AC Duct Design PDF

Diunggah oleh

kumar123rajuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

AC Duct Design PDF

Diunggah oleh

kumar123rajuHak Cipta:

Format Tersedia

AIR DUCT DESIGN

Air duct functions in transmitting air from the air handling units to the space to be airconditioned. The essential economics of an air transmission system is achieved by a proper balance between the initial or first cost and operating cost for the given flow rate of air. The first cost depends on the cost of duct sizes whereas operating cost is determined by the fan power consumption which depends on the pressure drop in the air handling equipment and the duct system. The pressure drop can be reduced by increasing the size of the ducts but it will increase the first cost. Thus an optimum solution has to be arrived at. FACTORS GOVERNING AIR DUCT DESIGN : In Telecom. bldgs the space to accommodate air duct assumes a dictating role. Noise generated, due to velocity of air in the duct also becomes a guiding factor. The ducts designed for Telephone Exchange bldgs. normally, air velocity is selected from following ranges for an overall economy (for TE/Telecom bldg) : ---------------------------------------------------------------------Application Main duct Branch duct Return air passage (M/mt) (M/mt) (M/mt) ---------------------------------------------------------------------Tech. Rooms 350-500 250-300 280-400 Nontech. Rooms 300-350 200-250 250-300 -----------------------------------------------------------------------Air distribution systems are divided into three pressure categories : low, medium and high (same as class I, class II and class III fans) as given below : Low pressure - upto 3.75 inch of water gauge, Medium pressure - 3.75 to 6.75 inch of wg, High pressure - 6.75 to 12.25 inch of wg . Medium and high pressure ducts may be used to meet space limitations. Thickness of sheets for rectangular ductwork shall however be as follows : ----------------------------------------------------------------------Longest side (mm) Minimum G.S sheet Thickness in (mm) in Gauge -------------------------------------------------------------------------750 and below 0.63 24 751 to 1500 0.80 22 1501 to 2250 1.00 20 2251 and above 1.25 18 --------------------------------------------------------------------------

R. Sharma (BSNL Electrical Zone Patna)

Keeping above factors into consideration a balance has to be struck between initial cost and operating cost. The following factors directly influence the first and operating cost : (i) Heat gain or loss from the duct (ii) Aspect ratio (Long side : Short side) of the duct (iii) Duct friction rate (iv) Type of fittings. The heat loss or gain through the duct system occurs if the duct passes through unconditioned space or a long duct runs through the conditioned space. The loss or gain, which may be considerable, should be taken into account while calculating heating/cooling load. It has been established that (a) Larger the duct aspect ratio, more the heat gain (b) Ducts carrying small air quantities at low velocity has the greatest heat gain. (c) Insulation of the duct decreases the heat gain. Now it is obvious that larger the duct aspect ratio, thickness of sheet metal required shall be more; thus increased initial cost, more heat gain i.e. increased operating cost. Accordingly, it is economical to use duct of low aspect ratio. Also heat gain/loss may also be reduced wherever required by insulating the same through a proper grade of insulating material and of proper thickness. In fact the ducting shall be insulated with following thickness of resin bonded fiber glass or resin bonded mineral wool with thermal conductivity not more than 0.03 K.Cal M/hr M2 0C at 100C mean temperature and density not less than 24 Kg/m3 in case of fiber glass and 48 Kgs/M3 in case of mineral wool. The following guide lines may be followed : ---------------------------------------------------------------------Length of ducts Thickness Insulation lengths/surface ----------------------------------------------------------------------SUPPLY DUCTS (i) upto 18 Meters Nil (ii) 18 to 45 Meters 25 mm Half duct length from tail end (iii) 45 to 60 Meters 25 mm Full duct length (iv) Above 60 Meters 50 mm Full duct length RETURN AIR BOXING/FALSE CEILING : (i) In conditioned space Nil (ii) In non-conditioned space weather maker wall 50 mm Full length A.C. SHAFT (i) Isolating non-conditioned (ii) Isolating conditioned 50 mm Nil Full surface

R. Sharma (BSNL Electrical Zone Patna)

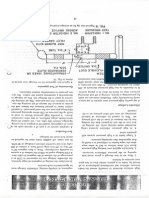

DUCT FRICTION : Continuous loss of pressure in a duct in which air is flowing is called the duct friction loss, given by the following formula : P = 0.03 f (L/d1.22) (V/1000)1.82 Where P = friction loss (in wg) f = interior surface roughness (0.9 for galvanised duct) L = Length of duct (ft) d = duct diameter (in) equivalent diam for rectangular duct work V = air velocity (fpm). This clearly indicates that higher the air velocity and lower the diameter, increased in the duct friction loss. Based on the above formula, the friction loss chart (enclosed) is drawn. DESIGN PROCEDURE :Duct lay out are made simple and symmetrical. There are three common methods for the sizing of ducts. They are : (i) Equal friction method, (ii) Velocity reduction method, (iii) Static regain method. In the EQUAL FRICTION METHOD, the frictional pressure drops per unit length of the duct is maintained constant. An initial velocity is selected near the fan, the sound level being the limiting factors. A suitable velocity in the main duct from sound level considerations is selected. Knowing the air flow rate and the velocity in the main duct, the size and friction loss are determined from the chart. The remaining ducts are then sized maintaining the friction loss per unit length at this value for their respective air flow rates. This method automatically reduces the air velocity in the direction of flow. In the VELOCITY REDUCTION METHOD the main duct is designed in the same manner as in the equal friction method. There after arbitrary reductions are made in the air velocity as we go down the duct run. Equivalent diameters are found as before from the friction chart. This method is used for most simple layout and can be used by persons having considerable practical experience and knowledge to design within reasonable accuracy. The basic principle of STATIC REGAIN METHOD is to size a duct run so that the increase in the static pressure (regain due to reduction in velocity) at each branch of air terminal just offsets the friction loss in the succeeding section of duct. The static pressure is then same before each terminal and at each branch. Comparison of the first and third method has also been done which is summarised as below :(i) Header duct size are same in both methods. (ii) Branch duct sized by static regain method are longer than by equal friction method (iii) Static regain method requires about 13% more sheet metal by weight (iv) Operating cost in case of equal friction method is slightly higher (about 5%) A few general rules may be followed while designing ducts : (i) Air should be conveyed as directly as possible to economise on power, material and space. (ii) Sudden changes in direction should be avoided. When bends are essential, turning vanes should be used to minimise pressure losses.

R. Sharma (BSNL Electrical Zone Patna)

(iii) Air velocities in ducts should be within permissible limit to minimise noise. (iv) Diverging section should be made gradual. The angle of divergence should not exceed 200. (v) Rectangular ducts should be made as nearly square as possible. An aspect ratio of 4 : 1 or less should be maintained. (vi) Ducts should be made of smooth materials such as galvanised iron (GI) or aluminum sheet metal. Whenever other materials are used allowance should be made for the roughness of materials. (vii) Dampers should be provided in each branch outlet for balancing the system. (viii) Avoid duct obstructions . EXAMPLE For a telephone exchange Total air quantity - 8800 cfm 4 air terminals - 7000 cfm, 600 cfm, 600 cfm & 600 cfm Operating pressure for all terminals - 0.15 in wg Radius elbows, R/D = 1.25 Find the duct sizes and total static pressure required at fan discharge using equal friction method. SOLUTION :Let us choose initial velocity as 1400 fpm Duct area = 8800/1400 = 6.286 sq.ft. thus a size of 46" x 22" is selected. Equivalent round duct diameter is 34.2 in Friction rate = 0.065 in wg. per 100 ft of equivalent length 40 A 1800cfm 20 1200cfm B 20 C 20 D

10 7000cfm 20

1

10 600 10 600 10 600cfm cfm cfm

8 12

10

2

10

9

10

10

3

10

11

10

13

10

10

7

R. Sharma (BSNL Electrical Zone Patna)

Duct section Air quantity CFM cap Duct area Area Duct size (cfm) (%) (%) (sq.ft) __________________________________________________________ To A A-B B-C C - 12 8800 1800 1200 600 100 20.41 13.64 6.82 100.00 27.41 20.00 11.40 6.29 20 X 52

_______________________________________________________________

1.724 20 X 14 1.258 20 X 10 0.717 12 X 10

12 - 13 300 3.41 6.12 0.385 10 X 6 __________________________________________________________ Equivalent length calculation :_______________________________________________________________________ DUCT SECTION ITEM LENGTH ADD. EQUIV. LENGTH (ft) (ft) _______________________________________________________________________ TO A DUCT ELBOW A-B B-C C - 12 DUCT DUCT DUCT ELBOW 12 - 13 DUCT 10 20 20 30 5 60 15

_______________________________________________________________________ 140 20 ______________________________________________________________________ Loss = 160 x 0.065/100 = 0.104 in wg Now we know that the total static pressure at fan discharge = Duct friction + terminal pressure - regain Here Velocity in initial section = 1218 fpm

R. Sharma (BSNL Electrical Zone Patna)

Velocity in last section = 720 fpm Using 75% regain coefficient Regain = 0.75 [(1218/4000)2 - (720/4000)2 ] = 0.044 in wg Total static pressure at fan discharge = 0.104 + 0.15 - 0.044 in Wg = 0.21 in Wg. RELATION OF CFM TO AREA FOR EQUAL FRICTION PER FOOT OF LENGTH _______________________________________________________________________ CFM Duct CFM Duct CFM Duct CFM Duct Capacity Area Capacity Area Capacity Area Capacity Area (%) (%) (%) (%) (%) (%) (%) (%) ----------------------------------------------------------------------------------------------------------1 2.0 26 33.5 51 59.0 76 81.0 2 3.5 27 34.5 52 60.0 77 82.0 3 5.5 28 35.5 53 61.0 78 83.0 4 7.0 29 36.5 54 62.0 79 84.0 5 9.0 30 37.5 55 63.0 80 84.5 6 10.5 31 39.0 56 64.0 81 85.5 7 11.5 32 40.0 57 65.0 82 86.0 8 13.0 33 41.0 58 65.5 83 87.0 9 14.5 34 42.0 59 66.5 84 87.5 10 16.5 35 43.0 60 67.5 85 88.5 11 17.5 36 44.0 61 68.0 86 89.5 12 18.5 37 45.0 62 69.0 87 90.0 13 19.5 38 46.0 63 70.0 88 90.5 14 20.3 39 47.0 64 71.0 89 91.5 15 21.5 40 48.0 65 71.5 90 92.0 16 23.0 41 49.0 66 72.5 91 93.0 17 24.0 42 50.0 67 73.5 92 94.0 18 25.0 43 51.0 68 74.5 93 94.5 19 26.0 44 52.0 69 75.5 94 95.0 20 27.0 45 53.0 70 76.5 95 96.0 21 28.0 46 54.0 71 77.0 96 96.5 22 29.0 47 55.0 72 78.0 97 97.5 23 30.5 48 56.0 73 79.0 98 98.0 24 31.5 49 57.0 74 80.0 99 99.0 25 32.5 50 58.0 75 80.5 100 100.0 -------------------------------------------------------------------------------------------------------------

Anda mungkin juga menyukai

- A Guide in Practical Psychrometrics for Students and EngineersDari EverandA Guide in Practical Psychrometrics for Students and EngineersBelum ada peringkat

- Chilled Water Pump - Primary, SecondaryDokumen5 halamanChilled Water Pump - Primary, SecondarySatya N.GBelum ada peringkat

- HVAC Duct Design GuideDokumen18 halamanHVAC Duct Design GuideAshokBelum ada peringkat

- TRANE - HVAC Resource Guide For LEED PDFDokumen36 halamanTRANE - HVAC Resource Guide For LEED PDFjupoc100% (1)

- UBC ASHRAE Competition Report PDFDokumen34 halamanUBC ASHRAE Competition Report PDFmech118100% (1)

- AHU Design Basics: Centrifugal Fans, Coils, Filters LayoutsDokumen29 halamanAHU Design Basics: Centrifugal Fans, Coils, Filters LayoutsHari Babu Dharmavarapu100% (2)

- Fcu PipingDokumen20 halamanFcu PipingRamadan RashadBelum ada peringkat

- Swimming Pool Heater SizingDokumen1 halamanSwimming Pool Heater SizingAmeer AbbasBelum ada peringkat

- The equal friction method for sizing ductsDokumen8 halamanThe equal friction method for sizing ductsRamil BelmonteBelum ada peringkat

- Eurovent 2.3Dokumen24 halamanEurovent 2.3pipipopo75100% (1)

- Diffuser Sizing GuidelinesDokumen1 halamanDiffuser Sizing Guidelinessyed mustafa aliBelum ada peringkat

- HAP 4.2 ManualDokumen148 halamanHAP 4.2 ManualMohamed Abdel Monem .Chicco80% (5)

- HVAC Equations, Data, and Rules of Thumb, Third EditionDari EverandHVAC Equations, Data, and Rules of Thumb, Third EditionBelum ada peringkat

- Cooling Coil Design (SI Units)Dokumen3 halamanCooling Coil Design (SI Units)Christopher PersaudBelum ada peringkat

- Fcu SizingDokumen12 halamanFcu SizingLloydBelum ada peringkat

- Expansion Vessel Calculation for Pressurization Unit ProjectDokumen1 halamanExpansion Vessel Calculation for Pressurization Unit Projectkumar123rajuBelum ada peringkat

- Measure RPA ROI with KPIsDokumen4 halamanMeasure RPA ROI with KPIsAdnan FarooqBelum ada peringkat

- Smacna Duct LeakageDokumen3 halamanSmacna Duct Leakageanton7786Belum ada peringkat

- Comparison of VRF Over ChillersDokumen2 halamanComparison of VRF Over ChillersAdil MohdBelum ada peringkat

- Heating and Cooling Load CalculationDokumen7 halamanHeating and Cooling Load Calculationirsalan_shahidBelum ada peringkat

- Dehumidification Handbook 2nd Ed - 12 Cs PDFDokumen228 halamanDehumidification Handbook 2nd Ed - 12 Cs PDFleak67% (3)

- High Velocity Duct Design Tips by TraneDokumen50 halamanHigh Velocity Duct Design Tips by TraneInventor SolidworksBelum ada peringkat

- Suffolk Bus S92 Schedule Effective 5-2712Dokumen2 halamanSuffolk Bus S92 Schedule Effective 5-2712RiverheadLOCAL67% (6)

- Cold Air Distribution Design ManualDokumen67 halamanCold Air Distribution Design ManualMohammed Jassim100% (2)

- Northwestern Chemical Fume Hood GuideDokumen11 halamanNorthwestern Chemical Fume Hood Guidekumar123rajuBelum ada peringkat

- Hydraulic Vs Mechanical+SnubbersDokumen1 halamanHydraulic Vs Mechanical+SnubbersJordana VeigaBelum ada peringkat

- Hap Ehelp 025Dokumen17 halamanHap Ehelp 025Abed NaemBelum ada peringkat

- Air Balancing Check ListsDokumen11 halamanAir Balancing Check Listskumar123rajuBelum ada peringkat

- Ashrae Duct PDFDokumen3 halamanAshrae Duct PDFAnonymous XhkjXCxxsTBelum ada peringkat

- Duct Construction Schedule & References PDFDokumen8 halamanDuct Construction Schedule & References PDFEslam ElsayedBelum ada peringkat

- 3 TB - Dehumidification and The Psychrometric ChartDokumen4 halaman3 TB - Dehumidification and The Psychrometric Chartashfaq-matte-7993100% (2)

- Design Control Document-MVACDokumen48 halamanDesign Control Document-MVACRudivic LumainBelum ada peringkat

- Supply Air Grille SizingDokumen12 halamanSupply Air Grille Sizingdynamitedragon100% (1)

- Secondary Loop Chilled Water in Super High Rise BLDGDokumen11 halamanSecondary Loop Chilled Water in Super High Rise BLDGocean220220Belum ada peringkat

- Duct Design - Equal Friction MethodDokumen35 halamanDuct Design - Equal Friction MethodAdhitya DarmadiBelum ada peringkat

- NYB Fan Handbook - 2007Dokumen112 halamanNYB Fan Handbook - 2007José Pedro Casagrande Trentín100% (1)

- Piping System DesignDokumen66 halamanPiping System DesignChinmoy12533995100% (2)

- Car Park Jet FanDokumen14 halamanCar Park Jet FanYan Aung100% (1)

- Air Distribution Engg GuideDokumen8 halamanAir Distribution Engg GuideNiong DavidBelum ada peringkat

- Noise Calculation Procedure - Simple MethodDokumen7 halamanNoise Calculation Procedure - Simple MethodZiyad AwaliBelum ada peringkat

- Intrinsic Safety Circuit DesignDokumen19 halamanIntrinsic Safety Circuit DesignMoralba SeijasBelum ada peringkat

- Examples of Psychrometric Calculations For Summer and Winter PDFDokumen9 halamanExamples of Psychrometric Calculations For Summer and Winter PDFamitbslpawarBelum ada peringkat

- AC Duct Design PDFDokumen6 halamanAC Duct Design PDFkumar123rajuBelum ada peringkat

- Hvac Air BalancingDokumen56 halamanHvac Air Balancingkumar123raju100% (1)

- 02 Stuck Pipe - Free Point & Back Off PDFDokumen31 halaman02 Stuck Pipe - Free Point & Back Off PDFام فاطمة البطاط100% (2)

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow Systems-Taylor PDFDokumen5 halamanASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow Systems-Taylor PDFYazan AkBelum ada peringkat

- Chilled Water FlowDokumen1 halamanChilled Water FlowKarthikeyan Sankarrajan100% (1)

- Wind Tunnel DesignDokumen9 halamanWind Tunnel Designgumua100% (1)

- Duct DesignDokumen49 halamanDuct DesignabianshbaralBelum ada peringkat

- Air Handling Units: CatalogueDokumen157 halamanAir Handling Units: Cataloguevarshneyrk@rediffmail.comBelum ada peringkat

- AX324 - Engineering HVAC Checklist Plant Room/Substation ReviewDokumen3 halamanAX324 - Engineering HVAC Checklist Plant Room/Substation Reviewkumar123rajuBelum ada peringkat

- 2 Way-3way Valves For Chilled Water SystemDokumen1 halaman2 Way-3way Valves For Chilled Water SystemLDhir100% (1)

- Labs Best Practices EnergyDokumen107 halamanLabs Best Practices EnergynumeriqueBelum ada peringkat

- Clearings 2018Dokumen22 halamanClearings 2018ldxb2001100% (1)

- Stair PressurizationDokumen11 halamanStair Pressurization185412Belum ada peringkat

- HVAC Duct Calculator For EngineersDokumen42 halamanHVAC Duct Calculator For EngineersMohammed O. Al-DushyBelum ada peringkat

- Humidification Load Calculator GuideDokumen22 halamanHumidification Load Calculator GuideAnvar Pa100% (1)

- Overview of Warehouse ACMV DesignDokumen23 halamanOverview of Warehouse ACMV DesignJojo TangalinBelum ada peringkat

- Hot Water Storage Systems GuideDokumen11 halamanHot Water Storage Systems GuideNadeesha BandaraBelum ada peringkat

- Barrel PonicsDokumen101 halamanBarrel Ponicsparaypan100% (1)

- ANSI-ASHRAE 170 Brief DiagramsDokumen1 halamanANSI-ASHRAE 170 Brief DiagramsLimBelum ada peringkat

- Technical Handbook Air CurtainsDokumen13 halamanTechnical Handbook Air Curtainsaca111111Belum ada peringkat

- Comprehensive HVAC System Design and Maintenance TrainingDokumen8 halamanComprehensive HVAC System Design and Maintenance TrainingSuresh Velu100% (1)

- ASHRAE Duct Noise Vs VelocityDokumen1 halamanASHRAE Duct Noise Vs Velocityasdthu100% (1)

- Equation-Loss Calc Large DuctsDokumen2 halamanEquation-Loss Calc Large Ductskumar123rajuBelum ada peringkat

- PRICE - Air Distribution GuideDokumen5 halamanPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Expansion tank calculationsDokumen5 halamanExpansion tank calculationspsjjoshi0% (1)

- Duct Design RevDokumen21 halamanDuct Design Revapi-25999517100% (1)

- Advanced Air Duct Design Part 2Dokumen29 halamanAdvanced Air Duct Design Part 2Timothy Bryant100% (1)

- Sizing Heaters and Steam Requirements For HotelDokumen17 halamanSizing Heaters and Steam Requirements For HotelantonpgmBelum ada peringkat

- DuctworkDokumen12 halamanDuctworkNiong David100% (1)

- The Specific Objectives of This Chapter Are To:: 38.2 - General Rules For Duct DesignDokumen6 halamanThe Specific Objectives of This Chapter Are To:: 38.2 - General Rules For Duct DesignSalehAfadlehBelum ada peringkat

- Qpedia Apr09 Basic Principles of Wind Tunnel Design9Dokumen3 halamanQpedia Apr09 Basic Principles of Wind Tunnel Design9Ryan FadhliBelum ada peringkat

- Design of Air Conditioning DuctsDokumen37 halamanDesign of Air Conditioning Ductsandu gashuBelum ada peringkat

- Abb-Ie4 Motor SizesDokumen6 halamanAbb-Ie4 Motor Sizeskumar123rajuBelum ada peringkat

- Application of An Environmentally OptimuDokumen12 halamanApplication of An Environmentally Optimukumar123rajuBelum ada peringkat

- Maury AsDokumen6 halamanMaury Askumar123rajuBelum ada peringkat

- DC Technical CodeDokumen75 halamanDC Technical Codekumar123rajuBelum ada peringkat

- Duct Area Calculator-R5Dokumen188 halamanDuct Area Calculator-R5kumar123rajuBelum ada peringkat

- Amca Fane Ffic GradesDokumen5 halamanAmca Fane Ffic Gradeskumar123rajuBelum ada peringkat

- EXCEL Formulae01Dokumen223 halamanEXCEL Formulae01kumar123rajuBelum ada peringkat

- Flowbar PerformanceDokumen14 halamanFlowbar Performancekumar123rajuBelum ada peringkat

- EXCEL Formulae01Dokumen223 halamanEXCEL Formulae01kumar123rajuBelum ada peringkat

- Halton Foodservice Catalogue Uk1211 PDFDokumen68 halamanHalton Foodservice Catalogue Uk1211 PDFkumar123raju0% (1)

- Sanitary Accessories Calculator for Building ProjectsDokumen1 halamanSanitary Accessories Calculator for Building Projectskumar123rajuBelum ada peringkat

- 63 HZ 125 HZ 250 HZ 500 HZ 1000 HZ 2000 HZ Sl. No. Component DescriptionDokumen5 halaman63 HZ 125 HZ 250 HZ 500 HZ 1000 HZ 2000 HZ Sl. No. Component Descriptionkumar123rajuBelum ada peringkat

- Demand Controlled Ventilation PDFDokumen8 halamanDemand Controlled Ventilation PDFkumar123rajuBelum ada peringkat

- Neuman Advanced Fu Me HoodDokumen34 halamanNeuman Advanced Fu Me Hoodkumar123rajuBelum ada peringkat

- Media Ceiling FOR LABORATORYDokumen10 halamanMedia Ceiling FOR LABORATORYkumar123rajuBelum ada peringkat

- Pipe Colour CodingDokumen9 halamanPipe Colour Codingkumar123rajuBelum ada peringkat

- EquationsDokumen36 halamanEquationsajitdshettyBelum ada peringkat

- Pipe Colour CodingDokumen9 halamanPipe Colour Codingkumar123rajuBelum ada peringkat

- Hydraulic Accumulator - Test and Charge: Cerrar SIS Pantalla AnteriorDokumen9 halamanHydraulic Accumulator - Test and Charge: Cerrar SIS Pantalla AnteriorHomer Yoel Nieto Mendoza100% (1)

- The Ultimate Guide to Building an Engaged CommunityDokumen24 halamanThe Ultimate Guide to Building an Engaged CommunityCarla UttermanBelum ada peringkat

- Hemera Creality CR10s Pro Upgrade Guide (Edition 1)Dokumen24 halamanHemera Creality CR10s Pro Upgrade Guide (Edition 1)gumushBelum ada peringkat

- Daniel Kipkirong Tarus C.VDokumen19 halamanDaniel Kipkirong Tarus C.VPeter Osundwa KitekiBelum ada peringkat

- JURNALfidyaDokumen20 halamanJURNALfidyaIrma NasridaBelum ada peringkat

- UN 9252-06 Part 1-UD-AU-000-EB-00020 PDFDokumen7 halamanUN 9252-06 Part 1-UD-AU-000-EB-00020 PDFManjeet SainiBelum ada peringkat

- The Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Dokumen20 halamanThe Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Gutenberg.orgBelum ada peringkat

- LGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityDokumen20 halamanLGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityFatima ZafarBelum ada peringkat

- Mobil Dynagear Series Performance ProfileDokumen2 halamanMobil Dynagear Series Performance ProfileXavier DiazBelum ada peringkat

- Nervous System Reaction PaperDokumen3 halamanNervous System Reaction PaperJohn Ruel Sanchez IIBelum ada peringkat

- Training Program for Newly Recruited AEEsDokumen7 halamanTraining Program for Newly Recruited AEEsakstrmec23Belum ada peringkat

- Openroads Designer User ManualDokumen112 halamanOpenroads Designer User ManualNilay BhavsarBelum ada peringkat

- Analytical ExpositionDokumen7 halamanAnalytical ExpositionEman FakotBelum ada peringkat

- ICN Question Bank Unit-1, 2 and 3 (Upto GSM Identifier)Dokumen1 halamanICN Question Bank Unit-1, 2 and 3 (Upto GSM Identifier)Snehal PatelBelum ada peringkat

- 2010 Final Exam (Answers)Dokumen10 halaman2010 Final Exam (Answers)T FBelum ada peringkat

- ED 107 162 Author Morphology. Pub Date Aug 69 Note Austin Edrs Price MF-$O.76 DescriptorsDokumen75 halamanED 107 162 Author Morphology. Pub Date Aug 69 Note Austin Edrs Price MF-$O.76 DescriptorsTalha KhanBelum ada peringkat

- Calibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Dokumen16 halamanCalibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Daniel Rolando Gutierrez FuentesBelum ada peringkat

- Single Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Dokumen1 halamanSingle Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Sunli Karla Sivincha RomeroBelum ada peringkat

- Valve Type Trim Type CF XTDokumen1 halamanValve Type Trim Type CF XTAye KyweBelum ada peringkat

- ResearchDokumen48 halamanResearchCai De JesusBelum ada peringkat

- SampleDokumen13 halamanSamplemypermatakoe71Belum ada peringkat

- Free Study PDF Download from pebexam BlogDokumen22 halamanFree Study PDF Download from pebexam Blogk_jaiswalBelum ada peringkat

- DLT - Ate 2022Dokumen28 halamanDLT - Ate 2022chellep.uniBelum ada peringkat

- Quenching & TemperingDokumen4 halamanQuenching & Temperingkgkganesh8116Belum ada peringkat