ECU Diagnostics

Diunggah oleh

esquisofDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ECU Diagnostics

Diunggah oleh

esquisofHak Cipta:

Format Tersedia

Series 1 All diagnostic connectors are located in the right hand side of the car in the large black

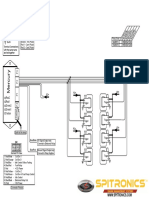

box. The cover can easily be removed by first removing the front cover exposing the relais followed by the top cover. This will expose the ECU's. From front to back the following ECU's can be found (dependant on the equipment installed) Hydroactive I or II, Engine ECU, ABS ECU. The diagnostic connectors can be found floating arround in the ECU compartment, and can be identified by their color. The diagnostic connectors are protected by a cover which can be removed. Hydroactive diagnostic connector : blue. Engine diagnostic connector : green (pin 2) ABS diagnostic connector : grey Airco diagnostic connector : black Series 2 I'm unsure from what, till what time the large 30 pins diagnostic connector is used. The connector is 3 pins wide and 10 pins long with the connector housing being brown. The pins are numbered 1,2,3 from top to bottom and A,B,C.,I,J from left to right. Hydroactive diagnostics pin : E2 Engine diagnostics pin : C3 ABS diagnostics pin : E1 Airco diagnostics pin : F1 The following circuit can be used to read out the diagnostic codes.

680 Ohm +12 V LED switch GND ( - of battery) To diagnostics pin

In case the large 30 pins diagnostic connector is present only a wire to connect the diagnostic pin to ground is needed. The readout will work via the diagnostic lights on the dashboard. (In case it doesn't work, one can always revert back to the circuit described above.) To start readout of the codes: 1. Connect the circuit above, with the switch opened. 2. Turn on ignition 3. Within 3 seconds close the switch for 3-5 seconds, and open it again 4. The start code 12 will apear. Blink, pause, blink,blink. 5. Press the switch again for 3-5 seconds, and open it again. 6a. Now the diagnostic codes will follow in case there is an error code stored. 6b. If no more codes are stored the end code 11 will apear. Blink, pause, blink. 7a repeat step 5 and 6 until all codes are read out 7b After the end code you can clear all codes. To clear all stored error codes: 1. First read out all codes described above 2. After the end code, close the switch for excactly 15 seconds. 3. Open the switch again 4. Now all stored codes are cleared. Alternatively you can erase all error codes by disconnecting the battery for 10 (or more) minutes. This will not only clear the codes, but also erase the 'learned' settings (eg for the engine) and refer back to factory default. To test engine components:

Code Description **** ECU XM Magneti Marelli G5 11 End test 12 Start test 13 Injection air temp sensor 14 Cooling water temp sensor 21 Throttle spindle potentiometer 22 Idling actuator / Idle speed regulator 23 Idle speed control failure 31 Automatic adjustment air/fuel ratio 33 Inlet manifold air pressure sensor 34 Canister discharge valve (active carbon filter) 41 Engine speed sensor 42 Fuel injector 45 Ignition coil 1-4

Check XM 2.0 RDZ XU10M Monopoint XM 2.0 R6A XU10J2 Monopoint (from '91)

Comp *** *** ***

4k@10C; 2,5k@20C; 680@55C 4k@10C; 2,5k@20C; 680@55C; 230@90C 4,5V max swing on pin 2

907 909 770 432

oxygen/lambda sensor too quick (disconnect heater element to resolve) 170 hPA : 0.25V, 1040 hPA : 4.8V between pin 9 and 12 (gnd) on ECU

900 903 430

52 Air/fuel mixture control loop 54 ECU malfunction 57 Ignition coil 2-3

345 Ohm between pin 14 and 31; check isolation to ground Check resistance of injector. 1.5 Ohm Check voltage between pin 1 and ground, should be +12V. Check primary windings should be 1.4 Ohm (between pin 1 and 4 on coil), secondary 8.6kOhm (Valeo) or 14kOhm (Bosch) inlet or outlet manifold leak or lambda-sensor failure Check voltage between pin 2 and ground, should be +12V. Check primary windings should be 1.4 Ohm (between pin 2 and 4 on coil), secondary 8.6kOhm (Valeo) or 14kOhm (Bosch)

152 570

142

Code Description Check **** ECU XM Bosch Motronic MP3.1 XM 2.0 RFZ XU10J2/Z Multipoint (till jun-93) 11 End test 12 Start test 13 Injection air temp sensor 14 Cooling water temp sensor 21 Throttle spindle potentiometer 22 Idling actuator / Idle speed regulator 31 Automatic adjustment air/fuel ratio

Comp *** *** ***

4k@10C; 2,5k@20C; 680@55C 4k@10C; 2,5k@20C; 680@55C; 230@90C Closed 0.5V, fully open 4.5V (minimal)

907 909 770 432 900

Check ogygen sensor, inlet&outlet manifold on leakage, fuel pressure, fuel injectors, spark plugs, air filter element, compression. 33 Inlet manifold air pressure sensor Is integrated in the ECU and cannot be checked. Check vacuum hose to ECU. 34 Canister discharge valve (active carbon filter) 245 Ohm between pin 23 and 25; check isolation to 41 Engine speed sensor ground When engine hot and running should constantly 51 Oxygen/lambda sensor change from 0 to 1V measured between pin 24 and pin 8. inlet or outlet manifold leak or lambda-sensor 52 Air/fuel mixture control loop failure 53 Sensor power supply Pin 16 and 5 should be connected to ground. Pin 18 should have +12V. 54 ECU malfunction

430 152 900

142

Code Description Check **** ECU XM Bosch Motronic MP3.2 XM 2.0 Turbo RGY or RGX XU10J2T/Z/L/L3 Multipoint Warning: Not checked against actual schematics! 11 End test 12 Start test 13 Injection air temp sensor 4k@10C; 2,5k@20C; 680@55C 14 Cooling water temp sensor 4k@10C; 2,5k@20C; 680@55C; 230@90C 21 Throttle spindle potentiometer Closed 0.5V, fully open 4.5V (minimal) 22 Idling actuator / Idle speed regulator Check ogygen sensor, inlet&outlet manifold on 31 Automatic adjustment air/fuel ratio leakage, fuel pressure, fuel injectors, spark plugs, air filter element, compression. 33 Inlet manifold air pressure sensor Is integrated in the ECU and cannot be checked. Check vacuum hose to ECU. 34 Canister discharge valve (active carbon filter) 330 Ohm between pin 48 and 49; check isolation to 41 Engine speed sensor ground 43 Engine knock control loop correct fuel grade, mechanical state engine 44 Anti-knock sensor Check mounting of sensor (torque: 20Nm) When engine hot and running should constantly 51 Oxygen/lambda sensor change from 0 to 1V measured between pin 28 and pin 10. inlet or outlet manifold leak or lambda-sensor 52 Air/fuel mixture control loop failure 53 Sensor power supply 54 ECU malfunction 65 Sensor reference cylinder Check fuel injector resistance. Should be 16 Ohm 71 Fuel injector 1 each. Check fuel injector resistance. Should be 16 Ohm 72 Fuel injector 2 each. Check fuel injector resistance. Should be 16 Ohm 73 Fuel injector 3 each. Check fuel injector resistance. Should be 16 Ohm 74 Fuel injector 4 each.

Comp ***

*** *** 907 909 770 432 900

430 152

150 900

142

Code Description **** ECU XM Bosch Motronic MP5.1 11 End test 12 Start test 13 Injection air temp sensor 14 Cooling water temp sensor 21 Throttle spindle potentiometer 22 Idling actuator / Idle speed regulator 31 Automatic adjustment air/fuel ratio

Check XM 2.0 RFZ XU10J2/Z Multipoint (from jul-93)

4k@10C; 2,5k@20C; 680@55C 4k@10C; 2,5k@20C; 680@55C; 230@90C Closed 0.5V, fully open 4.5V (minimal)

Comp *** *** *** 907 909 770 432 900

Check ogygen sensor, inlet&outlet manifold on leakage, fuel pressure, fuel injectors, spark plugs, air filter element, compression. 33 Inlet manifold air pressure sensor Is integrated in the ECU and cannot be checked. Check vacuum hose to ECU. 34 Canister discharge valve (active carbon filter) 41 Engine speed sensor 320-340 Ohm between pin 11 and 30; check isolation to ground 42 Fuel injectors Check resistance of each injector. Should be 16 Ohm each. 51 Oxygen/lambda sensor When engine hot and running should constantly change from 0 to 1V measured between pin 28 and pin 10. 52 Air/fuel mixture control loop inlet or outlet manifold leak or lambda-sensor failure 53 Sensor power supply Pin 19, 2 and 14 should be connected to ground. Pin 18, 37 should have +10-15.5V on them (+ from battery) 54 ECU malfunction

903 430 152 570 900

142

Code Description Check **** ECU XM Bosch Motronic MP5.1.1 XM 2.0 RFV XU10J4R/L/L3 (16V) Multiploint 11 End test 12 Start test 13 Injection air temp sensor 4k@10C; 2,5k@20C; 680@55C 14 Cooling water temp sensor 4k@10C; 2,5k@20C; 680@55C; 230@90C 21 Throttle spindle potentiometer Closed 0.5V, fully open 4.5V (minimal) 22 Idling actuator / Idle speed regulator 27 Vehicle speed sensor R=300 Ohm on sensor; When driving a speed relative signal on pin 9 31 Automatic adjustment air/fuel Check ogygen sensor, inlet&outlet manifold on ratio leakage, fuel pressure, fuel injectors, spark plugs, air filter element, compression. 33 Inlet manifold air pressure sensor Is integrated in the ECU and cannot be checked. Check vacuum hose to ECU. 34 Canister discharge valve (active carbon filter) 41 Engine speed sensor 320-340 Ohm between pin 11 and 30; check isolation to ground 42 Fuel injectors Check resistance of each injector. Should be 16 Ohm each. 43 Engine knock control loop correct fuel grade, mechanical state engine 44 Anti-knock sensor Check mounting of sensor (torque: 20Nm) 51 Oxygen/lambda sensor When engine hot and running should constantly change from 0 to 1V measured between pin 28 and pin 10. 52 Air/fuel mixture control loop inlet or outlet manifold leak or lambda-sensor failure 53 Sensor power supply Pin 19, 2 and 14 should be connected to ground. Pin 18, 37 should have +10-15.5V on them (+ from battery) 54 ECU malfunction

Comp *** *** *** 907 909 770 432 154 900

903 430 152 570

150 900

142

Code Description **** ECU XM V6 Fenix 3B 11 End test 12 Start test 13 Injection air temp sensor 14 Cooling water temp sensor 15 Fuel pump relais 21 Throttle spindle potentiometer 22 Idling actuator / Idle speed regulator 23 Throttle spindle potentiometer idle value 27 Vehicle speed sensor

Check

4k@10C; 2,5k@20C; 680@55C 4k@10C; 2,5k@20C; 680@55C; 230@90C 4,5V max swing on pin 9

Comp *** *** *** 907 909 807 770 432 770 154 900 903 430 818 152 570

0,5 +/- 0,1V between pin 9 and 17 (gnd)

R=300 Ohm on sensor; When driving 1,5Volt on pin 3 oxygen/lambda sensor too quick (disconnect heater 31 Automatic adjustment air/fuel ratio element to resolve) 33 Inlet manifold air pressure sensor 400Pa=2,5V; 600Pa=1,25V between pin 33 and 17 (gnd) 34 Canister discharge valve (active carbon filter) 36 Relais oxygen/lambda sensor heater 330 Ohm between pin 11 and 28; check isolation to 41 Engine speed sensor ground 14 Ohm each injector (2-3 Ohm between pin 20/21 42 Fuel injectors and pin 30) 43 Engine knock control loop correct fuel grade, mechanical state engine 44 Front anti-knock sensor When engine hot and running should constantly 51 Oxygen/lambda sensor change from 0 to 1V on pin 35 from pin 32 (gnd) 52 Air/fuel mixture control loop inlet or outlet manifold leak 53 Sensor power supply 10-15,5V on pin 4 ECU from gnd (pin 1). 54 ECU malfunction 56 Anti-theft start code not entered 62 Rear anti-knock sensor

150 900

142 176 151

Code Description **** ECU XM V6 Fenix 3B (activate components) Component activation is performed 91 Activate fuel pump relais 92 Activate fuel injectors 93 Activate idling actuator 94 Activate canister discharge valve 95 Activate relais airco compressor **** ECU XM V6 Fenix 3B (Mixture adjustment) 11 Make mixture richer 22 Make mixture leaner 33 Program start 99 upper or lower limit reached ECU XM V6 Fenix 3B (Ignition timing adjustment) 11 2 degrees advance 12 4 degrees advance 13 6 degrees advance 14 8 degrees advance 19 default setting 22 Program start 99 upper or lower limit reached

Comp **** 807 570 432 430 822 ****

****

****

Code Description Check Comp **** ECU Hydroactive I/II suspension Version HI and HII pinning are totally different. **** 11 End test *** 12 Start test *** 21 Brake pressure switch 670 Switch will open when firm brake pressure applied (HI measure between pin 7 white and ground, HII between pin 11 black and gnd) 22 Accelerator pedal position 771 Pedal up=3-4V; pedal down<3V. HI measure potentiometer (situated under between pin 10 white and ground. HII between pin pedal) 4 black and ground. 23 Steering wheel position sensor 159 Will alternate between 0 and +5V when slowly moving steering wheel. HI: Measure on both on pins 6 and 13 white to pin 12 white which is ground. HII: pin 9,10,15 black and 13 white are for steering wheel sensor. Two pins for position, other two for power supply and ground. 24 Vehicle speed sensor 154 HI: R=300 Ohm on speed sensor, when driving ca 1,5V on pin 13 black. HII: measure speed signal on pin 11 white. 25 Vehicle height sensor 153 Will alternate between 0 and +5V when vehicle height is changed. HI: Measure on both on pins 3 and 4 black to ground. HII measure on both pins 13 and 14 black to ground. 31 Electrovalve firm/soft suspension R=3-5 Ohm, when valve is operated suspension is 433 soft. HI: Measure between pin 9 black and ground. HII: Measure between pin 1 white and ground. When valve is acivated measure 12 volt, followed by an alternating signal at a few hundred Hertz. 32 Back electrovalve firm/soft Only present on Hydroactive II. R=3-5 Ohm, when suspension valve is operated suspension is soft. HII: Measure between pin 2 white and ground. When valve is acivated measure 12 volt, followed by an alternating signal at a few hundred Hertz. 53 ECU powersupply HI: check fuse 34. HII: check fuse 7. 54 ECU malfunction

Code Description **** ECU ABS (Teves version) 11 12 13 End test Start test Electrovalves supply

15 21 22 24 25 31 32 33 34 35 41 42 43

Electrovalves relais. Electrovalves relais. Electrovalves relais. LH rear wheel sensor RH front wheel sensor RH rear wheel sensor LH front wheel sensor LH rear wheel sensor signal RH front wheel sensor signal RH rear wheel sensor signal LH front wheel sensor signal Electrovalve RH front inlet Electrovalve RH front return

44

Electrovalve LH front inlet

45

Electrovalve LH front return

51

Electrovalve rear

55

Error in ECU memory

Check Comp Teves version is with two seperature units, Bendix has valves and ecu integrated. *** *** check resistance on electrovalves 2-4Ohm each. 41 Pin 1,2,3,4,5 on 7 pin connector against pin 5 on 5 pin connector Check resistance between pin 2 and 3 on 5 pin 41 connector 50-60Ohm Check resistance between pin 2 and 3 on 5 pin 41 connector 50-60Ohm Check wiring to electrovalves on shortcircuit or loose connection Measure R=1-1,4kOhm (after 3-94 R=2,2157 3,2kOhm), between pin 15 and 32 on ECU Measure R=1-1,4kOhm (after 3-94 R=2,2156 3,2kOhm), between pin 16 and 33 on ECU Measure R=1-1,4kOhm (after 3-94 R=2,2158 3,2kOhm), between pin 17 and 34 on ECU Measure R=1-1,4kOhm (after 3-94 R=2,2155 3,2kOhm), between pin 18 and 35 on ECU Check signal, check air-gap between teeth-sensor, 157 check teeth condition Check signal, check air-gap between teeth-sensor, 156 check teeth condition Check signal, check air-gap between teeth-sensor, 158 check teeth condition Check signal, check air-gap between teeth-sensor, 155 check teeth condition Check resistance of electrovalve between pin 2 on 41 7 pin connector and pin 5 on 5 pin connector Check resistance of electrovalve 2-4 Ohm between 41 pin 4 on 7 pin connector and pin 5 on 5 pin connector Check resistance of electrovalve 2-4 Ohm between 41 pin 3 on 7 pin connector and pin 5 on 5 pin connector Check resistance of electrovalve 2-4 Ohm between 41 pin 5 on 7 pin connector and pin 5 on 5 pin connector Check resistance of electrovalve 2-4 Ohm between 41 pin 1 on 7 pin connector and pin 5 on 5 pin connector 140

Code Description **** ECU ABS (Bendix version) 11 12 13 15 21 22 24 End test Start test Electrovalves supply Electrovalves relais. Electrovalves relais. Electrovalves relais. LH rear wheel sensor

Check Teves version is with two seperature units, Bendix has valves and ecu integrated.

25

RH front wheel sensor

31

RH rear wheel sensor

32

LH front wheel sensor

33 34 35 41 42 43 44 45 51 55

LH rear wheel sensor signal RH front wheel sensor signal RH rear wheel sensor signal LH front wheel sensor signal Electrovalve RH front inlet Electrovalve RH front return Electrovalve LH front inlet Electrovalve LH front return Electrovalve rear Error in ECU memory

Check Relais Check Relais Check Relais Measure R=1-1,4kOhm (Bendix type) or R=2,23,2kOhm (Bendix/Siemens type), between pin 19 and 28 on ECU Measure R=1-1,4kOhm (Bendix type) or R=2,23,2kOhm (Bendix/Siemens type), between pin 1 and 6 on ECU Measure R=1-1,4kOhm (Bendix type) or R=2,23,2kOhm (Bendix/Siemens type), between pin 29 and 31 on ECU Measure R=1-1,4kOhm (Bendix type) or R=2,23,2kOhm (Bendix/Siemens type), between pin 15 and 30 on ECU Check signal, check air-gap between teeth-sensor, check teeth condition Check signal, check air-gap between teeth-sensor, check teeth condition Check signal, check air-gap between teeth-sensor, check teeth condition Check signal, check air-gap between teeth-sensor, check teeth condition

Code Description **** ECU Airconditioning (Full automatic, Semi automatic with/without airco) 11 End test 12 Start test Airflow direction valve position 13 potentiometer signal 14 Airflow direction valve position potentiometer short-circuit 15 Recirculation valve position potentiometer signal 16 Recirculation valve position potentiometer short-circuit 17 Airflow direction valve position signal swing not correct 18 Hot air/cold air control valve position signal swing not correct. Hot air/cold air control valve 21 position potentiometer signal 22 Hot air/cold air control valve position potentiometer shortcircuit Evaporator temperature sensor signal Evaporator temperature sensor short-circuit Outdoor temperature sensor signal

Check

Comp

Full auto only; pin 3 black voltage should vary when changing vent position.

*** *** 710 710

Full auto only; pin 4 black voltage should change when changing recirculation.

711 711

710 Full automatic only. Electrovalve on RH side of mid-console. Full automatic only. Electrovalve on LH side of mid- 700 console. Full auto: pin 15 black. Other: pin 3 blue. Signal 700 should vary when changing temperature between min and max. 700

23

Full auto: Between pin 14 black and pin 1 black. Semi auto: Between pin 2 blue and pin 1 black. R=10k@10C; 6k@20C; 5k@25C; 4k@30C

912

24 25

912 In air-inlet. Full auto: Between pin 13 black and pin 908 1 black. Semi auto: Between pin 1 blue and pin 1 black. R=20k@10C; 12,5k@20C; 10k@25C; 8k@30C 908

26 27 31

32 33 34 35 36

41 42 43

44

Outdoor temperature sensor short-circuit 711 Recirculation valve position signal Full automatic only. Electrovalve on blower unit? swing not correct Interior temperature sensor signal Full auto: Between pin 10 blue and pin 1 black. 913 Semi auto: Between pin 5 black and pin 1 black. R=20k@10C; 12,5k@20C; 10k@25C; 8k@30C 913 Interior temperature sensor shortciruit Interior air blower motor signal Semi auto only. If only highest speed works, check 681 line interrupted transistors on control module on blower motor. Semi auto only. 681 Interior air blower motor signal line short-circuit Hot air/cold air flap motor line Full auto: Between pin 6 and 7 black. Semi auto: 700 interrupted Between pin 9 and 10 blue. R=50Ohm. Hot air/cold air flap motor line See fault 35. Typical fault are worn motor brushes, 700 short-circuit which cause short-circuit. Can be solved by reshaping brushes (eg. with a knife). Air blower speed potentiometer Semi auto only. Visually check potentiometer track 183 signal interrupted on pcb. Air blower speed potentiometer Semi auto only. Visually check potentiometer track 183 signal short-circuited on pcb. Semi auto only. Visually check potentiometer track 182 Temperature selection on pcb. potentiometer signal signal interrupted Semi auto only. Visually check potentiometer track 182 Temperature selection potentiometer signal signal short- on pcb.

Anda mungkin juga menyukai

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDari EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusBelum ada peringkat

- EPS ReportDokumen58 halamanEPS ReportAyush GhoshBelum ada peringkat

- Peugeot All Models Wiring Diagrams - GeneralDokumen30 halamanPeugeot All Models Wiring Diagrams - GeneralLoki_YOBelum ada peringkat

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDari EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualBelum ada peringkat

- HTG GCU GS7d36sg Installation v12Dokumen9 halamanHTG GCU GS7d36sg Installation v12Ioan Alexandru DragomirBelum ada peringkat

- L Jetronic PinoutDokumen3 halamanL Jetronic PinoutHlias AlafogiannisBelum ada peringkat

- Advanced Seat Suspension Control System Design for Heavy Duty VehiclesDari EverandAdvanced Seat Suspension Control System Design for Heavy Duty VehiclesBelum ada peringkat

- DTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureDokumen3 halamanDTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureOswaldo Sierra100% (1)

- Transit.2014.5. (08 2013-)Dokumen248 halamanTransit.2014.5. (08 2013-)Matija PiljekBelum ada peringkat

- Electude Simulator Challenge - Level 1Dokumen1 halamanElectude Simulator Challenge - Level 1dank12375% (4)

- NCV4276, NCV4276A 400 Ma Low-Drop Voltage Regulator: Dpak 5 PIN DT Suffix Case 175aaDokumen26 halamanNCV4276, NCV4276A 400 Ma Low-Drop Voltage Regulator: Dpak 5 PIN DT Suffix Case 175aaalmia tronicsBelum ada peringkat

- VolvoDokumen1 halamanVolvoAnonymous OFfJVrQY6Belum ada peringkat

- EFI2 HarnessDokumen1 halamanEFI2 Harnessracing snake50% (2)

- Diagnostic Manual-A-ECUDokumen27 halamanDiagnostic Manual-A-ECURıdvan KurtulduBelum ada peringkat

- WDS BMW Wiring Diagram System - Model 3 E46Dokumen1 halamanWDS BMW Wiring Diagram System - Model 3 E46Alex ZakutashviliBelum ada peringkat

- Audi AC Control UnitDokumen19 halamanAudi AC Control Unitredmouse10Belum ada peringkat

- Uni-Swc 3Dokumen48 halamanUni-Swc 3AbrahamAcostaGonzalez50% (2)

- Data Explorer Engine Ecu Decoding Version 6.0Dokumen7 halamanData Explorer Engine Ecu Decoding Version 6.0Beniamin CociorvanBelum ada peringkat

- Iot Ecuwiring PDFDokumen38 halamanIot Ecuwiring PDFBruno DuroBelum ada peringkat

- Hardware For SetConfig 4 - 0 PDFDokumen6 halamanHardware For SetConfig 4 - 0 PDFOvidiu MarinBelum ada peringkat

- Bosch Edc17cp05 Irom TC1797 Ford PDFDokumen6 halamanBosch Edc17cp05 Irom TC1797 Ford PDFAlpine LeeBelum ada peringkat

- 8cyl 8coil Ext PDFDokumen1 halaman8cyl 8coil Ext PDFwallyBelum ada peringkat

- DTC C1249/49 Open in Stop Light Switch Circuit: DescriptionDokumen4 halamanDTC C1249/49 Open in Stop Light Switch Circuit: DescriptionAmil AnAmBelum ada peringkat

- Fuel Injection System-405 GLX XU7 Siemens PetrolDokumen2 halamanFuel Injection System-405 GLX XU7 Siemens Petrolامین پارساBelum ada peringkat

- Maintenance Manual of Chery Karry - Circuit DiagramDokumen16 halamanMaintenance Manual of Chery Karry - Circuit DiagramUmar ShamsudinBelum ada peringkat

- CAN BUS Wire RepairDokumen1 halamanCAN BUS Wire RepairMMBelum ada peringkat

- CDS61236 Ethernet Superseal Connector Cable 1.8M (Rev A and Rev B)Dokumen2 halamanCDS61236 Ethernet Superseal Connector Cable 1.8M (Rev A and Rev B)JAVIER ROMEROBelum ada peringkat

- Throttle Body Explanation and CalibrationDokumen2 halamanThrottle Body Explanation and CalibrationReynaldo FloresBelum ada peringkat

- ADAS Description enDokumen10 halamanADAS Description enIonut-alexandru IordacheBelum ada peringkat

- Wiring Layout For Dta EcuDokumen5 halamanWiring Layout For Dta EcuJay Daffurn100% (3)

- Audi Q5 Quattro (8RB) - EWD HeadlampsDokumen43 halamanAudi Q5 Quattro (8RB) - EWD HeadlampsRodolfo DiazBelum ada peringkat

- Hitachi A56-Y8x Renault SamsungDokumen6 halamanHitachi A56-Y8x Renault SamsungXavi GuerreroBelum ada peringkat

- NGK Generator Honda EngineDokumen31 halamanNGK Generator Honda EnginebcqbaoBelum ada peringkat

- Fgtech Tested EcuDokumen9 halamanFgtech Tested EcuHarris RaoBelum ada peringkat

- KWP 2000Dokumen4 halamanKWP 2000mazacotesBelum ada peringkat

- Galletto 1260 Car ListDokumen28 halamanGalletto 1260 Car ListPosada Burgueño CarlosBelum ada peringkat

- ABS Mod - LAND ROVER CLUB V.IDokumen79 halamanABS Mod - LAND ROVER CLUB V.Itim yerbyBelum ada peringkat

- Honda Accord 24Dokumen5 halamanHonda Accord 24Osmar AugustoBelum ada peringkat

- Welcome Common Rail Diesel Fuel Systems: To A Technical Overview ofDokumen61 halamanWelcome Common Rail Diesel Fuel Systems: To A Technical Overview ofMuhammad DinataBelum ada peringkat

- Fusilera Peugeot 308 Mk2 2013-15Dokumen3 halamanFusilera Peugeot 308 Mk2 2013-15skpppBelum ada peringkat

- E90 PDC PinoutDokumen2 halamanE90 PDC PinoutkojcanBelum ada peringkat

- Dicktator Multi Tooth Plug LayoutDokumen1 halamanDicktator Multi Tooth Plug LayoutAndrew SueltzBelum ada peringkat

- Plano Electrico BMWDokumen5 halamanPlano Electrico BMWPosada Burgueño CarlosBelum ada peringkat

- BMW GS6-17BG-5Dokumen7 halamanBMW GS6-17BG-5Jordy PerezBelum ada peringkat

- 968 Fuse Box ChartDokumen1 halaman968 Fuse Box Chartdamon wBelum ada peringkat

- 04 Schematic DiagramDokumen48 halaman04 Schematic Diagramkovan1Belum ada peringkat

- MST-9000+ User's ManualDokumen13 halamanMST-9000+ User's ManualSoeAyeBelum ada peringkat

- MAC MPC Programmer ModificationDokumen5 halamanMAC MPC Programmer ModificationAlexandre Da Silva Pinto100% (1)

- Immo BypassDokumen1 halamanImmo BypassPaul LuczonBelum ada peringkat

- FIAT Car Radio Stereo Audio Wiring Diagram Autoradio Connector Wire Installation Schematic Schema Esquema de Conexiones Stecker Konektor Connecteur Cable ShemaDokumen15 halamanFIAT Car Radio Stereo Audio Wiring Diagram Autoradio Connector Wire Installation Schematic Schema Esquema de Conexiones Stecker Konektor Connecteur Cable ShemaxradosBelum ada peringkat

- V850ESDokumen6 halamanV850ESVictor Ramalho100% (1)

- Digifant MP 4.0Dokumen30 halamanDigifant MP 4.0victorvicvicBelum ada peringkat

- Opel Vectra BX 25 XeDokumen1 halamanOpel Vectra BX 25 XeNikola Lordan0% (1)

- Pinout-Schematic DiagramsDokumen14 halamanPinout-Schematic DiagramsIvan RdzBelum ada peringkat

- m1 5 5 PDFDokumen5 halamanm1 5 5 PDFEd Aguilar MartinsBelum ada peringkat

- SCHEMA Citroen C3 PDFDokumen4 halamanSCHEMA Citroen C3 PDFMani Fekkar (LuXar)Belum ada peringkat

- TC1797 - DS - V1 3Dokumen192 halamanTC1797 - DS - V1 3Anonymous xTGQYFrBelum ada peringkat

- Vehicle ListDokumen30 halamanVehicle ListRoger SegoBelum ada peringkat

- Code 368 PDFDokumen2 halamanCode 368 PDFesquisof0% (1)

- 428L2 PDFDokumen13 halaman428L2 PDFesquisofBelum ada peringkat

- Manual de Taller Chery QQDokumen635 halamanManual de Taller Chery QQOrlando Parra100% (1)

- Code 368 PDFDokumen2 halamanCode 368 PDFesquisof0% (1)

- Toyota Rav4 2008-U241e PDFDokumen396 halamanToyota Rav4 2008-U241e PDFesquisof78% (9)

- 15 - Automatic TransaxleDokumen246 halaman15 - Automatic TransaxleesquisofBelum ada peringkat

- Yaris 1nz-Fe (Engine)Dokumen12 halamanYaris 1nz-Fe (Engine)esquisofBelum ada peringkat

- Engine MechanicDokumen631 halamanEngine Mechanicgeorge100% (1)

- 1ktze Pinin-PinoutDokumen11 halaman1ktze Pinin-PinoutKooked100% (9)

- SolenoidDokumen34 halamanSolenoidesquisof100% (2)

- Diagnostics SRSDokumen172 halamanDiagnostics SRSesquisofBelum ada peringkat

- Fuso FE - FG PartDokumen156 halamanFuso FE - FG Partesquisof88% (8)

- K41A - CVT - General InfoDokumen60 halamanK41A - CVT - General Infoesquisof86% (7)

- Abbreviations Used in This ManualDokumen126 halamanAbbreviations Used in This ManualSteve Fisher100% (6)

- 1KR-FE Engine Control SystemDokumen346 halaman1KR-FE Engine Control SystemMortada Alsonni80% (20)

- 變速箱 A245E,A246E ZZE121Dokumen136 halaman變速箱 A245E,A246E ZZE121esquisof67% (9)

- Mercedes Benz Fault Code ManualDokumen107 halamanMercedes Benz Fault Code ManualAnthony75% (53)

- Toyota p1222Dokumen5 halamanToyota p1222esquisof71% (7)

- IawengDokumen55 halamanIawengajca1959Belum ada peringkat

- NissanDokumen312 halamanNissanesquisof86% (14)

- 9441 Panasonic SA-AK450P 450PC Sistema de Sonido Con CD Casette Manual de ServicioDokumen105 halaman9441 Panasonic SA-AK450P 450PC Sistema de Sonido Con CD Casette Manual de ServicioesquisofBelum ada peringkat

- Mercedes Benz Obd II Fault Code TableDokumen8 halamanMercedes Benz Obd II Fault Code TableTinko Stoyanov100% (1)

- Pages From 722 6 ETC Error Code-PartBDokumen22 halamanPages From 722 6 ETC Error Code-PartBesquisof71% (7)

- 02 WgetDokumen260 halaman02 WgetesquisofBelum ada peringkat

- Remove - Install Electronic Selector Lever Module (ESM)Dokumen2 halamanRemove - Install Electronic Selector Lever Module (ESM)esquisofBelum ada peringkat

- Building 16 PrintDokumen112 halamanBuilding 16 PrintNALEEMBelum ada peringkat

- Programmable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461Dokumen18 halamanProgrammable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461MAICK_ITSBelum ada peringkat

- Fire Protection Design For Healthcare FacilitiesDokumen34 halamanFire Protection Design For Healthcare Facilitiesapi_fabianBelum ada peringkat

- Logcat 1693362990178Dokumen33 halamanLogcat 1693362990178MarsBelum ada peringkat

- CT2000 Manual EN 20151202 PDFDokumen634 halamanCT2000 Manual EN 20151202 PDFKhang NguyenBelum ada peringkat

- Apple A9Dokumen10 halamanApple A9Savithri NandadasaBelum ada peringkat

- Cooling Water BasicsDokumen163 halamanCooling Water BasicsEduardo Castillo100% (1)

- GIT CloudDokumen20 halamanGIT CloudGyanbitt KarBelum ada peringkat

- Internet Intranet ExtranetDokumen28 halamanInternet Intranet ExtranetAmeya Patil100% (1)

- Class 7 Science Electric Current and Its EffectsDokumen7 halamanClass 7 Science Electric Current and Its Effectsshanna_heenaBelum ada peringkat

- Floor Plans & ElevationsDokumen6 halamanFloor Plans & Elevationsbryan cardonaBelum ada peringkat

- Omron ManualDokumen44 halamanOmron ManualHaroDavidBelum ada peringkat

- Chapter 2 Magnetic Effects of Current XDokumen25 halamanChapter 2 Magnetic Effects of Current XPawan Kumar GoyalBelum ada peringkat

- The Yield Stress MythDokumen5 halamanThe Yield Stress MythRavi Kiran TađaþanenǐBelum ada peringkat

- Suzuki B-King Indicator Mod CompleteDokumen9 halamanSuzuki B-King Indicator Mod Completehookuspookus1Belum ada peringkat

- Jrules Installation onWEBSPHEREDokumen196 halamanJrules Installation onWEBSPHEREjagr123Belum ada peringkat

- BEC198 (Finals)Dokumen180 halamanBEC198 (Finals)Lorenz BerroyaBelum ada peringkat

- PT 0817 Cebu Room Assignment PDFDokumen16 halamanPT 0817 Cebu Room Assignment PDFPhilBoardResultsBelum ada peringkat

- SA Flight Instructors Training ProceduresDokumen371 halamanSA Flight Instructors Training ProceduresGuilioBelum ada peringkat

- M Block PDFDokumen45 halamanM Block PDFKristina ViskovićBelum ada peringkat

- Heat ExchangersDokumen25 halamanHeat ExchangersMohammed Kabiruddin100% (7)

- Advanced Lathe Milling Report Batch 2Dokumen3 halamanAdvanced Lathe Milling Report Batch 2Tony SutrisnoBelum ada peringkat

- Computer SoftwareDokumen3 halamanComputer SoftwareCyrine CalagosBelum ada peringkat

- CambuzaDokumen45 halamanCambuzaMia Marin Pâslaru100% (2)

- Practice Exam 1Dokumen7 halamanPractice Exam 1425Belum ada peringkat

- 200 Questions AnswersDokumen150 halaman200 Questions AnswersvempadareddyBelum ada peringkat

- DO 178 B Brief NotesDokumen18 halamanDO 178 B Brief NotesMani Shankar PrasadBelum ada peringkat

- APP157 CoP For Site Supervision 2009 202109Dokumen92 halamanAPP157 CoP For Site Supervision 2009 202109Alex LeungBelum ada peringkat

- Wear Study On SS316L, Ti-6Al-4V, PEEK, Polyurethane and Alumina Used As Bio-MaterialDokumen5 halamanWear Study On SS316L, Ti-6Al-4V, PEEK, Polyurethane and Alumina Used As Bio-MaterialRing MasterBelum ada peringkat

- LMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceDokumen2 halamanLMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceTrong Hung NguyenBelum ada peringkat

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDari EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerPenilaian: 4.5 dari 5 bintang4.5/5 (54)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDari EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyPenilaian: 5 dari 5 bintang5/5 (1)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDari EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestPenilaian: 4 dari 5 bintang4/5 (28)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsDari EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsPenilaian: 5 dari 5 bintang5/5 (4)

- Automotive Wiring and Electrical SystemsDari EverandAutomotive Wiring and Electrical SystemsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionDari EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionPenilaian: 5 dari 5 bintang5/5 (2)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsDari EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsPenilaian: 4.5 dari 5 bintang4.5/5 (17)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsDari EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsBelum ada peringkat

- Common Rail Fuel Injection Technology in Diesel EnginesDari EverandCommon Rail Fuel Injection Technology in Diesel EnginesBelum ada peringkat

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingDari EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingPenilaian: 4.5 dari 5 bintang4.5/5 (9)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Why We Drive: Toward a Philosophy of the Open RoadDari EverandWhy We Drive: Toward a Philosophy of the Open RoadPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Troubleshooting and Repair of Diesel EnginesDari EverandTroubleshooting and Repair of Diesel EnginesPenilaian: 1.5 dari 5 bintang1.5/5 (2)

- Classic Car Museum Guide: Motor Cars, Motorcycles & MachineryDari EverandClassic Car Museum Guide: Motor Cars, Motorcycles & MachineryBelum ada peringkat

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Dari EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Penilaian: 3 dari 5 bintang3/5 (4)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Dari EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Penilaian: 4 dari 5 bintang4/5 (3)

- Trucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsDari EverandTrucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsPenilaian: 5 dari 5 bintang5/5 (2)

- High-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionDari EverandHigh-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionBelum ada peringkat