Water 126116.3

Diunggah oleh

Gene Citrone Jr.Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Water 126116.3

Diunggah oleh

Gene Citrone Jr.Hak Cipta:

Format Tersedia

August/September 2012 - Vol.

27, Issue 4

www.wwinternational.com

Priority

Substances

Impact on European Utilities

Asias Leaky

Lessons

Urban Water Management Focus

Better Biosolids

Thermal Hydrolysis Experience in UK

Danish Dynamo

CEO Carsten Bjerg speaks

exclusively on Grundfos

new direction

Click here

to access

Spring 2012

Energy Catalog

The SE and SL ranges of wastewater

pumps are the highest total efciency

pumps currently available. Innovative

technologies from Grundfos bring

together intelligence, motors, hydraulics

and functionality to meet the challenges

of modern wastewater, maximising

the hydraulic, electrical and mechanical

efciency of your pumps.

ITS ABOUT

WIRE-TO-WATER

EFFICIENCY

The SE and SL ranges ofer the highest total

efciency yet in a wastewater pump.

Highest wire-to-water efciency: The best

yet, reducing your total costs and making life

easier

Best hydraulic efciency: No compromise on

free passage, meaning better solids handling

and greater non-clogging capabilities

Continual operation: Unprecedented

reliability from high motor and mechanical

efciency, with all aspects of pump operation

controlled intelligently

See more at www.grundfos.com/no-compromise

Scan the code and see

the technologies that

achieve the highest

total efciency.

be

think

innovate

For Info. http://wwi.hotims.com RS# 1

1

August/September | 2012 www.wwinternational.com

August/September 2012 - Vol. 27, Issue 4

www.wwinternational.com

Priority

Substances

Impact on European Utilities

Asias Leaky

Lessons

Urban Water Management Focus

Better Biosolids

Thermal Hydrolysis Experience in UK

Danish Dynamo

CEO Carsten Bjerg speaks

exclusively on Grundfos

new direction

Cover image courtesy

Grundfos

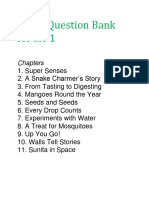

Contents

August/September 2012 Vol. 27 Issue 4

$67 Single copies US & Intl, $44 Digital (worldwide)

To receive this magazine in a digital format, go to wwi.omeda.com

10

24 40

Technology Roundup

Editorial Focus

MICROPOLLUTANTS

24 The European Commission is proposing to add 15 additional chemi-

cals to the list of pollutants to be monitored and controlled by water utilities.

This article addresses what improvements would need to be measure these

Priority Substances.

COLLECTION & DISTRIBUTION SYSTEMS

28 Around 29 billion cubic meters of water is lost each year in Asia. Yet

certain utilities have reduced non-revenue water down to a mere 6%. Why

the disparity? A look at the Philippines, Cambodia and India.

STORMWATER MANAGEMENT

32 South Korea has learnt to harvest rainwater to cope with monsoon

conditions, followed by drought. A look at where this originated in Star City.

SLUDGE PROCESSING/BIOSOLIDS

36 The UKs Davyhulme facility is not only one of the worlds largest bio-

solids facilities, its also proving the importance of thermal hydrolysis tech-

4 Perspective

6 News

50 International Show Preview: WEFTEC

54 Technology Roundup: Computer Software

55 Product Review: Water Storage

56 Diary/ Ad Index/Web Promo

WATER LEADER FOCUS

10 Global pump manufacturing giant Grundfos is diversifying into water

treatment. CEO Carsten Bjerg speaks exclusively to WWi about the move

and the firms recent S-tube impeller launch.

CREATIVE FINANCE

16 The latest report from industry analysts Frost & Sullivan investigates

efficiency priorities for the top five European water utility markets (France,

Germany, Italy, Spain and the UK).

Regulars

Regional Spotlight

EASTERN EUROPE

20 Bucharests Boom: utility Apa Nova Bucharest explains the story

behind how the city has transformed its wastewater infrastructure since pri-

vatization and future opportunities for the global water sector.

54 Computer Software & Automation Technology: Texan utility imple-

ments Dercetos Aquadapt energy management software; SCADA educa-

tional software update from InduSoft; particle/water analysis software; mass

flow transmitter from Endress+Hauser.

Product Review

53 Water Storage: modular pH sensor for open tanks from Sensorex; elas-

tomeric lining to reduce cracking on secondary containment structures and

GEOlight stormwater storage units from SDS.

News Highlights

6 Recycle Phosphorus and prevent future food crisis

6 Nano-toilet could eliminate water needed for sanitation

8 Reverse Osmosis confirmed for Gaza desalination plant

nology for sludge treatment.

40 Organic food leftovers and wastewater are usually treated anaerobi-

cally, but separately. This article addresses why, given the similarities in

technologies, there should be more co-digestion.

INDUSTRIAL WATER/WASTEWATER

44 Added micronutrients to a brewery in Spain helped enhance biogas

production and stabilize digestors following poor performance from anaero-

bic digestors.

46 Landfill leachate disposal is now requiring more complicated filtration

techniques to meet increasing regulations. A look at how UF and RO mem-

branes are being applied.

Symphony Plus Total Plant Automation. The power

of a well orchestrated performance.

Symphony

TM

Plus is the new generation of ABBs total plant automation for

the power and water industries. Designed to maximize plant efficiency and

reliability through automation, integration and optimization of the entire plant,

Symphony Plus offers a simple, scalable, seamless and secure solution.

Tune to Symphony Plus and experience the power of a well orchestrated

performance. www.abb.com/powergeneration

ABB Ltd.

Business Unit Power Generation

P.O. Box 8131

8050 Zurich, Switzerland

Tel. +41 ( 0) 43 317 5380

For Info. http://wwi.hotims.com RS# 2

3

August/September | 2012 www.wwinternational.com

SUBSCRIBER SERVICE: P.O.Box 3264 Northbrook, IL USA 60065-3264, Tel: (847) 559-7501 Fax: (847) 291-4816 E-mail: wwi@omeda.com, Water & Wastewater International is published six times a year. Authorization to photocopy items for internal or

personal use is granted by Water & Wastewater International. No part of Water & Wastewater International may be reproduced without the express written permission of the publisher. The statements made or opinions expressed do not necessarily reflect

the views of Water & Wastewater International or PennWell Corporation. Subscriptions: $271 a year,single $61; Digital-$152, single $40. POSTMASTER: Send address changes to Subscriber Service, Water & Wastewater International, P.O. Box 3209, Northbrook, IL USA 60065-3209

PETER S. CARTWRIGHT

President Cartwright

Consulting Co. [Oegstgeest,

The Netherlands]

FRDRICK COUSIN, PRODUCT

MANAGER Degrmont

Technologies [Paris, France]

BEATRIZ LPEZ LINARES

Environmental Superintendent

DaimlerChrysler [Toluca, Mexico]

IAN LOMAX Global Marketing

Manager - Desalination Dow

Water Solutions [Rheinmuester,

Germany]

PAUL OVERBECK

Executive Director International

Ozone Association-PAG

and International Ultraviolet

Association [Phoenix, USA]

ANDREW WARNES

Senior Product Manager -

Systems Pentair Residential

Filtration - A Joint Venture of

GE & Pentair [Chicago, USA]

EDITORIAL ADVISORY COMMITTEE

PUBLISHER Timm Dower

tdower@Pennwell.com

CHIEF EDITOR Tom Freyberg

TomF@pennwell.com

DESIGN EDITOR Heather Skeith

heathers@pennwell.com

DIGITAL MEDIA EDITOR Angela Godwin

angelag@Pennwell.com

PRODUCTION MANAGER Rae Lynn Cooper

raec@pennwell.com

MARKETING MANAGER Tim Chambers

Tchambers@pennwell.com

CIRCULATION & AUDIENCE Emily Martha Martin

DEVELOPMENT MANAGER emilym@pennwell.com

CORPORATE HEADQUARTERS, PENNWELL CORPORATION

1421 S. SHERIDAN ROAD, TULSA, OK 74112 USA

SR. VP & GROUP PUBLISHER: Tom Fowler

PRESIDENT/CEO: Robert F. Biolchini

CHAIRMAN Frank T. Lauinger

ADVERTISING SALES EUROPE:

Roy Morris - Sales Manager

T: +44 (0)1992 656 613 E: rmorris@Pennwell.com

UNITED STATES/CANADA:

EASTERN CANADA, NORTHEAST USA:

Craig Wiggins - Regional Manager

T: +1 610-430-8181 E: craigw@pennwell.com

SOUTHEAST USA:

Dottie LaFerney - Sales Manager

T: +1 512-858-7927 E: dottiel@pennwell.com

MIDWEST & WESTERN COAST USA:

Amy Bailie - Regional Manager

T: +1 918-832-9241 E: amyb@pennwell.com

BULLETIN BOARDS:

Tonya Hobson - Sales Manager

T: +1 918-835-3161 E: tonyah@pennwell.com

ASIA: SINGAPORE:

Joanna Wong-Monis - Advertising Manager

T: +(65) 9062 6227 E: joanna@pennwell.sg

HONG KONG:

Adonis Mak - Media Representive

T: +8 52 2838 6298 E: adonism@actintl.com.hk

JAPAN:

Manami Konishi, Masaki Mori and Kimie Takemura, ICS Convention

Design. Inc., 6F Chiyoda Bldg., 1-5-18 Sarugakucho, Chiyoda-ku,

Tokyo 101-8449, Japan; Tel: +81-3-3219-3641; Fax: +81-3-3219-

3628; E-mail: konishi-manami@ics-inc.co.jp, masaki.mori@ics-inc.

co.jp, takemura-kimie@ics-inc.co.jp

INDIA:

Paresh Shingala - Media Representive

T: +(91) 44 535 8075 E: shingala_asso@vsnl.net

RUSSIA:

Svetlana Strukova - Regional Manager

T: +7 095 1136 370 E: Svetlanas@pennwell.com

REPRINTS:

T: +1 866 879-9144 E: pennwellreprint@fosterprinting.com

PennWell International Publications

The Water Tower, Gunpowder Mill,

Powdermill Lane, Waltham Abbey,

Essex. EN9 1BN. UK

Tel: +44 (0) 7904867746

Editorial Offices

PennWell Corporation

1421 South Sheridan Road

Tulsa, Oklahoma 74112-6600 USA

T: 918-831-9176

ISSN: 1069-4994

For Info. http://wwi.hotims.com RS# 3

Perspective

4

August/September | 2012 www.wwinternational.com

Tom Freyberg

Chief Editor

L

ike any other red blooded carnivore, Ive

been partial to a good steak in the past. A

medium-rare Wagyu sirloin, to be precise,

was one of the highlights of my steak eat-

ing conquests.

In the past Ive not really put any thought like

the majority of Westerners in the journey a par-

ticular steak has taken to make it from feld to fork

for my enjoyment. Even having a strict vegetarian

fance hasnt changed my eating habits over the

years.

Yet recently my diet has changed. Its always

been healthy but over the last month its got better.

Ive cut down on the amount of red meat, increased

grilled, lean white meat such as chicken, reduced

carbohydrates and increased fruit, salad and veg-

etables.

Why the change? Firstly it was a decision to

cut down on saturated fat (a known baddie in

red meat). Food labels, including Guideline Daily

Amounts (GDA), were once considered annoying

coloured spots getting in the way of a good meal.

Now, instead, I take note of ingredients and these

GDAs, choosing healthier options where possible.

Secondly its because Im training for a half-mara-

thon distance event, coming up in three months

time so diet is a key part of the training.

Yet, there is another factor now impacting peo-

ples diets and choices of food: virtual water. Many

of you will be aware of the amount of embedded

water in products and the often quoted fgure that it

takes 15,000 liters of water to produce 1 kilo of beef.

To date I dont think such stark statistics would

have impacted on shopping habits when people

are at shops or supermarkets. Are consumers

thinking about the water footprint of a product be-

fore making a conscience effort to buy it? Probably

not. Decisions are driven by price, taste, impulse

and brand loyalty. Even carbon mile labels arent

enough to break these habits. And thats certainly

one topic that has been in the public eye longer

than virtual water.

Yet a new report hopes to change these percep-

tions and provoke more discussion. Called Feeding

a thirsty world: Challenges and opportunities for a

water and food secure world, the Stockholm In-

ternational Water Institute's latest report addresses

water scarcity and food production.

It states

that with 70% of water with-

drawals used in agriculture, growing more food to

feed an additional two billion people by 2050 will

place greater pressure on water and land.

Most of us are aware that were exhausting the

worlds resources at an alarming pace, but what is

the report recommending we do? Improvements in

on-farm water effciency; reductions in losses and

waste in the food supply chain; enhanced response

networks and early warning systems in agricultural

emergencies are all recommended.

The UN recommends that we should all fol-

low a healthier, sustainable diet and consume less

water-intensive products. This is as well as reduce

the 30% of wasted food which is produced and im-

prove current production methods. The theme of

the World Water Day earlier this year was even Wa-

ter and Food Security to try and hammer home the

message.

Nor should these global, political challenges be

seen as out of reach from the water sector, includ-

ing technology providers.

As WWi featured earlier this year in its Middle

Eastern spotlight, a small group of farming settle-

ments in the Negev region, Israel, solved the prob-

lem of inadequate freshwater sources. The farmers

pooled their resources together and funded an ef-

fuent reuse system, which was situated next to a

nearby wastewater treatment plant. Filtration and

UV technology was provided by a major water pu-

rifcation company and reused water was piped to

the felds.

In conclusion, its worth noting a comment made

back in 1974 at the frst World Food Summit by US

Secretary of State, Henry Kissinger. He boldly said:

No child will go to bed hungry within ten years.

This aim/prediction couldnt have been more

wrong. Today there remains one billion undernour-

ished people. This raises the question that if the

worldwide population will reach its predicted nine

billion by 2050, how on earth will everyone be fed?

And if agriculture is increased, even if super

crops are developed which require less water to be

grown in arid climates, what will this increase mean

for the water industry? Its certainly worth thinking

about the next time you tuck into a meal. WWi

Eating Our Way to a

Thirsty Planet

A new report highlights threats and

opportunities for food and water

scarcity. Can the West change its

water intensive eating habits?

Since 2009, the Wastewater Industry

Has Had Its Eyes on Us

www.sulzer.com

Get Ready for WEFTEC,

Where the World-Class

Range Will Be Complete

TheABSEffeXRevolutioncontinues

When we launched the premium-efficiency ABS submersible

sewage pump XFP, it was only the starting shot of the ABS EffeX

Revolution. In the years since, weve introduced more products

that raise the bar for energy savings, efficiency and reliability.

You wont believe what were introducing now.

Prepare to be amazed at the Sulzer Pumps stand: Hall I,

Stand 7239. Cannot make it to the show? See what all

the excitement is about at: www.ABSEffeX.com

Nowtherewillbe

awholelot

moretosee

Sulzer Pumps

For Info. http://wwi.hotims.com RS# 4

6

August/September | 2012 www.wwinternational.com

Worldwide News

Europe/Middle East

Threats/opportunities

outlined in SIWI report

on water and food

security

Continuing current trends in food

production could lead to increased

shortages and intense competition for

scarce water resources in many re-

gions across the world, the Stockholm

International Water Institute (SIWI) has

said.

The fndings were documented in its

new report entitled Feeding a thirsty

world: Challenges and opportunities for

a water and food secure world. It noted

that 900 million people are hungry and

two billion more people are under nour-

ished in spite of the fact that per capita

production continues to increase.

With 70% of all water withdrawals

used in agriculture, growing more food

to feed an additional two billion people

by 2050 will place greater pressure on

available water and land.

The authors spotlight a number of

essential and largely overlooked chal-

lenges where dedicated action can

help ensure food security to a growing

global population with available water

resources.

These included improvements in

on-farm water effciency, reductions in

losses and waste in the food supply

chain, enhanced response networks to

early warning systems for agricultural

emergencies, and increased investment

to close the gender gap in agricultural

production. The fndings also investi-

gated the impact of the recent surge in

foreign direct investment to lease land

in developing countries on local and

regional water resources. SIWI said this

phenomenon requires more stringent

regulation to ensure that the water and

land rights of local farming communities

are upheld.

Authors behind the report included

SIWI, the Food and Agriculture Orga-

nizations of the United Nations and the

IWMI.

FIELD NOTES

Urgent action is needed to reduce

the rate of phosphorus depletion, the

Chartered Institution of Water and En-

vironmental Management (CIWEM) said

in its latest Policy Position Statement

(PPS).

The PPS outlines the main issues

relating to the worlds supply of useable

phosphate and highlighted the need for

urgent action to achieve its recovery to

improve food security and reduce geo-

political risk.

The statement highlighted how the

mining of inorganic phosphates are re-

lied upon for agriculture and industry.

At the present rate of extraction,

todays phosphate mines will be ex-

hausted by the end of the 21st century

and estimates of future reserves range

from 200 to 400 years (at the current

rate of extraction). China and the USA

have both tried to implement measures

to reduce exports of phosphate as they

have already realised its strategic im-

portance.Wastewater treatment could

recover 95% of the phosphate from

urban wastewater, the statement said.

CIWEM said land application of suit-

ably treated biosolids (sewage sludge)

is invariably the best way to conserve

and recycle the phosphate it contains.

Currently only 20% of the phosphate in

urban wastewater in the EU is recycled.

In order to increase this, CIWEM

called on all governments to follow the

examples of Sweden and Germany and

make phosphate recovery from urban

wastewater a legal requirement.

Nick Reeves OBE, executive direc-

tor at CIWEM, said: Phosphorus is

scarce and resources are being de-

pleted rapidly. To date, attention has

focussed on removing phosphate from

wastewater streams to prevent the eu-

trophication of waters.

But phosphate is of huge strategic

value over the longer term and we must

also act to recover phosphate from

waste-streams for use. The economics

of extensive phosphate recovery from

wastewater would be quite favourable

if we viewed phosphorus as a resource,

rather than the conventional approach

of treating it as a pollutant in the envi-

ronment, and mining it in mineral form

to fertilise our crops.

Canadian frm Ostara Nutrient Re-

covery Technologies is working with UK

utility Thames Water to recover phos-

phorous from the Slough WWTP.

Itron has been awarded a contract for

more than 11,000 advanced residential

water meters equipped with communi-

cation modules, as well as the fxed net-

work infrastructure to support customers

in Floresti, Moldova. Servicii Comunale

Floresti, the water utility servicing several

municipalities, will deploy Itron technol-

ogy over the course of six months begin-

ning later this year.

Itrons water meters will replace ag-

ing meters and will be installed on new

subscribers homes throughout the city.

Consumption data will be transmitted

through the fxed network. The automa-

tion of the entire meter reading process

is hoped to reduce operational costs and

improve effciency.

As part of our water distribution net-

work modernization project, mainly f-

nanced by the World Bank and European

Bank of Reconstruction and Develop-

ment, we decided to select Itron to im-

plement high-end metering technologies

and the EverBlu advanced data collection

system, said Sergiu Rusu, director of

Servicii Comunale Floresti. Itrons wire-

less solution is ideally suited to our needs

for collecting data from hard-to-read me-

ters in urban and semi-rural areas.

As part of the Gates Foundation

global challenge to reinvent the toilet in

developing nations, the UKs Cranfeld

University has designed a solution that

uses nano and advanced water treat-

ment technologies.

The university received $800,000

worth of funding from the Reinvent the

Toilet Challenge of the Bill & Melinda

Gates Foundation Water.

Cranfelds Nano Membrane Toilet

can treat human waste on-site without

external energy or water, allowing it to

be safely transported away and poten-

tially reused.

The concept uses a combination of

nano and advanced water treatment

technologies and works by essentially

reducing the water content of the sludge

through membranes that allow extrac-

tion of water as a vapour, using a mech-

anism powered by the user. Resulting

sludge moves downwards under gravity

and is encapsulated in briquette form,

with the potential for reuse in combust-

ing or applying to land as a fertiliser.

Cranfeld University said the reinvent-

ed toilet will also have potential in devel-

oped as well as developing countries,

such as Africa.

The results of the frst round of grants

were showcased at the Reinvent the

Toilet Fair on August 14 and 15, 2012

at the foundations offces in Seattle,

Washington.

The fair showcased innovations from

around the world, working towards the

shared vision for a reinvented toilet.

A prototype of the Cranfeld concept is

due for completion next year.

Moldova upgrades water meters

Nano-toilet could eliminate

water needed for sanitation

Recycle Phosphorus and

prevent future food crisis

News Briefs

MBBR order

in Egypt helps

Headworks Bio

enter market

The General Egyptian Company

for Buildings (GEC) in Cairo has

contracted Texas-based Headworks

BIO to retroft a wastewater treat-

ment plant in Alexandria.

The Mubarak facility in Alexandria

was initially designed to treat 4,000

m

3

/day and was commissioned in

2001. However, the plant was taken

out of service in 2009 after suffering

from membrane fouling challenges.

Headworks BIO was asked to

review the performance of the exist-

ing plant and evaluate the options

available for refurbishment. The pro-

posed system involves retroftting

MBR (Membrane Bioreactor) aera-

tion tanks with a Moving Bed Bioflm

Reactor (MBBR) to treat 4,000 m

3

/

day and convert the remaining vol-

ume into a secondary clarifer.

The retroft will help the facil-

ity produce a consistent effu-

ent quality of 50:80:50 mg/L for

BOD:COD:TSS. The biological

treatment process will remove the

infuent BOD to meet the required

effuent target and require minimal

maintenance because each piece

of media self-maintains an optimum

level of productive bioflm, according

to the company.

The Flygt heritage of groundbreaking innovations

continues, as yet again our application expertise

and engineering excellence lead the way. From

the development of the worlds rst submersible

pump which revolutionized the worlds municipal

wastewater infrastructure, to sustaining high

efciency with our innovative N-hydraulics. Time

and again, we listen to you to understand your daily

operations. This, together with our pioneering

spirit, inspires us to achieve the extraordinary.

Now its time for the leaders to move forward

once again

ygt.com/ygtexperior

For Info. http://wwi.hotims.com RS# 5

8

August/September | 2012 www.wwinternational.com

Worldwide News

Europe/Middle East

OK, so it can't fly to the moon. But for anything that needs measuring, controlling and metering,

the new Brkert multiCELL multi-channel transmitter / controller Type 8619 is the ideal choice.

With its new signal input card, the sky really is the limit with the 8619: as well as two additional

digital inputs for flow sensors, two analogue inputs mean that virtually any measuring device

available on the market can be connected. This gives you more flexibility, expands the range of

possible applications including those that you might not even have thought of yet and gives

you precisely the support you need when you need it.

Out-of-

this-world

versatility.

Want to know more? Give us a call: +49 (0) 7940/10-91 111 or visit us at www.burkert.com.

News Briefs

Saudi Arabian SWRO facility

upgrades using BEL vessels

Al Fatah Water and Power has select-

ed BEL Composite Industries pressure

vessels for the second phase extension

of the seawater desalination plant using

Reverse Osmosis technology in Al Jubail

City, Saudi Arabia.

The system is designed to a capacity

of 58,500 m

3

/day and is expected to be

completed by January 2013.

Worlds largest pumping

station project in UAE moves

forward

As part of the Abu Dhabi Sewerage

Services Companys (ADSSC) major

wastewater tunnel project, the service

provider has contracted Mott MacDonald

to the role of engineer of what has already

been deemed as the worlds largest

pumping station.

Located in the Emirate of Abu Dhabi,

United Arab Emirates, the pumping sta-

tion will be over 100 m deep and ap-

proximately 40 m in diameter and will

have an ultimate peak pumping capacity

of approximately 3.3 million cubic metres

per day.

Mott MacDonald will undertake the role

of engineer for the contract administration

and construction oversight. This will involve

project, design, cost, contract and health,

safety and environment management.

As part of ADSSCs Strategic Tunnel

Enhancement Programme (STEP), the

focus is a deep 41km long tunnel sewer

and several systems of link sewers. These

will collect and transport wastewater to a

main pumping station for onward treat-

ment at the Al Wathba Independent Sew-

age Treatment Plants (ISPTs).

Link sewers will intercept the fows

from existing gravity sewers upstream of

the existing pumping stations, both on

Abu Dhabi Island and the mainland. These

fows will be channelled by gravity into the

deep tunnel.

At the downstream end of the deep

tunnel, in the AI Wathba area, an under-

ground pumping station will be built to lift

the sewage to the surface, and into newly

constructed ISTPs. The project is due for

completion towards the middle of 2015.

For Info. http://wwi.hotims.com RS# 6

Reverse Osmosis confrmed for Gaza desalination plant

The controversial 55 million m

3

/year

Gaza desalination facility will use mem-

brane-based, reverse osmosis (RO) tech-

nology for water fltration with the aim of

producing water at a cost of US$0.70 per

cubic meter, WWi has learnt.

The Palestinian Water Authority (PWA)

confrmed that unless the planned desali-

nation facility is in operation by 2020, the

aquifer currently supplying water to the

country would be irrereversibly dimin-

ished, if extraction continues at the cur-

rent rate.

Addressing the World Water Week in

Stockholm, Dr. Shaddad Attili, minister

and head of PWA emphasised the impor-

tance of water security and said there are

1.6 million Palestinians living in the most

densely population area on earth with wa-

ter unft for drinking.

Later in a press conference, Eng.

Rebhy El-Sheikh, deputy chairman of

PWA told WWi that the facility would use

RO technology as the thermal equivalent

(multi-stage fash or multi-effect distilla-

tion) was deemed not appropriate for

the project.

When asked about the expected op-

eration expense to produce one cubic

meter of water, El-Sheikh said PWA is

estimating a US$0.70 cost.

In March WWi reported that France

would be donating 10 million euros into

the project.

The Islamic Development Bank has

signaled support for 50% of the total

$455 million project costs, according

to PWA. These include the desalination

plant, as well as wider rehabilitation work

in Gaza, including efforts to reduce non-

revenue water. PWA said that the target is

to have a water system effciency of 80%

by 2017 - the slated date for the desalina-

tion plant to be operational.

Also, a North-South conveyance sys-

tem will be constructed that will allow the

distribution of freshwater throughout the

Gaza strip.

The desalination facility will be crucial

to relieve current over-abstraction from

the regions aquifer. Total abstraction is

170 million m

3

/year and PWA warned that

salinity levels in the aquifer far exceed the

World Health Organisation guidelines.

Dr. Rafq Husseini, deputy secretary

for environment and water of the Union

for the Mediterranean said the project is

seeking similar donations from other Eu-

ropean countries, as well as France.

Minister Attili said this week that he

has had meetings with the Swedish min-

istry and will be travelling to Finland next,

in a bid to secure support and funding

from Europe towards the project.

9

August/September | 2012 www.wwinternational.com

Worldwide News

Americas/Asia

8r|t|sh water supports

uK |nternat|ona| trade

Ihe fo||ow|n 12 uK water and wastewater

compan|es esh|h|ted at the uK Pat|||on at

S|napore |nternat|ona| water week 2012.

Partner w|th them for |nnotat|te so|ut|ons

and sert|ces.

Io|n our forthcom|n

|nternat|ona| etents:

17-18 0ctoher, kesource |re|and

uK Irade & |ntestment rants of 1000 are

ata||ah|e for e|||h|e SNLs to esh|h|t at the

|ead|n |r|sh water Lsh|h|t|on

4-11 Notemher, Irade V|s|t to atar and 0man

Neet |ead|n contractors and consu|tants and

others w|nn|n projects |n these markets

4-6 Iehruar, water wor|d N|dd|e Last

uK Irade & |ntestment rants of 1400 are

ata||ah|e for s|s e|||h|e SNLs.

V|s|t www.hr|t|shwater.co.uk to t|ew |nternat|ona|

etents, phone +44 (0j207 957 4554.

Aqua Netro|o Sstems - IN-100 opt|m|ses IN remed|at|on

processes, www.aquametro|osstems.com.

8|water - 0es|n, hu||d, operate and ma|nta|n water projects

|nternat|ona||, www.h|water.com

8|uewater 8|o - \8A0S, a patented \8r|d A0t|tated S|ude

process, powered h SNAkI un|ts, www.h|uewaterh|o.com.

0eeter L|ectron|cs - 0es|n, dete|opment & manufacture of

e|ectron|c |ete| sensors & contro| |nstrumentat|on, www.deeter.co.uk.

Lnpure - 0|oha| process en|neer|n and project manaement,

www.enpure.co.uk.

Iree kad|ca|s Iechno|o - Adtanced |ow ener e|ectro|s|s

wastewater treatment process, www.3frt.com.

|20 water - Award-w|nn|n Adtance Pressure Nanaement sstem,

www.|20water.com.

K||hr|de |ndustr|a| Sert|ces L|m|ted - Iphoon, the award-w|nn|n

p|pec|ean|n sstem, www.k||hr|de-|ndustr|a|.com.

Nodern water - 0|oha| prot|der of techno|o|es |nc|ud|n N|crotos

0IN, a reto|ut|onar cont|nuous on||ne tos|c|t mon|tor,

www.modernwater.co.uk

Portas||o - Lead|n wor|dw|de manufacturer and supp||er of hu|k

hand||n sstems, www.portas||o.co.uk.

- A wor|d |eader |n stat|c m|s|n techno|o for the water and

process |ndustr|es, www.stat|0o.net.

wLI Puh||cat|ons - water Lnt|ronment Iederat|on, Presert|n and

Lnhanc|n the 0|oha| water Lnt|ronment, www.wef.or.

News Briefs

Brazilian utility Copasa to

expand water meters

Companhia de Saneamento de Minas

Gerais (COPASA), Brazils second largest

water utility, has selected Elster to supply

up to 110,000 S120 single-jet water me-

ters in Brazil over the next eight months.

The company will deploy the meters to

provide more accurate water usage mea-

surement, to improve revenue generation

and to reduce water leakage.

Water scarcity could result

from Chinas coal expansion,

says Greenpeace

A plan from China to increase its coal fred

power plants by 2015 could trigger a se-

vere water crisis in the countrys arid North-

west, a report by environmental activists

Greenpeace has claimed. According to the

report Thirsty Coal: A Water Crisis Exacer-

bated by Chinas New Mega Coal Power

Bases, the 16 new facilities to be situated

in provinces such as Inner Mongolia could

consume ten billion cubic meters of water.

Industrial wastewater

treatment boosted in

Singapore by Sembcorp

Sembcorp Industries has started com-

mercial operation of its S$40 million ($32

million) industrial wastewater treatment

facility on Jurong Island. The S$40 million

plant will treat 9600 m

3

per day of com-

plex wastewater from 16 companies on

the island and has helped to double the

frms capacity in Singapore. The waste-

water treatment plant is part of Semb-

corps upcoming S$960 million cluster of

facilities to serve Jurong Island.

Desalination plant in Karachi

Port, Pakistan awarded

The Port Qasim Authority in Karachi,

Pakistan has awarded Aeromix Systems

a USD$775 million contract to develop a

97 million gallon per day desalination facil-

ity. The project involves the design, build,

operation and fnancing to serve the fresh

water needs of approximately 500 industri-

al buildings. The fnancing of the facility will

allow the Pakistani Authorities to pay Aero-

mix for the treatment plants through the

purchase of the treatment water over time.

Shipboard desalination set for

sail with the U.S. Navy

The U.S. Navy, under the Offce of Naval

Research (ONR), has contracted Pall for

a multi-phase project to develop an ad-

vanced shipboard desalination system

specifcally for the challenges. During the

frst six-month phase of the project, Pall

scientists will adapt hollow-fber microfl-

tration and reverse osmosis membrane

technologies to design a solution capable

of producing 4,000 gallons per day of

potable water. In the year-long second

phase of the program, a prototype sys-

tem will be developed and tested on land.

In the fnal 18-month phase, a fully com-

pliant system will be tested for six months

on a naval ship.

WesTech acquires Microfoc

and General Filter from Siemens

WesTech Engineering has signed an

agreement to purchase the conventional

water treatment business of Siemens

Industry that includes the Microfoc and

General Filter product portfolios. The

agreement includes all active projects,

associated assets and liabilities, inven-

tory, and associated patents and trade-

marks, as well as the facility in Ames,

Iowa. Sixty-two active employees dedi-

cated to this business will join WesTech.

Dr. Lukas Loeffer, CEO Water Technolo-

gies of Siemens said the product lines are

solid businesses but that they did not ft

within the companys portfolio.

Fuel cells: a replacement for wastewater

activated sludge treatment?

For Info. http://wwi.hotims.com RS# 7

Microbial fuel cells could produce elec-

tricity directly from wastewater and replace

activated sludge and anaerobic digestion

methods, researchers have claimed. En-

gineers at Oregon State University (OSU)

have found that microbial fuel cells can

produce electricity directly from wastewater,

which they said will mean that wastewater

treatment plants could eventually generate

enough power to sell excess electricity.

OSU claimed the technology can now

produce 10 to 50 more times the electric-

ity, per volume, than most other approaches

using microbial fuel cells, and 100 times

more electricity than some.

Researchers said this could eventually

change the way that wastewater is treated

all over the world, replacing the widely used

activated sludge process that has been in

use for almost a century.

The fndings have just been published

in Energy and Environmental Science, a

professional journal, in work funded by the

National Science Foundation.

The technology cleans wastewater us-

ing a different approach than the aerobic

bacteria. Bacteria oxidize the organic matter

and, in the process, produce electrons that

run from the anode to the cathode within the

fuel cell, creating an electrical current.

OSU researchers reported several years

ago on the promise of this technology but at

that time the systems in use produced far

less electrical power. With new concepts

reduced anode-cathode spacing, evolved

microbes and new separator materials the

technology can now produce more than

two kilowatts per cubic meter of liquid reac-

tor volume, OSU claimed.

The system has been tested on a labo-

ratory scale and OSU said the next stage

is a pilot study, for which funding is being

sought. A food processing plant has been

suggested as a possible testing ground.

Once advances are made to reduce

high initial costs, researchers estimated that

the capital construction costs of this new

technology should be comparable to that of

the activated sludge systems now in wide-

spread use today and even less expensive

when future sales of excess electricity are

factored in.

Making Ripples: Water Leader Focus

10

August/September | 2012 www.wwinternational.com

10

www.wwinternational.com

T

he interview with Carsten Bjerg should be focusing upon

the water industry. Instead, the conversation takes an im-

mediate turn towards the 2012 Olympic Games. Den-

mark has just taken a gold medal its second overall

in Olympic track cycling. Bjerg is clearly proud of the

achievement.

A regular gym goer, supporter and follower of a local handball

team (one of the top two in the country), its clear that the Grundfos

CEO is active outside of the boardroom. After the conversation goes

onto team Great Britains efforts (I cant help but bring up the 20+

gold medals to date), Bjerg likens the results with those of his com-

pany. Investment put into athletics at grassroots level years ago is

now paying off, just in time for the Olympics, he says.

And in answering the question of how the company reported an

8% growth on pump sales in 2011 with a turnover of DKK21.2 billion

(2.8 billion Euros), he attributes this to the same reason: investment.

We are seeing payback on the globalization of our company that

we have invested in over the last 15 years. This of course helps in a

period when growth in Europe is not so strong. Europe used to be

our strongest market but we now have much more of the sales out-

side of the region, he says.

The Far East, including China, as well as ASEAN (Association

of Southeast Asian Nations), not to mention Eastern Europe, Rus-

sia and the US markets have

helped contribute to Grundfos

turnover growth despite Eu-

ropes decline.

Just like investing into up

and coming athletes, Bjerg

prizes his efforts over the last

decade in investing into R&D

and new products, which have

now been released onto the

market and are helping with the

fnancial bottom line.

Theres also another reason

why despite being a European

competitor in the Olympics,

Denmark-born Bjerg speaks

highly of Great Britains efforts.

A mechanical engineer by train-

ing, he spent a year at Cambridge University in England complet-

ing a Masters Degree in ACPMM (Advanced Course in Production

Methods and Management). Since then he spent 14 years with Dan-

ish pump and automation manufacturer Danfoss and has been with

Grundfos for the last 15 years. So within the space of two compa-

nies, Bjerg has risen to the role of the CEO.

DIVERSIFICATION: PUMPS TO UV AND MEMBRANES

Olympics fever to one side, in order to discuss the recent develop-

ment and direction of the company, its important to frstly understand

its roots. Grundfos is owned by the Poul Jensen Foundation, set up

by the company founder in 1975. Today the foundation owns 86.7%

of the shares, alongside 2% that are owned by staff and the rest

owned by the founders family.

The foundation is asking us, asking me to ensure that Grundfos

makes a positive difference to the world, the CEO says. And spe-

cifcally over recent years we have come to the conclusion that we

ought to also play a role in water treatment.

And it is this decision that led the company to recently acquire

Enaqua, an American company that focuses on the use of Ultraviolet

(UV) technology to disinfect water, as well as membranes for water

purifcation. The purchased frm produces UV disinfection systems

that range in sizes up to 100 million gallons per day for municipal and

industrial applications.

Discussing the change in direction away from pumps, Bjerg says:

This is not necessarily the investment that has the maximum pay-

back for us. Today we are still a pump company and there is still

enough for us to do there. Yet we are also seeking ways to create a

position for ourselves as a water treatment provider.

Will we see more of this? he asks. The answer is hopefully, yes.

We would like to do more than what this acquisition is making possi-

ble for us. We are looking for other entries into that market with direct

Pump Prodigy

Grundfos CEO Gains Ground

Danish pump manufacturing giant Grundfos is diversifying into

water treatment. CEO Carsten Bjerg speaks exclusively to Tom Freyberg

about the companys plans and how leakages can be reduced globally.

Refecting on success: After rising to the role of

CEO during the course of his 15 years at Grundfos,

Bjerg led the company to turnover 2.8 billion euros

during 2011

Flagship purchase: The founda-

tion owning Grundfos has helped

push Grundfos into the water

treatment market, leading to the

acquisition of U.S. frm Enaqua,

which focuses on UV and mem-

brane fltration

SUSTAINABLE MBR

SOLUTION FOR MUNICIPALITIES

WWW.X-FLOW.COM

X-FLOW

AIRLIFT MBR MEGABLOCK

With the Airlift MBR Megablock, Pentair X-Flow

revolutionizes the construction and upgrading of

municipal wastewater treatment plants.

It is designed as a future-proof system as it enables

water companies to invest only in what they need now

and expand as circumstances demand. Modularly

designed block units can easily be added at any time,

which reduces up-front investments.

KEY FEATURES

High flux rates of 50 l/mh and up

Removal of all suspended solids

Optimal flow distribution

No sludge carryover

High biomass concentration

Zero cleaning chemical waste discharge

Very good anti-fouling behavior

For Info. http://wwi.hotims.com RS# 8

Making Ripples: Water Leader Focus

12

August/September | 2012 www.wwinternational.com

acquisitions, as well as research and development. Again, we do not

seek to become a provider across the board of equipment for the in-

dustry. But when we identify technology breakthroughs then yes, we

can help the industry and build on the position weve established.

LOWER PRESSURE, LOWER LEAKAGES

Nor is it just manufacturing and selling pumps that make up the core

of Grundfos business. Bjerg says its also about educating the indus-

try on potential savings that can be made. One of these savings is the

area of water leakages and non-revenue water. With the World Bank

estimating that 45 million cubic meters of perfectly usable, potable

water is lost in the network everyday through worldwide leaks: its a

worthy cause for the CEO to turn his hand too.

Rather than focusing on reactively

acting on leaks once theyve occurred,

Grundfos believes the solution lies earlier

in the cycle. Demand Driven Distribution,

or DDD for short. Thats the name the

company gives to the set-up of mul-

tiple pumps operating at proportional

pressures, all in unison. The system is

designed to supply precisely the fow

needed at the pressure required, with

numerous pumps running effciently instead of one big pump.

According to the frm, when you reduce pump pressure by 50%,

you can reduce leakage loss by at least 30%. This is one topic that

the CEO is clearly passionate about.

You have to make sure that you reduce the risk for leakages by

adjusting the pressure of the system, he says. Again here you have

the application where its very common to have full pressure in the

system independent from the demand. This doesnt make sense en-

ergy wise, nor does it make sense when it comes to leakages. So our

main contribution to this is to offer solutions whereby with alternative

controls you are ensuring that you adjust the pressure in the system

according to the amount of water required.

Bjerg says DDD can lead to three benefts: energy saving, reduc-

ing leakages and optimizing the effciency of the system, reducing the

overall maintenance required. Speaking more broadly, he suggests

that the way in which utility leakages are perceived should change.

This is one of the tricky issues because in many places around

the world you do not have the market mechanisms punishing the

water industry if they have leakages in the system. I think we should

pay much more attention to this matter.

So regulatory enforcement/fnes on utilities could help reduce

leakages?

I just think that if you take it from the global challenge we have

on water, it is establishing how you can lose so much drinking water

without that being a problem for anyone.

Indeed, fndings from the Asian Development Bank suggest that

by cutting the amount of lost water across Asia in half, 150 million

people could be supplied with treated water (see feature on page 28).

I think that you could argue, as a consumer for water each of

us how much should we pay for water that is pumped up from the

ground to make it possible for us to drink water? However, its also

important not to blame the water industry because if you provide

water for society and do not beneft from reducing leakages, then

why should you put investment in?

S-TUBE IMPELLER

Shortly before the Enaqua announcement in June, Bjerg was busy

helping to launch Grundfos S-tube impeller at the IFAT Entsorga

show in Munich, Germany. A tube-shaped impeller in a pump hous-

ing that matches the tube shape through the entire pump, Grundfos

claims this design offers greater hydraulic effciency than any other

type of wastewater impeller and doesnt compromise free passage.

So how long has the impeller been in development?

Historically, on wastewater pumps it was always acclaimed that

you cannot use the most energy effcient solutions as you would

have problems with the free passage and problems with clogging on

the pumps, says the CEO. Here we have invented an impeller that

does not compromise on either of the two accounts. This is I believe

the frst in our industry. You have optimal effciency and at the same

time free passage for the impeller. This is actually something weve

had in our laboratories for some years. The frst time I was involved in

discussing this theoretical solution was almost ten years ago.

Reducing unnecessary water losses is also a focus area for the

companys global operations. Like any major industrial manufacturer,

water consumption is a big concern, not to mention expense. In

2010 the company consumed just over 650,000 m

3

. A year later

in 2011, this had dropped to just over 530,000 m

3

. How was this

achieved?

We are preaching the message that this is something that all

companies should be doing, says Bjerg. Weve given it a lot of at-

In many places around the world you do not have

the market mechanisms punishing the water

industry if they have leakages in the systems. I think

we should pay much more attention to this matter.

Hard line: Bjerg strongly believes

that market mechanisms should

be put in place to incentivise

utilities to reduce leakages

For Info. http://wwi.hotims.com RS# 9

Making Ripples: Water Leader Focus

14

August/September | 2012 www.wwinternational.com

tention. Weve been looking across the entire organization for

opportunities to save water. The result is down to multiple so-

lutions implemented across our many companies around the

world. Its not down to one technology or one example. One of

the things we do is to use our own technology or products in

our own operations.

ENERGY

Its diffcult to talk with the CEO of one of the worlds largest

pump companies without discussing energy. Pumps, along

with aeration equipment at wastewater facilities, are often

pointed to and blamed for high energy costs. And with esti-

mates suggesting that pumps alone are responsible for 10%

of the worlds entire global electricity consumption, its fnger

pointing that is not likely to go away. So what is being done and

what can be done to address this?

Thats right pumps do actually consume a relatively big

share of the global electricity production across the world at 10%.

This means theres a huge opportunity for improvement. Its not that

you can cut the usage entirely away as pumps are needed in many

places and provide an important role. Its important that its done in

the most energy effcient way.

The CEO adds: We decided that we will go beyond what legis-

lation requires. We have introduced the Bluefux-labelling, which is

something we put on all our products that use our best technology

motors and frequency converters. This is a result of investing in tech-

nology. I would say the investments in technology and R&D are the

major reasons for making this happen.

Legislation requirements on pumps, as mentioned by the CEO,

are now major considerations. The Energy Using Product Directive

is a European Commission energy effciency framework, setting the

future or energy effcient products in the EU. The Directive has also

been revised to include energy related products.

With the new requirements, high effciency, variable speed circula-

tors must be used as a standalone pump. This will mean that invest-

ment in new product development and production lines, as well as

adaptation of tooling, test and production equipment will be a huge

challenge for the pump industry. Grundfos is already actively market-

ing its EuP ready integrated circulators.

FINAL WORDS

When asked to describe himself in fve words, Bjerg avoids the ques-

tion. Instead he describes the reasons why hes remained with only

two companies since his education; a rarity today with the amount of

competition and opportunities inevitably springing up.

I think in my career theres a reason why Ive been with only

two companies and that is that Im very dedicated and committed

to what I do and dont jump from one company to another every

second year. I think that is important. I would have a diffcult time in

working for a company that I dont believe in the business priorities

but also the ability to commit to the purpose of the company. Its im-

portant to me to continue to be the person I am. Everyone will know

me as Carsten and thats the way I like it.

Its clear that Bjerg, sorry Carsten, doesnt preach the environ-

mental message for the sake of it. Both the CEO and the foundation

behind Grundfos believe that the profts from the company should

be invested to help the frm divert into water purifcation for the bet-

ter of the planet. This is an aim thats been clearly backed up by the

Enaqua acquisition. And testament to Bjergs love for the environ-

ment, he spends a great deal of his spare time tending forests and

felds around his house.

For the huge challenges the world is facing on energy, climate

change and water; technology is the answer. I always say that as

a manager and CEO, there is a limit to how much of a difference

you can make. The difference is made by the many people of the

organization. I see my job to provide the best possible framework for

employees to thrive.

Just as I expect the CEO to make another analogy of comparing

people or products to Olympic athletes, news comes through the

wires of another Olympic gold medal. Needless to say, both of us are

hoping its either Denmark or Great Britain as the victor. WWi

Enquiry No. 100

Bright outlook: An engineer by training, the Grundfos

CEO believes that technology will play a pivotal role in

future energy, climate and water challanges

Eastern promise: In light of Europes lagging economy, Grundfos has

found success in the Far East, including China as well as the Eastern

European and Russian markets

FEATURED PRODUCT!

F12 Transmitter with Hart or Modbus Interface

With ATIs F12 Transmitter, monitoring toxic gases in the workplace has never been easier.

Providing the ultimate in application fexibility, the F12 is available in either a transmitter only

version or a version with integral alarm relays.

FEATURES

Accepts up to 32 Diferent Toxic Gas Sensors

Loop-powered Transmitter or AC Power with relays

Exclusive Auto-TestSensor Self-Test Option

Integral or Remote Sensors

Gas Measurement Solutions

MODULAR GAS DETECTOR

Model A14/A11 GasSens

FEATURES

Optional Auto-Test Eliminates Manual Sensor Test

Display, Visual & Audible Alarm, and Analog

Output in a Compact Unit

Expandable for Multi-Point Measurement

2-WIRE TRANSMITTER

Model UniSens

FEATURES

Non-Intrusive Controls

Intrinsically Safe and Explosion Proof

Detects 28 Diferent Gases

Auto-Test Sensor Verifcation

PORTABLE GAS LEAK DETECTOR

Model PortaSensII

FEATURES

Interchangeable Smart Sensorsfor Over 30 Gases

Internal Sample Pump and External Sampling Wand

One-hand Pistol Grip Design

Internal Data-logger with RS-232 Output

.c/cz/~ -e: z/~ -e//e.q ze>, c -ccz/~ qc.~.

AsH

3

B

2

H

6

Br

2

C

2

H

2

C

2

H

4

O C

2

H

6

O CH

4

Cl

2

ClO

2

CO COCl

2

F

2

GeH

4

H

2

H

2

O

2

H

2

S

H

2

Se HCHO HCl HCN HF HX I

2

NH

3

NO NO

2

O

2

O

3

PH

3

SiH

4

800.959.0299 www.analyticaltechnology.com

Smart Sensor design for Ease of Calibration

Nema 4X Enclosure for Wall or Pipe Mounting

Internal Data-Logging

The O/ Ce;c to 7:..z

When You Require the 3~.z in

Water Quality & Gas Monitoring!

For Info. http://wwi.hotims.com RS# 10

Creative Finance

16

August/September | 2012 www.wwinternational.com

16

www.wwinternational.com

T

he Big Five water utility markets in 2012 are predicted

to account for almost $50 billion of CAPEX and OPEX

spending in Europe. As such, they are leaders and cru-

cial testing grounds for new technologies and innovative

practices. Water utility investment has not collapsed in

these countries but is instead getting smarter and looking at opportu-

nities that provide greater confdence in returns. At the broadest level

there are seven market priority areas for innovation and effciency

within water utilities: chemical management, decentralisation, energy

effciency and production, leakage and non-revenue water, sludge,

smart water technologies and water charges.

CHEMICAL MANAGEMENT

Over $346 million is being spent on coagulants, focculants and disin-

fection chemicals in Europe by the Big Five this year and this market

will continue to be needed in the water industry to ensure quality and

safety. This market, however, is changing and seeing different invest-

ment trends and in some cases a decline in demand on account of

disruptive technologies. Direct investment in chemicals is decreasing

slightly due to non-chemical technology alternatives in disinfection,

through UV and membrane use. Furthermore, a decline in overall vol-

umes of water and wastewater treated with early adoption of green

chemical alternatives has started in Germany. While chemical alter-

native is an established

and steadily increasing

trend to the water in-

dustry, they have great

potential to move wa-

ter utilities away from

reliance on traditional

chemicals that are at

the mercy of fuctuating

oil prices. At the same

time innovation in the

sophistication and ef-

fectiveness of chemi-

cals, along with the

price tag, has grown

for focculation pro-

cesses which means

the overall market will

remain relatively steady

over the coming years.

It is worth noting in the

marketplace that tradi-

tional chemical com-

panies, such as BASF,

are making moves into

chemical alternatives

and membrane tech-

nology.

DECENTRALISATION

Decentralisation is increasingly seen as an answer to changes in ser-

vice requirements in Europe. In the UK, for example, while there are

6,400 sewage treatment works, only 76% of those serve popula-

tions of two thousand or less. This occurs at the same time as the

dramatic shift in many European population centres towards urban

shrinkage. While the urban development process began with com-

pact cities and subsequently leading to urban sprawl, more recently

Water Utility Eff ciency Priorities:

What are they?

The European water industry is predicted to spend $64 billion in 2012 but fnds itself in the

middle of a wider prolonged economic slowdown. So what are the main objectives when it

comes to effciency in Europes top fve water utility markets? Seth Cutler looks at France,

Germany, Italy, Spain and the UK.

Figure 1. Total water and wastewater CAPEX and OPEX, Europe (2012, 2017)

0.0

2012 2017

10,000.0

20,000.0

30,000.0

40,000.0

50,000.0

60,000.0

70,000.0

80,000.0

90,000.0

$

M

i

l

l

i

o

n

United Kingdom

Benelux

Alpine

Greece

Others

Big 5

Other Europe

Spain

France

Germany

Nordic

Italy

Portugal

$11,489.13

million

$7,484.12

million

$7,392.96

million

$3,456.27

million

$4,892.39

million

$646.76

million

$900.61

million

$10,823.90

million

$12,527.25

million

nce

$3,334.19

million

$985.16

million

17

August/September | 2012 www.wwinternational.com

a contraction and perforation of the urban core has

occurred .

This has serious implications for large capac-

ity European water networks, developed to satisfy

a period of intense urban growth; water networks

are increasingly unft for purpose and, as a result,

ineffcient. There is also a growing recognition that

relatively simple source to consumer to discharge

water systems neither provide the greatest beneft

nor account for differences in urban and rural supply

and demand patterns. The requirement for smaller,

localised, decentralised water supplies, but espe-

cially for decentralised wastewater treatment plants

is therefore growing.

ENERGY EFFICIENCY AND PRODUCTION

The total electricity consumption of Germanys

10,000 urban wastewater treatment plants in 2009

was roughly 4,400 GWh/year. In the UK, the 2009/10

energy use by the water industry rose to 9,012GWh,

representing a 10% increase over the previous eight

years. In a business as usual scenario it is likely that

energy prices will continue to rise and demand for

electricity will continue to grow. This has major impli-

cations for the water industry as energy consumes,

on average, 28% of water utility operating costs.

Within this pumps account for up to 60% of en-

ergy needed for water distribution and aerators con-

sume 55% of energy used in wastewater treatment.

While this exemplifes the importance and depen-

dence of water utilities on pumps and aerators, it

also exposes specifc targets for greater effciencies

in energy consumption.

Indeed, the sixth World Water Forum sets a tar-

get of 20% reduction in water utility energy use. In-

novations that help reduce energy consumption will

have direct relief for utility budgets. We are currently

seeing this through energy saving pump initiatives

by Grundfos and i2o and also in aerators through

Israeli company, DIffusaire.

The complimentary advancement is to see

wastewater treatment plants and water distribu-

tion networks as untapped sources of energy. The

wastewater to energy movement has very strong

potential to reduce energy demands and carbon

footprints, to reduce waste volumes and to move

further towards net zero energy and energy positive

water utilities. An example of this is Sydney Water in

Australia that has committed itself to being carbon

neutral in energy use by 2020. France is now home

to the worlds frst carbon neutral wastewater treat-

ment plant, Aquaviva.

LEAKAGE, NON-REVENUE WATER AND

SMART WATER TECHNOLOGIES

A key concern of the Big Five water industry

markets is leakage, which averages 22.2% across

the region. Often labelled as an element of non-

revenue water, this is essentially synonymous with

leakage as theft in this region can be considered

Red Val ve Company and Ti defl ex

Technol ogi es

600 North Bel l Avenue Carnegi e, PA 15106

Phone: 412. 279. 0044 Fax: 412. 279. 7878

www.redvalve.com www.tideflex.com

PINCH VALVES

CONTROL VALVES

SLURRY KNIFE

GATE VALVES

CHECK VALVES

INLINE CHECK VALVES

AERATION SYSTEMS

POTABLE WATER

MIXING SYSTEMS

EFFLUENT DIFFUSERS

WEFTEC 2012

Visit Us At

Booth # 1733 Red Valve

Only one company manufactures the

extraordinary kind of valves that live up to

the worlds toughest challenges - Red Valve.

Over the past 60 years, we have practically

reinvented flow control by using the latest

in elastomer technology for the most

demanding industrial, municipal, slurry and

chemical applications. From Tideflex

Check

Valves and large-diameter pinch valves, to

an ever expanding line of innovative new

technologies, no other valve compares to a

Red Valve. Call or visit our website today for

more information.

Series 75

Pinch Valve

Tideflex

TF-1

Check Valve

CheckMate

Inline

Check Valve

Celebrating 60 Years of Innovation and Quality

For Info. http://wwi.hotims.com RS# 11

Creative Finance

18

August/September | 2012 www.wwinternational.com

quite low, as can permissible non-billed water use. The leakage av-

erage means that almost one quarter of billable water is lost, which

produces both fnancial and environmental consequences that

sometimes result in highly ineffcient water distribution networks.

Considering the total length of water distribution and wastewater

pipes, almost 1.2 million km in France alone, there is a vast pipe

surface area and geography to monitor for leaks and bursts. Wa-

ter utilities in the Big Five will continue phased pipe replacement

schemes and also more urgent replacements as they appear. Ongo-

ing replacements, however, are

likely to use enhanced materials,

such as polyphenlyether, and

coatings to ensure pipe longev-

ity and install acoustic and other

sensors to detect leaks and limit

burst events.

Installing sensors and data

communicating devices in water

networks to produce near-real

time control is the essence of smart water technologies. A central

factor that increases the attractiveness of smart water technologies

is that it is not requiring a fundamental reconfguration of water indus-

try processes, but instead enhances and makes more responsive

system operations and management. By attaching sensors and te-

lemetry to key pieces of water utility infrastructure, data is produced

and relayed to central servers where algorithms and analysis gener-

ate information, relationships and indicators to enhance the decision-

making process.

This has the ability to make day-to-day operations and manage-

ment, investment and business planning, reporting standards and

understanding of historical performance much more accurate and

insightful, producing a better run utility that maximises fnancial in-

vestment. Data analysis and information production can be handled

internally to water utilities, but increasingly options for software-as-a-

service are emerging. Outsourcing data management can enhance

the drive for opera-

tion effciencies of

water utilities.

BI O- SOLI DS/

SLUDGE MAN-

AGEMENT

Sludge volumes are

on the rise in Eu-

rope, in large part

due to stricter leg-

islation that is esti-

mated to increase

volumes by 50%

alone. As a result

sludge manage-

ment practices are

advancing mainly

on two fronts: frst,

the implementation

of biogas and nu-

trient recovery sys-

tems; and second,

the development of

sludge volume re-

duction solutions such as ozonation and ultrasonic irradiation.

Nutrient recovery is, like wastewater to energy, a natural step for-

ward to reduce sludge volumes, to remove harmful elements and

to produce a new sustainable revenue generation stream by selling

nitrates, phosphorous and other minerals taken from wastes to sell

in raw form or turned into fertilizers. A contract signed between Ca-

nadian frm Ostara and UK utility Thames Water highlights this op-

portunity. Ultrasonic irradiation is similar in that it has proven to reduce

the volume and weight of sludge generated in wastewater treatment

plants, along with a host of other benefts including increased biogas

production, which can subsequently be harnessed for further energy

generation. Working to implement better sludge management tech-

niques helps to reduce sludge as a waste product and turn it into rev-

enue generating stream through recovered nutrients and fertilizers,

decreased waste volumes and increased energy production.

WATER TARIFFS AND COST RECOVERY PRINCIPLE

During the eight years from 2003 to 2011, water charges in the Big

Five markets have increased an average of 4.8%. Rates by coun-

try, however, vary widely with Germany home to the highest charges

through implementation of full cost recovery.

Water tariffs are a controversial tug-of-war between essential

rights of public access and the full cost of recovery principle, to not

only cover operating costs but enable sustainable investment for the

future. Unlike other utility commodities of electricity and gas, water

It is worth noting in the marketplace that traditional

chemical companies, such as BASF, are making moves

into chemical alternatives and membrane technology

Figure 2. Modern challenges facing water utilities

Chemical management

Smart water

Energy effciency

and production

Decentralization

Leakage/non

revenue water

Water changes

Sludge

19

August/September | 2012 www.wwinternational.com

is a prerequisite to life and as such must remain affordable to all. This under-

standing often keeps the cost of water low and below market rate through

public subsidies.

As service costs rise (through regular infation, necessary investments,

stricter legislative requirements and ineffciencies) the costs must be borne

by customers or further paid for through subsidisation. Considering the tough

fnancial situation faced by many water utilities in Europe, the cost of water

for customers is set to increase over the coming years. Going forward busi-

ness models will need to change to ensure water charge rises are aligned

with the cost recovery principle and better appropriately communicated to

the customer.

FUNDING OPPORTUNITIES

While the areas for investment outlined above vary in attractiveness at national

and local level, it shows a clear movement towards technologies and services

that provide quantifable fnancial, operational and sustainable returns for wa-

ter utilities. With the ongoing economic and capital problems in the Eurozone,

how likely is it that the Big Five markets will make strong advancements over

the next fve to ten years?

The answer, of course, is complex. It is easiest to talk at a regional or

national level, but practically-speaking these areas for investment will require

creative business models that are aligned more towards performance based

payment schemes. As a result, development will be erratic and based on

the strategies of individual utilities. At the utility-level there continues to be

funding available and it is not a case of whether there will or will not be invest-

ment, but how well businesses have aligned their products and solutions with

evolving utility requirements to be seen as part of the solution to their priority

challenges.

In order to increase access to capital, which is likely for ambitious and lead-

ing utilities, there are creative fnancing tools at their disposal. Public private

partnerships are likely to viewed with renewed interest in the water industry

due to their secure, albeit slower, returns. Remondis, for example, is active

in Germany providing water and wastewater treatment services for utilities.

Design, build, operate and fnance models will go ahead in the industry as

it gives investors greater say in the day-to-day operations concerning their

investment. This level of access will provide greater confdence and security

to stakeholders who might traditionally overlook the water sector.

A second likely action by water utilities in countries like Spain and Italy will

be the consolidation of small, local utilities into larger operational structures

that provide greater critical mass for fnancial investments. This is likely to help

bring advanced innovations into rural areas.

Thirdly, securing a better balance between capital expenditures and op-

erational expenditures will also help further the penetration of innovative tech-

nologies. For companies to shift capital investment into longer-term payment

schemes or pay-back through the leasing of equipment can help alleviate any

issues with access to large fund reserves in the near-term, with confdence in

the long-term availability of capital.

Finally, a less likely scenario would be the growth in privatisation of the

water industry. Currently the UK, and to a lesser extent France, have majority

shares of private water and wastewater services, but the other three countries

have an overwhelming system of public operation.

Countries like Italy and Spain could see investment benefts through this

practice, but face stiff opposition from the public. Evidence of this from Italy

is the recent attempts to push through regulations that would open up and

encourage privatisation of the water industry being strongly rejected in a ref-

erendum.

Times are not all doom and gloom in Europes water industry, but effciency

remains a top priority for water utilities and is set to create a favourable en-

vironment for innovation and innovative solutions as well as creative fnance

and business models. WWi Enquiry No. 101

IN THE

HARSHEST CONDITIONS.

SIPOS 5 FLASH

THE INTELLIGENT ACTUATOR

RELIABLE SERVICE

SIPOS Aktorik GmbH Im Erlet 2 90518 Altdorf Germany www.sipos.de

Tel.: +49 9187 9227- 0 Fax: +49 9187 9227-5111 info@sipos.de

When using actuators, you need to be assured of reliable

performance. You need absolute confidence that your actuation

technology will continue to perform, without loss of torque, even

if faced with unreliable power supplies. At SIPOS, we can offer

this assurance.

Using intelligent electronics incorporating an integrated frequency

converter, SIPOS 5 Flash compensates for fluctuations in voltage

and frequency: The guarantee for actuator functionality, even in

the harshest conditions.

Top marks in all disciplines

High tolerance to supply voltage variation

Ability to maintain torque under

severe voltage/frequency variations

220 V -10 % ... 230 V +15 %

380 V -10 % ... 460 V +15 %

Operating frequency range

40-70Hz

High availability