Moletronics

Diunggah oleh

rahulsharmadausa17_5Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Moletronics

Diunggah oleh

rahulsharmadausa17_5Hak Cipta:

Format Tersedia

Perspective on Science 07

Molecular Electronics: An Overview

Chau Nguyen Yale University, Department of Electrical Engineering May 4, 2007 Abstract

In recent years, the study of molecular electronics as an alternative technology to conventional silicon-based CMOS microelectronics has yielded rapid success and progress. This paper introduces the exciting field of molecular electronics by discussing some theoretical and practical aspects of molecular nanodevice fabrication and electrical characterization methods. The paper concludes with the proposal of a novel method for SAM-based nanodevice fabrication using conducting polymers as the top contact. The advantages and feasibility of the new method will be explored by performing testing experiments over the summer.

I. Introduction:

The microelectronics and computer revolution arguably is one of the most important technological advancement of our times, one that has drastically changed the way we work and live. The success of the microelectronics industry is attributed in large parts to our ability to shrink the transistor size in complementary metal-oxide semiconductor (CMOS) integrated circuits down to an ever smaller dimension (currently at 60 nm). This increasing miniaturization has allowed an exponential growth in computing power as the number of transistors in integrated circuits doubles every 18 months. This is the famous Moores law [1]. However, as the size of the transistor

Perspective on Science 07 approaches the nanoscale, it has now become increasingly difficult to sustain the Moore rate of improvement. Thus new methods for computation are required if computer processing power is to continue growing. One of the most promising candidates currently is Molecular Electronics, where active electronics devices are made up of a single molecule or a molecular monolayer. Before we proceed to the discussion of molecular electronics, a brief treatment of the principles of conventional CMOS microelectronics and its current limitations is necessary to understand the motivation behind molecular electronics.

Figure 1(a): Schematic diagram of a Field Effect Transistor (N-type shown here) Source [30]

II. CMOS microelectronics: basic principles and limitations:

Figure 1(b): Schematic cross-section of a N-type MOS transistor. (a) The transistor shown in the schematic cross section is the basic building block of microcomputers. N: N-doped Si containing excess electrons. P: P-doped Si containing holes( lack of electrons). Gate Oxide refers to SiO2 (b) When there is no voltage applied to the gate electrode, no current can flow through the semiconductor. (c) However, when voltage is applied to the gate electrode, the electrons (negative circles) segregate from the holes (positive circles) to form a channel which permits current (large white hatched arrows) to flow between the source and the drain. Source [32]

Perspective on Science 07

The basic building block for every digital circuit is the transistor. Transistors are two states devices that act like switches. The state of the transistor is used to change the voltage of a wire between high and low, representing the two logic states 1 and 0. Arithmetic and logic functions are built from this switching behavior of transistors. By far, the most common type of transistors is the Field Effect Transistor (FET) in which a voltage is applied to switch the transistor on or off. Bipolar Junction Transistor (BJT) also exists, wherein a current is used as the switching agent. In CMOS microelectronics, the transistor used is the MOSFET or metal-oxide semiconductor field-effect transistor, named after its fabricating material. The essential features of the MOSFET are the source, the drain and gate electrodes. MOSFETs come in two types: N-type and P-type. N-type transistors let current pass through from the source to the drain electrode when the gate voltage is high while P-type transistors exhibit the opposite behaviors (see Fig. 1 for how they work). Using N and P transistors, it is possible to build digital Logic Gates (NOT, AND, OR, NAND, NOR, XOR, XNOR) and then more complex Arithmetic/Logic units. These are combinatorial devices whose outputs are binary functions of their inputs. Figure 2 shows, as an illustration, how the NOT-gate is implemented using the MOSFET transistors and how a 1-bit Full-Adder can be made from AND, OR and XOR gates.

Perspective on Science 07

Figure 2(a): A NOT-gate constructed from P-type MOSFET (top) and N-type (bottom). When Vin is low, the top transistor is on and the bottom is off. Vout is thus = Vdd (high). When Vin is high, the reverse occurs, Vout =0 Source [30]

XOR

Figure 2(b): An 1-bit Full-Adder using AND, OR and XOR logic gates A and B are the inputs. S is their sum. Cin is the carrier from another adder. Cout is the carrier to another adder. OR

AND With logic gates as the building blocks, sequential devices can be implemented using feed-back; these are devices whose outputs are determined not only by their inputs but also by their current states. They are the basis for memory. Microprocessors, the heart of computers, are built by combining the logic and memory devices. Figure 2(c) illustrates how an SR flip-flop, an elemental memory device, can be made from two NOR gates with feedback. The SR flip-flop (also known as the SR latch) retains its state (which outputs at Q) until a voltage is applied to the reset (R) terminal to make it 0 or to the set (S) terminal to make it 1. Figure 2(c): An SR latch. Feed-back is used to maintain the state of the latch until either input is asserted. SR-latch is the basic element from which more complex memory devices such as Dlatch, D flip-flop, register, register files and memory are built.

Perspective on Science 07

Future prospects: CMOS microprocessors are fabricated by etching a Si crystalline chip using a method called photolithography. With photolithography, it is possible to decrease the size of the transistors by dictating ever-smaller dimensions. However, such increasing miniaturization cannot be sustained as CMOS microelectronics is faced with physical, lithographic as well as economic limits [3-7]. a) The physical limit: At thickness less than 1nm, SiO2 will no longer be a good insulator and leak current will occur, generating too much heat [2]. In addition, quantum effects become significant at lower dimensions, interfering with the operation of the transistor. Moreover, as the device becomes smaller, the number of doping atoms used also decreases, leading to greater fluctuation of the number of dopant atoms and thus greater variation among the transistors. b) The lithographic limit: The current technology can only produce a minimum feature size of 130 nm. Other techniques such as extreme ultraviolet, x-ray or electron beam lithography are required to produce features of smaller dimensions. c) The economic limit: Chip fabrication facilities, also known as fabs, are becoming increasingly expensive. The state-of-the-art fabs now cost about 10B$. Further reduction in transistor size will require more expensive equipment that will not make economic sense. Thus a new approach using molecules as the unit of computing has been developed. The following sections will discuss theoretical and practical aspects of molecular nanodevices.

Perspective on Science 07

III. Molecular Electronics:

Compared to CMOS, the use of molecules in Molecular electronics offers a number of advantages. Organic molecules are extremely diverse and their behaviors can be tailored by chemical synthesis. There is also a great potential for a bottom-up approach to manufacture integrated circuits using self-assembly. While it is becoming prohibitively expensive to fabricate Si of increasingly smaller dimensions due to stringent environmental conditions, self-assembly and chemical synthesis are relatively cheaper to perform. More importantly, because of their small size, very dense circuits could be built. As all molecules of one type are identical, they should also have identical characteristics, thus avoiding the present problem of variability in components. The field of Molecular electronics started with Avirams and Ratners theoretical work on a molecular rectifier in 1974 [8]. Since then, the field has fast grown into an exciting and diverse body of theoretic and experimental research encompassing various areas of physics, chemistry, computer science and engineering. For the purpose of this paper, we will only focus on the implementation of molecular electronics devices and techniques for electrical characterization of molecules. With the background knowledge in these two areas, we will then discuss a novel fabrication method for a nanodevice using conducting polymers as a top contact.

IV. Molecules as electronics devices:

Firstly, it is important to recognize that molecules can conduct current. Mechanisms of electron transport through single organic molecules include direct tunneling, Fowler-Nordheim tunneling, thermionic emission and hopping conduction. For

Perspective on Science 07 a detailed treatment of electron transport theory, please refer to reference [24]. Here we are interested in the fact that the conductance of a molecule can be changed with an applied electric field, exhibiting an FET-like behavior. Molecular electronics devices have been implemented using carbon nanotubes , nanowires, or organic molecules. Among these, methods using thin-film organic molecule are currently the most developed.

1. Carbon nanotubes:

Carbon nanotube (CNT) belongs to fullerene, a class of allotrope of Carbon. Its structure assembles a sheet of graphene rolled up into a tube. There are two main types: single-walled and multi-walled nanotubes. Single-walled carbon nanotubes hold great promise for future electronics as they exhibit a range of conductivities from metallic to semi-conducting depending their atomic arrangement [9]. CNTs have been synthesized using electric arc discharge [10] or chemical vapour deposition [11] methods. The metallic tubes are then burnt off leaving behind the semiconducting ones. By using semiconducting CNT as the channel connecting the source and the drain electrodes, it has been possible to make FET-like transistors. CNTFETs have been implemented with bottom gate [12,17], top gate[13] and vertical gate electrodes [14] (Fig. 3 ).CNTFETs can be made to be P-type if exposed to air or O2 [15] , or N-type if annealed in vacuum[16]. NOT, NOR, NAND, and AND gates [15,17] as well as memory cells such as flip-flops [17] have also been fabricated from these transistors. The advantage of using CNT lies in its mechanical strength. The length of CNTs makes it easy to connect them to electrodes. In addition, they are simple to fabricate and allow good control of electronic properties. On the other hand, there is no good

Perspective on Science 07 reproducibility. Right now the coupling between the gate and the nanotube is still not strong enough for amplification. Thus it is difficult to use the output of one device to control another, the requirement for higher level of integration. Currently, there is no method to mass-produce CNTs and there is also a lack of method for accurate placing during fabrication.

Figure 3: Carbon nanotube field effect transistor (a) bottom gate (b) top gate Source [31]

2. Nanowires:

Figure 4:

Nanowires are wires of thickness in the range of nanometers. Semiconductor nanowires (GaP, GaN, Si, InP) have been produced for use in electronics. The common technique for the synthesis of nanowires is Vapour-Liquid-Solid growth [18]. Just like solid-state Si, semiconductor nanowires can

(A) Schematic of a SiNW FET showing metal source and drain electrodes with the NW and contacts on the surface of SiO2/Si substrate. (inset) High resolution transmission electron micrograph of a 5 nm diameter SiNW; the scale bar is 5 nm. (B) Scanning electron micrograph of a SiNW FET device; the scale bar is 500 nm. Source[33]

be doped chemically to give p- and n-nanowires. Employing the same principles as the 8

Perspective on Science 07 MOSFET, nanowire-based FETs have been made using p- or n-nanowires as the channels and Si substrate as the gate (Fig. 4). A different method using a crossed nanowire structure has also been proposed that potentially can achieve higher circuit density. Diodes, bipolar transistors, FETs, and simple logic gates as well as a-bit full 1-adder circuits have been made from such crossbar structures[ 19] (Fig. 5). In addition, as charged nanowires conduct differently from uncharged ones, there is a possibility for information storage using two states of conductance. The states can be changed by transferring charge with an applied voltage. A memory device can be made from this principle. Figure 5: Crossed nanowires as an FET. A nanowire serves as the channel while another serves as its gate in a crossed configuration Source [38] Most advanced research in this area has involved the production and usage of inorganic nanotubes (inspired by carbon nanotubes). Cross junction switches have been made from metallic and semiconducting nanotubes [25] Unlike carbon nanotubes which can be semiconducting or metallic, inorganic nanowires are always semiconducting. Another advantage is the relative ease at which Sinanowires can be integrated into the current silicon industry process and fabrication. Moreover, nanowire FETs have been found to respond faster than conventional MOSFETs[33]. One disadvantage is the high cost of large-scale production of nanowires FETs. Recently, however, researchers at Caltech have demonstrated a relatively cheap method to produce high-density nanowires circuits using a combination of the

Perspective on Science 07 superlattice nanowire pattern transfer (SNAP) patterning method and the nanoimprinting replication method [34].

3. Organic molecules:

Compared to large macromolecular CNT-based and NW-based electronics, circuits using simple organic molecules are more sensitive to molecule-electrode interfaces at the atomic level. Molecular electronics with simple organic molecules also faces the central problem of interconnecting molecular devices for complex operations and connecting to the larger external circuits. There have been proposals for wires, diodes [8,20], transistors [21], memory cells[22], and logic gates [23] using the conductance properties of small organic molecules. Quantum-mechanical devices which are not field effect transistors (FETs) such as single electron transistors (SETs, using Coulomb blockade effect), resonant tunneling transistors ( RTTs, using negative differential resistance) have also been demonstrated to be possible using organic molecules [35,36]. This section, however, will focus mainly on bistable molecular switches as they can be used as the basic for memory and logic devices. Molecular switches are reconfigurable molecules which exist in two stable states with different conductivities. The conductivity change is a result of the modification of the structures of the frontiers orbitals: HOMO ( highest occupied molecular orbitals ) and LUMO ( lowest unoccupied molecular orbitals). If the energy gap between HOMO and LUMO is large, the molecule is non-conducting and vice versa. The physical process that causes the state change can be a redox process, a configuration change, a conformation change or electronic excitation. For example, -conjugation in a molecular wire can be destroyed by oxidation, resulting in the low conductance state of the molecule (Fig. 6). Molecular

10

Perspective on Science 07 switches using redox is by far the most important class. They can be divided into 2 categories. Figure 6: How the conjugation in a conjugated molecular wire may be destroyed by oxidation: (right) the quinone group, resulting from dehydrogenation of the hydroquinone group (left), destroys the -conjugation [39] a) Internal redox: In internal redox, the molecule has a Donor-Spacer-Acceptor structure. The unionized states D0SA0 can be brought to a meta-stable ionized state D+SA- via internal redox reaction by applying a potential difference. The most famous example of such molecule is the Aviram-Ratner molecular rectifier, which has been demonstrated experimentally [37]. Rectifiers are devices closely related to diodes, which allow current flow in only one direction. The Aviram- Ratner rectifier consists of a donor -system and an acceptor system separated by a sigma-bonded tunneling bridge (Fig 7). Electron is theorized to move by hopping in 3 stages from the cathode to the acceptor, from the acceptor to the donor and then to the anode. The flow of electron from the donor to the acceptor is downhill in energy terms ( from excited state D+SA- to ground state D0SA0 ) while a large energy barrier in the opposite direction prevents electron conduction. This is the basis for the rectifying effect.

11

Perspective on Science 07

b) External redox: In this category, the molecule contains only the acceptor or donator part. The Figure 7 : Molecular rectifier Source [39] ionized state is obtained by external redox

reaction with the electrode (electron transfer). The most studied class of such molecules are rotaxanes. They are supramolecular systems consisting of interlocking parts that resemble ring and axle. The positions of the ring at either end of the axle represent two states with different conductivities (fig. 8). The state can be changed by applying a voltage (2V) to the molecule, and it remains as such after the removal of the voltage (irreversible)[39]. To read the state, apply a low voltage (0.02V) to measure the conductivity of the molecule. Since the discovery of rotaxanes, scientists have found many other useful molecular switches such as catenanes [26] and reversible switches [27] Figure 8: Rotaxane Source [39] HP-UCLA crossbar structure: Molecular electronic devices have been made from rotaxanes and catenanes molecular films sandwiched between crossbars array of metallic nanowires. The films act as switches depending on their redox states which are changed by applying voltage on the wires. Such films have been used to make molecular random access memory cells and demultiplexers [28]. There is also potential for making Programmable Gate Logic Arrays (PGLA), a method that program an existing arrays of devices (diodes in this case) to perform any logic function. Figure 9 explains how such crossbars array can be used to

12

Perspective on Science 07 implement an AND logic gate. There are a number of advantages of the crossbar structures including scalability to smaller dimension, the small number of wires used ( 2N to address 2N junctions), and easy fabrication due to the regular structure. In addition, PLGA allows designers to circumvent defective parts of the chip, which are often inevitable in the fabrication process.

Figure 9(a): Implementation of an AND and an OR gate in diode-resistor logic. For the AND gate, if either A or B is low, current will flow and voltage drops across the resistor giving a low voltage as output. If both A and B are high, neither diode conducts and the output is high For the OR gate, if either A or B is high, the current will flow across the diode and the output will be high. If both A and B are low, no current flows and output remains at ground. Source[30]

Figure 9(b): An AND gate using a programmable logic array. At each junction of the crosswires is a molecular switch. The switch acts as a diode in the on state and acts as an open circuit in the off state. (compared with 9(a)). More complex logic such as a half-adder can also be implemented.

The HP-UCLA crossbar structure has inspired advanced architecture for molecular electronics involving NanoFabrics and NanoBlocks. Interested readers can refer to reference [30] for a comprehensive description of such system. Such advancement in computer architecture for molecular electronics has been accompanied

13

Perspective on Science 07 by a gradual progress in electrical characterization methods of molecules, which will be discussed in the next session.

V. Techniques for electrical characterization of molecules:

A major part of research in molecular electronics is the development of experimental techniques for measuring electrical conductance of organic molecules. As contact with a single molecule is difficult, a self-assembled monolayer (SAM) is often used. These are single layers of molecules on a substrate arranged in regular ways. The physical process that forms SAMs is thought to be Van der Waal interaction between the chains of molecules. The most well-studied SAM system is alkanedithiol on gold [42]. Proposed methods for studying molecular electron conductance include scanning tunneling microscope, break junction, nanopore and mercury drop methods [29]

Figure 10: Various techniques to measure electronic properties of molecules. (A) Hg drop junction. (B) Mechanically controlled break junctions. (C) Nanopore. (D) Nanowire. (E) Nanoparticle bridge. (F) Crossed wires. (G) STM. (H) Contact CP-AFM. (I) Nanoparticle coupled CP-AFM. Source [29]

14

Perspective on Science 07

1. Scanning tunneling microscope:

This method uses an STM tip to scan over the SAM-covered surface, keeping the tunneling current constant or monitoring the current. The surface acts as the first electrode while the STM tip acts as the second one. The junction is thus asymmetric as the surface and the STM tip has different chemical potentials due to their difference in shape. This is a disadvantage of scanning tunneling microscope method. The advantage is that both the image and the information about conductance can be provided at the same time. Atomic force microscope (AFM) can also be used in two ways (i) conductive probe ATM and (ii) nanoparticle coupled conductive probe AFM.

2. Break junction:

In this method, a notched metal nanowire (usually Au) is fixed to a flexible substrate. The nanowire is then mechanically broken by controllable bending of the substrate. Bridge of single molecules can then be formed between the electrodes. The advantage of the break junction method is that it is symmetrical. However, unwanted parallel currents can occur as there can be more than 1 molecular bridge between the electrodes. It is also not suitable for transistor fabrication because of difficulty in placing the gate electrode on the structure.

3. Nanopore fabrication:

E-beam lithography and following plasma etching are used to make a pore on a suspended Silicon Nitride membrane. Gold is then deposited on the pore to form the top contact using vapor deposition techniques. The structure is subsequently immersed in

15

Perspective on Science 07 alkanedithiol solution to develop a SAM. Au is then evaporated to form the bottom contact of an Au-SAM-Au junction. However, this deposition method can be quite harsh on the organic SAM layer. It is also impossible to know the configuration of the SAM layer once the metal contact is sealed. In addition, due to the geometry of the nanopore, the orientation or status of the SAM layer is also not known even before the top contact is deposited [29].

4. Mercury-drop junction method:

A mercury drop is used as an electrode on which a SAM develops Another SAM is developed on a metal substrate. Mechanical contact is then form between the two SAMs to form a Mercury-SAM-SAM-Metal structure. This method is fast and the junction is easily constructed, allowing multiple SAMs to be investigated concurrently. However, it can only be used for ensemble measurements and cannot be performed at cryogenic temperatures [40].

VI. Proposed summer research. Nanodevice fabrication using conducting polymers as the top contact:

During the fabrication of Metal-Sam-Metal junction involving metal as the top contact (such as the nanopore method), there might be defective junctions due to the formation of metal filaments (figure 11). These filaments provide a conducting path for electrons to flow between the two metal electrodes, bypassing the SAM layer. The problem could be avoided if conducting polymer is used instead of metal. Due to the larger size of the conducting polymer molecule, the SAM layer will be less disrupted and thus there will be a low chance for filament formation. 16

Perspective on Science 07

Figure 11: Formation of a metal filament Source[42]

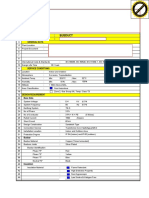

The general process flow for the fabrication of a nano-junction using conducting polymer is given below in figure 12 (taken from a paper by Akkerman[41]). The conducting polymer used is PEDOT:PSS.

Figure 12: Nano device fabrication with PEDOT:PSSS as the top contact Source [41]

. The method that we will pursue in the summer is an improved version based on the above scheme. We also hope to make more devices per chip than the Akkerman group. There are 8 steps involved in our fabrication process. A Si wafer with 200 nm thermal oxide layer is used as the inert substrate. 1) Photoresist pattern is first deposited on the substrate using standard lithography method.

17

Perspective on Science 07

2) Next, a 5nm layer of Ti and a 100nm layer of Au are deposited on top by e-beam evaporation. The more reactive Ti layer is required to help Au stick to the surface.

3) Acetone is then used to wash away all photoresist, leaving behind the desired Au pattern.

4) Another layer of photoresist is then deposited similarly by lithography to form nanoholes for the coming SAM. Subsequently, the whole wafer is baked for 1 hour at 1450C to harden the photoresist ( for protection against alcoholic solvent in the SAM solution).

5) The wafer is then dipped in a solution of alkanedithiol for 24 hours to deposit a SAM layer. This step is conducted in inert N2 as the thiol may react with O2 in air.

18

Perspective on Science 07

6) Next, conducting polymer PEDOT:PSS is spin-deposited on top and let to dry under vacuum to remove the water present in the PEDOT:PSS preparation.

7) A 50 nm layer of Au is then formed using shadow evaporation (e-beam evaporation with a mask). This layer acts as the top metallic contact for connection to the external circuit.

8) Uncovered PEDOT is subsequently removed using oxygen plasma for 3 min under 100W in a process called ash-ing.

This method is expected to produce fewer defective junctions compared to other described methods for nanodevice fabrication. Good junctions will have reasonable resistance. Defectives junctions in which there is no SAM layer will have almost infinite resistance while those with filament formations will have zero resistance. I will spend the summer testing the method, finding the causes for the defective junctions and proposing ways to reduce the defective rate.

19

Perspective on Science 07

VII. Conclusion:

Molecular electronics is an exciting emergent field of study. The reward of research in this area is enormous as the birth of molecular computer implies unprecedented processing power that may enable breakthroughs in artificial intelligence. This paper has given a glimpse at how such an endeavor might be accomplished by introducing the basic ideas in molecular device implementation and electrical characterization methods. The path towards a full working system is still a long one, yet the prospects are bright and great strides have been taken.

Acknowledgement The author would like to thank Professor Mark Reed and Graduate student Stan Guthrie for their invaluable help and support.

Reference

1. G.E. Moore, Cramming more components onto integrated circuits, Electronics 38, 114-117 (1965). 2. Y. Taur et al, CMOS scaling into the nanometer regime, Proc IEEE 85, 486 (1997). 3. P.A. Packan, Pushing to the limits, Science 285, 2079-281 (1999). 4. P.S. Peercy, The drive to miniaturization, Nature 406, 1023-1026 (2000).

20

Perspective on Science 07 5. R.W. Keyes, Fundamental limits of silicon technology, Proc. IEEE 89, 259-288 (2001). 6. T. Ito and S. Okazaki, Pushing the limits of lithography, Nature 406, 1027-1031 (2000). 7. L.R. Harriott, Limits of lithography, Proc. IEEE 89, 366-374 (2001). 8. A. Aviram and M. Ratner, Molecular rectifiers, Chem. Phys. Lett. 29, 277-283 (1974). 9. M. S. Dresselhaus, G. Dresselhaus and P. Avouris, Carbon Nanotubes: Synthesis, Structure, Properties, and Applications, Springer, (2001). 10. S. Iijima , Helical microtubules of graphitic carbon, Nature 354, 56 ( 1991); Journet C, Maser W K, Bernier P, Loiseau A, delaChapelle M L, Lefrant S, P. Deniard, R. Lee andJ. E. Fischer, Large-scale productionof single-walled carbon nanotubesby the electric-arc technique, Nature 388, 756 (1997). 11. J. KongJ, H. T. Soh , A. M. Cassell, C. F. Quate and H. J. Dai, Synthesis of individual single-walled carbon nanotubes on patterned silicon wafers, Nature 395, 878 (1998). 12. R. Martel , H-S P. Wong, K. Chan and P. Avouris , Carbon Nanotube Field Effect Transistors for Logic Applications, IEDM 01, 159-162 (2001). 13. S. J. Wind, J. Appenzeller , R. Marte, V. Derycke and P. Avouris , Vertical scaling of carbon nanotube field effect transistors using top gate electrodes, Appl. Phys. Lett. 80, 3817 (2002). 14. K. Xiao et al, High-mobility thin-film transistors based on aligned carbon nanotubes, Appl. Phys. Lett. 83, 150 (2003).

21

Perspective on Science 07 15. A. Javey , Q. Wang , A. Ural, Y. Li and H. Dai, Carbon nanotube transistor arrays for multistage complementary logic and ring oscillators, Nano Lett. 2 929 (2002). 16. P. Avouris , R. Martel , V. Derycke and J. Appenzeller , Carbon nanotube transistors and logic circuits, Physica B 323, 6 (2002). 17. A. Bachtold, P. Hadley ,T. Nakanishi and C. Dekker, Logic circuits with carbon nanotube transistors, Science 294, 1317 (2001). 18. A. M. Morales and C. M Lieber, A laser ablation method for the synthesis of crystalline semiconductor nanowires, Science 279, 208 (1998). 19. Y. Huang , X. Duan ,Y. Cui , L. J. Lauhon, K.H. Kim and C. M. Lieber, Logic gates and computation from assembled nanowire building blocks, Science 294, 1313 (2001). 20. R. M. Metzger, Unimolecular rectification down to 105 K and spectroscopy of hexadecylquinolinium tricyanoquinodimethanide, Synthetic Met. 109, 23 (2000). 21. M. Di Ventra , S. T. Pantelides and N. D. Lang, The benzene molecule as a molecular resonant-tunneling transistor, Appl. Phys. Lett. 76, 3448 (2000). 22. J. M. Seminario, A. G. Zacarias and P. A. Derosa, Theoretical analysis of complementary molecular memory devices, J. Phys. Chem. A 105, 791 (2001). 23. J. C. Ellenbogen and J. C. Love , Architectures for molecular electronic computers. I. Logic structures and an adder designed from molecular electronic diodes, Proc. IEEE 88, 386 (2000). 24. S. M. Sze, Physics of Semiconductor devices, Wiley: New York (1981). 25. C. M. Sotomayor torres et al, Nanoimprint lithography: an alternative nanofabrication approach, Mater. Sci. Eng. C 23, 23 (2003).

22

Perspective on Science 07 26. C, P. Collier et al, A [2]catenane-based solid state electronically reconfigurable switch, Science 289,1172 (2000). 27. Z. J. Donhauser et al , Conductance switching in single molecules through conformational changes, Science 292, 2303 (2001). 28. Y. Chen et al, Nanoscale molecular-switch crossbar circuits, Nanotechnology 14, 462-468 (2003). 29. B. A Mantooth, and P.S. Weiss, Fabrication, assembly, and characterization of molecular electronic components, Proc. IEEE 91, 1785-1802 (2003). 30. S. C. Goldstein and M. Budiu, Molecules, Gates, Circuits, and Computers, in Molecular Nanoelectronics, edited by M. A. Reed and T. Lee, American SP, 327388 (2003). 31. K. Nikolic and M. Forshaw, Nanoelectronic devices, in 3-D Nanoelectronic computer architecture and implementation, edited by D. Crawley, K. Nikolic and M. Forshaw, Institute of Physics 60 (2005). 32. D. Goldhaber-Gordon, M. S. Montemerlo, J. C. Love, G. J. Opiteck, and J. C. Ellenbogen, Overview of nanoelectronic devices, Proc. IEEE 85, 521-540 (1997). 33. Y. Cui, Z. Zhong, D. Wang, W. U. Wang and C. M. Lieber, High performance silicon nanowire field effect transistors, Nano. Lett 3,149-152 (2003). 34. G.Y. Jung, W. Wu, Z. Yu, S.Y. Wang, Z. Li, R.S. Williams, E. JohnstonHalperin, J.E. Green, A. Boukai, Y. Bunimovich and J.R. Heath, Nanowire Circuit Fabrication at 34 nm pitch by nanoimprint lithography, NanoLett. 6, 351354 (2006).

23

Perspective on Science 07 35. J. Park et al, Coulomb blockade and the Kondo effect in single-atom transistors, Nature 417, 722 (2002). 36. J. Chen , M. A. Reed ,A. M. Rawlett and J. M. Tour, Large On-Off Ratios and Negative Differential Resistance in a Molecular Electronic Device, Science 286 (1999). 37. G. J. Ashwell, J. R. Sambles, A. S. Martin, W. G. Parker and M. Szablewski, Rectifying characteristics of Mg/(C 16H 33-Q3CNQ LB film)/Pt structures, J. Chem. Soc. Chem. Commun. 1374 (1990). 38. X. Duan et al, Nanowire Nanoelectronics, Molecular Nanoelectronics, edited by M. A. Reed and T. Lee, American SP, 327-388 (2003). 39. G. F. Cerofolini and D. Mascolo, Hybrid route from CMOS to Nano/Molecular Electronics, in Nanotechnology for electronic materials and devices, edited by A. Korlin et al, Springer, 1-61(2006). 40. M. A. Rampi and G. M. Whitesides , A versatile experimental approach for understanding electron transport through organic materials, Chem. Phys. 281, 373391 (2002). 41. B. H. Akkerman , P. W. M. Blom , Dago M. de Leeuw and Bert de Boer, Towards molecular electronics with large-area molecular junctions, Nature 441, 69-72 (2006). 42. J. C. Love, L. A. Estroff, J. K. Kriebel, R. G. Nuzzo, and G. M. Whitesides, Selfassembled monolayers of thiolates on metals as a form of nanotechnology, Chem. Rev. 105, 1103-1169 (2005)

24

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Zero Sequence ImpedanceDokumen3 halamanZero Sequence Impedanceferdad4realBelum ada peringkat

- DB Erq-Aw1 2014 PDFDokumen39 halamanDB Erq-Aw1 2014 PDFSlobodan BanicBelum ada peringkat

- Microcontroller Based Solar Power Inverter: Ruchika Thukral, Ankit Gupta, Nilesh Kumar Verma, Shivanchal AsthanaDokumen9 halamanMicrocontroller Based Solar Power Inverter: Ruchika Thukral, Ankit Gupta, Nilesh Kumar Verma, Shivanchal AsthanaBubai BhattacharyyaBelum ada peringkat

- Data Sheet BusductDokumen4 halamanData Sheet BusductR Bambang WidiatmokoBelum ada peringkat

- Technical Specification STS-3000K-H1 20kV 50Hz For 200 - 215KTL - V6.0 (France ONLY)Dokumen19 halamanTechnical Specification STS-3000K-H1 20kV 50Hz For 200 - 215KTL - V6.0 (France ONLY)Sav Sasha100% (1)

- Snx4Ahct14 Hex Schmitt-Trigger Inverters: 1 Features 3 DescriptionDokumen34 halamanSnx4Ahct14 Hex Schmitt-Trigger Inverters: 1 Features 3 DescriptionVysakh SharmaBelum ada peringkat

- Photoelectric TG e 8 3 PDFDokumen17 halamanPhotoelectric TG e 8 3 PDFWahyu IkhsannudinBelum ada peringkat

- AISHWARYDokumen26 halamanAISHWARYShubham SoniBelum ada peringkat

- B.SC - PhysicsCBCS OUDokumen45 halamanB.SC - PhysicsCBCS OUMD Saif SiddBelum ada peringkat

- 06 Contactors1Dokumen44 halaman06 Contactors1Yash TavseBelum ada peringkat

- Science Quarter 2 Module 4Dokumen3 halamanScience Quarter 2 Module 4Christian AlbosBelum ada peringkat

- Dell Monitor Repair Likom L705xxx Model With No Power SymptomDokumen3 halamanDell Monitor Repair Likom L705xxx Model With No Power SymptomMr. SadatBelum ada peringkat

- BE Semester-VI (Electrical Engineering) Question Bank (E 605 Electrical Power System - Ii) All Questions Carry Equal Marks (10 Marks)Dokumen5 halamanBE Semester-VI (Electrical Engineering) Question Bank (E 605 Electrical Power System - Ii) All Questions Carry Equal Marks (10 Marks)Adesh Bhortakke100% (1)

- Arc Rersistance TestDokumen18 halamanArc Rersistance TestMMFAWZYBelum ada peringkat

- User ManualDokumen2 halamanUser ManualLintom Marpaung0% (1)

- Sample Question PDFDokumen1.175 halamanSample Question PDFsignalcontrolspjBelum ada peringkat

- 3238018C10MDokumen8 halaman3238018C10MAlbita PintoBelum ada peringkat

- 02 PDFDokumen4 halaman02 PDFJosBelum ada peringkat

- ASI, VSI, AltimeterDokumen6 halamanASI, VSI, AltimeterAsari HammadBelum ada peringkat

- 1 Introduction MechatronicsDokumen77 halaman1 Introduction MechatronicsJeewan AtwalBelum ada peringkat

- 8000-Line/Spectra Motor Control Center: Renewal Parts BulletinDokumen31 halaman8000-Line/Spectra Motor Control Center: Renewal Parts BulletinJesus David Rueda Espinosa100% (1)

- HARS-X and X2 High Accuracy Resistance Substituter User and Service ManualDokumen15 halamanHARS-X and X2 High Accuracy Resistance Substituter User and Service Manualb4tipibeBelum ada peringkat

- Equivalent Circuit of Transformer Referred To PrimaryDokumen5 halamanEquivalent Circuit of Transformer Referred To PrimaryGideon Moyo100% (1)

- Irg4Ph50Ud: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Ultrafast Copack IgbtDokumen11 halamanIrg4Ph50Ud: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Ultrafast Copack IgbtChAmirShokatGujjarBelum ada peringkat

- Electrical Machines-I Question BankDokumen8 halamanElectrical Machines-I Question BankPapasani srividyaBelum ada peringkat

- Frekventni RegulatoriDokumen6 halamanFrekventni RegulatoriGogyBelum ada peringkat

- Automatic Night Lamp With Morning AlarmDokumen14 halamanAutomatic Night Lamp With Morning Alarmfrancis mollinoBelum ada peringkat

- Power Monitor Chip: Features Pin AssignmentDokumen9 halamanPower Monitor Chip: Features Pin Assignmentchafic WEISSBelum ada peringkat

- Tps 65235Dokumen39 halamanTps 65235raiden84Belum ada peringkat

- Limitation of KCL KVLDokumen1 halamanLimitation of KCL KVLSeijuro AkashiBelum ada peringkat