Reologíacickpea

Diunggah oleh

Eleazar EscamillaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Reologíacickpea

Diunggah oleh

Eleazar EscamillaHak Cipta:

Format Tersedia

CHEMISTRY/BIOCHEMISTRY

Flow Properties of Chickpea Proteins

L.H. LIU and T.V. HUNG

ABSTRACT Flow properties of aqueous chickpea protein dispersions were investigated. The dispersions had Newtonian flow behavior at concentrations up to 4%. Flow behavior became progressively less Newtonian as concentration increased above 4%. The apparent viscosity of the dispersions was pH and concentration dependent, being higher at the proteins most soluble pHs (pH 2 and 9) and lower at the isoelectric point (pH 4-5). Within the investigated temperatures (15, 25, 35 and 55 C), power law constants were unchanged up to 35 C but the flow behavior became non-Newtonian at 55 C. Denaturation by urea and sodium dodecyl sulphate (SDS) increased the consistency index (m), casson yield stress and apparent viscosities, and the flow became more pseudoplastic with a decrease in the flow index (n). Key Words: chickpea, protein dispersions, flow properties

MATERIALS & METHODS

Chickpea protein isolate

INTRODUCTION

CHICKPEA (CICER ARIETINUM L.) IS A PROtein rich crop, ranked as the 5th most important grain legume produced in the world (Uebersax and Ruengsakulrach, 1989). Chickpea seeds have been used for many traditional foods (Pushpamma and Geervani, 1987) and as ingredients in bakery products, imitation milk, infant formula and meat products (Verma et al., 1985; Morcos et al., 1983; Fermandez and Berry, 1989; Sosulski et al., 1978; Hung and Nithianandan, 1993). The nutritional value of chickpea protein compares favorably with that of other grain legumes (Williams and Singh, 1987; Pushpamma and Geervani, 1987). The effective utilization of proteins in the food industry depends on nutrient value and functional properties (Kinsella, 1976). Unlike soybean and other grain legume proteins, information on functional properties, particularly quantitative flow properties, of chickpea protein dispersions is scarce (Hulse, 1991; Chavan and Salunkhe, 1986). Flow properties are important in the design of unit operations such as mixing and pumping as well as the formulation of the most popular forms of chickpea based foods such as paste or beverages (Hermansson, 1975; Fermandez, 1987; Rao, 1977). Flow properties of protein dispersions are affected by environmental factors such as pH, ionic strength, temperature and conditions under which the protein is processed (Rha, 1978). Such factors, influence the geometry and behavior of a protein. Consequently, changes in flow behavior of a protein dispersion under certain conditions reflect changes in protein molecular structure and/or proteinprotein interactions caused by environmental and processing condition (Tung, 1978;

Howell and Lawrie, 1987). Our objective was to determine quantitative flow properties of chickpea protein dispersions and the relevant factors affecting their behavior.

The isolate was prepared from whole seed flour of the Kaniva cultivar, grown in Horsham, Victoria. The procedure was described previously (Liu et al., 1994) and as outlined (Fig. 1) was applied to produce isolates at a pilot scale plant at the Food Science Australia, Melbourne. The flour (40 kg) was extracted with water (200 L), and the extract adjusted to pH 9 with 3M NaOH at 25 C for 60 min. The slurry was separated with a commercial decanter (SD230, Nilsen company) and the residue was extracted with another 100 L of water. The combined extracts were desludged and precipitated at pH 4.2 with 3M HCl. The crude precipitated curd was

Authors Liu and Hung are with Food Science Australia, Private Bag 16, Werribee, Victoria, 3030, Australia.

Fig. 1 Schematic of chickpea protein isolate procedure.

Volume 63, No. 2, 1998JOURNAL OF FOOD SCIENCE

229

Flow Properties of Chickpea Proteins . . .

washed, neutralized and pasteurized before spray drying. The isolate contained about 89% protein, measured by a LECO combustion system (Liu et al., 1994).

Protein dispersions and flow properties

solution. The dispersions were prepared by mixing the protein for 1 h in urea or SDS solution at 25 C.

RESULTS & DISCUSSION

Effect of concentration

Protein dispersions (2, 4, 8, 12, 16 and 20% by weight of dry matter) were prepared by mixing the protein in an ultramixer (Ultra Turrax, TS25, 20,000 rpm) for 5 min. Each dispersion was adjusted to pH 7 with 1M NaOH. The protein dispersions were kept at 5C for 24h before their flow properties were examined. After being placed in the rheometer, each sample was equilibrated at the designated temperature for 25 min, before four readings were recorded at each shear rate. The shear rate/shear stress characteristics of each protein dispersion were measured with a Rheometer (Rheometer 30, Germany), based on rotational stresses at shear rates from 0.599 sec 1 to 1955 sec 1 at 25 C. For a thin dispersion, a coaxial cylinder type cup MSO was used while cup A, B or C was used for thick dispersions, based on the initial measurement with the rheometer. The following power law equation was used to express the flow properties of chickpea protein dispersions (Ma, 1983): m or log nlog

n

The flow curves of chickpea protein dispersions at different concentrations were established (not shown) and their slopes increased with increasing concentration. Up to 8%, the flow curves were linear, indicating Newtonian or near Newtonian behavior. Shear stress ( ) was a function of shear rate on a logarithmic scale for these chickpea protein dispersions (Fig. 2). Flow properties of many food protein dispersions have been reported to be characterized by the power Eq. (2) at several concentrations. Hermansson (1975) found that the flow properties of soy protein isolate, caseinate and whey protein concentrate conformed with the power equation at several concentrations. Similar observations were reported

for aqueous sunflower protein dispersions (Lefebvre and Sherman, 1977). Mita and Matsumoto (1980) found an excellent linearity of shear stress-shear rate plots at a shear rate range of 100-1000 sec 1 for gluten dispersions of different concentrations. Similar results were observed in our study for chickpea protein dispersions with good linearity at shear rates of 100 to 1750 sec 1. The effect of protein concentration was studied on power law constants and apparent viscosity of chickpea protein dispersions (Table 1). Up to 8% concentration, the dispersions were Newtonian (n 1) or near Newtonian as the apparent viscosities were unchanged with different shear rates (81.4 and 950 sec 1). At higher concentrations, non-Newtonian behavior became more pronounced (n 0.94 to 0.85). The apparent viscosities were affected by the change of shear rates, particularly at low range ( 100 sec 1) (Fig. 3). The consistency coefficient (m) increased exponentially with increasing concentrations (m Aec, Fig. 4a). An exponential increase

(1) logm (2)

is the shear stress (mPa), is the shear rate (sec 1), n is the flow index, m is the consistency coefficient. The yield values of the protein dispersions were calculated by the Casson equation:

k0

k1

(3)

The yield stress value ( y = k02) was obtained by extrapolating the rheogram of vs to zero shear rate. The apparent viscosity was calculated by: m

n 1

Fig. 2Shear stress ( ) as a function of shear rate (sec 1) on a log scale for chickpea protein dispersions at several concentrations.

Fig. 3Effect of protein concentration on the apparent viscosity of chickpea protein dispersions.

(4)

Effect of temperature and pH

Protein dispersions at 8% concentration were used to investigate the effects of temperature (15, 25, 35 and 55 C). Similarly, protein dispersions at 8% concentration were readjusted to pH 2, 5, 7 or 9 with 1M NaOH or HCl and measured at 25 C using the Rheometer as above.

Effect of ionic strength and protein denaturation

Protein dispersions at 8% concentration were prepared with 0.2, 0.5, 1 and 2M NaCl solution and flow properties were measured at 25 C and at pH 7. The effect of protein denaturation on flow properties was examined using 8% protein dispersions in 6M urea and in 1% sodium dodecyl sulphate (SDS)

230

Fig. 4The consistency index (m) of chickpea protein dispersions has exponential correlation with protein concentration (a), and is a function of protein concentration on a semilog scale (b).

JOURNAL OF FOOD SCIENCEVolume 63, No. 2, 1998

Flow Properties of Chickpea Proteins . . .

in the consistency coefficient with increasing protein concentration has been reported for oat protein (Ma, 1993). An index of viscosity (m) is a semilogarithmic function of concentration (ln m ln A c, Fig. 4b). The Casson Eq. (3) was fitted to the rheological data from chickpea dispersions (Fig. 5). From 16% a yield stress was apparent, both yield stress and apparent viscosities markedly increased with increasing concentrations (Table 1). The consistency coefficient (m) increased but the flow behavior index (n) decreased progressively with increasing concentration, reflecting a clear tendency towards pseudoplastic behavior with increasing concentrations. A concentration dependence was found for viscosity of chickpea protein. Similar relationships were reported for soy protein (Hermansson, 1975), faba bean protein (Schmidt et al., 1986), oat protein (Ma, 1983), beta-lactoglobulin (Pradipasena and Rha, 1977) and single cell protein concentrate (Huang and Rha, 1971). These results suggest a protein network was formed at high concentrations due to protein-protein interactions (Hermansson, 1975).

Effect of temperature

Table 1Effect of concentration on the power law constants and apparent viscosities of chickpea protein dispersionsa Conc (%) 2 4 8 12 16 20 nb 1.00 (r2 = 0.998) 0.99 (r2 = 0.998) 0.99 (r2 = 1.000) 0.94 (r2 = 1.000) 0.89 (r2 = 0.999) 0.85 (r2 = 0.997) mc (mPa) Casson yield stress (mPa) 1.06 1.85 4.68 13.3 32.4 82.4 0.00 0.02 0.17 3.40 36.3 80.2 Apparent Viscosity (mPa.s) 81.4 sec 1 950 sec 1 1.33 1.68 4.75 10.6 19.7 40.4 1.31 1.85 4.65 9.13 16.1 31.6

a Averages of four determinations at pH 7 and 25 C. bn flow behavior index. cm consistency coefficient.

Table 2Effect of temperature ( C) on the power law constants and apparent viscosities of 8% chickpea protein dispersionsa Temp ( C) 15 25 35 55 nb 0.98 0.99 0.97 0.68 mc (mPa) 5.13 4.68 5.50 44.7 Casson yield stress (mPa) 0.22 0.17 1.09 25.4 Apparent viscosity (mPa.s) 81.4 sec 1 950 sec 1 4.82 4.75 4.90 11.2 4.70 4.65 4.43 5.02

a Averages of four determinations of 8% protein dispersions at pH 7. bn flow behavior index. cm consistency coefficient.

The effect of temperature were determined on power law constants and apparent viscosity of 8% protein dispersions (Table 2). Up to 35 C, changes were minimal in either power law constants or apparent viscosities. At 55 C, the flow behavior index exponentially decreased, the consistency coefficient increased greatly and a yield stress became apparent. The flow behavior became more pseudoplastic. Apparent viscosities of chickpea protein dispersions markedly increased when the temperature increased from 35 to 55 C (Fig. 6) but the apparent viscosity at 55 C decreased at high shear rate (950 sec 1), in-

dicating that the flow deviated from Newtonian behavior. Increasing viscosity of protein dispersions in blood plasma protein associated with increasing temperature had been reported (Howell and Lawrie, 1987). Similar results were found with whey protein (Voutsinas et al., 1983), faba bean (Schwenke et al., 1990) and oat protein (Ma, 1983). The sensitivity of protein dispersion to thermal increase depends on the type of protein. Blood plasma protein is more thermally sensitive than beta lactoglobulin (Plock et al., 1992; Howell and Lawrie, 1987). The viscosity of blood plasma protein increased greatly at relatively low temperature (76 C) but whey protein was only affected at higher temperatures ( 80 C). The increase in viscosity of such protein dispersions indicated a change in the shape of the proteins as a result of the protein unfolding due to thermal treatment (Lee and Rha, 1979; Catsimpool-

as, 1970; Ma, 1983). In contrast to these observations, Mita and Matsumoto (1980) found that the apparent viscosities of 12% gluten and gluten methyl ester dispersion decreased from 20 to 50 C. When thermal effects were stronger than intermolecular interactions, contributed by hydrogen bonding, the apparent viscosity decreased. Consequently, other investigations indicated that the thermal effects on flow properties of protein, as with emulsifying properties (Voutsinas et al., 1983) were not consistent. The slight thermal effect on the apparent viscosities of chickpea protein dispersions suggests its characteristics are rather heat stable.

Effect of salts

Fig. 5Shear stress ( ) as a function of shear rate on a square root scale for chickpea protein dispersions at different concentrations.

Fig. 6Effect of temperatures on apparent viscosity of chickpea protein dispersions.

The effects of salt concentration on the power law constants, Casson yield stress and apparent viscosity of 8% protein dispersion were compared (Table 3). The flow curve was nearly linear up to 0.2M NaCl, indicating a Newtonian flow (not shown). The flow curves progressively deviated from Newtonian, between 0.2M and 1M NaCl but a reversal was observed at 2M NaCl. The flow behavior index (m) progressively decreased with increasing salt concentration up to 1M (n 0.99-0.73), indicating a shear thinning effect. In contrast no notable trend was noted for the consistency coefficient, which initially dropped at 0.2M, but, then increased up to 1M. The apparent viscosities reduced with salt addition and varied with a change of shear rate (81.4-950 sec 1). This indicated a progressive deviation of flow curves from Newtonian behavior. Reversal in trends in the apparent viscosity and other power law constants (n, m) occurred between 1 and 2M NaCl. Ma (1983) reported a similar tendency with oat protein dispersions at 1M salt concentration. Hermansson noted a similar reversal in apparent viscosity of a soy protein isolate between 0.5 and 1M NaCl. This reversal in trends was attributed to a salt con231

Volume 63, No. 2, 1998JOURNAL OF FOOD SCIENCE

Flow Properties of Chickpea Proteins . . .

centration critical for protein solubilization (Megen, 1974). Flow properties of protein dispersions were markedly influenced by ionic strength. Different salt concentrations (NaCl) increased or decreased the apparent viscosities of protein isolate dispersions. At low shear rate (10 sec 1) the apparent viscosities of 11.4% canola protein increased with salt concentration but at a high shear rate (1,000 sec 1) the apparent viscosities were decreased (Paulson and Tung, 1988). Hermansson reported that apparent viscosity of soy protein dispersions decreased with increasing salt concentration but a reversal was observed with caseinate. The different response of soy protein and caseinate to an ionic environment was influenced by a structural difference between the two proteins. Similarly, the flow behavior index of oat globulin dispersions (15%) decreased progressively with increasing salt concentration, showing an increasing pseudoplastic tendency. In our results, the addition of salt produced an insignificant effect on the apparent viscosity of chickpea protein dispersions. These results suggest that chickpea protein had a rather rigid structure which barely altered in a salt medium.

Effect of pH

Table 3Effect of salt concentration (NaCl/M) on the power law constants and apparent viscosities of 8% chickpea protein dispersionsa NaCl conc (M) 0.0 0.2 0.5 1.0 2.0 nb 0.99 0.98 0.84 0.73 0.78 mc (mPa) 4.68 3.02 9.33 22.1 16.2 Casson yield stress (mPa) 0.17 0.05 0.25 55.6 36.3 Apparent viscosity (mPa.s) 81.4 sec-1 950 sec-1 4.75 1.71 1.87 1.98 1.95 4.65 0.21 0.22 0.22 0.22

a Averages of four determinations of 8% protein dispersions at pH7 and 25 C. bn flow behavior index. cm consistency coefficient.

Table 4Effect of pH on the power law constants and apparent viscosities of 8% chickpea protein dispersionsa pH 2 5 7 9

bn cm

n(2) 0.91 (r2 = 1.000) 0.84 (r2 = 0.995) 0.99 (r2 = 1.000) 0.85 (r2 = 0.999)

flow behavior index. consistency coefficient.

mc (mPa) 12.9 6.01 4.68 20.4

Casson yield stress (mPa) 10.9 11.8 0.17 28.7

Apparent viscosity (mPa.s) 81.4 sec-1 950 sec-1 8.70 2.85 4.75 10.3 7.14 1.96 4.65 7.62

a Averages of four determinations of 8% protein dispersions at 25 C.

Table 5Effect of chemical modification (Urea/SDS) on the power law constants and apparent viscosities of 8% chickpea protein dispersionsa Sample Chickpea protein 6M urea treatedd 1% SDSe nb 0.99 0.84 0.54 mc (mPa) 4.70 39.5 326 Casson yield stress (mPa) 0.17 24.5 525 Apparent viscosity (mPa.s) 81.4 sec-1 950 sec-1 4.75 17.3 36.5 4.65 13.9 14.1

The effects of pH on power law constants, Casson yield stress and apparent viscosities of 8% protein dispersions were compared (Table 4). At pH 7, the flow was Newtonian with n 0.98, no yield stress and apparent viscosities unchanged at 81.4 and 950 sec 1. The flow progressively deviated from Newtonian behavior at both alkaline and acidic pHs with a decrease in flow behavior index and lower viscosities at high shear rate. The viscosity-pH curve resembled the typical solubility curve of chickpea protein. Minimum solubility occurred at the isoelectric pH (45) with much higher solubility at acidic or alkaline pH (2 or 9). Since apparent viscosities were concentration dependent, the viscosity was high at the proteins most soluble pHs (2 or 9) and was low at the isoelectric pH at which most protein was present as aggregates (Fig. 7). Like soy and canola protein (Ishino and Okamoto, 1975; Lee and Rha; 1979; Paulson and Tung, 1988) the high viscosity of chickpea protein at pH 9 is considered to be a combined effect of alkaline induced protein unfolding, dissociation into subunits and an increased protein solubility.

Effect of protein denaturing agents

a Averages of four determinations of 8% protein dispersions at pH7 and 25 C. bn flow behavior index. cm consistency coefficient. d 8% protein dispersion in 6M urea solution e 8% protein dispersion in 1% SDS

ment caused a decrease in n value and increases in m, yield stress and apparent viscosity. The effect of 1% SDS treatment on the flow characteristic of chickpea protein was much more pronounced. A sharp decrease in n value and increases in m, yield stress and apparent viscosity were observed. The flow behavior was much more pseudoplastic. A similar result was reported for oat globulin when treated with SDS and urea (Paulson and Tung, 1993). The marked increased in apparent viscosities of oat protein

was attributed to the unfolding effect of the denaturing agents (SDS and urea). Arce et al. (1991) reported that the dispensability of soy protein concentrate could be improved by up to 65% with SDS addition. Consequently, the improved solubility of chickpea protein caused by SDS and urea probably contributed to the change of flow behavior through changes in conformation of the proteins.

CONCLUSION

FLOW PROPERTIES OF CHICKPEA PROTEINS were considerably influenced by several environmental factors. Chickpea protein dispersions exhibited Newtonian behavior at low protein concentration or low salt concentration. Viscosity and pseudoplasticity increased with an increasing protein and/or salt concentration. The change in flow behavior resulted from the formation of a protein network, dissociation, ionic and hydrophobic interactions and particularly the changes in solubility of chickpea protein under different environmental conditions.

The effects of SDS and urea on the power law constants and apparent viscosity of chickpea protein dispersions were compared (Table 5). SDS has been used to improve the solubility of rapeseed, sunflower and soy protein (Nakai et al., 1980; Arce et al., 1991). The pronounced effect of 6-8 M urea on the unfolding of soy protein was noted (Shibasaki et al., 1969). In our results, urea treat232

REFERENCES

Arce, C.B., Pilosof, A.M.R. and Bartholomai, G.B. 1991. Sodium dodecyl sulfate and sulfite improve some functional properties of soy protein concentrates. J. Food Sci. 56: 113-115. Catsimpoolas, N. and Myer, E.W. 1970. Gelation phenomena of soybean globulins. Protein-protein interactions. Cereal Chem. 48: 559-570. Chavan, J.K. and Kadam, S.S. 1986. Biochemistry and technology of chickpea (Cicer arietinum L.) seeds.

Fig. 7Effect of pH on apparent viscosity (measured at 81.4 sec 1 ) and solubility curves of chickpea protein dispersions.

JOURNAL OF FOOD SCIENCEVolume 63, No. 2, 1998

Flow Properties of Chickpea Proteins . . .

CRC Critical Rev. Food Sci. Nutr. 25: 107-158. Fermandez, L.T. and Berry, J.W. 1987. Characteristics of a chocolate beverage from germinated chickpeas. J. Food Sci. 52: 726-728. Hermansson, A.M. 1975. Functional properties of proteins for foodsflow properties. J. Texture Stud. 5: 425-439. Howell, N.K. and Lawrie, R.A. 1987. Functional aspects of blood plasma protein V. Viscosity. Int. J. Food Sci. Technol. 22: 145-151. Huang, F. and Rha, C.K. 1971. Rheological properties of single cell protein concentrate: Dope formation and its flow behavior. J. Food Sci. 13: 1131-1134. Hulse, J.H. 1991. Keynote address: Nature, composition and utilisation of grain legumes, in Uses of Tropical Grain Legumes, p. 1-30, Proc. of a consultants meeting 27-30 March 1989 ICRISAT Center, India. Hung, T.V. and Nithianandan, V. 1993. Preparation and evaluation of noodles supplemented with lupin and chickpea flours. ASEAN Food J. 8: 26-31. Ishino, K. and Okamoto, S. 1975. Molecular interaction in alkali denatured soybean proteins. Cereal Chem. 52: 9-21. Kinsella, J.E. 1976. Functional properties of proteins in foods: a survey. Critical Review Food Sci. Nutr. 7: 219280. Lee, C.H. and Rha, C.K. 1979. Accelerated sedimentation test for the determination of dispersion stability of protein isolates. J. Food Sci. 44: 419-424. Lefebvre, J. and Sherman, P. 1977. Rheological properties of aqueous sunflower protein dispersions. J. Texture Stud. 8: 449-462. Liu, L.H., Hung, T.V., Black, R.G. and Trewhella, M.A. 1994. Solubility of grain legume proteins measured by infra-red spectroscopy. ASEAN Food J. 9: 24-29. Ma, C.Y. 1983. Flow properties of oat protein dispersions. J. Texture Stud. 24: 311-323. Megen-Van, W.H. 1974. Solubility behaviour of soybean globulins as a function of pH and ionic strength. J. Agric. Food Chem. 22: 126-129. Mita, T. and Matsumoto, H. 1980 Flow properties of aqueous Gluten and Gluten Methyl Ester Dispersions. Cereal Chem. 58: 57-61. Morcos, S.R., Said, A.K., Gabrial, G.N. and Hady, N.A.E. 1983. Supplementary and weaning foods for the Egyptian child. Nahrung 27: 295-304. Nakai, S., Ho, L., Tung, M.A. and Quinn, J.R. 1980. Solubilization of rapeseed, soy, sunflower protein isolates by surfactant and proteinase treatments. Can. Inst. Food Sci. Technol. J. 13: 14-22. Paulson, A.T. and Tung, M.A. 1988. Rheology and microstructure of succinylated canola protein isolate. J. Food Sci. 53: 821-825. Plock, J. and Kessler, H.G. 1992. Whey protein preparations use as additives in sour milk products. Leb. Milchwirtschaft 113: 928-932. Pradipasena, P. and Rha, C. 1977. Pseodoplastic and rheopectic properties of a globular protein (beta-lacto globulin) solution. J. Texture Stud. 8: 311-325. Pushpamma, P. and Geervani, P. 1987. Utilization of chickpea. in The Chickpea, M.C. Saxena and K.B. Singh (Ed), 357-381, Wallington, Oxon, U.K. CAB International, U.K. Rao, M.A. 1977. Rheology of liquid foods- A review. J. Texture Stud. 8: 135-168. Rha, C.K. 1978. Rheology of fluid foods. Food Technol. (7) 77-82. Schmidt, G., Schmendke, H. and Schottel, R. 1986. Viscosity behavior of Vicia faba bean protein isolates and their acetylated derivatives. Acta Alimentaria 15: 175-186. Schwenke, K.D., Prahl, L., Danilenko, A.N., Grinberg, V.J. and Tolstoguzov, V.B. 1990. Continuous conformational change in succinylated faba bean protein isolates. Nahrung 34: 399-401. Shibasaki, K., Kimura, Y. and Okubo, K. 1969. Food chemical studies on soybean proteins. Part VI. The viscotic behaviour of urea denatured protein. Nippon Shokuhin Kogyo gakkaishi 16: 298-303. Sosulski, F.W., Chakraborty, P. and Humbert, E.S. 1978. Legume based imitation and blended milk products. Can. Inst. Food Sci. Tech. J. 11: 117-123. Tung, M.A. 1978. Rheology of protein dispersions. J. Texture Stud. 9: 3-31. Uebersax, M.A. and Ruengsakulrach, S. 1989. Utilization of field beans, peas and lentils in Vegetable Protein Utilization in Human Foods and Animal Feedstuff, T.H. Applewhite (Ed.), p. 123-130, AOCS, Champaign, IL. Verma, M.M., Ledward, D.A. and Lawrie, R.A. 1988. Utilization of chickpea flour in sausages. Meat Sci. 11: 109-121. Voutsinas, L.P., Cheung, E. and Nakai, S. 1983. Relationships of hydrophobicity to emulsifying properties of heat denatured proteins. J. Food Sci. 48: 26-32. Williams, P.C. and Singh, U. 1987. Nutritional quality and the evaluation of quality in breeding programmes. In The Chickpea, M.C. Saxena and K.B. Singh (Ed.), p.329-356, Wallington, Oxon, CAB International, U.K. Ms received 3/25/97; revised 10/26/97; accepted 10/30/97.

We thank Drs. B. Imison, M. Palmer (AFISC) and U. Singh (ICRISAT, India) for discussions and Ms. D. Womersley (AFISC) for technical assistance. The financial support of the Australian Grains Research & Development Corporation (GRDC) and the collaboration of Victoria University of Technology are acknowledged.

Volume 63, No. 2, 1998JOURNAL OF FOOD SCIENCE

233

Anda mungkin juga menyukai

- Ciência e Técnica Vitivinícola Journal: ReviewDokumen2 halamanCiência e Técnica Vitivinícola Journal: ReviewEleazar EscamillaBelum ada peringkat

- Gac1, A Gene Encoding A Putative Gtpase-Activating Protein, Regulates Bikaverin Biosynthesis in Fusarium VerticillioidesDokumen9 halamanGac1, A Gene Encoding A Putative Gtpase-Activating Protein, Regulates Bikaverin Biosynthesis in Fusarium VerticillioidesEleazar EscamillaBelum ada peringkat

- Mathematical DescriptionDokumen6 halamanMathematical DescriptionEleazar EscamillaBelum ada peringkat

- Poultry Slaughter Wastewater Treatment With An Up - Ow Anaerobic Sludge Blanket (UASB) ReactorDokumen7 halamanPoultry Slaughter Wastewater Treatment With An Up - Ow Anaerobic Sludge Blanket (UASB) ReactorEleazar EscamillaBelum ada peringkat

- InTech-Airlift Bioreactors Hydrodynamics and Rheology Application To Secondary Metabolites ProductionDokumen44 halamanInTech-Airlift Bioreactors Hydrodynamics and Rheology Application To Secondary Metabolites ProductionEleazar EscamillaBelum ada peringkat

- Optimal Biocatalyst Loading in A Fixed BedDokumen7 halamanOptimal Biocatalyst Loading in A Fixed BedEleazar EscamillaBelum ada peringkat

- Capsaicin Recovery From A Cell Culture BrothDokumen5 halamanCapsaicin Recovery From A Cell Culture BrothEleazar EscamillaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Wild Plant SeedsDokumen14 halamanWild Plant Seedsmikebike123Belum ada peringkat

- Gout and FoodsDokumen2 halamanGout and Foodsfakename4bugmenotBelum ada peringkat

- Taxonomy (Biology)Dokumen11 halamanTaxonomy (Biology)jayeshepBelum ada peringkat

- Verbal Reasoning - 3 - Test BookletDokumen24 halamanVerbal Reasoning - 3 - Test BookleteidwisamBelum ada peringkat

- Nigerian Food Journal: Adetuyi, F.O. and Ibrahim, T.ADokumen10 halamanNigerian Food Journal: Adetuyi, F.O. and Ibrahim, T.AAndrea MarceloBelum ada peringkat

- How To Cultivate Curly Chilies in Pots-1Dokumen2 halamanHow To Cultivate Curly Chilies in Pots-1Nurul Rachman NasutionBelum ada peringkat

- s11274 022 03373 7Dokumen14 halamans11274 022 03373 7NisrinaBelum ada peringkat

- Flow SwitchDokumen16 halamanFlow Switchsales1068100% (1)

- Anther or Pollen CultureDokumen15 halamanAnther or Pollen Culturej131089Belum ada peringkat

- Sutton Chatter May 2018Dokumen16 halamanSutton Chatter May 2018Toby VueBelum ada peringkat

- Chemistry Biodiversity - 2023 - Antonio PereiraDokumen27 halamanChemistry Biodiversity - 2023 - Antonio PereiraMarcos RodriguesBelum ada peringkat

- Improving Grazing Management Measure To ManageDokumen8 halamanImproving Grazing Management Measure To ManageRemzi ZarateBelum ada peringkat

- BonsaiDokumen8 halamanBonsaiAllanBelum ada peringkat

- Uniit 9 399-408 DepEd-IPDokumen10 halamanUniit 9 399-408 DepEd-IPpeucogcoBelum ada peringkat

- Peninsula Gardens Improves Cannabis Cultivation With Condair RS SeriesDokumen4 halamanPeninsula Gardens Improves Cannabis Cultivation With Condair RS SeriesRuk RukBelum ada peringkat

- Biology SrSecDokumen12 halamanBiology SrSecdadan vishwakarmaBelum ada peringkat

- Water Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideDokumen10 halamanWater Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideKaushikBelum ada peringkat

- Cambridge Primary Science Skills Builder 1 PDFDokumen16 halamanCambridge Primary Science Skills Builder 1 PDFDilovar0% (2)

- GPP NarrativeDokumen13 halamanGPP NarrativeRaniel Alemania Lacuarin100% (1)

- Class 2 G.KDokumen8 halamanClass 2 G.Kborntowin08Belum ada peringkat

- STM 007 Gen Biology ReviewerDokumen12 halamanSTM 007 Gen Biology ReviewerAllessandra AlejandroBelum ada peringkat

- Madrasah Tsanawiyah Negeri Siak: Kementerian AgamaDokumen7 halamanMadrasah Tsanawiyah Negeri Siak: Kementerian AgamaAan_Kunaifi_5855Belum ada peringkat

- Mr. Johnny R. Galacio Address: 425 Clean Ville Manuyo I, Las Piñas City Contact Number: +639125627629 Email Address: Applying Position: PIPE FITTERDokumen4 halamanMr. Johnny R. Galacio Address: 425 Clean Ville Manuyo I, Las Piñas City Contact Number: +639125627629 Email Address: Applying Position: PIPE FITTERJustine Ralph BautistaBelum ada peringkat

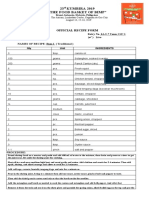

- 23 KUMBIRA 2019 "The Food Basket of Bimp": Official Recipe FormDokumen2 halaman23 KUMBIRA 2019 "The Food Basket of Bimp": Official Recipe FormRona GutierrezBelum ada peringkat

- Quote To Swimming PoolDokumen5 halamanQuote To Swimming PoolchaitanyaBelum ada peringkat

- Field Guide 0Dokumen54 halamanField Guide 0AfiQah AzizBelum ada peringkat

- Moong Dal RecipeDokumen6 halamanMoong Dal RecipeAnonymous QvdxO5XTRBelum ada peringkat

- 24 VASQ Method VitA Intake 2006Dokumen60 halaman24 VASQ Method VitA Intake 2006aruniakpBelum ada peringkat

- 100 Strains Printable PDFDokumen1 halaman100 Strains Printable PDFTarun A ChouhanBelum ada peringkat

- Irregular Verbs, Parts of Spech and Fruit, Vegitable NamesDokumen44 halamanIrregular Verbs, Parts of Spech and Fruit, Vegitable NamesYasir DharejoBelum ada peringkat