Safety Section: Technical Guide P12Y/En T00/A11 Micom P125/P126/P127

Diunggah oleh

Kopi143Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Safety Section: Technical Guide P12Y/En T00/A11 Micom P125/P126/P127

Diunggah oleh

Kopi143Hak Cipta:

Format Tersedia

Technical Guide MiCOM P125/P126/P127

P12y/EN T00/A11

Safety Section

Technical Guide Safety Section MiCOM P125/P126/P127

P12y/EN T00/A11 Page 1/8

CONTENTS

1.

1.1 1.2

SAFETY INSTRUCTION

Health and safety Explanation of symbols and labels

3

3 3

2. 3.

3.1 3.2 3.3 3.4

INSTALLING, COMMISSIONING AND SERVICING EQUIPMENT OPERATING CONDITIONS

Current transformer circuits External resistors Battery replacement Insulation and dielectric strength testing

4 5

5 5 5 5

4. 5.

DECOMMISSIONING AND DISPOSAL TECHNICAL SPECIFICATIONS

6 7

P12y/EN T00/A11 Page 2/8

Technical Guide Safety Section MiCOM P125/P126/P127

Technical Guide Types MiCOM P125, P126, P127 Directional/non Directional Relays

HANDLING OF ELECTRONIC EQUIPMENT

A person's normal movements can easily generate electrostatic potentials of several thousand volts. Discharge of these voltages into semiconductor devices when handling electronic circuits can cause serious damage, which often may not be immediately apparent but the reliability of the circuit will have been reduced. The electronic circuits of ALSTOM T&D Protection & Control Ltd products are immune to the relevant levels of electrostatic discharge when housed in their cases. Do not expose them to the risk of damage by withdrawing modules unnecessarily. Each module incorporates the highest practicable protection for its semiconductor devices. However, if it becomes necessary to withdraw a module, the following precautions should be taken to preserve the high reliability and long life for which the equipment has been designed and manufactured. 1. Before removing a module, ensure that you are at the same electrostatic potential as the equipment by touching the case. 2. Handle the module by its front-plate, frame, or edges of the printed circuit board. 3. Avoid touching the electronic components, printed circuit track or connectors. 4. Do not pass the module to any person without first ensuring that you are both at the same electrostatic potential. Shaking hands achieves equipotential. 5. Place the module on an antistatic surface, or on a conducting surface, which is at the same potential as you. 6. Store or transport the module in a conductive bag. More information on safe working procedures for all electronic equipment can be found in BS5783 and IEC 60147-0F. If you are making measurements on the internal electronic circuitry of equipment in service, it is preferable that you are earthed to the case with a conductive wrist strap. Wrist straps should have a resistance to ground between 500k 10M ohms. If a wrist strap is not available, you should maintain regular contact with the case to prevent the build up of static. Instrumentation which may be used for making measurements should be earthed to the case whenever possible. ALSTOM T&D Protection & Control Ltd strongly recommends that detailed investigations on the electronic circuitry, or modification work, should be carried out in a Special Handling Area such as described in BS5783 or IEC 60147-0F.

Technical Guide Safety Section MiCOM P125/P126/P127

P12y/EN T00/A11 Page 3/8

1.

1.1

SAFETY INSTRUCTION

This Safety Section should be read before commencing any work on the equipment. Health and safety The information in the Safety Section of the product documentation is intended to ensure that products are properly installed and handled in order to maintain them in a safe condition. It is assumed that everyone who will be associated with the equipment will be familiar with the contents of the Safety Section.

1.2

Explanation of symbols and labels The meaning of symbols and labels which may be used on the equipment or in the product documentation, is given below.

*Note

The term earth used throughout the product documentation is the direct equivalent of the North American term ground.

P12y/EN T00/A11 Page 4/8

Technical Guide Safety Section MiCOM P125/P126/P127

2.

INSTALLING, COMMISSIONING AND SERVICING

Equipment connections Personnel undertaking installation, commissioning or servicing work on this equipment should be aware of the correct working procedures to ensure safety. The product documentation should be consulted before installing, commissioning or servicing the equipment. Terminals exposed during installation, commissioning and maintenance may present a hazardous voltage unless the equipment is electrically isolated. If there is unlocked access to the rear of the equipment, care should be taken by all personnel to avoid electric shock or energy hazards. Voltage and current connections should be made using insulated crimp terminations to ensure that terminal block insulation requirements are maintained for safety. To ensure that wires are correctly terminated, the correct crimp terminal and tool for the wire size should be used. Before energising the equipment it must be earthed using the protective earth terminal, or the appropriate termination of the supply plug in the case of plug connected equipment. Omitting or disconnecting the equipment earth may cause a safety hazard. The recommended minimum earth wire size is 2.5 mm2, unless otherwise stated in the technical data section of the product documentation. Before energising the equipment, the following should be checked: Voltage rating and polarity; CT circuit rating and integrity of connections; Protective fuse rating; Integrity of earth connection ( where applicable)

Technical Guide Safety Section MiCOM P125/P126/P127

P12y/EN T00/A11 Page 5/8

3.

EQUIPMENT OPERATING CONDITIONS

The equipment should be operated within the specified electrical and environmental limits.

3.1

Current transformer circuits Do not open the secondary circuit of a live CT since the high voltage produced may be lethal to personnel and could damage insulation.

3.2

External resistors Where external resistors are fitted to relays, these may present a risk of electric shock or burns, if touched.

3.3

Battery replacement Where internal batteries are fitted they should be replaced with the recommended type and be installed with the correct polarity, to avoid possible damage to the equipment.

3.4

Insulation and dielectric strength testing Insulation testing may leave capacitors charged up to a hazardous voltage. At the end of each part of the test, the voltage should be gradually reduced to zero, to discharge capacitors, before the test leads are disconnected.

P12y/EN T00/A11 Page 6/8

Technical Guide Safety Section MiCOM P125/P126/P127

4.

DECOMMISSIONING AND DISPOSAL Decommissioning: The auxiliary supply circuit in the relay may include

capacitors across the supply or to earth. To avoid electric shock or energy hazards, after completely isolating the supplies to the relay (both poles of any dc supply), the capacitors should be safely discharged via the external terminals prior to decommissioning. It is recommended that incineration and disposal to water courses is avoided. The product should be disposed of in a safe manner. Any products containing batteries should have them removed before disposal, taking precautions to avoid short circuits. Particular regulations within the country of operation, may apply to the disposal of lithium batteries.

Disposal:

Technical Guide Safety Section MiCOM P125/P126/P127

P12y/EN T00/A11 Page 7/8

5.

TECHNICAL SPECIFICATIONS

Insulation class : IEC 61010-1:1990/A2: 1995 Class I EN 61010-1:1993/A2: 1995 Class I Installation Category (OverVoltage) : IEC 61010-1:1990/A2: 1995 Category III EN 61010-1: 1993/A2: 1995 Category III This equipment requires a protective (safety) earth connection to ensure user safety. Distribution level, fixed installation. Equipment in this category is qualification tested at 5kV peak, 1.2/50s, 500W, 0.5J, between all supply circuits and earth and also between independent circuits. Compliance is demonstrated by reference to generic safety standards. Compliance with the European Commission Low Voltage Directive. 1993/A11:1997 Compliance Is demonstrated by reference to generic safety standards.

Environment :

IEC 61010-1:1990/A2: 1995 Pollution degree 2 IEC 61010-1:1993/A2: 1995 Pollution degree 2

Product safety :

72/73/EEC

EN61010-1:1993/A2: 1995 EN60950:

EMC compliance : Generic standards where used to Compliance with the establish conformity. European Commission EMC Directive. Generic standards EN50081-2: 1994 where used to establish EN60952-2: 1995 conformity.

P12y/EN T00/A11 Page 8/8

Technical Guide Safety Section MiCOM P125/P126/P127

BLANK PAGE

Anda mungkin juga menyukai

- The IEE Wiring Regulations Explained and IllustratedDari EverandThe IEE Wiring Regulations Explained and IllustratedPenilaian: 4 dari 5 bintang4/5 (14)

- Tg8614a P342, P343 PDFDokumen298 halamanTg8614a P342, P343 PDFErick FalconiBelum ada peringkat

- Files RELAYS ALSTOM P14 P14x-En-T-A22Dokumen506 halamanFiles RELAYS ALSTOM P14 P14x-En-T-A22Mohamed ElmoghazyBelum ada peringkat

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- P341Dokumen290 halamanP341Pradeep Kumar SukumaranBelum ada peringkat

- I400 Enm A11Dokumen28 halamanI400 Enm A11Rinda_Rayna100% (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsDari EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsBelum ada peringkat

- KVTR 100Dokumen114 halamanKVTR 100gutman0464289Belum ada peringkat

- R5888C Quadramho A4RBDokumen336 halamanR5888C Quadramho A4RBdbeard811100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- Kavr100 DDokumen130 halamanKavr100 DIndra Aryana0% (1)

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageDari EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageBelum ada peringkat

- Commissioning Instructions Motormaster 200 Motor Protection RelaysDokumen20 halamanCommissioning Instructions Motormaster 200 Motor Protection RelaysRinda_RaynaBelum ada peringkat

- Offshore Electrical Engineering ManualDari EverandOffshore Electrical Engineering ManualPenilaian: 4 dari 5 bintang4/5 (9)

- R8005C MvawDokumen20 halamanR8005C MvawRinda_RaynaBelum ada peringkat

- Service Manual Type LFCB102 Digital Current Differential RelayDokumen211 halamanService Manual Type LFCB102 Digital Current Differential RelayRinda_RaynaBelum ada peringkat

- Areva MFACDokumen30 halamanAreva MFACFerry A ViawanBelum ada peringkat

- Service Manual Type MRSU 04 Rotor Earth Fault RelayDokumen24 halamanService Manual Type MRSU 04 Rotor Earth Fault RelayRinda_RaynaBelum ada peringkat

- Service Manual Type MYTU 04 Field Failure RelayDokumen28 halamanService Manual Type MYTU 04 Field Failure RelayRinda_RaynaBelum ada peringkat

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsDari EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsBelum ada peringkat

- Tg8614a P342, P343 PDFDokumen298 halamanTg8614a P342, P343 PDFRicardo LyraBelum ada peringkat

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsDari EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsBelum ada peringkat

- Service Manual Type MCSU 01 Sensitive Earth Fault RelayDokumen24 halamanService Manual Type MCSU 01 Sensitive Earth Fault RelayRinda_Rayna100% (1)

- C264 en o C80 PDFDokumen828 halamanC264 en o C80 PDFAnonymous g0InJ4BLBBelum ada peringkat

- R8054J PDFDokumen32 halamanR8054J PDFanilerBelum ada peringkat

- GFR Gec Mcgg22Dokumen32 halamanGFR Gec Mcgg22Cakasana Alif Bathamantri100% (2)

- C264 en o C80Dokumen828 halamanC264 en o C80Natarajan SubramanyanBelum ada peringkat

- R8102e Mitz02Dokumen24 halamanR8102e Mitz02Rinda_RaynaBelum ada peringkat

- KCGG Kceg Service ManualDokumen284 halamanKCGG Kceg Service Manualisola_zhou100% (1)

- KVGC 102 - R8552BDokumen166 halamanKVGC 102 - R8552BDIEGOBelum ada peringkat

- LFCB 102Dokumen211 halamanLFCB 102Văn Quang NgôBelum ada peringkat

- Type MCAG 14, 34: High Stability Circulating Current RelaysDokumen30 halamanType MCAG 14, 34: High Stability Circulating Current Relaysrenjithas2005100% (2)

- P34x - Application Guide PDFDokumen210 halamanP34x - Application Guide PDFchidambara_2013Belum ada peringkat

- MCGG Over Current RelayDokumen34 halamanMCGG Over Current Relaysilkwormfrog100% (2)

- R8124B MJTW01Dokumen150 halamanR8124B MJTW01Rinda_RaynaBelum ada peringkat

- AREVA MVAP22 Voltage Balance RelayDokumen22 halamanAREVA MVAP22 Voltage Balance Relayadeelzafar100Belum ada peringkat

- MVAJ053Dokumen38 halamanMVAJ053Yusof BasriBelum ada peringkat

- KCGG Relay ManualDokumen284 halamanKCGG Relay Manualmfulk3100% (1)

- I9-083G Novar 300Dokumen16 halamanI9-083G Novar 300Rinda_Rayna0% (1)

- Kavs100 R8506iDokumen96 halamanKavs100 R8506iedcielebuen0123Belum ada peringkat

- MTRKA - EN - M - C Manual GB PDFDokumen60 halamanMTRKA - EN - M - C Manual GB PDFWendy CaseyBelum ada peringkat

- Alstom MicomDokumen502 halamanAlstom MicommohamedayazuddinBelum ada peringkat

- Areva MVTT Relay ManualDokumen42 halamanAreva MVTT Relay ManualjbatoyBelum ada peringkat

- Regulador de Voltage KVGC 202Dokumen168 halamanRegulador de Voltage KVGC 202mimiii36Belum ada peringkat

- Regulador de Voltage KVGC 202Dokumen168 halamanRegulador de Voltage KVGC 202enriqueunoBelum ada peringkat

- Manual m2x3 Enm b11Dokumen94 halamanManual m2x3 Enm b11pondokjituBelum ada peringkat

- Mvaj 05 10 20 Manual GBDokumen38 halamanMvaj 05 10 20 Manual GBsamlash100% (2)

- R8033C MvtiDokumen28 halamanR8033C MvtiRinda_RaynaBelum ada peringkat

- KVTR100 AutorecloserDokumen114 halamanKVTR100 AutorecloserBrian KirbyBelum ada peringkat

- Service Manual Type MCAG 14, 34 High Stability Circulating Current RelaysDokumen28 halamanService Manual Type MCAG 14, 34 High Stability Circulating Current RelaysIsmir Pobric100% (1)

- Micom P124: Self & Dual Powered Overcurrent RelaysDokumen370 halamanMicom P124: Self & Dual Powered Overcurrent RelaysAdip ChyBelum ada peringkat

- MHOR04 Manual GB PDFDokumen31 halamanMHOR04 Manual GB PDFniketsaliBelum ada peringkat

- Service Manual Type MHOA 04, MHOB 04, MHOC 04 Translay Feeder Protection SchemesDokumen36 halamanService Manual Type MHOA 04, MHOB 04, MHOC 04 Translay Feeder Protection SchemesRinda_RaynaBelum ada peringkat

- Over Current Time RelayDokumen5 halamanOver Current Time RelayKopi143Belum ada peringkat

- Case DimensionsDokumen2 halamanCase DimensionsKopi143Belum ada peringkat

- Transmission LinesDokumen8 halamanTransmission LinesKopi143Belum ada peringkat

- Negative Phase Sequence Protection Inverse Time Characteristic Curve I2 ElementDokumen2 halamanNegative Phase Sequence Protection Inverse Time Characteristic Curve I2 ElementKopi143Belum ada peringkat

- Micom P740: Numerical Busbar ProtectionDokumen4 halamanMicom P740: Numerical Busbar ProtectionKopi143Belum ada peringkat

- Meter Installation GuidelinesDokumen4 halamanMeter Installation GuidelinesKopi143Belum ada peringkat

- Substation BasicsDokumen16 halamanSubstation BasicsAhmedEEEBelum ada peringkat

- Maintenance TypesDokumen31 halamanMaintenance TypesKopi143Belum ada peringkat

- 3 Circuit BreakersDokumen99 halaman3 Circuit BreakersKopi143Belum ada peringkat

- Basic Electrical SafetyDokumen28 halamanBasic Electrical SafetyKopi143Belum ada peringkat

- Amd3 MeDokumen40 halamanAmd3 MeKopi143Belum ada peringkat

- Maintenance TypesDokumen31 halamanMaintenance TypesKopi143Belum ada peringkat

- Micom p211 Io 01 enDokumen8 halamanMicom p211 Io 01 enKopi143Belum ada peringkat

- 13 Accessories and Spare PartsDokumen2 halaman13 Accessories and Spare PartsKopi143Belum ada peringkat

- P63 XENM50 Chap 11Dokumen6 halamanP63 XENM50 Chap 11Kopi143Belum ada peringkat

- PP904PHEDokumen7 halamanPP904PHEKopi143Belum ada peringkat

- 2nd Sess SolDokumen4 halaman2nd Sess SolAwais ShamsBelum ada peringkat

- Product Datasheet: NIGHT RACER 110 - Halogen Headlight Lamps For MotorcyclesDokumen4 halamanProduct Datasheet: NIGHT RACER 110 - Halogen Headlight Lamps For MotorcycleswetgarbdsfbdbfBelum ada peringkat

- Westinghouse Feb. 1978 Large Lamp CatalogDokumen52 halamanWestinghouse Feb. 1978 Large Lamp CatalogAlan Masters100% (1)

- The Collected Home by Darryl CarterDokumen23 halamanThe Collected Home by Darryl CarterCrown Publishing GroupBelum ada peringkat

- Powerpoint ELK-3 - 420 - ApparatusDokumen39 halamanPowerpoint ELK-3 - 420 - ApparatusMahmoud MoezBelum ada peringkat

- Electrical ListDokumen54 halamanElectrical ListhamzadarbarBelum ada peringkat

- SLD-3 PrintDokumen1 halamanSLD-3 PrintSharif 087Belum ada peringkat

- Electric Diagram: YZF155 2019 (B2P1)Dokumen3 halamanElectric Diagram: YZF155 2019 (B2P1)Devi KhoirudinBelum ada peringkat

- Final Qty. & Upto Rar-18 Qty. Compare 02.01.22.Dokumen128 halamanFinal Qty. & Upto Rar-18 Qty. Compare 02.01.22.Iqbal ShaikBelum ada peringkat

- En Odm1Dokumen2 halamanEn Odm1Fathi MusaBelum ada peringkat

- Lesson 1-17: Identifying Ports: IC Training - Module One: Computing FundamentalsDokumen2 halamanLesson 1-17: Identifying Ports: IC Training - Module One: Computing FundamentalsVinMarBelum ada peringkat

- KP Sharma Estimate PDFDokumen3 halamanKP Sharma Estimate PDFSudip GhimireBelum ada peringkat

- Starter Solenoid Wiring DiagramDokumen1 halamanStarter Solenoid Wiring Diagramnetemma97Belum ada peringkat

- Lab Report I.E Chapter 2Dokumen3 halamanLab Report I.E Chapter 2syahmimisahfani0% (1)

- kbpb125 ManualDokumen30 halamankbpb125 ManualCesar RosilloBelum ada peringkat

- ElectronicFuelManagementAPSI60 A HI PDFDokumen7 halamanElectronicFuelManagementAPSI60 A HI PDFMatt RoyBelum ada peringkat

- Bang Gia MCB MCCB Acb Schneider 04 2013Dokumen203 halamanBang Gia MCB MCCB Acb Schneider 04 2013letrungtinhBelum ada peringkat

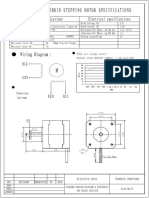

- High Torque Hybrid Stepping Motor Spe Cificatio NSDokumen2 halamanHigh Torque Hybrid Stepping Motor Spe Cificatio NSYadira GonzalezBelum ada peringkat

- 9320A093GDokumen4 halaman9320A093GKevin TtitoBelum ada peringkat

- Bertram BOMDokumen4 halamanBertram BOMwacibi6434Belum ada peringkat

- Green Ray New Product Catalogue 2014 - Final Version - Draf - 1.1Dokumen37 halamanGreen Ray New Product Catalogue 2014 - Final Version - Draf - 1.1Jesus Augusto Molina MatuteBelum ada peringkat

- Capacitor ManualDokumen5 halamanCapacitor ManualvyroreiBelum ada peringkat

- Sylvania Fluorescent Lifeline High Output Lamps Brochure 1964Dokumen4 halamanSylvania Fluorescent Lifeline High Output Lamps Brochure 1964Alan Masters100% (1)

- Posi-Strut - Posi Strut Floor Roof Installation ManualDokumen32 halamanPosi-Strut - Posi Strut Floor Roof Installation ManualLê Hoàng TháiBelum ada peringkat

- Modulo XD: Three Phase CapacitorsDokumen3 halamanModulo XD: Three Phase CapacitorsNGUYEN VAN THIBelum ada peringkat

- PCC1300 O&M ManualDokumen54 halamanPCC1300 O&M ManualThein Htoon lwinBelum ada peringkat

- DKG 114Dokumen2 halamanDKG 114Vu TuongBelum ada peringkat

- Electrical Systems in A BuildingDokumen30 halamanElectrical Systems in A Buildingpipeds100% (6)

- Varistor - Test: SMCS - 4466-081Dokumen6 halamanVaristor - Test: SMCS - 4466-081Rudi BilahBelum ada peringkat

- Fixing and Bracing Guidelines For Timber Roof Trusses 2015 - Issue 1Dokumen32 halamanFixing and Bracing Guidelines For Timber Roof Trusses 2015 - Issue 1Arnel DodongBelum ada peringkat

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDari EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DonePenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessDari EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessBelum ada peringkat

- Laws of UX: Using Psychology to Design Better Products & ServicesDari EverandLaws of UX: Using Psychology to Design Better Products & ServicesPenilaian: 5 dari 5 bintang5/5 (9)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDari EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsBelum ada peringkat

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionDari EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionBelum ada peringkat

- 507 Mechanical Movements: Mechanisms and DevicesDari Everand507 Mechanical Movements: Mechanisms and DevicesPenilaian: 4 dari 5 bintang4/5 (28)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsDari EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsPenilaian: 4 dari 5 bintang4/5 (5)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDari EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableBelum ada peringkat

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDari EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperiencePenilaian: 4 dari 5 bintang4/5 (19)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDari EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchPenilaian: 4 dari 5 bintang4/5 (10)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesDari EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesBelum ada peringkat

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)