IAB 252 07 Personnel Responsibility Welding Coordination

Diunggah oleh

woutersmartHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

IAB 252 07 Personnel Responsibility Welding Coordination

Diunggah oleh

woutersmartHak Cipta:

Format Tersedia

IIW Guideline PERSONNEL WITH RESPONSIBILITY FOR WELDING COORDINATION

Minimum Requirements for the Education, Examination and Qualification

IAB-252-07

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

MINIMUM REQUIREMENTS FOR THE EDUCATION, TRAINING, EXAMINATION, AND QUALIFICATION

Personnel with Responsibility for Welding Coordination

(as described in ISO 14731 and other International and National Standards)

International Welding Engineer (IWE)

former : Doc. IAB-002-2000/EWF-409 Rev. 2

International Welding Technologist (IWT)

former : Doc. IAB-003-2000/EWF-410 Rev. 2

International Welding Specialist (IWS)

former : Doc. IAB-004-2000/EWF-411 Rev. 1

International Welding Practitioner (IWP)

former : Doc. IAB-005-2002/EWF-451 Rev. 1

Prepared and issued by the IAB-International Authorisation Board Under the authority of the IIW-International Institute of Welding

Published by:

EWF-IAB/IIW Secretariat Av. Prof. Dr. Cavaco Silva, 33 Taguspark Apartado 012 P-2741-901 Porto Salvo Portugal +351.21 4211351 +351.21 4228122 ewf-iab@isq.pt www.iiw-iis.org

Tel: Fax: E-mail:

Personnel with Responsibility for Welding Coordination

Approved: January 2007

0 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

TABLE OF CONTENTS

Preface 2 1. Introduction .......................................................................................................................................3 2. Routes to Qualification .........................................................................................................................3 2.1 Standard Route ....................................................................................................................3 2.2 Alternative Route ..................................................................................................................4 2.3 Distance Learning Programs ................................................................................................4 2.4 Teaching Hours ....................................................................................................................4 3. General Access Conditions ..................................................................................................................4 3.1 International Welding Engineer IWE ....................................................................................4 3.2 International Welding Technologist IWT ...............................................................................5 3.3 International Welding Specialist IWS ...................................................................................5 3.4 International Welding Practitioner IWP .................................................................................7 4. Special Requirement ............................................................................................................................7 4.1 Standard Route ....................................................................................................................7 4.2 Alternative Route ..................................................................................................................8 4.2.1 International Welding Engineer IWE ............................................................................8 4.2.2 International Welding Technologist IWT .......................................................................9 4.2.3 International Welding Specialist IWS ...........................................................................9 4.2.4 International Welding Practitioner IWP .......................................................................10 Section I: Theoretical and Practical Education Part 1; Part 2 and Part 3, Syllabus and Performance Objectives for IWE; IWT; IWS and IWP ....................................................12 I.1 Theoretical Education Part 1 and Part 3 ..12 Module 1: Welding Processes and Equipment ....................................................................12 Module 2: Materials and their Behaviour During Welding ...................................................34 Module 3: Construction and Design ....................................................................................57 Module 4: Fabrication, Applications Engineering ................................................................80 I.2 Specific for IWS Module 0 ................................................................................................81 I.3 Practical Education Part 2 ................................................................................................88 I.3.1 For IWE; IWT and IWS ................................................................................................88 I.3.2 For IWP ........................................................................................................................88 Section II: Examination and Qualification .............................................................................................90 1. Introduction ...........................................................................................................................90 2. Approval of postgraduate training (for IWE, IWT, IWS, IWP) course ...................................90 3. Board of Examiners ..............................................................................................................90 4. Admission to the Examination ..............................................................................................90 5. Examination Procedures ......................................................................................................90 5.1 Written Examination .......................................................................................................91 5.2 Oral Examination ...........................................................................................................91 5.3 Practical Examination ...................................................................................................91 6. Evaluation of Performance ...................................................................................................91 7. Re-Examination and Appeals Procedure .............................................................................92 8. International Welding Diplomas ............................................................................................92 9. Transition Arrangements ......................................................................................................92 Appendix I: Requirements for Equipment, Facilities and Specimens for courses leading to the award of IIW qualifications .......................................................................................93 Appendix II: Abbreviations ....................................................................................................................94 Appendix III: ANB Detailed Assessment ..............................................................................................95 Appendix IV: List of Referenced Standards .......................................................................................102

Personnel with Responsibility for Welding Coordination

Approved: January 2007

1 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Preface

This document is based upon the European Welding Engineer/ Technologist/ Specialist/ Practitioner Guidelines as developed by the European Federation for Welding, Joining and Cutting (EWF), through an Agreement first signed 19 July, 1997, at the Annual Meeting of the International Institute of Welding (IIW) in San Francisco, California, USA and which has been renewed and further developed since then. It has been established in that Agreement that the International Welding Engineer/ Technologist/ Specialist/ Practitioner Diploma is equivalent to the European Welding Engineer/ Technologist/ Specialist/ Practitioner Diploma. The former EWF ANBs may issue the European Welding Engineer/ Technologist/ Specialist/ Practitioner diplomas for as long as these qualifications are referenced in the standard EN 719. Copies of this document are available from the IIW IAB Secretariat or their designated distributor.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

2 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

MINIMUM REQUIREMENTS FOR THE EDUCATION, TRAINING, EXAMINATION AND QUALIFICATION OF PERSONNEL

1. Introduction

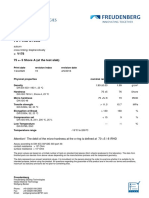

This guideline for the international education, training, examination and qualification of welding personnel has been prepared, evaluated and formulated by Group A Education, Training and Qualification of the International Authorisation Board (IAB) of the International Institute of Welding IIW. Section I of the guideline covers the minimum requirements for education and training, agreed upon by all IIW Authorised National Bodies (ANB), in terms of objectives, scope, expected results and the teaching hours to be devoted to achieving them. It will be revised periodically by IAB Group A to take into account changes to reflect the "state of the art". Students having successfully completed this course of education and the appropriate examinations will be expected to be capable of applying the technology required in welding engineering as covered by this guideline. Section II of the guideline covers the rules for examination and qualification. The contents are given in the following structure (overview): teaching hours* IWT IWS IWP MT P1 MT P1 MT P1 76 35 45 14 22 14 82 39 47 18 22 12 40 14 22 4 8 0 80 0 53 0 28 0 278 88 167 36 80 26 60 60 60 338 227 140

IWE MT P1 1. Welding processes and equipment 93 35 2. Materials and their behaviour during welding 111 39 3. Construction and design 64 14 4. Fabrication, applications engineering 110 0 Sub-total 378 88 Fundamental practical skills (Part 2) 60 Total 438 * teaching hours are the minimum for the Standard Route, see 2.4; MT = Module Total (Part 1 + Part 3); P1 = Part 1; Figures under P1 are given for the Standard Route (see 4.1).

Modules of Theoretical Education and fundamental practical skills

It is to be noted that the overall structure of the syllabus for all levels (IWE, IWT, IWS, and IWP) is similar, but some topics are not considered in all levels of qualification. These topics are indicated by 0 hours in this guideline. The depth to which a topic is dealt with is indicated by the number of hours allocated to it in the guideline. This will be reflected in the scope and depth of the examination.

2.

Routes to Qualification

Three distinct routes to gaining the qualifications described in this document have been agreed. 1. The Standard Route 2. The Alternative Route 3. Distance Learning Programs

2.1

The Standard Route

The Standard Route requires attendance at IIW approved Training Courses designed to meet all the requirements in this Guideline. This is the route (Route 1 in diagrams 1, 2, 3, and 4) recommended by IIW as offering the fastest, most comprehensive manner in which the syllabus may be covered. Personnel with Responsibility for Welding Coordination

Approved: January 2007

3 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

The Standard Route also allows for a limited amount of prior learning (Part 1 of each qualification course; see Section I) to be taken into account, for example during University or College courses or by distance learning (Route 2 in diagrams 1, 2, 3, and 4). This prior learning shall be approved by the ANB.

2.2

The Alternative Route

The Alternative Route allows those who have gained the knowledge of the syllabus in the full detail defined in this Guideline and who can demonstrate their capability in all respects, to proceed to examination without compulsory attendance at an ANB approved Training Course.

2.3

Distance Learning Programs

The Part 1 theory module may be taught in Distance Learning Programs under control of the ANB. When the Part 1 and Part 3 theory modules are combined or the Part 3 theory module is taught separately the requirements of the Distance Learning Guideline IAB 195-2004 shall be followed.

2.4

Teaching hours

The meaning of the teaching hours is the following: Standard Route: Alternative Route: Distance Learning: Part 1: minimum number of hours devoted to the subject recommended number of hours devoted to the subject recommended number of hours devoted to the subject maximum number of hours devoted to the subject in Part 1

A "teaching hour" shall contain at least 50 minutes of direct teaching time.

3.

General Access Conditions

In a separate document (Directory of Access Conditions, Doc. IAB-020-2000) the defined access conditions approved by Group B Implementation and Authorisation of the International Authorisation Board (IAB) of the International Institute of Welding IIW are given in detail for all countries participating in the IAB system. Applicants not fulfilling the access conditions may follow the course as guests, but entry to the IIW examination is not permitted. The following general conditions shall be observed when passing through the IWE, IWT, IWS and IWP courses: 1. Students who have successfully passed the intermediate examination of Part 1 of the course are allowed to attend Part 2 and Part 3 of the course; 2. The implementation of the access conditions is the responsibility of the ANB.

3.1

International Welding Engineer IWE

It is agreed that entry to the program should be on a postgraduate level. Participants should have a primary degree in an engineering discipline or its equivalent recognised by the national government and assessed by the ANB. Therefore, it would be expected that participants should have at least a Bachelor degree. In case of co-operation arrangements, e.g. with universities, according to which the IWE Part 1 of the curriculum structure (see Section I) is presented under careful control of the ANB, the participant is allowed to enter the IWE course through the Route 2 (see item 2.1 and the diagram 1). Personnel with Responsibility for Welding Coordination

Approved: January 2007

4 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

The following additional conditions shall be observed for the different routes through the IWE course: 1. Students who have authenticated evidence that they have passed the examinations in all subjects of their engineer study except the diploma thesis are allowed to attend Part 2 and Part 3 of the IWE course and the corresponding written parts of the final examination; 2. Students shall present their degree diploma to the Board of Examiners before being allowed to take the final oral examination for IWE.

Intermediate examination

Route 1

All university exams passed IWE 2 60 h

STOP

Engineers Diploma WE STOP OE Final examination IWE Diploma

IWE 1 Max. 88 h

IWE 3 Min. 290 h

Route 2 WE: written examination OE: oral examination

Diagram 1 3.2 International Welding Technologist IWT

It is agreed that entry to the program should be on the basis of a higher technical education below that required for the International Welding Engineer. Participants should have a primary degree in an engineering discipline or its equivalent recognised by the national government and assessed by the ANB. In case of co-operation arrangements, e.g. with technical colleges, according to which the IWT Part 1 of the curriculum structure (see Section I) is presented under careful control of the ANB, the participant is allowed to enter the IWT course through the Route 2 (see item 2.1 and the diagram 2).

Intermediate examination

Route 1

Final examination IWT Diploma

IWT 1 Max. 88 h

IWT 2 60 h

IWT 3 Min. 190 h

Route 2

Diagram 2 3.3 International Welding Specialist IWS

It is agreed that entry to the program through the Routes 1 and 2 should be on the basis of a specific technical education below that required for the International Welding Technologist. In case of co-operation arrangements, e.g. with technical colleges, according to which the IWS Part 1 of the curriculum structure (see Section I) is presented under careful control of the ANB, the participant is allowed to enter the IWS course through the Route 2 (see item 2.1 and the diagram 3). Personnel with Responsibility for Welding Coordination

Approved: January 2007

5 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Route 2

Intermediate examination IWS 1 Max. 36 h IWS 2 60 h

Final examination IWS Diploma

Route 1

IWS 3 Min. 131 h

Entry test Check (IWS 0 examination)

Option 3

Option 4

IWS 0 71 h

Option 2 Professional Worker 22 years old 3 years experience IWP 20 years old 2 years experience

Route 3

Diagram 3

The following additional conditions shall be observed for the different routes through the IWS course: 1. Route 1 and 2: a minimum age of 20 years including 2 years of job related experience is required; 2. Route 3: For the access to the module IWS Part 0 the minimum requirements are:

International Welding Practitioner (IWP) or (see on above diagram option 2) Qualification of a professional worker (with diploma after examination) in metalworking professions and minimum 3 years experience in welding related activities, and a minimum age of 22 years. National definitions are given in the Directory of Access Conditions (see on above diagram option 2). 3. A qualified professional worker (as stated above) or an IWP Diploma holder not fulfilling the IWS National Access Requirements should be allowed to go directly to the IWS Part 0 examination if they can prove that they have achieved the knowledge prescribed by the IWS Part 0 (see on above diagram option 3). 4. If the IWP Diploma holder fulfills the IWS National Access Requirements, he may skip the entry test (IWS Part 0 examination) and IWS Part 1 and only perform the IWS Part 1 intermediate exam (see on above diagram option 4).

Personnel with Responsibility for Welding Coordination

Approved: January 2007

6 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

3.4

International Welding Practitioner IWP

In order to enter the International Welding Practitioner course, participants are required to be skilled in practical welding and to have had experience as a welder in industry. As well as assuming theoretical education, the International Welding Practitioner course also serves to entrance the practical welding skills level of the participants. In case of co-operation arrangements, e.g. with technical colleges, according to which the IWP Part 1 of the curriculum structure (see Section I) is presented under careful control of the ANB, the participant is allowed to enter the IWP course through the Route 2 (see item 2.1 and the diagram 4). The following standard access conditions are applicable to the IWP course. Applicants are required to 1. Hold a valid welder qualification certificate ISO 9606 H-L045 ss nb in one of the welding processes listed in 5.1 of ISO 9606, or equivalent, e.g. EN 287 H-L045 ss nb, or ASME IX 6G. hold a valid welder qualification as a plate welder for the following conditions: PE ss nb or PC and PF ss nb, according to ISO 9606 at least in one process, and/or other national equivalent in the IIW member country. Be a minimum age of 20 years including 2 years experience as a welder.

or

2.

Max. 33 h

Final examination Written Di l IWP 2 60 h IWP 3 Min. 54 h IWP Diploma

Route 1

IWP 1 Max. 26 h

Route 2

Diagram 4 4. 4.1 Special Requirements Standard Route

An applicant (excluding guests) shall satisfy the ANB access conditions. If the ANB decides that the access conditions are adequately met, the applicant is then required to attend a training course conducted by an Approved Training Body (ATB) giving as a minimum the hours of instruction detailed in this Guideline as teaching hours. At the conclusion of this course of instruction the student may enter the examinations for the award of the applicable IIW Diploma. The maximum amount of hours of the lectures, which can be included in Part 1 are given after P1= in the following definition of the theoretical education (see Section I). The definition of the precise syllabus of Part 1 is the responsibility of the ANB. It is not obligatory to follow exactly the order of the topics given in this guideline and choice in the arrangement of the syllabus is permitted. The depth to which each topic is dealt with is indicated by the number of hours allocated to it in the guideline. This will be reflected in the scope and depth of the examination.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

7 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

The rules for the conduct of the final examination by the ANB are prescribed under Examination and Qualification Section in this guideline (Section II). The intermediate examination is mandatory for access Route 2 and it is the responsibility of the training school to ensure that those entering by this Route 2 have achieved the required knowledge of Part 1 to enter Part 2 and Part 3 of the course. Failure in the intermediate examination will require the student to enter Part 1 of the course.

4.2

Alternative Route

An applicant shall submit to the ANB the documents indicated in the items 4.2.1, 4.2.2, 4.2.3 and 4.2.4 for a paper assessment together with an application form.

The ANB shall determine through a paper assessment if the application is suitable for further detailed assessment (Appendix III). The following Access Conditions for the alternative route shall be checked by a paper assessment (see the list of access conditions, doc IAB-020-2000). This assessment is an evaluation of practice of related job function in welding.

4.2.1

International Welding Engineer IWE

Standard Route

(see Diagram 1 for more details)

IWE 3 IWE 1 IWE 2

Modules 1 2 3 4

Final exams

IWE Diploma

no

yes

Project or Technical Interview

yes At the discretion of the ANB no Paper assessment yes no ANB check no IWT or IWS standard or alternative route no Professional assessment

interview

yes

Alternative Route

1. Engineer degree (see National Access Conditions). 2. Curriculum Vitae resum (professional information): min. 4 years job function in welding (engineer level); justification of candidates experience, training, and education to become IWE (may include other test results).

A copy of a diploma showing graduation in an engineering subject complying with the Access Conditions. A curriculum vitae (CV) - resume containing professional information: evidence of at least 4 years job function in welding at the level of an engineer (in a period of 6 years before application); justification of candidates experience, training, and education to become IWE (may include other test results).

Diagram 5 Alternative versus Standard Routes for IWE qualification (see also appendix III)

Personnel with Responsibility for Welding Coordination

Approved: January 2007

8 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

4.2.2

International Welding Technologist IWT

A copy of a diploma showing graduation as technologist complying with the Access Conditions. A curriculum vitae (CV) - resume containing professional information: evidence of at least 4 years job function in welding at the level of a technologist (in a period of 6 years before application); justification of candidates experience, training, and education to become IWT (may include other test results).

Standard Route

(see Diagram 2 for more details)

IWT 3 IWT 1 IWT 2

Modules 1 2 3 4

Final exams

IWT Diploma

no

yes

Project or Technical Interview

yes At the discretion of the ANB no Paper assessment yes no ANB check no IWS standard or alternative route no Professional assessment

interview

yes

Alternative Route

1. Technology degree (see National Access Conditions). 2. Curriculum Vitae resum (professional information): min. 4 years job function in welding (technologist level); justification of candidates experience, training, and education to become IWT (may include other test results).

Diagram 6

Alternative versus Standard Routes for IWT qualification (see also appendix III)

Personnel with Responsibility for Welding Coordination

Approved: January 2007

9 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

4.2.3

International Welding Specialist IWS

A copy of documentary proof showing compliance with the Access Conditions for IWS. A curriculum vitae (CV) - resume containing professional information: evidence of at least 3 years job function in welding at a level equivalent to that of a specialist (in a period of 6 years before application); justification of candidates experience, training, and education to become IWS (may include other test results).

Standard Route

(see Diagram 3 for more details)

IWS 3 IWS 1 IWS 2

Modules 1 2 3 4

Final exams

IWS Diploma

no

yes

Project or Technical Interview

yes At the discretion of the ANB no Paper assessment yes no ANB check no IWP standard or alternative route no

Professional assessment interview

yes

Alternative Route

1. Specialist qualification (see National Access Conditions, see also chapter 3.3). 2. Curriculum Vitae resum (professional information): min. 3 years job function in welding (specialist level); justification of candidates experience, training, and education to become IWS (may include other test results).

Diagram 7

Alternative versus Standard Routes for IWS qualification (see also appendix III)

Personnel with Responsibility for Welding Coordination

Approved: January 2007

10 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

4.2.4

International Welding Practitioner IWP

A copy of a valid welder qualification certificate according with chapter 3.4 of the standard route. A curriculum vitae (CV) - resume containing professional information: min. 3 years job function in welding as a certified plate or tube welder in a period of 5 years before application plus min. 1 year job function in welding practitioner level in a period of 3 years before application; justification of candidates experience, training, and education to become IWP (may include other test results).

Standard Route

(see Diagram 3 for more details)

IWP 3 IWP 1 IWP 2

Modules 1 2 3 4

Final exams

IWP Diploma

no

yes

Project or Technical Interview

yes At the discretion of the ANB no Paper assessment yes no ANB check

1. Welder Qualification Certificate (see chapter 3.4). 2. Curriculum Vitae (professional information): min. 3 years job function as certified welder; min. 1 year job function in welding (practitioner level); justification of candidates experience, training, and education to become IWP.

no Professional assessment

interview

yes

Alternative Route

Diagram 8

Alternative versus Standard Routes for IWP qualification (see also appendix III)

Personnel with Responsibility for Welding Coordination

Approved: January 2007

11 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Section I:

Theoretical and Practical Education Part 1, Part 2 and Part 3, Syllabus and Performance Objectives

(Figures are teaching hours. Those after P1= are maximum teaching hours which can be included in Part 1)

I.1.

Theoretical Education - Part 1 and Part 3

Module 1: Welding processes and equipment

1.1 General introduction to welding technology

Objective for IWE, IWT and IWS: Understand (gain knowledge to understand in general) the developments in welding processes including accepted terminology, standards and abbreviations. Objective for IWP: Explain the different welding processes including terminology, standards and abbreviations. Qualification IWE IWT IWS IWP Teaching hours 3 3 1 1 Scope: P1=3 P1=3 P1=1 P1=1 History .... X X Definitions .. X X X X Schematic presentation of welding processes . X X X X Terminology ... X X X X Picture and brief description with characteristics .... X X X X Applicability of the most common welding processes .... X X X X General applications for welding .... X X X X Abbreviations used for welding processes ... X X X X Hints in use for welding processes .... X X X X Classification of welding processes (IIW, ISO, CEN and national standards) ............ X X X X Expected Result for IWE: 1. Detail the differences between each major type of welding process, e.g. arc, resistance, flame, forge, etc. 2. Differentiate between processes with reference to standards. 3. Recognise a welding process by the common abbreviation. 4. Explain the historical evolution of welding. Expected Result for IWT: 1. List the differences between each major type of welding process, e.g. arc, resistance, flame, forge, etc. 2. Differentiate between processes with reference to standards. 3. Recognise a welding process by the common abbreviation. 4. Explain the historical evolution of welding. Expected Result for IWS: 1. Outline the major differences between each main type of welding process, e.g. fusion arc, resistance, flame, forge, etc. 2. Differentiate between processes with reference to standards. 3. Recognise a welding process by the common abbreviation. Expected Result for IWP: 1. Identify the differences between each major type of welding process. 2. Designate a welding process by the common abbreviation.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

12 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.2 Oxy-gas Welding and related processes

Objective: Understand (gain knowledge to understand) /associate the fundamentals of oxy-gas combustion, characteristics of the different fuel gases, equipment, safety and typical applications. Qualification IWE IWT IWS IWP Teaching hours 2 2 2 2 Scope: P1=2 P1=2 P1=2 P1=2 Process principles . X X X X Range of Application X X X X Types of Flames ... X X X X Characteristics of fuel gases, (acetylene, propane, etc.) ... X X X Combustion reactions... X X X X Temperature distribution effects . X X X Equipment .. X X X X Acetylene cylinder component parts...... X X X X Fuel gas generation . X X Handling and storage of gases .. X X X X Typical joint design for welding .. X X X X Methods of welding techniques, rightward, leftward ... X X X X Standards for filler materials ... X X X X Welding applications, typical problems and imperfections.. X X X Special techniques and their methods of use (preheating, straightening, cleaning, etc.) X X X X Health and safety issues specific to the process . X X X X Expected Result for IWE: 1. Explain fully the characteristics of the three flame types and reasons for application of each. 2. Detail the characteristics of flames produced by different fuel gases. 3. Define the potential hazards and methods of safe handling and working. 4. Explain the purpose and working principle of each component of the equipment. 5. Interpret appropriate standards. 6. Define the range of application for this process and potential problems to overcome. Expected Result for IWT: 1. Explain the characteristics of the three flame types and reasons for application of each. 2. Detail the characteristics of flames produced by different fuel gases. 3. Define the potential hazards and methods of safe handling and working 4. Explain the purpose and working principle of each component of the equipment 5. Interpret appropriate standards. 6. Define the range of application for this process and potential problems to overcome. Expected Result for IWS: 1. Outline the characteristics of the three flame types and typical applications for each type. 2. Compare the characteristics of flames produced by different fuel gases. 3. Recognise and define in general the potential hazards and methods of safe handling, storage and working practices. 4. Outline the purpose and working principle of each component of the equipment. 5. Basic knowledge on how to use appropriate standards. 6. Identify the limitations and the range of application of the process and recognise how to overcome the potential problems associated with this process. Expected Result for IWP: 1. Interpret the characteristics of the different types of flames and their application. 2. Illustrate potential hazards and methods of safe handling and working. 3. Name the working principle of each component of the equipment. 4. Translate appropriate standards

Personnel with Responsibility for Welding Coordination

Approved: January 2007

13 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.3 Electrotechnics, a review

Objective for IWE, IWT and IWS: Understand (gain knowledge to understand in general) the basics of electricity in relation to the requirements of welding technology and appreciate the key electronic components used in welding power sources. Objective for IWP: Have an outline working knowledge of electricity and the characteristics of the most important electrical components used in electrical welding power sources. Qualification IWE IWT IWS IWP Teaching hours 2 2 2 2 Scope: P1=2 P1=2 P1=2 P1=2 Basics of electricity and electronics (define current, voltage and resistance) ................ X X X X Ohm's Law . X X X X Parallel and serial circuits ... X X X X Direct current (DC), polarity, alternating current (AC) .... X X X X Magnetism in welding .. X X X Capacity, condenser X X X X Transformer, and rectifying bridge (half wave and full wave rectification) .. X X X X Transistor, thyristor, Inductance, inductors... X X X Hazard X X X X Health and safety .. X X X X Expected Result for IWE: 1. Define and explain the effect of current, voltage and electrical resistance in welding. 2. Detail the functions of the most important components of welding power sources. 3. Discuss competently the differences between DC and AC current. 4. Interpret and apply knowledge of electricity and electronics to welding applications. Expected Result for IWT: 1. Define and explain the effect of current, voltage and electrical resistance in welding. 2. Detail the functions of the most important components of welding power sources. 3. Discuss competently the differences between DC and AC current. 4. Interpret and apply knowledge of electricity and electronics to welding applications. Expected Result for IWS: 1. Outline the relation between current, voltage and electrical resistance, and also define each electrical parameter. 2. Outline the major functions of the most important components of welding power sources. 3. Describe the major differences between DC and AC current and give examples of their individual application to different welding processes. 4. Demonstrate and apply knowledge related to electricity and electronics in welding applications. Expected Result for IWP: 1. General outline of current, voltage and resistance. 2. Recognise and give examples of the functions of the main components of a welding power source. 3. Give examples of the main differences between DC and AC current. 4. Show practical application of knowledge of electricity to welding.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

14 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.4 The arc

Objective for IWE, IWT and IWS: Understand in detail (gain knowledge to understand in general) the fundamentals of an electric arc, its characteristics, limitations and application in welding, including arc stability problems. Objective for IWP: Describe what is an electric arc, its characteristics, limitations and application in welding. Qualification IWE IWT IWS IWP Teaching hours 4 4 1 1 Scope: P1=4 P1=4 P1=0 P1=0 Arc physics (producing an electric arc, the main arc areas, stability of the arc) .. X X X X Voltage distribution across the arc ..... X X X X Heat generation at the cathode and anode... X X X X Polarity and arc characteristics in AC and DC and its control for the key welding processes.... X X X X Influence on the welding process .. X X Temperature distribution in the arc and effects ...... X X X X Influence of the magnetic fields on the arc (why, how to solve) ... X X X X Limits of application ..... X X X X Expected Result for IWE: 1. Explain in detail the fundamental physics of an electrical arc, including the main parameters influencing arc stability. 2. Detail the generation of heat in the arc and the arc voltage distribution. 3. Explain the influence of magnetic fields on the electric arc. 4. Predict how to solve magnetic deflection problems. 5. Explain arc characteristics for DC and AC including control and limitations. Expected Result for IWT: 1. Explain in detail the fundamental physics of an electrical arc, including the main parameters influencing arc stability. 2. Detail the generation of heat in the arc and the arc voltage distribution. 3. Outline the influence of magnetic fields on the electric arc. 4. Predict how to solve magnetic deflection problems. 5. Explain arc characteristics for DC and AC including control and limitations. Expected Result for IWS: 1. Describe an electrical arc; its main areas and their importance to welding and arc stability. 2. Outline the generation of heat in the arc and the arc voltage distribution. 3. Give examples of the influence of magnetic fields on the electric arc. 4. Outline appropriate solutions to solve magnetic deflection problems. 5. Describe arc characteristics for DC and AC. Expected Result for IWP: 1. Give examples of the main arc areas, and their importance to welding. 2. List the hot arc areas and their influence on the weld pool. 3. Explain the arc characteristics of DC and AC. 4. Outline the influence of magnetic fields on an electric arc. 5. Give examples of solving magnetic deflection problems.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

15 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.5 Power sources for arc welding Objective for IWE, IWT and IWS: Understand in detail (gain knowledge to understand in general/having a outline working knowledge) the characteristics and main components of arc welding power sources. Objective for IWP: Understand (gain knowledge to understand in general/having a outline working knowledge) of components of arc welding power sources. Qualification Teaching hours IWE IWT IWS IWP 4 4 3 2 P1=4 P1=4 P1=1 P1=1

Scope: Power source classification, types and characteristics (static and generators, and each sub-group) X X X X Power source electrical characteristics (static and dynamic)..... X X X X Relationship between static characteristic and welding process .. X X X X Control of the electrical static characteristic (flat and drooping) ... X X Arc stability for the main processes (MMA, TIG, MIG/MAG, SAW, PAW) .. X X X X The operation working point ... X X X X Inverter technology ... X X X Power sources controlled by a CPU .. X X X Stability of processes in AC and DC .. X X X AC (sine wave and square wave) and DC power sources . X X X X Open circuit voltage, short circuit current, power factor of transformers . X X X Duty cycle of a power source and typical values for the most common arc welding processes . X X X X Voltage losses, relationship between welding current value and cable section.. X X X X Pulse welding techniques X X X X Arc striking methods and devices, slope up and down, pre- and post-flow . X X X X Current and voltage setting (electromagnetic and electronic devices) . X X Standards related with welding power sources and their requirements X X X X Expected Result for IWE: 1. Explain each type of arc welding power source for both AC and DC including the most common devices used. 2. Detail for each type of welding power source the static and dynamic electrical characteristics, operation point and control of arc stability. 3. Explain the meaning of open circuit voltage, short circuit current, duty cycle of a power source, voltage losses, and welding current to cable cross section relationship. 4. Explain the differences of the above characteristics for each type of power source and welding process. 5. Recognise the various functions and switches on different power sources and their effects. Expected Result for IWT: 1. Explain each type of arc welding power source for both AC and DC including the most common devices used. 2. For each type of welding power source detail the static and dynamic electrical characteristics, operation point and control of arc stability. 3. Explain the meaning of open circuit voltage, arc voltage short circuit current, duty cycle of a power source, voltage losses, and welding current to cable cross section relationship. 4. Explain the differences of the above characteristics for each type of power source and welding process for a specific application. 5. Recognise the various functions and switches on different power sources and their effects.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

16 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Expected Result for IWS: 1. Outline how each type of welding power source works (AC and DC) including the most common devices used. 2. Describe for each type of arc welding power source the static characteristic, operation point and control of arc stability. 3. Outline the meaning of open circuit voltage, arc voltage short circuit current, duty cycle of a power source, voltage losses, and current to cable section relationship. 4. Be able select the appropriate power sources for a given welding process. 5. Recognise the various settings and switches on different power sources and their effects. Expected Result for IWP: 1. Outline how each type of welding power source works (AC and DC) including the most common devices used. 2. Describe for each type of arc welding power source the static characteristic, operation point and control of arc stability. 3. Outline the meaning of open circuit voltage, arc voltage short circuit current, duty cycle of a power source, voltage losses, and current to cable section relationship. 4. Be able select the appropriate power sources for a given welding process. 5. Recognise the various settings and switches on different power sources and their effects.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

17 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.6 Introduction to gas shielded arc welding Objective for IWE, IWT and IWS: Understand (gain knowledge to understand in general/gain an outline working knowledge) the principles and physical phenomena of gas shielded welding processes. Objective for IWP: Understand (gain knowledge to understand in general/gain an outline working knowledge) the principles of gas shielded welding processes. Qualification Teaching hours IWE IWT IWS IWP 2 2 2 2 P1=2 P1=2 P1=2 P1=2 X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Scope: Physical phenomena ... Operating principles of TIG, MIG/MAG and flux-cored .. Shielding gases (inert, active) and their effect on arc characteristics . Handling and storage of gases .. Filler materials .. Standards (International and National) for shielding gases and filler materials .... Expected Result for IWE: 1. Explain the characteristics and operating principles of TIG, MIG/MAG and Flux-cored welding. 2. Interpret arc characteristics associated with each type of shielding gas used for each process. 3. Detail the methods for safe handling and storage of shielding gases. 4. Interpretation and use of standards for shielding gases and filler materials. Expected Result for IWT: 1. Explain the characteristics and operating principles of TIG, MIG/MAG and Flux-cored welding. 2. Interpret arc characteristics associated with each type of shielding gas used for each process. 3. Detail the methods for safe handling and storage of shielding gases. 4. Interpretation and use of standards for shielding gases and filler materials.

Expected Result for IWS: 1. Describe and compare the characteristics and operating principles of TIG, MIG/MAG and Flux-cored welding. 2. Compare and outline arc characteristics associated with each type of shielding gas used for each process. 3. Outline the methods for safe handling and storage of shielding gases. 4. Demonstrate the use of standards for shielding gases and filler materials. Expected Result for IWP: 1. Differentiate the operating principles of TIG, MIG/MAG and Flux-cored welding. 2. Outline the arc characteristics associated with each type of shielding gas used. 3. Demonstrate a general knowledge of the basic rules of handling and storing shielding gases.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

18 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.7 TIG Welding

Objective for IWE, IWT and IWS: Understand in detail/gain knowledge to understand in general/explain TIG welding fundamentals, including equipment, applications, procedures and specific problems. Objective for IWP: Understand in detail (gain knowledge to understand in general/explain) TIG welding fundamentals, including equipment, and applications.

6 6 4 2 Scope: P1=4 P1=4 P1=2 P1=2 Power source characteristics ...... X X X X Methods for arc ignition and necessary equipment .......................... X X X X Equipment and accessories: torches, gas lens, control panel, up and down slope, pulse techniques..... X X X X Effect of current type and polarity: DC(+), DC(-) and AC.... X X X X Specific requirements for different materials, e.g. Al... X X X Consumables: shielding gases, filler materials, electrodes ... X X X X Welding parameters: current, voltage, travel speed, gas flow rate X X X X Joint preparation: typical joint design for welding, fit-up, cleaning. X X X X Welding procedures ..... X X X Special techniques: spot-welding, key-hole, hot-wire, orbital welding, tube to tube and tube to sheet , and others....... X X X Standards for filler materials, electrodes, and gases ..... X X X X Welding applications, typical problems and how to solve them .... X X X X Health and safety issues specific to the process .... X X X X Expected Result for IWE: 1. Explain in detail the principles of TIG welding including arc ignition methods and their applications. 2. Explain the selection of appropriate type of current, polarity, shielding gas and electrode type according to application. 3. Detail the range of application, appropriate joint preparations and potential problems to be overcome. 4. Detail appropriate welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Interpret appropriate standards. 7. Define potential hazards and methods of safe handling and working. 8. Recognise the various settings and switches on different TIG power sources and their effects. Expected Result for IWT: 1. Explain and compare in detail the principles of TIG welding including arc ignition methods and their applications. 2. Explain the selection of appropriate type of current, polarity, shielding gas and electrode type according to application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome 4. Identify appropriate welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Interpret appropriate standards. 7. Define potential hazards and methods of safe handling and working. 8. Recognise the various settings and switches on different TIG power sources and their effects. Expected Result for IWS: 1. Describe and compare the principles of TIG welding including arc ignition methods and their applications. 2. Explain the selection of appropriate type of current, polarity, shielding gas and electrode type according to the application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify an appropriate range of welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Interpret the use of appropriate standards. 7. Describe potential hazards and methods of safe handling and working.

Qualification Teaching hours

IWE

IWT

IWS

IWP

Personnel with Responsibility for Welding Coordination

Approved: January 2007

19 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Expected Result for IWP: 1. Outline TIG welding including arc ignition methods and their most common applications. 2. Give examples of the most common applications for each type of current, polarity and electrode. type 3. Give examples of the most important applications and select the appropriate values for welding parameters. 4. Know how to use and care for the equipment and accessories. 5. Read given standards for consumables. 6. Give examples of TIG applications, joint preparation and potential problems to overcome. 7. Outline potential hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

20 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.8 MIG/MAG and Flux Cored Arc Welding

Objective for IWE, IWT, IWS and IWP: Understand in detail/gain knowledge to understand in general/explain MIG/MAG and Flux Cored Arc welding fundamentals, including equipment, applications, procedures and common problems Qualification Teaching hours IWE IWT IWS IWP 6 6 4 2 P1=4 P1=4 P1=2 P1=2

Scope: Power source characteristics for conventional process and CPU controlled power sources.... X X X X Effect of current type and polarity....... X X X Equipment and accessories: torches, wire feeders, hose assembly, control panel. X X X X Metal transfer modes (dip, globular, spray, pulsed and rotating), and their Application............. X X X X Welding parameters and settings: current, voltage, travel speed, gas flow rate, etc.................. X X X X Consumables: shielding gases, filler materials (solid and flux cored wires), and their combinations............. X X X X Joint preparation: typical joint design for welding, fit-up, cleaning. X X X X Welding procedures................. X X X X Special techniques: electro-gas welding, high efficiency processes...... X X X Standards for filler materials, and gases............. X X X X Welding applications, typical problems and how to solve them.......... X X X X Health and safety specific to the process................ X X X X Expected Result for IWE: 1. Explain in detail the principles of MIG/MAG and Flux Cored Arc welding including metal transfer modes and their applications. 2. Explain the selection of appropriate type of current, polarity and electrode according to application. 3. Detail the range of application, appropriate joint preparations and potential problems to be overcome. 4. Detail appropriate welding parameters for particular applications. 5. Define potential hazards and methods of safe handling and working. 6. Explain the purpose and functions of each component of the equipment and accessories. 7. Interpret appropriate standards 8. Explain selection of consumables. 9. Recognise the various settings and switches on different MIG/MAG and Flux Cored power sources and effects. Expected Result for IWT: 1. Explain and compare in detail the principles of MIG/MAG and Flux Cored Arc welding including metal transfer modes and their applications. 2. Compare the selection of appropriate type of current, polarity and electrode according to application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify appropriate welding parameters for particular applications. 5. Define potential hazards and methods of safe handling and working. 6. Explain the purpose and functions of each component of the equipment and accessories. 7. Interpret appropriate standards 8. Explain selection of consumables. 9. Recognise the various settings and switches on different MIG/MAG and Flux Cored power sources and effects.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

21 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Expected Result for IWS: 1. Describe and compare the principles of MIG/MAG and Flux Cored Arc welding including metal transfer modes and their applications. 2. Identify the most common applications for each type of current, polarity and electrode. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify an appropriate range of welding parameters for particular applications. 5. Describe potential hazards and methods of safe handling and working. 6. Outline the various functions of the main components of the equipment and accessories. 7. Demonstrate the use of appropriate standards 8. Give examples on how consumables should be selected. Expected Result for IWP: 1. Outline MIG/MAG and Flux Cored Arc welding, comparing metal transfer modes and their application. 2. Give examples of the most common applications of each type of current, polarity and electrode. 3. Give examples of the most important applications and select appropriate welding parameters. 4. Know how to use and care for the equipment and accessories. 5. Read given standards for consumables. 6. Give examples of MIG/MAG application range, joint preparation and potential problems to overcome. 7. Outline potential hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

22 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.9 MMA Welding

Objective for IWE, IWT, IWS and IWP: Understand in detail/gain knowledge to understand in general/explain MMA welding fundamentals, including equipment, applications, procedures and common problems Qualification Teaching hours IWE IWT IWS IWP 8 6 4 2 P1=4 P1=4 P1=2 P1=2 X X X X X X X X

Scope: Process principles and arc characteristics ................ Effect of current type and polarity ................... Power source characteristics applicable to MMA (open circuit voltage, static and dynamic characteristics, types of current, arc striking methods) X X X X Equipment and accessories................... X X X Process application range, typical problems and how to solve them....... X X X X Covered electrodes (functions of the coating and rod, types of electrodes, X slag-metal and gas-metal covered reactions) ...................... X X X Production of electrodes (how, typical defects) ................ X X X Handling and storage of electrodes (storage environment, redrying)..... X X X X Electrode classification (International and national standards) . X X X Selection of covered electrodes for applications ............... X X X X Welding parameters: current, voltage, run out length, etc ............ X X X Joint preparation: typical joint design for welding, fit-up, cleaning, welding X position. X X X Relationship between electrode diameter and current range, rod material, X electrode length and welding position ................. X X X X Welding procedures ................ X X X Special techniques (gravity welding, vertical down welding, on-site welding)........ X X X Health and safety specific to this process .............. X X X Expected Result for IWE: 1. Explain in detail the principles of MMA welding including special techniques, arc striking methods and their applications. 2. Explain the selection of the appropriate type of current, polarity and electrode according to application. 3. Detail the range of application, appropriate joint preparations and potential problems to be overcome. 4. Detail appropriate welding parameters for particular applications. 5. Define potential hazards and methods of safe handling and working. 6. Explain the purpose and functions of each component of the equipment and accessories. 7. Explain the handling and storage of the various types of electrodes. 8. Interpret appropriate standards. 9. Identify the influence of electrode coating on droplet transfer and weld metal properties. 10.Recognise the various functions and switches on different MMA power sources and their effects. Expected Result for IWT: 1. Explain in detail the principles of MMA welding including with particular emphasis on special techniques, arc striking methods and their applications. 2. Explain the selection of the appropriate type of current, polarity and electrode according to application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify appropriate welding parameters for particular applications. 5. Define potential hazards and methods of safe handling and working. 6. Explain the purpose and functions of each component of the equipment and accessories. 7. Explain the handling, control and storage of the various types of electrodes. 8. Interpret appropriate standards. 9. Identify the influence of electrode coating on droplet transfer and weld metal properties.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

23 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Expected Result for IWS: 1. Describe the principles of MMA welding 2. Describe how to select the appropriate type of current, polarity and electrode according to application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify an appropriate range of welding parameters for particular applications. 5. Describe potential hazards and methods of safe handling and working. 6. Outline the purpose and functions of each component of the equipment and accessories. 7. Describe the appropriate methods of handling, control and storage of the various types of electrodes. 8. Demonstrate the use of appropriate standards. 9. Describe the influence of electrode coating on droplet transfer and weld metal properties. Expected Result for IWP: 1. Outline MMA welding working principles, special techniques, arc striking methods and their applications. 2. Outline the handling and storage of each type of consumable. 3. Give examples of the most important applications and select appropriate welding parameters. 4. Know how to use and care for the equipment and accessories. 5. Read given standards for electrodes. 6. Give examples of MMA application range, joint preparation and potential problems to overcome. 7. Outline potential hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

24 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.10 Submerged-Arc Welding

Objective for IWE, IWT, IWS and IWP: Understand in detail/get a complete knowledge/explain SAW welding fundamentals, including equipment, applications, procedures and common problems.

IWE IWT IWS IWP 6 4 2 2 Scope: P1=4 P1=4 P1=0 P1=0 SAW process principles and arc characteristics ............. X X X X Effect of current type and polarity.................. X X X X Power source characteristics applicable to SAW (open circuit voltage, static and dynamic characteristics, types of current, arc striking methods) Equipment and accessories ................. X X X X Process application range, typical problems and how to solve them....... X X X Consumables (functions of the flux and wire -solid or flux cored-, types of X X X X flux and wire, wire-flux combination, slag-metal and gas-metal reactions) X Production of consumables (how, typical defects) X X X Handling and storage of consumables (storage environment, re-drying) X X X Consumable classification (International and national standards) X X X X Welding parameters: current, voltage, travel speed, type of flux and partiX X X cle size, stick-out, etc .............................. X X X X Joint preparation: typical joint design for welding, fit-up, cleaning ......... X X X Relationship between the wire-flux combination and the characteristics of X deposited material............................ X X X X Welding procedures.................. X X X X Single-wire and multi -wire techniques ............... X X X Special techniques (strip-cladding, iron-powder addition, cold and hot wire addition) .................... X X X Health and safety specific to SAW process................. X X X Expected Result for IWE: 1. Explain in detail the principles of SAW process including arc striking methods, special techniques and their applications. 2. Explain the selection of appropriate type of current, polarity and consumable according to application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify appropriate welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Explain slag-metal/gas-metal reactions and their influence on weld metal properties 7. Interpret appropriate standards. 8. Define potential hazards and methods of safe handling and working. Expected Result for IWT: 1. Explain in detail the principles of SAW process including arc striking methods, special techniques and their applications. 2. Explain the selection of appropriate type of current, polarity and consumable according to application. 3. Identify the range of application, appropriate joint preparations and potential problems to be overcome. 4. Identify appropriate welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Explain slag-metal/gas-metal reactions and their influence on weld metal properties. 7. Interpret appropriate standards. 8. Define potential hazards and methods of safe handling and working. Qualification Teaching hours

Personnel with Responsibility for Welding Coordination

Approved: January 2007

25 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

Expected Result for IWS: 1. Explain the principle of the SAW process including arc striking methods, special techniques and their applications. 2. Explain the criteria for evaluating the applicable welding parameters. 3. Identify the application range, joint edge preparation and potential problems to overcome. 4. Clarify the procedures for the set-up of power sources. 5. Explain the criteria for the selection of flux-wire combinations. 6. Interpret appropriate standards and welding procedures. 7. Define welding instructions for welders and operators. 8. Define potential hazards and methods of safe handling and working. Expected Result for IWP: 1. Explain the principles of SAW process including arc striking methods , special techniques, and their applications. 2. Outline the handling and storage of each type of consumable. 3. Identify the application range, appropriate joint preparation and potential problems to overcome. 4. Know how to use and care for the equipment and accessories. 5. Read given standards for consumables. 6. Give examples of SAW application range, joint preparation and potential problems to overcome. 7. Define potential hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

26 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.11 Resistance Welding

Objective for IWE, IWT, and IWS: Understand in detail/get a complete knowledge/explain resistance welding fundamentals, applications and specifications, including common problems and their solution. 0 Scope: P1=0 Process principles and overview on types of processes (spot, projection, butt, seam, and flash).. X X X Joule effect and temperature distribution... X X X Equipment and accessories .......... X X X Process application range and typical problems (welding thin to thick material, welding of coated/ painted materials, welding dissimilar materials, mass effect, shunt effect, Peltier effect, resistance brazing).. X X X Electrodes (functions, types, shapes, material)... X X X Electrode classification (International and national standards).. X X X Welding parameters: current, pressure, time, type of current, pulse, etc X X X Joint preparation: typical joint design for welding, fit-up, cleaning .......... X X X Relationship between welding parameters and the characteristics of the weld nugget .................. X X X Monitoring systems, process control, measuring X X Specific testing... X X Welding procedures.. X X X Health and safety specific to this process.. X X X Expected Result for IWE: 1. Explain in detail the principles of resistance welding and the application of the various sub-processes. 2. Explain the selection of appropriate parameters to give sound welds. 3. Identify the range of application, appropriate material preparation and potential problems to be over come. 4. Identify appropriate welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Interpret appropriate standards. 7. Define potential hazards and methods of safe handling and working. 8. Recognise the various settings and switches on different power sources and their effects. Expected Result for IWT: 1. Explain in detail the principles of resistance welding and the application of the various sub-processes. 2. Explain the selection of appropriate parameters to give sound welds. 3. Identify the range of application, appropriate material preparation and potential problems to be overcome. 4. Identify appropriate welding parameters for particular applications. 5. Explain the purpose and functions of each component of the equipment and accessories. 6. Interpret appropriate standards. 7. Define potential hazards and methods of safe handling and working. 8. Recognise the various settings and switches on different power sources and their effects. Expected Result for IWS: 1. Explain the principle of the resistance welding process and the application of the various subprocesses. 2. Explain the selection of appropriate parameters to give sound welds 3. Explain the criteria for the selection of the correct pressure and current cycles and clarify the procedures for the setting up the power sources. 4. Discuss the influence of the surface characteristics on the final quality of the joints. Explain the causes of the common discontinuities and their prevention. 5. Interpret appropriate standards and welding procedures. 6. Define welding instructions for welders and operators. 7. Define potential hazards and methods of safe handling and working. Expected Result for IWP: Not Applicable Qualification Teaching hours

IWE

8 P1=0

IWT

6 P1=0

IWS

2 P1=0

IWP

Personnel with Responsibility for Welding Coordination

Approved: January 2007

27 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.12.1 Other Welding Processes LASER; Electron Beam; Plasma

Objective for IWE, IWT, and IWS: Understand in detail/get a complete knowledge/explain the principle and the filed of application of plasma; electron beam; LASER. Fundamentals, including equipment, applications, procedures and common problems. Objective for IWP: Gain an outline knowledge of plasma; electron beam; LASER, their application and most common problems. Qualification Teaching hours Scope: Basic principles for all mentioned processes.... Heat generation for each type of process ..... Equipment and accessories for each type of process .... Typical process applications and problems .. Consumables.. Welding parameters for each process ... Joint preparation: typical joint design for welding, fit-up, cleaning ....... Relationship between welding parameters and joint configuration .. Comparison between high energy processes .. Health and safety specific to the processes ..... Appropriate national and international standards for each process ..... IWE IWT IWS IWP 5 3 2 1 P1=0 P1=0 P1=0 P1=0 X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Expected Result for IWE: 1. Explain the principles of the processes mentioned in the objective and their application. 2. Determine appropriate applications for each type of process, and the precautions necessary to achieve a sound weld. 3. Describe the welding parameters, appropriate joint preparations and potential problems to be overcome for each process for a given application. 4. Explain the purpose and functions of each major component of the equipment and accessories. 5. Interpret appropriate standards. 6. Define potential hazards and methods of safe handling and working. Expected Result for IWT: 1. Explain the principles of the processes mentioned in the objective and their application. 2. Determine appropriate applications for each type of process, and the precautions necessary to achieve a sound weld. 3. Describe the welding parameters, appropriate joint preparations and potential problems to be overcome for each process for a given application. 4. Explain the purpose and functions of each major component of the equipment and accessories. 5. Interpret appropriate standards. 6. Define potential hazards and methods of safe handling and working. Expected Result for IWS: 1. Explain the principles of the processes mentioned in the objective and their application. 2. Explain the common applications of the processes in the different industrial fields. 3. Define and describe, for each process, the suitable welding parameters. 4. Define potential hazards and methods of safe handling and working. Expected Result for IWP: 1. Outline the working principles of the processes mentioned in the objective and their application. 2. Give examples of typical applications of different types of process. 3. Know how to use and care for the equipment and accessories for different processes. 4. Outline potential hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

28 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.12.2 Other Welding Processes, other than 1.12.1

Objective for IWE, IWT, and IWS: Understand in detail/get a complete knowledge/explain the principle and the field of application electro-slag, friction; friction stir, magnetically impelled arc butt (MIAB); magnetic pulse welding, ultrasonic; explosive; diffusion; aluminothermic; high-frequency; stud, cold-pressure welding, hybrid processes, etc. Fundamentals, including equipment, applications, procedures and common problems. Objective for IWP: Gain an outline knowledge of electro-slag, friction; explosive; diffusion; aluminothermic; high-frequency; cold-pressure welding their application and most common problems. Qualification Teaching hours Scope: Basic principles for all mentioned processes.... Heat generation for each type of process ..... Equipment and accessories for each type of process .... Typical process applications and problems .. Consumables.. Welding parameters for each process ... Joint preparation: typical joint design for welding, fit-up, cleaning ....... Relationship between welding parameters and joint configuration .. Comparison between high energy processes .. Health and safety specific to the processes ..... Appropriate national and international standards for each process ..... IWE IWT IWS IWP 5 3 2 1 P1=0 P1=0 P1=0 P1=0 X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Expected Result for IWE: 7. Explain the principles of the processes mentioned in the objective and their application. 8. Determine appropriate applications for each type of process, and the precautions necessary to achieve a sound weld. 9. Describe the welding parameters, appropriate joint preparations and potential problems to be overcome for each process for a given application. 10.Explain the purpose and functions of each major component of the equipment and accessories. 11.Interpret appropriate standards. 12.Define potential hazards and methods of safe handling and working. Expected Result for IWT: 7. Explain the principles of the processes mentioned in the objective and their application. 8. Determine appropriate applications for each type of process, and the precautions necessary to achieve a sound weld. 9. Describe the welding parameters, appropriate joint preparations and potential problems to be overcome for each process for a given application. 10.Explain the purpose and functions of each major component of the equipment and accessories. 11.Interpret appropriate standards. 12.Define potential hazards and methods of safe handling and working. Expected Result for IWS: 5. Explain the principles of the processes mentioned in the objective and their application. 6. Explain the common applications of the processes in the different industrial fields. 7. Define and describe, for each process, the suitable welding parameters. 8. Define potential hazards and methods of safe handling and working. Expected Result for IWP: 5. Outline the working principles of the processes mentioned in the objective and their application. 6. Give examples of typical applications of different types of process. 7. Know how to use and care for the equipment and accessories for different processes. 8. Outline potential hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

29 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.13 Cutting and other edge preparation processes

Objective for IWE, IWT, IWS and IWP: Understand in detail/get a complete knowledge/explain/interpret the basic principles and the field of application of the most common cutting and edge preparation processes used in weld construction, including equipment, procedures and common problems. IWE IWT IWS IWP 4 4 2 2 Scope: P1=2 P1=2 P1=0 P1=0 Survey of edge preparation processes..... X X X X Mechanical cutting X X Principles of flame and flame powder cutting, equipment, applications and auxiliaries....... X X X X Flame cutting parameters, edge quality, oxygen purity grades. X X X X X Materials suitable for flame cutting.... X X X Basic principles of the various arc cutting processes (arc-air, carbon and metal-arc, oxy-arc cutting, gauging with carbon electrode) equipment and X auxiliaries... X X X Materials suitable for arc-cutting, applications, cutting parameters for each X process... X X X X Fundamentals of plasma cutting, equipment and auxiliaries. X X X Materials suitable for plasma cutting, applications, cutting parameters, X cutting gases.. X X X Plasma cutting special applications (under water cutting, cutting with water vortex)... X X X Plasma gouging.... X X X Fundamentals of electron beam drilling and LASER cutting, equipment, parameters, applications.. X X X Fundamentals of water jet cutting, equipment, parameters, applications X X X Fundamentals of arc gouging and flame gouging, parameters and appliX cations. X X X X Appropriate national and international standards for each process. X X X X Health and safety.. X X X Expected Result for IWE: 1. Explain in detail the principles of: mechanical, flame, arc, plasma, electron beam, LASER, and water jet cutting. 2. Explain the influence of each parameter for the abovementioned processes on the edge surface quality. 3. Detail the range of applications for: flame, arc, plasma, electron beam, and water jet cutting. 4. Define potential risks, hazards and methods of safe handling and working. Expected Result for IWT: 1. Explain in detail the principles of: mechanical, flame, arc, plasma, electron beam, LASER, and water jet cutting. 2. Explain the influence of each parameter for the abovementioned processes on the edge surface quality. 3. Identify the range of applications for: flame, arc, plasma, electron beam, and water jet cutting. 4. Identify potential risks, hazards and methods of safe handling and working. Expected Result for IWS: 1. Explain the principles of: mechanical, flame, arc, plasma, electron beam, LASER, and water jet cutting. 2. Identify the characteristic parameters for the above mentioned processes 3. Make a comparison among different edge preparation processes, considering technical and economic aspects. 4. Evaluate potential risks and hazards related with edge preparation processes. Qualification Teaching hours Expected Result for IWP: 1. Explain the principles of flame, arc, plasma, Laser, water jet cutting and gouging. 2. Identify the influence of characteristic parameters on the edge surface quality. 3. Point out the range of applications for flame, arc, plasma and Laser cutting. 4. Outline potential risks, hazards and methods of safe handling and working.

Personnel with Responsibility for Welding Coordination

Approved: January 2007

30 of 103

IAB INTERNATIONAL AUTHORISATION BOARD

IAB-252-07

1.14 Surfacing and Spraying