Wall THK Calculation Asme b31.4

Diunggah oleh

Dwi HermawanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Wall THK Calculation Asme b31.4

Diunggah oleh

Dwi HermawanHak Cipta:

Format Tersedia

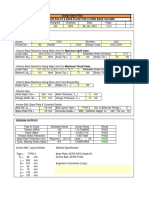

Document No. 081113B-CL-300 Rev.

A

1

2

3 DESIGN INPUT

4 Design Code ASME B31.8

5 Pipeline Size / Nominal O.D D 48 in 1219 mm

6 Corrosion Allowance A 1 mm

7 Location Class 4

8 Design Factor F 0.4

9

10 Steel Coefficient of Expansion, 0.0000117 per deg C 6.50E-06 in/in/

O

C

11 Modulus of Elasticity E 2.07E+05 Mpa

12 3.05E+07 Psi

13 Pressure and Temperature Data

14 Design Pressure P 960.0 psi g 66.2 bar g

15 Design Temperature T

d 182.2 F 85 C

16 Installation (backfill) Temp T

i 27.9 F 13 C

17 Weld joint factor E 1

18 Temperature Derating Factor T 1

19

20

21 A. WALL THICKNESS

22 Grade X65

23 SMYS of Line Pipe S 65000 psi

24 Wall Thickness Calculated t

min 23.5 mm 0.926 inch

25 t

min

= P x D / (2x Sx Fx E x T) + A

26 Next higher API wall thickness p.62 t 23.8 mm 0.938 inch

27 D/t Check ( Should be < 96) 51

28

29

30 B. EQUIVALENT STRESS CHECK FOR NON CORRODED PIPE CONDITION

31 Wall thickness (t) 23.8 mm

32

33 Hoop Stress = 169.32 Mpa

34 24558 psi

35 Thermal Stress = 174.38 Mpa

36 25291 psi

37

Longitudinal Stress = S

L

= S

th

- v.S

h

123.58 Mpa

38

S

allowable

= SMYS * 0.9 403.34 Mpa

39

Von Mises Equivalent Stress 151.71 Mpa

40 Von Mises Equivalent Stress S

allowable OK

41

42 C. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION

43 Wall thickness - Corrosion Allowance (t-A) 22.8 mm

44

45 Hoop Stress = 176.74 Mpa

46 25634 psi

47 Thermal Stress = 174.38 Mpa

48 25291 psi

49

Longitudinal Stress = S

L

= S

th

- v.S

h

121.36 Mpa

50

S

allowable

= SMYS * 0.9 403.34 Mpa

51

Von Mises Equivalent Stress 156.57 Mpa

52 Von Mises Equivalent Stress S

allowable OK

53

42

43 D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

44 Inner bend radius divided by diameter, (n) 40.0

45 % of Wall thining = 50 / (n+1) 1.220 %

46 Pipe thk. before bending = cal thk/(1-thinning %) 23.8 mm

47 Available thickness for bending (= Selected thk) 23.8 mm

48 Adequacy Check (Pipe thk before bending < Available thk) OK

\\vboxsrv\conversion_tmp\scratch_3\[127480656.xls.ms_office.xls]24"hass

ATTACHMENT - 1

Wall Thickness Calculation of 48HASS GAS PIPELINE (Location Class-4, D.F.=0.4, Corr. Allow.=1mm)

G

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = t 2D P h S = ( ) E T T S i d th = s | |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s

t t D wPe ) 0.02466( = ( ) w Pe L e L w W + =

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s t 2D P h S = s ebstress o s

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

s

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

s

Page 1 of 5

Document No. 081113B-CL-300 Rev. A

1

2

3 DESIGN INPUT

4 Design Code ASME B31.4

5 Pipeline Size / Nominal O.D D 24 in 610 mm

6 Corrosion Allowance A 1 mm

7 Design Factor F 0.72

8

9 Steel Coefficient of Expansion, 0.0000117 per deg C 6.50E-06 in/in/

O

C

10 Modulus of Elasticity E 2.07E+05 Mpa

11 3.05E+07 Psi

12 Pressure and Temperature Data

13 Design Pressure P 720.0 psi g 49.6 bar g

14 Design Temperature T

d 182.2 F 85 C

15 Installation (backfill) Temp T

i 27.9 F 13 C

16 Weld joint factor E 1

17

18 A. WALL THICKNESS

19 Grade X52

20 SMYS of Line Pipe S 52000 psi

21 Wall Thickness Calculated t

min 6.9 mm 0.270 inch

22 t

min

= P x D / (2x Sx Fx E ) + A

23 API wall thickness selected by DUSUP t 9.5 mm 0.375 inch

24 D/t Check ( Should be < 96) 64

25 B. EQUIVALENT STRESS CHECK FOR NON CORRODED PIPE CONDITION)

26 Wall thickness (t) 9.5 mm

27

28 Hoop Stress = 158.86 Mpa

29 23040 psi

30 Thermal Stress = 174.38 Mpa

31 25291 psi

32

Longitudinal Stress = S

L

= S

th

- v.S

h

126.72 Mpa

33

S

allowable

= SMYS * 0.9 322.67 Mpa

34

Von Mises Equivalent Stress 145.47 Mpa

35 Von Mises Equivalent Stress S

allowable OK

36

37 C. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION)

38 Wall thickness - Corrosion allowance (t-A) 8.5 mm

39

40 Hoop Stress = 177.49 Mpa

41 25743 psi

42 Thermal Stress = 174.38 Mpa

43 25291 psi

44

Longitudinal Stress = S

L

= S

th

- v.S

h

121.13 Mpa

45

S

allowable

= SMYS * 0.9 322.67 Mpa

46

Von Mises Equivalent Stress 157.08 Mpa

47 Von Mises Equivalent Stress S

allowable OK

48

49 E. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

50 Inner bend radius divided by diameter, (n) 40.0

51 % of Wall thining = 50 / (n+1) 1.220 %

52 Pipe thk. before bending = cal thk/(1-thinning %) 6.9 mm

53 Available thickness for bending (= Selected thk) 9.5 mm

54 Adequacy Check (Pipe thk before bending < Available thk) OK

\\vboxsrv\conversion_tmp\scratch_3\[127480656.xls.ms_office.xls]24"hass

ATTACHMENT - 2

Wall Thickness Calculation of 24HASS Diesel PIPELINE (D.F.=0.72, Corr. Allow.=1mm)

G

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s

t t D wPe ) 0.02466( = ( ) w Pe L e L w W + =

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s t 2D P h S = s ebstress o

s

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

s

Page 2 of 5

Document No. 081113B-CL-300 Rev. A

1

2

3 DESIGN INPUT

4 Design Code ASME B31.4

5 Pipeline Size / Nominal O.D D 24 in 610 mm

6 Corrosion Allowance A 1 mm

7 Design Factor F 0.72

8

9 Steel Coefficient of Expansion, 0.0000117 per deg C 6.50E-06 in/in/

O

C

10 Modulus of Elasticity E 2.07E+05 Mpa

11 3.05E+07 Psi

12 Pressure and Temperature Data

13 Design Pressure P 720.0 psi g 49.6 bar g

14 Design Temperature T

d 182.2 F 85 C

15 Installation (backfill) Temp T

i 27.9 F 13 C

16 Weld joint factor E 1

17

18 A. WALL THICKNESS

19 Grade X52

20 SMYS of Line Pipe S 52000 psi

21 Wall Thickness Calculated t

min 6.9 mm 0.270 inch

22 t

min

= P x D / (2x Sx Fx E ) + A

23 API wall thickness selected by DUSUP t 9.5 mm 0.375 inch

24 D/t Check ( Should be < 96) 64

25 B. EQUIVALENT STRESS CHECK FOR NON CORRODED PIPE CONDITION)

26 Wall thickness (t) 9.5 mm

27

28 Hoop Stress = 158.86 Mpa

29 23040 psi

30 Thermal Stress = 174.38 Mpa

31 25291 psi

32

Longitudinal Stress = S

L

= S

th

- v.S

h

126.72 Mpa

33

S

allowable

= SMYS * 0.9 322.67 Mpa

34

Von Mises Equivalent Stress 145.47 Mpa

35 Von Mises Equivalent Stress S

allowable OK

36

37 C. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION)

38 Wall thickness - Corrosion allowance (t-A) 8.5 mm

39

40 Hoop Stress = 177.49 Mpa

41 25743 psi

42 Thermal Stress = 174.38 Mpa

43 25291 psi

44

Longitudinal Stress = S

L

= S

th

- v.S

h

121.13 Mpa

45

S

allowable

= SMYS * 0.9 322.67 Mpa

46

Von Mises Equivalent Stress 157.08 Mpa

47 Von Mises Equivalent Stress S

allowable OK

48

49 D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

50 Inner bend radius divided by diameter, (n) 40.0

51 % of Wall thining = 50 / (n+1) 1.220 %

52 Pipe thk. before bending = cal thk/(1-thinning %) 6.9 mm

53 Available thickness for bending (= Selected thk) 9.5 mm

54 Adequacy Check (Pipe thk before bending < Available thk) OK

\\vboxsrv\conversion_tmp\scratch_3\[127480656.xls.ms_office.xls]24"hass

ATTACHMENT - 3

Wall Thickness Calculation of 24LEHB Diesel PIPELINE (D.F.=0.72, Corr. Allow.=1mm)

G

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s

t t D wPe ) 0.02466( = ( ) w Pe L e L w W + =

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s t 2D P h S = s ebstress o

s

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

s

Page 3 of 5

Document No. 081113B-CL-300 Rev. A

1

2

3 DESIGN INPUT

4 Design Code ASME B31.8

5 Pipeline Size / Nominal O.D D 48 in 1219 mm

6 Corrosion Allowance A 1 mm (as per DUSUP instruction)

7 Location Class 4

8 Design Factor F 0.4

9

10 Steel Coefficient of Expansion, 0.0000117 per deg C 6.50E-06 in/in/

O

C

11 Modulus of Elasticity E 2.07E+05 Mpa

12 3.05E+07 Psi

13 Pressure and Temperature Data

14 Design Pressure P 600.0 psi g 41.4 bar g

15 Design Temperature T

d 182.2 F 85 C

16 Installation (backfill) Temp T

i 27.9 F 13 C

17 Weld joint factor E 1

18 Temperature Derating Factor T 1

19

20

21 A. WALL THICKNESS

22 Grade X65

23 SMYS of Line Pipe S 65000 psi

24 Wall Thickness Calculated t

min 15.1 mm 0.593 inch

25 t

min

= P x D / (2x Sx Fx E x T) + A

26 Next higher API wall thickness p.62 t 15.9 mm 0.625 inch

27 D/t Check ( Should be < 96) 77

28

29

30 B. EQUIVALENT STRESS CHECK FOR NON CORRODED PIPE CONDITION

31 Wall thickness (t) 15.9 mm

32

33 Hoop Stress = 158.86 Mpa

34 23040 psi

35 Thermal Stress = 174.38 Mpa

36 25291 psi

37

Longitudinal Stress = S

L

= S

th

- v.S

h

126.72 Mpa

38

S

allowable

= SMYS * 0.9 403.34 Mpa

39

Von Mises Equivalent Stress 145.47 Mpa

40 Von Mises Equivalent Stress S

allowable OK

41

42 C. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION

43 Wall thickness (t) 14.9 mm

44

45 Hoop Stress = 169.53 Mpa

46 24589 psi

47 Thermal Stress = 174.38 Mpa

48 25291 psi

49

Longitudinal Stress = S

L

= S

th

- v.S

h

123.52 Mpa

50

S

allowable

= SMYS * 0.9 403.34 Mpa

51

Von Mises Equivalent Stress 151.85 Mpa

52 Von Mises Equivalent Stress S

allowable OK

42

43 D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

44 Inner bend radius divided by diameter, (n) 40.0

45 % of Wall thining = 50 / (n+1) 1.220 %

46 Pipe thk. before bending = cal thk/(1-thinning %) 15.3 mm

47 Available thickness for bending (= Selected thk) 15.9 mm

48 Adequacy Check (Pipe thk before bending < Available thk) OK

49

50

\\vboxsrv\conversion_tmp\scratch_3\[127480656.xls.ms_office.xls]24"hass

ATTACHMENT - 4

Wall Thickness Calculation of 48-RM2 GAS PIPELINE (Location Class-4, D.F.=0.4, Corr. Allow.=1mm)

G

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = t 2D P h S = ( ) E T T S i d th =s | |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s

t t D wPe ) 0.02466( = ( ) w Pe L e L w W + =

| |2 1 2 L h 2 L 2 h e 3T S S S S S + + = s t 2D P h S = s ebstress o s

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

s

| |

2

1

2

L h

2

L

2

h e

3T S S S S S + + =

t 2

D P

h

S =

( ) E T T S

i d th

=

s

s

t t D wPe ) 0.02466( = ( ) w Pe L e L w W + = t t D wPe ) 0.02466( = ( ) w Pe L e L w W + =

Page 4 of 5

1

2

3

4 48" HASSYAN GAS PIPELINE

5 Design Data

6 Pipe outside diameter D 1219 mm

7 Grade X65

8 SMYS of Line Pipe S 65000 psi

9 Design pressure P 960 psi

10 Design factor F 0.4

11 Weld joint factor E 1

12 Temp. derating factor T 1

13 Corrosion Allowance A 0 mm (as agreed with DUSUP)

14

15 Calculations

16 Calculated required thk, t (mm) 22.5

17 t = P x D / (2x Sx Fx E x T) + A

18 n, Inner Bend radius divided by diameter 4.5

19 % of wall thinning (50)/(n+1) 5.0 (see note)

20 Pipe Thk. Before bending (cal thk)/(1-thinning %) 23.7

21 The API available thickness for bend making (mm) 23.8

22 Adequacy Check (Pipe thk before bending < Available thk) OK

23 48" RM2 GAS PIPELINE

24 Design Data

25 Pipe outside diameter D 1219 mm

26 Grade X65

27 SMYS of Line Pipe S 65000 psi

28 Design pressure P 600 psi

29 Design factor F 0.4

30 Weld joint factor E 1

31 Temp. derating factor T 1

32 Corrosion Allowance A 0 mm (as agreed with DUSUP)

33

34 Calculations

35 Calculated required thk, t (mm) 14.1

36 t = P x D / (2x Sx Fx E x T) + A

37 n, Inner Bend radius divided by diameter 4.5

38 % of wall thinning (50)/(n+1) 5.0 (see note)

39 Pipe Thk. Before bending (cal thk)/(1-thinning %) 14.8

40 The API available thickness for bend making (mm) 15.9

41 Adequacy Check (Pipe thk before bending < Available thk) OK

42 24"HASS DIESEL PIPELINE

43 Design Data

44 Pipe outside diameter D 610 mm

45 Grade X52

46 SMYS of Line Pipe S 52000 psi

47 Design pressure P 720 psi

48 Design factor F 0.72

49 Weld joint factor E 1

50 Temp. derating factor T 1

51 Corrosion Allowance A 1

52

53 Calculations

54 Calculated required thk, t (mm) 6.9

55 t = P x D / (2x Sx Fx E x T) + A

56 n, Inner Bend radius divided by diameter 4.5

57 % of wall thinning (50)/(n+1) 5.0 (see note)

58 Pipe Thk. Before bending (cal thk)/(1-thinning %) 7.2

59 The API 5L available thickness for bend making (mm) 9.5

60 Adequacy Check (Pipe thk before bending < Available thk) OK

60 24"LEHB DIESEL PIPELINE

61 Design Data

62 Pipe outside diameter D 610 mm

63 Grade X52

64 SMYS of Line Pipe S 52000 psi

65 Design pressure P 720 psi

66 Design factor F 0.72

67 Weld joint factor E 1

68 Temp. derating factor T 1

69 Corrosion Allowance A 1

70

71 Calculations

72 Calculated required thk, t (mm) 6.9

73 t = P x D / (2x Sx Fx E x T) + A

74 n, Inner Bend radius divided by diameter 4.5

75 % of wall thinning (50)/(n+1) 5.0 (see note)

76 Pipe Thk. Before bending (cal thk)/(1-thinning %) 7.2

77 The API 5L available thickness for bend making (mm) 9.5

78 Adequacy Check (Pipe thk before bending < Available thk) OK

79 Note: Wall thinning is limited to 5% as per appendix 2 of Doc. No. 081113B-SP-307 Induction Bends Specification

80

81

5D Induction Bend Radius

\\vboxsrv\conversion_tmp\scratch_3\[127480656.xls.ms_office.xls]24"hass

Induction Bend thinning Calculation

ATTACHMENT - 5

Document No. 081113B-CL-300 Rev. A

As per BS 8010 Section 2.8

G

Page 5 of 5

Anda mungkin juga menyukai

- Wall THK Calculation Asme b31.4Dokumen7 halamanWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Dokumen1 halamanWall Thickness Calculation - ASME B31.8 2007 (Template)Hendra Yudistira100% (1)

- Wall Thickness Calculation of 36in Gas PipelineDokumen1 halamanWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- Permissible Elastic Bend Limit Calculations for PipelinesDokumen4 halamanPermissible Elastic Bend Limit Calculations for Pipelinesheldermanuel100Belum ada peringkat

- Wall Thickness Calculation ASME B31!8!2007Dokumen1 halamanWall Thickness Calculation ASME B31!8!2007shafeeqm3086Belum ada peringkat

- Pipe Thickness Calculation PDFDokumen1 halamanPipe Thickness Calculation PDFHeny Martha67% (3)

- ASME 31 - 8mDokumen1 halamanASME 31 - 8mMarcoAlbaBelum ada peringkat

- Reinforcement CheckDokumen2 halamanReinforcement Checkviv0102Belum ada peringkat

- Wall Thickness Calculation Verification under StressDokumen1 halamanWall Thickness Calculation Verification under StresshhgjdfBelum ada peringkat

- Thickness Analysis ReportDokumen9 halamanThickness Analysis ReportEhtisham AndrAbiBelum ada peringkat

- PIPELINE WALL THICKNESS CALCULATIONSDokumen24 halamanPIPELINE WALL THICKNESS CALCULATIONSMohsin RazaBelum ada peringkat

- ASME 31 - 4 CalcDokumen1 halamanASME 31 - 4 CalcMarcoAlbaBelum ada peringkat

- Area Reinforcement CalculatorDokumen5 halamanArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- ISO 13623 pipe wall thickness calculation for Mahani-2 projectDokumen6 halamanISO 13623 pipe wall thickness calculation for Mahani-2 projectRanjan KumarBelum ada peringkat

- ASME B31.8 Riser CalcDokumen12 halamanASME B31.8 Riser CalcSalz EngineeringBelum ada peringkat

- Blind flange design calculationDokumen4 halamanBlind flange design calculationmukesh100% (2)

- Calculation For Reinforced PadDokumen4 halamanCalculation For Reinforced Padjsridhar_34750% (2)

- Elastic Bending Radius Calculation of PIPELINESDokumen1 halamanElastic Bending Radius Calculation of PIPELINESmailmaverick816777% (13)

- PIPE THICKNESS CALCULATIONDokumen11 halamanPIPE THICKNESS CALCULATIONvazzoleralex6884100% (1)

- Pipe Wall Thickness Calculation ASME B31.8Dokumen16 halamanPipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- Pipe Is Under Clamping ForceDokumen7 halamanPipe Is Under Clamping Forcejosediaz141Belum ada peringkat

- Calculation of PipeReinforcement ASMEB31.1Dokumen3 halamanCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Upheval Bukling CalculationDokumen2 halamanUpheval Bukling Calculationbaghelrohit100% (7)

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDokumen117 halamanThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanBelum ada peringkat

- ASME B31.3.4.8 Wall Thickness CalculatorDokumen26 halamanASME B31.3.4.8 Wall Thickness Calculatoreko123Belum ada peringkat

- Gas Line - 20 BargDokumen22 halamanGas Line - 20 Bargsaravanakkumar boominahtan100% (1)

- SU Blind Plate ThicknessDokumen2 halamanSU Blind Plate Thicknessmanoj19801226100% (1)

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDokumen7 halamanPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiBelum ada peringkat

- Wall Thickness Pipeline (Gas) B31Dokumen25 halamanWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- Asme B31.8Dokumen14 halamanAsme B31.8omar equihua100% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Dokumen1 halamanPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadBelum ada peringkat

- Pipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionDokumen2 halamanPipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionImmanuel SBelum ada peringkat

- New - Reinforcement of NozzleDokumen24 halamanNew - Reinforcement of NozzleVaniya GoelBelum ada peringkat

- Pipeline Anchor Length CalculationsDokumen3 halamanPipeline Anchor Length Calculationslsatchithananthan100% (3)

- Above Ground Piping Wall Thickness CalculationsDokumen7 halamanAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Trunnion Calcualtion SheetDokumen22 halamanTrunnion Calcualtion SheetAbhijit0% (1)

- Pipe Wall Thickness CalculationDokumen1 halamanPipe Wall Thickness Calculationmahesh070Belum ada peringkat

- Upheaval Buckling CalculationDokumen6 halamanUpheaval Buckling Calculationheldermanuel100100% (2)

- Branch Reinforcement Pad Requirement CalculationDokumen2 halamanBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- ASME B31.4-Wall Thickness Calc For 6 InchDokumen2 halamanASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoBelum ada peringkat

- Blind Flange Thickness CalculationDokumen3 halamanBlind Flange Thickness CalculationKannapiran Krishnamoorthy75% (4)

- Area replacement calculation for CC1 E-1A LNG Vaporizer branchDokumen2 halamanArea replacement calculation for CC1 E-1A LNG Vaporizer branchJahsbuck100% (1)

- BlindDokumen3 halamanBlindSajal KulshresthaBelum ada peringkat

- Pipeline Wall Thickness Calculation PresentationDokumen31 halamanPipeline Wall Thickness Calculation PresentationGodwin0% (1)

- Pipeline Calculations - ASAB Gas Lift LinesDokumen11 halamanPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqBelum ada peringkat

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDokumen49 halamanDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Belum ada peringkat

- Pipe Bend Againts Coating 3LPE AnalisisDokumen25 halamanPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Pipe wall thickness calculation sheet for high pressure natural gas lineDokumen1 halamanPipe wall thickness calculation sheet for high pressure natural gas lineAris KancilBelum ada peringkat

- Miter B1 ADokumen55 halamanMiter B1 AFarid TataBelum ada peringkat

- Moment Connection - Flush End Plate-19.01.06Dokumen48 halamanMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- L 8 IhjnmklgfDokumen27 halamanL 8 IhjnmklgfbrintopvBelum ada peringkat

- Pipe Sizing and Wall Thickness Calculation SheetDokumen2 halamanPipe Sizing and Wall Thickness Calculation SheetWijayantoBelum ada peringkat

- Section VIII CalDokumen19 halamanSection VIII CalPradeep Kothapalli100% (1)

- SPAN Calc.Dokumen48 halamanSPAN Calc.yoi_123Belum ada peringkat

- ASME SECTION I CALCULATION FOR TUBE WALL THICKNESSDokumen9 halamanASME SECTION I CALCULATION FOR TUBE WALL THICKNESSgopaltryBelum ada peringkat

- K-4b Perhitungan PipaDokumen51 halamanK-4b Perhitungan PipaIndra MaulanaBelum ada peringkat

- Steam Drum, Water Wall & Evaporator - VWHA054Dokumen36 halamanSteam Drum, Water Wall & Evaporator - VWHA054Mani SunBelum ada peringkat

- Design of anchor bolts and base plate for a fixed base columnDokumen4 halamanDesign of anchor bolts and base plate for a fixed base columnSuryaSinghBelum ada peringkat

- GAS PIPELINE CALCULATIONDokumen37 halamanGAS PIPELINE CALCULATIONrasnowmah2012Belum ada peringkat

- Hydrotest Pressure CalculationDokumen26 halamanHydrotest Pressure CalculationChetan B Kapadia100% (13)

- 24x6 TappingDokumen1 halaman24x6 TappingDwi HermawanBelum ada peringkat

- Canalcrossing 139Dokumen3 halamanCanalcrossing 139Subuk NgaboBelum ada peringkat

- TIA 222 G ExplainedDokumen44 halamanTIA 222 G Explainedอภิรักษ์ มานะกิจศิริสุทธิBelum ada peringkat

- API 650 Storage Tank Design GuideDokumen58 halamanAPI 650 Storage Tank Design GuideDwi HermawanBelum ada peringkat

- Tower C - CDokumen42 halamanTower C - CDwi Hermawan100% (1)

- AHP TechniqueDokumen11 halamanAHP TechniqueManoj Singh100% (1)

- Ast 650, 653Dokumen1 halamanAst 650, 653Dwi HermawanBelum ada peringkat

- Life Cycle Shale GasDokumen52 halamanLife Cycle Shale GasDwi HermawanBelum ada peringkat

- Design of Piled FoundationDokumen62 halamanDesign of Piled FoundationSana UllahBelum ada peringkat

- Marwan and Waseem Al-Iraqi profileDokumen517 halamanMarwan and Waseem Al-Iraqi profileDwi Hermawan100% (1)

- AHP TechniqueDokumen11 halamanAHP TechniqueManoj Singh100% (1)

- Marwan and Waseem Al-Iraqi profileDokumen517 halamanMarwan and Waseem Al-Iraqi profileDwi Hermawan100% (1)

- Design of Piled FoundationDokumen62 halamanDesign of Piled FoundationSana UllahBelum ada peringkat

- International Codes V8iDokumen950 halamanInternational Codes V8iDwi HermawanBelum ada peringkat

- AHP TechniqueDokumen11 halamanAHP TechniqueManoj Singh100% (1)

- Engineering Drawing Symbols v1Dokumen122 halamanEngineering Drawing Symbols v1shaikh_nazarBelum ada peringkat

- Artigo Saaty 2008 AHPDokumen16 halamanArtigo Saaty 2008 AHPSeema DeviBelum ada peringkat

- Engineering Drawing Symbols v2Dokumen98 halamanEngineering Drawing Symbols v2shaikh_nazarBelum ada peringkat

- HDD Calculation (Template)Dokumen4 halamanHDD Calculation (Template)bebas_amarah87% (15)

- Horizontal Directional Drilling GuidelinesDokumen82 halamanHorizontal Directional Drilling GuidelinesDwi Hermawan86% (7)

- Perhitungan Box Culvert EnglishDokumen22 halamanPerhitungan Box Culvert EnglishDwi HermawanBelum ada peringkat

- Visual Assessment Manual FinalDokumen101 halamanVisual Assessment Manual FinalDwi HermawanBelum ada peringkat

- Perhitungan Sag KabelDokumen6 halamanPerhitungan Sag KabelDwi Hermawan100% (2)

- BEAMCOL13Dokumen8 halamanBEAMCOL13Dwi HermawanBelum ada peringkat

- Comparison of GB & ASME StandardsDokumen34 halamanComparison of GB & ASME StandardsMatin Maldar100% (2)

- Tutorial 3Dokumen2 halamanTutorial 3prasoon jhaBelum ada peringkat

- Power Bi ProjectsDokumen15 halamanPower Bi ProjectssandeshBelum ada peringkat

- Types of LogoDokumen3 halamanTypes of Logomark anthony ordonioBelum ada peringkat

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDokumen106 halamanManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoBelum ada peringkat

- 4 - Complex IntegralsDokumen89 halaman4 - Complex IntegralsryuzackyBelum ada peringkat

- Color Codes and Irregular Marking-SampleDokumen23 halamanColor Codes and Irregular Marking-Samplemahrez laabidiBelum ada peringkat

- Hotel and Restaurant at Blue Nile FallsDokumen26 halamanHotel and Restaurant at Blue Nile Fallsbig johnBelum ada peringkat

- EE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherDokumen23 halamanEE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherMirza Azhar HaseebBelum ada peringkat

- CIGB B164 Erosion InterneDokumen163 halamanCIGB B164 Erosion InterneJonathan ColeBelum ada peringkat

- The Invisible Hero Final TNDokumen8 halamanThe Invisible Hero Final TNKatherine ShenBelum ada peringkat

- Crash Cart - General Checklist For Medical Supplies On Crash CartsDokumen3 halamanCrash Cart - General Checklist For Medical Supplies On Crash CartsYassen ManiriBelum ada peringkat

- 40 Multiple Choice Questions in Basic StatisticsDokumen8 halaman40 Multiple Choice Questions in Basic StatisticsLevi CorralBelum ada peringkat

- Accidental PoisoningDokumen3 halamanAccidental PoisoningBRUELIN MELSHIA MBelum ada peringkat

- Fisher FIELDVUE DVC2000 Digital Valve Controller: Instruction ManualDokumen108 halamanFisher FIELDVUE DVC2000 Digital Valve Controller: Instruction ManualsrinuvoodiBelum ada peringkat

- OLA CAB MARKET ANALYSIS AND TRENDSDokumen55 halamanOLA CAB MARKET ANALYSIS AND TRENDSnitin gadkariBelum ada peringkat

- Voltaire's Candide and the Role of Free WillDokumen3 halamanVoltaire's Candide and the Role of Free WillAngy ShoogzBelum ada peringkat

- Java MCQ QuestionsDokumen11 halamanJava MCQ QuestionsPineappleBelum ada peringkat

- Ne 01 20 09 2018Dokumen436 halamanNe 01 20 09 2018VaradrajBelum ada peringkat

- Marijuana Grow Basics - Jorge CervantesDokumen389 halamanMarijuana Grow Basics - Jorge CervantesHugo Herrera100% (1)

- STERNOL Specification ToolDokumen15 halamanSTERNOL Specification ToolMahdyZargarBelum ada peringkat

- Body Scan AnalysisDokumen9 halamanBody Scan AnalysisAmaury CosmeBelum ada peringkat

- Startups Helping - India Go GreenDokumen13 halamanStartups Helping - India Go Greensimran kBelum ada peringkat

- 277Dokumen18 halaman277Rosy Andrea NicolasBelum ada peringkat

- English Skills BookDokumen49 halamanEnglish Skills BookAngela SpadeBelum ada peringkat

- Overview for Report Designers in 40 CharactersDokumen21 halamanOverview for Report Designers in 40 CharacterskashishBelum ada peringkat

- IEC-60721-3-3-2019 (Enviromental Conditions)Dokumen12 halamanIEC-60721-3-3-2019 (Enviromental Conditions)Electrical DistributionBelum ada peringkat

- HP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityDokumen65 halamanHP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityAlexandru BotnariBelum ada peringkat

- W1inse6220 PDFDokumen11 halamanW1inse6220 PDFpicalaBelum ada peringkat

- Donny UfoaksesDokumen27 halamanDonny UfoaksesKang Bowo D'wizardBelum ada peringkat