An Undergraduate Experiment in Polyester (PET) Synthesis

Diunggah oleh

Ronald WoodJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

An Undergraduate Experiment in Polyester (PET) Synthesis

Diunggah oleh

Ronald WoodHak Cipta:

Format Tersedia

In the Laboratory

An Undergraduate Experiment in Polyester (PET) Synthesis

Andrew N. Cammidge* School of Chemical Sciences, University of East Anglia, Norwich NR4 7TJ, UK

At UEA, first-year undergraduate chemistry students are encouraged to take an extra laboratory course if their timetable allows. The current course entitled Macromolecules and Molecular Assemblies is also compulsory for students enrolled on our degree course Chemistry with Advanced Materials. All experiments are chosen to reinforce some fundamental principles of chemistry under this common theme. Experiments in this unit include liquid crystal synthesis, inorganic and organic polymers and colloids. Each experiment is introduced by a one-hour lecture, in which the science and industrial relevance of the experiment is put into context. The laboratory experiments themselves aim to introduce some more advanced practical techniques and encourage independent investigation. An important part of the course is the introduction of polymer science through the synthesis of both organic and inorganic polymers. The polymers chosen are intended to be of relevance to industry (silicones, nylons, etc.). For this reason a laboratory experiment introducing polyesters (1) was required. To our surprise, no suitable undergraduate experiment could be found. This paper details the experiment we developed and incorporated successfully into the first-year laboratory program. The Experiment

Description The most important polyester manufactured industrially is PET (polyethyleneterephthalate). The industrial preparation is a two-step procedure from terephthalic acid and ethane diol (ED). This procedure is not suitable for direct modification to a laboratory experiment (high temperature and pressure), but can be mimicked using a transesterification reaction starting from dimethylterephthalate (DMTP) (Scheme I).

O H3CO O

2

OCH3

HO

OH

O HO O

O OH O

At this stage the students are assembled around the chalkboard to discuss the procedure. They are asked to predict the temperature reading on the thermometer at reflux. The answer is usually ~190 C (bp of ED). By working through the equilibria setup in the reaction, a consensus is reached that the expected temperature is ~65 C (bp of MeOH). The students return to their apparatus to find that the reflux temperature is indeed ~65 C. After fluxing for 30 min the apparatus is cooled and converted to distillation (the Y adapter is kept in place as a crude fractionation column). Heat is reapplied and a measuring cylinder is used to collect methanol. The students are asked to predict the volume of methanol expected (reinforcing basic calculations). When the head temperature reaches 180 C the heat is turned off and the mixture is allowed to cool slightly. The hot solution is decanted from the antibumping granules and left to crystallize. (The experiment can be left at this point.) Crystallization can be induced by scratching the flask or adding water, if necessary. The crystals are filtered off under vacuum for analysis by 1H NMR spectroscopy. (NOTE: another base such as sodium methoxide could be employed, but use of sodium metal makes the procedure conceptually simple and does not interfere with the subsequent calculation of the expected volume of methanol distillate). Polymerization Small samples of the intermediate are dried between filter papers and placed in crucibles or on microscope slides. The samples are heated carefully on a hot-plate, ED is evaporated, and the physical properties of the sample are monitored as the sample is re-cooled. To some preparations, a small crystal of p-toluene sulfonic acid is added during the heating process. This polymerization requires some care to be successful. Low-molecular-weight polymer (oligomer) cools to form waxy, semicrystalline material. Samples left longer (with acid catalyst) form sticky polymeric masses, which cool further to give clear glassy solids. These properties

2 CH3OH

O OH O

O O

O O O

HO O

heat

HO

OH

Scheme I

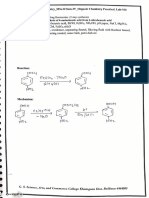

The intermediate formed in the first step (bis-(2-hydroxyethyl)terephthalate (2, 3) is identical to that formed in the industrial synthesis. In the first step the students assemble reflux apparatus inserting a Y adapter (with thermometer) between the round-bottom flask and condenser. The roundbottom flask is charged with DMTP and excess ED. A small piece of sodium metal is added and the heating mantle is switched on (Fig. 1).

*Email: a.cammidge@uea.ac.uk.

Figure 1. The apparatus: (a) reflux assembly; (b) distillation assembly.

236

Journal of Chemical Education Vol. 76 No. 2 February 1999 JChemEd.chem.wisc.edu

In the Laboratory

are used to qualitatively monitor polymerization. (Samples left too long simply char.) Students wash the bulk sample with water and dry it thoroughly. A sample is submitted for NMR, which the students discuss in their report.

Procedure Place dimethyl terephthalate (5 g), ethane diol (80 mL) and some antibumping granules in a 250-mL round-bottom flask. Add a small (~0.1-g) piece of sodium metal (CAUTION!). Fit a Y adapter, thermometer, and reflux condenser and heat the mixture to reflux for 45 minutes using a heating mantle. Cool the mixture somewhat and modify the apparatus for distillation, leaving the Y adapter in place for fractional distillation. Distill off the methanol, stopping the collection when the head temperature reaches 180 C. Decant the solution from antibumping granules and allow it to cool. Collect the crystals that form by suction filtration. Dry a sample thoroughly between filter papers and place it in a crucible or on a microscope slide. Heat this strongly on a hot-plate, carefully removing samples from time to time to check their physical properties as they cool. Repeat with another dry sample, this time adding a small crystal of p-toluene sulfonic acid to the molten material. Wash the bulk sample with water and dry thoroughly before submitting a sample for 1H NMR analysis.

Conclusion This experiment is designed to reinforce important concepts in organic chemistry and introduce polymer synthesis. Students are able to observe, in real time, equilibration of a reaction mixture and see how product composition can be determined by removal of one component (methanol) or use of excess reagent (ED). They perform fractional distillations and apply knowledge of the reaction to calculate predicted volume of distillate. (This was the first time these students had performed a distillation.) The NMR of the intermediate allows the concepts of coupling, chemical shift, and integration to be demonstrated. More advanced experiments could involve D2O exchange. Acknowledgments I would like to thank the students of CHE-1H04 for providing feedback on this experiment, and Amy King for running NMR spectra. Literature Cited

1. Billmeyer, F. W. Textbook of Polymer Science, 3rd ed.; Wiley: New York, 1984. 2. Zahn, H.; Krzikalla, R. Makromol. Chem. 1957, 23, 3153. 3. Allan, R. J. P.; Iengar, H. V. R.; Ritchie, P. D. J. Chem. Soc. 1957, 21072113.

JChemEd.chem.wisc.edu Vol. 76 No. 2 February 1999 Journal of Chemical Education

237

Anda mungkin juga menyukai

- Chemical Thermodynamics: Plenary Lectures Presented at the Fourth International Conference on Chemical Thermodynamics Université des Sciences et Techniques de Languedoc, Montpellier, France 26–30 August 1975Dari EverandChemical Thermodynamics: Plenary Lectures Presented at the Fourth International Conference on Chemical Thermodynamics Université des Sciences et Techniques de Languedoc, Montpellier, France 26–30 August 1975J. RouquerolBelum ada peringkat

- Jurnal Analitik Jahlela Sari Kimia Bahasa InggrisDokumen14 halamanJurnal Analitik Jahlela Sari Kimia Bahasa InggriskhairiyatiBelum ada peringkat

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesDari EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesBelum ada peringkat

- RuCl2(PPh3)3 catalyzed alcohol oxidation labDokumen19 halamanRuCl2(PPh3)3 catalyzed alcohol oxidation labKiki AimaBelum ada peringkat

- The Preparation and Purification of Methyl-3-Nitrobenzoate Student SheetDokumen5 halamanThe Preparation and Purification of Methyl-3-Nitrobenzoate Student SheetSajidAbdullahBelum ada peringkat

- UiTM Organic Chemistry Aldol Condensation ExperimentDokumen7 halamanUiTM Organic Chemistry Aldol Condensation ExperimentNurul izzatiBelum ada peringkat

- Preparation and Analysis of Potassium: Tris (Oxalato) Ferrate (LLL) TrihydrateDokumen2 halamanPreparation and Analysis of Potassium: Tris (Oxalato) Ferrate (LLL) TrihydrateKevin David AlvarezBelum ada peringkat

- 2004 Chem 2OB3 Lab Manual - Experiment 5. Synthetic PolymersDokumen5 halaman2004 Chem 2OB3 Lab Manual - Experiment 5. Synthetic PolymersBasheer AhammadBelum ada peringkat

- New Segmented Polyurethane Ureas Based On 4,4'-Dicyclohexylmethane Diisocyanate and On Various Soft Segments Samson 1998Dokumen19 halamanNew Segmented Polyurethane Ureas Based On 4,4'-Dicyclohexylmethane Diisocyanate and On Various Soft Segments Samson 1998WSERBelum ada peringkat

- Howard 1981Dokumen26 halamanHoward 1981Érika Lorena OliveiraBelum ada peringkat

- Thermal and catalytic pyrolysis of polyethyleneDokumen9 halamanThermal and catalytic pyrolysis of polyethyleneKatiane MesquitaBelum ada peringkat

- Chemistry Lab ReportDokumen16 halamanChemistry Lab Reportapi-334420312Belum ada peringkat

- Williamson Synthesis Lab ReportDokumen5 halamanWilliamson Synthesis Lab ReportNicholas Johnson100% (2)

- Exp't 13: Phase-Transfer-Catalyzed Alkylation of Diethyl MalonateDokumen5 halamanExp't 13: Phase-Transfer-Catalyzed Alkylation of Diethyl MalonatelovehopeBelum ada peringkat

- Synthesis of donor-acceptor monomersDokumen16 halamanSynthesis of donor-acceptor monomersSamuel Siow Wei JianBelum ada peringkat

- Heat of Neutralization - Group4 - 1CDokumen13 halamanHeat of Neutralization - Group4 - 1CAfifah.r0seBelum ada peringkat

- CH2103 Lab Manual 2016Dokumen29 halamanCH2103 Lab Manual 2016AditiBelum ada peringkat

- Kamimura Et Al-2008-Polymers For Advanced TechnologiesDokumen5 halamanKamimura Et Al-2008-Polymers For Advanced TechnologiesMonique PadovanBelum ada peringkat

- Catalytic Conversion of Plastic Waste To Fuel: ISSN: 2394-1766Dokumen7 halamanCatalytic Conversion of Plastic Waste To Fuel: ISSN: 2394-1766Nirajkumar NairBelum ada peringkat

- STK1084 Lab ManualDokumen40 halamanSTK1084 Lab Manualpc355chyiBelum ada peringkat

- Experiment 5a - Water of HydrationDokumen5 halamanExperiment 5a - Water of HydrationTiurma Debora Simatupang0% (1)

- 4 +Proline-Catalyzed+AsymmetriDokumen8 halaman4 +Proline-Catalyzed+Asymmetricmc107Belum ada peringkat

- 9701 Practical Booklet 06 (Accompanies Scheme of Work 2016)Dokumen19 halaman9701 Practical Booklet 06 (Accompanies Scheme of Work 2016)Jonathan StashBelum ada peringkat

- MgH2 NaAlH4 PDFDokumen6 halamanMgH2 NaAlH4 PDFMohammad IsmailBelum ada peringkat

- Chemistry Nucleophilic Aromatic Substitution Experiment PDFDokumen5 halamanChemistry Nucleophilic Aromatic Substitution Experiment PDFMaii MendiiölaBelum ada peringkat

- ReactoresDokumen7 halamanReactoresAriday BeltránBelum ada peringkat

- Microwave-Mediated Synthesis of Lophine: W Developing A Mechanism To Explain A ProductDokumen3 halamanMicrowave-Mediated Synthesis of Lophine: W Developing A Mechanism To Explain A ProductDannyBelum ada peringkat

- Chemical Reactions Lab ReportDokumen7 halamanChemical Reactions Lab ReportAithne K TiarrahBelum ada peringkat

- Ahmad Zakwan Bin Kassim - CHM557 - Exp4Dokumen14 halamanAhmad Zakwan Bin Kassim - CHM557 - Exp4Ahmad ZakwanBelum ada peringkat

- LabDokumen16 halamanLabMuhamad Hafifi AjwadBelum ada peringkat

- 2007 Polymer Deg & Stab 2007 v92 1061-1071Dokumen11 halaman2007 Polymer Deg & Stab 2007 v92 1061-1071Giselle GalloBelum ada peringkat

- Direct Hydration of Propylene in Liquid Phase and Under Supercritical Conditions in The Presence of Solid Acid CatalystsDokumen6 halamanDirect Hydration of Propylene in Liquid Phase and Under Supercritical Conditions in The Presence of Solid Acid Catalystsssargo100% (1)

- Sintesis de HachDokumen2 halamanSintesis de HachJuan Felipe Amaya LunaBelum ada peringkat

- Melting Point and Boiling Point of Organic CompoundsDokumen3 halamanMelting Point and Boiling Point of Organic CompoundsCarlo Aguas Tayag71% (7)

- Exp't 61: 1,4-Di-T-Butylbenzene Via Friedel-Crafts AlkylationDokumen6 halamanExp't 61: 1,4-Di-T-Butylbenzene Via Friedel-Crafts AlkylationlovehopeBelum ada peringkat

- PolyesterDokumen3 halamanPolyesterdanielBelum ada peringkat

- In Uence of Time and Temperature On Pyrolysis of Plastic Wastes in A Semi-Batch ReactorDokumen10 halamanIn Uence of Time and Temperature On Pyrolysis of Plastic Wastes in A Semi-Batch ReactorBagoes KurniadiBelum ada peringkat

- Chemical Recycling of Polystyrene: D.S. Achilias, I. Kanellopoulou, P. MegalokonomosDokumen8 halamanChemical Recycling of Polystyrene: D.S. Achilias, I. Kanellopoulou, P. MegalokonomosLuizaBelum ada peringkat

- PolystyreneDokumen9 halamanPolystyreneclcontact15Belum ada peringkat

- Geothermal Sampling Analysis TechniquesDokumen8 halamanGeothermal Sampling Analysis TechniquesRaul Antonio Hernandez DelgadoBelum ada peringkat

- Characterization of Recycled/ Virgin PET Polymers and Their CompositesDokumen6 halamanCharacterization of Recycled/ Virgin PET Polymers and Their CompositesZe Wei NgBelum ada peringkat

- Extraction and Gas Chromatographic Determination of Ethanol in BeveragesDokumen12 halamanExtraction and Gas Chromatographic Determination of Ethanol in BeveragesJonathanBelum ada peringkat

- PLA - em Dioxano - TIPS - 2005Dokumen9 halamanPLA - em Dioxano - TIPS - 2005Rui CarloBelum ada peringkat

- Synthesis of Carbon Nanodots From Cellulose NanocrDokumen6 halamanSynthesis of Carbon Nanodots From Cellulose NanocrMarniatiBelum ada peringkat

- Sustainable Ecosystems and Human ActivityDokumen5 halamanSustainable Ecosystems and Human ActivityMarina XuBelum ada peringkat

- Wu 2018Dokumen24 halamanWu 2018torquendoBelum ada peringkat

- 03 Bleach Oxidation HandoutDokumen6 halaman03 Bleach Oxidation HandoutBrian PermejoBelum ada peringkat

- Poly-å-Caprolactam: 1. ProcedureDokumen3 halamanPoly-å-Caprolactam: 1. ProcedureMathaneshan RajagopalBelum ada peringkat

- LAB#7 - Enthalpy Change of A ReactionDokumen4 halamanLAB#7 - Enthalpy Change of A ReactionShemar LanfermanBelum ada peringkat

- Introducing Plastics in The LaboratoryDokumen2 halamanIntroducing Plastics in The LaboratoryNiku SamarthBelum ada peringkat

- 10 1021@ie0107643Dokumen7 halaman10 1021@ie0107643noviBelum ada peringkat

- Nanosize and Bimodal Porous Polyoxotungstate-Anatase TiO2 Composites: Preparation and Photocatalytic Degradation of Organophosphorus Pesticide Using Visible-Light ExcitationDokumen9 halamanNanosize and Bimodal Porous Polyoxotungstate-Anatase TiO2 Composites: Preparation and Photocatalytic Degradation of Organophosphorus Pesticide Using Visible-Light ExcitationLenin HuertaBelum ada peringkat

- Advanced Experiments in Physical and Analytical Chemistry CM3292 (II)Dokumen41 halamanAdvanced Experiments in Physical and Analytical Chemistry CM3292 (II)Qu TingBelum ada peringkat

- zhao2007Dokumen7 halamanzhao2007barti koksBelum ada peringkat

- BenzocaineDokumen5 halamanBenzocainejanglu ingleBelum ada peringkat

- Naicker Omasha 2006Dokumen142 halamanNaicker Omasha 2006EdwardBelum ada peringkat

- Journal - Solid-State Polycondensation of Poly (Ethylene Terephthalate) Recycled From Postconsumer Soft-Drink Bottles. I.Dokumen8 halamanJournal - Solid-State Polycondensation of Poly (Ethylene Terephthalate) Recycled From Postconsumer Soft-Drink Bottles. I.y.s.6saputroBelum ada peringkat

- Major Project E-Logbook Samuel Siow Updated 180712Dokumen23 halamanMajor Project E-Logbook Samuel Siow Updated 180712Samuel Siow Wei JianBelum ada peringkat

- Uplc - MS As A Powerful Technique For Screening The Nonvolatile Contaminants in Recycled PETDokumen8 halamanUplc - MS As A Powerful Technique For Screening The Nonvolatile Contaminants in Recycled PETAmin ShariatmadarBelum ada peringkat

- Novel Preparation of Hybrid Polypropylene/Silica Nanocomposites in A Slurry-Phase Polymerization ReactorDokumen8 halamanNovel Preparation of Hybrid Polypropylene/Silica Nanocomposites in A Slurry-Phase Polymerization ReactorDaniel Escobar EsquivelBelum ada peringkat

- Matlab For SolidworksDokumen18 halamanMatlab For SolidworksAle' AmoudiBelum ada peringkat

- Cambridge International AS & A Level: Mathematics 9709/13Dokumen20 halamanCambridge International AS & A Level: Mathematics 9709/13Justin OngBelum ada peringkat

- Exogenous Driver Analysis Driver Relative GDP GrowthDokumen107 halamanExogenous Driver Analysis Driver Relative GDP GrowthBhagya FoodsBelum ada peringkat

- Sherco 450 Se R Workshop Manual 1Dokumen79 halamanSherco 450 Se R Workshop Manual 1miguelBelum ada peringkat

- Analytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeDokumen2 halamanAnalytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeJhon dave SurbanoBelum ada peringkat

- Moral Theories: Presented By: Sedrick M. MallariDokumen27 halamanMoral Theories: Presented By: Sedrick M. MallariAlyssa De PaduaBelum ada peringkat

- SEFT Islamic care effect on hypertension patients' blood pressureDokumen12 halamanSEFT Islamic care effect on hypertension patients' blood pressureSopian HadiBelum ada peringkat

- Motherboards Tuf z270 Mark 2Dokumen70 halamanMotherboards Tuf z270 Mark 2Jonah HexBelum ada peringkat

- Nutrition and Athletic PerformanceDokumen16 halamanNutrition and Athletic PerformancemarisolBelum ada peringkat

- AWWA M28 Rehabilitation of Water Mains 3rd Ed 2014Dokumen133 halamanAWWA M28 Rehabilitation of Water Mains 3rd Ed 2014millini67% (3)

- March 17, 2016 Strathmore TimesDokumen24 halamanMarch 17, 2016 Strathmore TimesStrathmore TimesBelum ada peringkat

- MSDS Corn CobDokumen2 halamanMSDS Corn CobMUHAMMAD YOGA BRILLIANTOBelum ada peringkat

- 692pu 6 6Dokumen1 halaman692pu 6 6Diego GodoyBelum ada peringkat

- HTTP Verbs GET POST PUT PATCH DELETE (39Dokumen12 halamanHTTP Verbs GET POST PUT PATCH DELETE (39Jefferson EducacionBelum ada peringkat

- Painting, DrawingDokumen22 halamanPainting, DrawingMithilesh_Kuma_7083Belum ada peringkat

- Msds PentaneDokumen6 halamanMsds PentaneMuhammad FikriansyahBelum ada peringkat

- Malaria Epidemiology & PreventionDokumen92 halamanMalaria Epidemiology & PreventionritikaritikaBelum ada peringkat

- BR A Consumables Catalog ElecDokumen31 halamanBR A Consumables Catalog Elecdweil1552Belum ada peringkat

- Tribology - Lubricants and LubricationDokumen330 halamanTribology - Lubricants and LubricationJosé Ramírez100% (2)

- Numerical Simulation of Screw Displacement Pile Interaction With Non-Cohesive SoilDokumen12 halamanNumerical Simulation of Screw Displacement Pile Interaction With Non-Cohesive Soilmohamed magdyBelum ada peringkat

- JJ309 Fluid Mechanics Unit 6Dokumen30 halamanJJ309 Fluid Mechanics Unit 6Adib AzharBelum ada peringkat

- Personal Care Na Hair GuideDokumen8 halamanPersonal Care Na Hair GuideIsabellaBelum ada peringkat

- Water System BOQ 16.12.2023 R0Dokumen144 halamanWater System BOQ 16.12.2023 R0moinu85Belum ada peringkat

- Wire Rope: - Bright - 6 X 19 - Fibre CoreDokumen8 halamanWire Rope: - Bright - 6 X 19 - Fibre CoreQuynh NguyenBelum ada peringkat

- 2tak Vs 4takDokumen3 halaman2tak Vs 4takTaufiq AlhakimBelum ada peringkat

- Toaz - Info Chemtech Reviewer PRDokumen1 halamanToaz - Info Chemtech Reviewer PRchristy janioBelum ada peringkat

- Conflict and Factional Disputes - Siegel & BealsDokumen12 halamanConflict and Factional Disputes - Siegel & BealsDanielBelum ada peringkat

- Making Soap From WoodDokumen6 halamanMaking Soap From WoodmastabloidBelum ada peringkat

- Eb4069135 F enDokumen13 halamanEb4069135 F enkalvino314Belum ada peringkat

- Ratana Outdoor FurnitureDokumen107 halamanRatana Outdoor FurnitureNova TechieBelum ada peringkat

- A-level Biology Revision: Cheeky Revision ShortcutsDari EverandA-level Biology Revision: Cheeky Revision ShortcutsPenilaian: 5 dari 5 bintang5/5 (5)

- Quantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityDari EverandQuantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityPenilaian: 2 dari 5 bintang2/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsDari EverandCoating and Drying Defects: Troubleshooting Operating ProblemsPenilaian: 5 dari 5 bintang5/5 (1)

- The Periodic Table: A Very Short IntroductionDari EverandThe Periodic Table: A Very Short IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Lower Secondary Science Workbook: Stage 8Dari EverandLower Secondary Science Workbook: Stage 8Penilaian: 5 dari 5 bintang5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingDari EverandIt's Elemental: The Hidden Chemistry in EverythingPenilaian: 4 dari 5 bintang4/5 (10)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDari EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeDari EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifePenilaian: 5 dari 5 bintang5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDari EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsPenilaian: 4 dari 5 bintang4/5 (146)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableDari EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TablePenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthDari EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthPenilaian: 4.5 dari 5 bintang4.5/5 (197)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDari EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolBelum ada peringkat

- On Teaching Science: Principles and Strategies That Every Educator Should KnowDari EverandOn Teaching Science: Principles and Strategies That Every Educator Should KnowPenilaian: 4 dari 5 bintang4/5 (2)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeDari EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifePenilaian: 4 dari 5 bintang4/5 (9)

- How to Teach Nature Journaling: Curiosity, Wonder, AttentionDari EverandHow to Teach Nature Journaling: Curiosity, Wonder, AttentionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDari EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilPenilaian: 5 dari 5 bintang5/5 (1)

- How to Think Like a Lawyer--and Why: A Common-Sense Guide to Everyday DilemmasDari EverandHow to Think Like a Lawyer--and Why: A Common-Sense Guide to Everyday DilemmasPenilaian: 3 dari 5 bintang3/5 (1)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDari EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsPenilaian: 5 dari 5 bintang5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDari EverandChemistry for Breakfast: The Amazing Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (90)

- Napoleon's Buttons: 17 Molecules That Changed HistoryDari EverandNapoleon's Buttons: 17 Molecules That Changed HistoryPenilaian: 4 dari 5 bintang4/5 (25)

- Simple STEAM: 50+ Science Technology Engineering Art and Math Activities for Ages 3 to 6Dari EverandSimple STEAM: 50+ Science Technology Engineering Art and Math Activities for Ages 3 to 6Belum ada peringkat

- A-Level Chemistry Revision: Cheeky Revision ShortcutsDari EverandA-Level Chemistry Revision: Cheeky Revision ShortcutsPenilaian: 4 dari 5 bintang4/5 (5)

- Creative Investigations in Early Engineering and TechnologyDari EverandCreative Investigations in Early Engineering and TechnologyBelum ada peringkat

- Stay Curious and Keep Exploring: 50 Amazing, Bubbly, and Creative Science Experiments to Do with the Whole FamilyDari EverandStay Curious and Keep Exploring: 50 Amazing, Bubbly, and Creative Science Experiments to Do with the Whole FamilyBelum ada peringkat

- Guidelines for Asset Integrity ManagementDari EverandGuidelines for Asset Integrity ManagementPenilaian: 5 dari 5 bintang5/5 (1)