude vs. frequency and phase angle. 3-D CAD model assigning motion to each individual vibration data point. Create animations of the pump

262

Operating Deflection Shape

Pump 1B ODS @ 29.9 Hz

263

Operating Deflection Shape

Pump 1B ODS @ 81 Hz

264

Operating Deflection Shape

Pump 2B ODS @ 29.9 Hz

265

Operating Deflection Shape

Pump 2B ODS @ 81 Hz

266

Finite Element Analysis (FEA)

267

Axi-symmetric Model and FEA Breakup

268

Axi-symmetric Model Impeller Loading

Axial displacement in displacement (mils pk-pk) and acceleration (gs)

[mil] 600m

Time(Signal 1 - Mark 1 2) Working : 1B Linear Ave at 100 GPM : Input : FFT Analyzer

400m

29.5 Hz 28.3 Hz

200m

- 200m

- 400m

- 600m 0 100m 200m 300m 400m 500m [s] 600m 700m 800m 900m

269

Axi-symmetric Model Impeller Loading

Load Step 1: Initiate and complete the interference fit between the impeller and the shaft (2 mils diametral interference) Constrain the outboard end of shaft at the thrust bearing Load Step 2: Ramp up an axially applied pressure of 75 psi load to the inboard end over 0.0001sec (30 gs peak acceleration). Load Step 3: Ramp pressure down to a 0 psi over an additional 0.0001sec. Load Step 4: Run for an additional 0.001 sec to monitor the traveling of the acoustic waves and the impeller interface conditions.

270

Axi-symmetric Model FEA Results

Transient dynamic analysis revealed that acoustic wave propagation past the impellers can result in micromotion at the press fit interfaces. An idealized axi-symmetric model of the pump shaft and the last stage impeller predicted an impeller to shaft sliding condition.

This sliding condition led to fretting damage and the crack initiation.

271

Axi-symmetric Model FEA Results

272

FEA-Based Fracture Mechanics Approach

Assume that relative sliding velocity between the impeller and shaft is equal to the peak axial shaft velocity measured on the end of shaft near the thrust bearing. Assume that fretting condition and asperities on shaft surface cause the impeller to axially lock-up against the shaft. Model the lock-up behavior as an axial impact between the shaft and impeller in the region of the assumed 5 mil crack. Using transient dynamic FEA predict the stress distribution near the crack and calculate the stress intensity factor. Check whether crack propagation can be expected.

273

FEA-Based Fracture Mechanics Approach

0.005 inch crack explicitly modeled

Impact Velocity 31 in/s pk (15 gs pk at 29.9Hz)

274

FEA-Based Fracture Mechanics Approach

Double Peak due to Impeller Flexing and Spring-back

von Mises Stress (psi) at Root of Crack During Impact Event

275

FEA-Based Fracture Mechanics Approach

von Mises Stress Distribution (psi) Macro View

276

FEA-Based Fracture Mechanics Approach

von Mises Stress Distribution (psi) In Vicinity of Crack Impact Location

K =

Z

a (1 . 1 )

Crack Root

ANSYS Calculated Stress Intensity Factor KI = 16.3 ksiin

277

FEA-Based Fracture Mechanics Approach

ANSYS Ki Output

Calculate mixed-mode stress intensity factors Assume plane strain conditions. Assume a full-crack model (use 5 nodes) Extrapolation path is defined by nodes: 2044520, 2044672, 2044683, 2047304, 2047315 With node 2044520 as the crack-tip node. Use material properties for material number 1 with Ex = 0.29e+08 xy = 0.30 at temp = 0.00. Ki = 16315. , Kii = 7826.4 , kiii = 0.0000

278

Implemented Fixes

A new gear set was installed in the last outage in Fall 2009. Both gear couplings were replaced. New pump element installed. Monitoring of pump shaft axial vibration and gear drive vibration adjusted to address imposed duty on pump shaft due to less than smooth mesh of gears. Gear set removed mapped.

279

Conclusions

The root cause of the repetitive cracking of the pump shaft is due to a fatigue process while the pump shaft is oscillating axially driven by the gear tooth circumferential run-out. The axial mismatch of the helical gear set (apex) was the cause of the axial displacement of the pump shaft at the drivers operating speed, generating an impulsive displacement load due to a geometric abnormality of the gear teeth of the input shaft gear (axial run-out). The ODS test performed on Pump 1B at the running speed of the motor (30 Hz) indicated high axial motion of the pump shaft driving the OBB with a vertical rocking motion. The gearbox moved axially with some phase lag with respect to the pump shaft and the motor casing.

280

Conclusions

The vibration test performed on Pump 2B did not indicate any abnormal axial motion of the pump shaft at the running speed of the motor (0.04 mils pk-pk versus 0.5 mils pk-pk measured on Pump 1B). Traditional troubleshooting approaches probably would not have indicated a gear/pump inter-related problem, and would not have provided such clear visual evidence for decision makers. ODS / EMA coupled with appropriate analysis is a powerful troubleshooting tool to facilitate and visually understand the most difficult vibration problems in turbomachinery and pumping systems.

281

282

Thank you Any Questions?

Anda mungkin juga menyukai

- Fundamentals of Machine Component Design - Student Solutions ManualDokumen137 halamanFundamentals of Machine Component Design - Student Solutions ManualAmanda Silva82% (28)

- Material ManagementDokumen106 halamanMaterial ManagementRomi AfriansyahBelum ada peringkat

- HR 1 - 2008Dokumen1.642 halamanHR 1 - 2008Jay Rameshbhai ParikhBelum ada peringkat

- KMP-0-BLR-V009-M-002 (FD Fan Erection Manual)Dokumen68 halamanKMP-0-BLR-V009-M-002 (FD Fan Erection Manual)Pradeep Yadav50% (2)

- Required Spare List of Ash Handling System 1.dome Valve Assembly SR Nos Item Discription Part No. QuantityDokumen5 halamanRequired Spare List of Ash Handling System 1.dome Valve Assembly SR Nos Item Discription Part No. Quantityapi-19887390Belum ada peringkat

- US Manual EnglishDokumen101 halamanUS Manual EnglishFernando ChavezBelum ada peringkat

- Cure For All Advanced CancersDokumen634 halamanCure For All Advanced Cancerse33aticBelum ada peringkat

- PDS1 Transmisi Air Bersih MCPK PumpDokumen5 halamanPDS1 Transmisi Air Bersih MCPK PumpBudi SBelum ada peringkat

- Deep Submersible Hayward MotorsDokumen33 halamanDeep Submersible Hayward MotorsKasinathan MuniandiBelum ada peringkat

- Ebara Pumps Catalog DVS CatalogueDokumen30 halamanEbara Pumps Catalog DVS CataloguePutry Tria ChristyBelum ada peringkat

- List of Part-3Dokumen2.000 halamanList of Part-3Gỗ MộcBelum ada peringkat

- Flameproof MotorsDokumen16 halamanFlameproof MotorsKiran KumarBelum ada peringkat

- Instructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Dokumen50 halamanInstructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Denar PurnamaBelum ada peringkat

- Failure of Gearbox Cooling Tower Fan in Cement Mill 1607659041Dokumen15 halamanFailure of Gearbox Cooling Tower Fan in Cement Mill 1607659041Muhtiar Darja100% (1)

- Vertical Turbine Canal Recirculation & CT Make-Up Water PumpDokumen37 halamanVertical Turbine Canal Recirculation & CT Make-Up Water PumpSanto EBelum ada peringkat

- WILO Mather and Platt Pumps Pvt. LTD: Performance ChartDokumen1 halamanWILO Mather and Platt Pumps Pvt. LTD: Performance ChartSumitBhaumikBelum ada peringkat

- Vibration RecordDokumen1 halamanVibration RecordĐỗ Đình DũngBelum ada peringkat

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaDokumen21 halamanCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaBelum ada peringkat

- Iom Vertical Turbine PumpDokumen33 halamanIom Vertical Turbine PumpSanto EBelum ada peringkat

- Spare Part Turbin PLTA Bengkok PDFDokumen1 halamanSpare Part Turbin PLTA Bengkok PDFAditya PrajasBelum ada peringkat

- Configurator Solutions - Actuator SSCPQ - v2 - 31 Aug 2015Dokumen24 halamanConfigurator Solutions - Actuator SSCPQ - v2 - 31 Aug 2015sahirprojectsBelum ada peringkat

- Sew PDFDokumen140 halamanSew PDFJorge A Vilal100% (1)

- (98 86 603) Driving Gear NG 250 - 20190313 - 034240Dokumen1 halaman(98 86 603) Driving Gear NG 250 - 20190313 - 034240SenthilKumarBelum ada peringkat

- Katalog ARITA - 2019Dokumen68 halamanKatalog ARITA - 2019Sugeng Arief Van'tbowoBelum ada peringkat

- MHI Table ContentsDokumen16 halamanMHI Table ContentsGhulam AhmadBelum ada peringkat

- 100 300 10stageDokumen1 halaman100 300 10stagemsh16000Belum ada peringkat

- Operation and Maintenance Manual of Hogging Vacuum Pump - 2BW5 400Dokumen197 halamanOperation and Maintenance Manual of Hogging Vacuum Pump - 2BW5 400AhmadBelum ada peringkat

- BalancingValve Selection Guide PDFDokumen1 halamanBalancingValve Selection Guide PDFsahirprojectsBelum ada peringkat

- Checklist For Roof Skin CasingDokumen7 halamanChecklist For Roof Skin CasingRamalingam PrabhakaranBelum ada peringkat

- Equivalent Length of A Reducer - Google SearchDokumen3 halamanEquivalent Length of A Reducer - Google SearchzoksiBelum ada peringkat

- Process Pumps: Made by KSBDokumen16 halamanProcess Pumps: Made by KSBEdgar CalatayudBelum ada peringkat

- APH PresentationDokumen36 halamanAPH PresentationBhargav Chaudhari100% (1)

- Valve Inspection ChecklistDokumen1 halamanValve Inspection ChecklistTengku Mohd ImranBelum ada peringkat

- Fluxi 2000 TZ EN-03 - 18Dokumen4 halamanFluxi 2000 TZ EN-03 - 18Praveen KumarBelum ada peringkat

- Pump SelectionDokumen2 halamanPump Selectiongroup2sd1314Belum ada peringkat

- Etanorm KSBDokumen28 halamanEtanorm KSBAlusine Tarawally100% (1)

- Steam Turbine Combined Reheat Stop Description and Control ValvesDokumen2 halamanSteam Turbine Combined Reheat Stop Description and Control Valvesparthibanemails5779100% (1)

- Sulzer Pumps Finland Oy Product Specification: GeneralDokumen3 halamanSulzer Pumps Finland Oy Product Specification: GeneralGerman Zuleta100% (1)

- Bifold UpdatedDokumen8 halamanBifold UpdatedGopinath GunasekaranBelum ada peringkat

- Multiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataDokumen2 halamanMultiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataRabah Semassel100% (1)

- Air, Steam Vent Silencer - Enquiry Data SheetDokumen1 halamanAir, Steam Vent Silencer - Enquiry Data Sheetkishore1214Belum ada peringkat

- Boiler Feed Water Pump Inspection at Jubail TM.P. Workshop PDFDokumen17 halamanBoiler Feed Water Pump Inspection at Jubail TM.P. Workshop PDFAlaina Hood100% (1)

- Petrosadid - Centrifugal (API 617)Dokumen16 halamanPetrosadid - Centrifugal (API 617)lafsifatBelum ada peringkat

- Schematic Diagram For Hydrotest.Dokumen1 halamanSchematic Diagram For Hydrotest.vsBelum ada peringkat

- Goulds PumpsDokumen44 halamanGoulds PumpscridavarBelum ada peringkat

- TDBFP Manul PDFDokumen266 halamanTDBFP Manul PDFsantoshBelum ada peringkat

- Spherical ValveDokumen4 halamanSpherical ValveHrshiya SharmaBelum ada peringkat

- Nkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationDokumen7 halamanNkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationAbhishek KumarBelum ada peringkat

- O & M Manual For w4.1zk-56 L & T, 111386Dokumen19 halamanO & M Manual For w4.1zk-56 L & T, 111386anupraja100% (1)

- Seal Air FanDokumen1 halamanSeal Air FanAnkit MathurBelum ada peringkat

- Bomba Desaladora AlternativaDokumen6 halamanBomba Desaladora AlternativawaricateBelum ada peringkat

- Air Eliminator DatasheetDokumen2 halamanAir Eliminator DatasheetbecpavanBelum ada peringkat

- Condensate Polishing PDFDokumen2 halamanCondensate Polishing PDFGiovanni NoriegaBelum ada peringkat

- Dec 09Dokumen35 halamanDec 09Krishnan SanthanarajBelum ada peringkat

- Fan Pre-Balance ChecksDokumen4 halamanFan Pre-Balance ChecksMachineryengBelum ada peringkat

- Bhel Pipe Color Code-Aa10630 1Dokumen7 halamanBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniBelum ada peringkat

- My Latest CV - EngineerDokumen3 halamanMy Latest CV - EngineersasibhushanBelum ada peringkat

- Emerson Compact Prover Datasheet - Dec20Dokumen16 halamanEmerson Compact Prover Datasheet - Dec20GUSTAVO HERNANDEZBelum ada peringkat

- Coupled Vibration Analysis For PumpDokumen0 halamanCoupled Vibration Analysis For Pumpilmu2Belum ada peringkat

- Experience With Torsional Vibration at Reciprocating CompressorsDokumen14 halamanExperience With Torsional Vibration at Reciprocating CompressorsÏmŗäņPŗïņċëBelum ada peringkat

- Eee 321Dokumen7 halamanEee 321faisal sbennaBelum ada peringkat

- Diagnosis of A Recurring Pump Shaft FailureDokumen13 halamanDiagnosis of A Recurring Pump Shaft FailureelshafeiBelum ada peringkat

- Finite Element AnalysisDokumen70 halamanFinite Element AnalysisDinesh PerumalsamyBelum ada peringkat

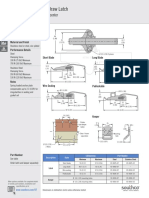

- V2 Draw Latch: Over-CenterDokumen2 halamanV2 Draw Latch: Over-CentermariomatoBelum ada peringkat

- Theory of MachinesDokumen41 halamanTheory of MachinesC V CHANDRASHEKARA75% (4)

- Flexmove Plastic Slat Conveyors SystemDokumen16 halamanFlexmove Plastic Slat Conveyors SystemmariomatoBelum ada peringkat

- 155710Dokumen56 halaman155710mariomatoBelum ada peringkat

- Effective Modal Masses: 1 AbstractDokumen4 halamanEffective Modal Masses: 1 AbstractmariomatoBelum ada peringkat

- Bolt PretensionDokumen6 halamanBolt Pretensionsujayan2005Belum ada peringkat

- STRESS ANALYSIS and FATIGUE of Welded StructuresDokumen20 halamanSTRESS ANALYSIS and FATIGUE of Welded Structuresmatteo_1234100% (1)

- Notes MechV PDFDokumen21 halamanNotes MechV PDFzamburittiBelum ada peringkat

- WangDokumen18 halamanWangnagarajucruxBelum ada peringkat

- Full Text DocumentDokumen62 halamanFull Text Documentvinoo13Belum ada peringkat

- 155710Dokumen56 halaman155710mariomatoBelum ada peringkat

- Unit 25 Essential Working Practices in Vehicle TechnologyDokumen10 halamanUnit 25 Essential Working Practices in Vehicle TechnologymariomatoBelum ada peringkat

- Meccan Is MoDokumen1 halamanMeccan Is MomariomatoBelum ada peringkat

- Beam FEM Ss AxialDokumen10 halamanBeam FEM Ss AxialmariomatoBelum ada peringkat

- Introduction To Finite Element ModelingDokumen5 halamanIntroduction To Finite Element Modelingmastura_rahim_3Belum ada peringkat

- Some Recent Advances For Practical Finite Element AnalysisDokumen11 halamanSome Recent Advances For Practical Finite Element AnalysismariomatoBelum ada peringkat

- Methods of Nonlinear Random Vibration Analysis: AbstractDokumen27 halamanMethods of Nonlinear Random Vibration Analysis: AbstracttuanphamcktBelum ada peringkat

- CETE ScilabTEC2013Dokumen30 halamanCETE ScilabTEC2013mariomatoBelum ada peringkat

- EQE Ceresa EtalDokumen22 halamanEQE Ceresa EtalmariomatoBelum ada peringkat

- Aikido Shudokan Emag 2012Dokumen61 halamanAikido Shudokan Emag 2012mariomato100% (2)

- Fatigue Life Evaluation of Mechanical Components Using Vibration Fatigue Analysis TechniqueDokumen7 halamanFatigue Life Evaluation of Mechanical Components Using Vibration Fatigue Analysis TechniquemariomatoBelum ada peringkat

- Guideline For The Assessment of Existing StructuresDokumen48 halamanGuideline For The Assessment of Existing StructuresAnonymous q0irDXlWAmBelum ada peringkat

- Solidworks Simulation WeldsDokumen38 halamanSolidworks Simulation Weldsfiuto_rights_1404802100% (2)

- 9554327Dokumen254 halaman9554327mariomatoBelum ada peringkat

- Weld Design by FEADokumen11 halamanWeld Design by FEAAdarsh D. KarkiBelum ada peringkat