Axial Flow

Diunggah oleh

Rifat Sanjani DipuHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Axial Flow

Diunggah oleh

Rifat Sanjani DipuHak Cipta:

Format Tersedia

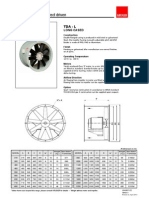

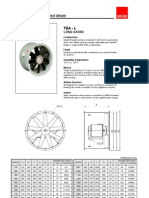

ADJUSTABLE PITCH AXIAL FLOW FANS

B

FEATURES

The AP Series of duct mounted adjustable pitch axial flow fans is available in the following variants:AP Series - direct-drive APV Series - direct-drive vertical mounted APS Series - direct-drive smoke-spill APB Series - belt-drive BFA Series - bifurcated, direct-drive

ANCILLARY EQUIPMENT

C..P - Circular silencers Ref. H-4/8

Vibration isolators Ref. I-1

MF - Matching flange Ref. J-4

Construction

The casings are of mild steel, hot-dip galvanised after manufacture. Impeller blades shall have an aerofoil section and be pressure die-cast aluminium, injection-moulded glassreinforced plastic or nylon. Anti-static blades for hazardous applications up to 1400mm diameter, are also available.

F - Mounting foot Ref. J-6

IC - Inlet cone Ref. J-7

FG - Finger guards Ref. J-9

Motors

Type - squirrel cage induction motor which can be selected to suit virtually any specification. Electricity supply - single or three-phase to suit a wide range of voltages and frequencies. Bearings - ball. See pages N-3/4 for details on motors. Motors to meet Australian Ex e, Ex d, Ex n or D.I.P Standards . can be fitted.

Inverter Ref. L-9

SMOKE-SPILL APPLICATIONS

The APS Series has been tested to meet the air performance and high temperature test requirements of Standards AS/NZS1668.1:1998 and AS/NZS4429:1999; both tests are mandatory. For advice on smoke-spill wiring requirements refer to the above Standards. See page C-7 for details of the smoke-spill range available.

Internal Thermal Protection

Can be provided as an optional extra.

Testing

Air flow testing:315-1000mm diameter - BS848:Part 1, 1980 1250-2000mm diameter - ISO5801:1997 Noise testing all sizes to BS848:Part 2, 1985

Special Features

Suitable for a wide range of applications, ranging from handling ambient filtered air to hot, toxic and noxious gases. Hazardous fume applications AP Series fans can be made to accommodate requirements for corrosive fume and explosion risk applications. Special coatings and alternative materials, such as stainless steel, are available as well as increased safety motors and anti-static impellers. Our sales engineers are able to assist with requirements, which must be specified at time of quotation.

HOW TO ORDER

AP - direct drive APV - vertical APS - smoke spill APB - belt drive BFA - bifurcated Fan diameter in cm Fan speed, no. of poles Hub diameter code A =150 D= 400 B = 250 F = 550 C = 350 G = 255 Aluminium blades, A GRP , P Nylon, N Antistatic blades, E No. of blades Blade pitch angle, deg.

Wiring Diagram

See pages M-6/7, diagrams DD 1, 2, 3, 7, 8, 9.

Weights

See pages C-112/113 to determine unit weights.

Dimensions

See pages C-110/111 for dimensions.

FANTECH 2008

DUCT MOUNTED FANS

B-31

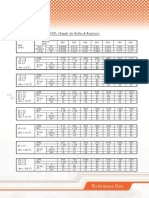

AXIAL FLOW FANS QUICK SELECTION GRAPHS

The quick selection curves on these pages are designed to assist users to determine the fan diameter, speed, approximate noise level and dimensions of the fan to meet the specified duty.

SUGGESTED SPECIFICATION

The axial fans shall be of the AP/APV/APS/APB/BFA design(s) as manufactured by Fantech Pty. Ltd.. All performances shall be based upon BS848:Part 1, 1980 or ISO5801:1997 and BS848:Part 2, 1985. Casings shall be hot-dip galvanised mild steel. Impellers shall be of aerofoil section glass-reinforced plastic (GRP), nylon, or aluminium; GRP is standard where selection permits.

Refer to Section C for detailed selection information.

Detail including the number of blades and power absorbed is shown on pages C-11/109 or is available from the Fantech CD program. Pages C-2/8 provide detailed information on these products. An example of how to use the curves is shown on page C-9. The dimensions for all fans are on pages C-110/111. Weights can be determined from details on pages C-112/113.

Model Numbers

AP - direct-driven; 315 to 2000mm diameter APV - direct-driven; 315 to 2000mm diameter APS - direct-driven; 315 to 2000mm diameter APB - belt driven; BFA - bifurcated; 315 to 2000mm diameter 400 to 1250mm diameter

3000 2000

91 95 88 80 80 71 65 70 78 75 90 92

2 Pole 48 rev/sec

1000

92

pSF - Fan Static Pressure, Pa

600 400 200 100 60 0.2 0.4

3

0632 0502 0562

0712

0802

em st s Sy ine L

0312

65

0402

68

71

80

78

94

95

91

0.6

1.0

2.0

4.0

6.0

10.0

20.0

30.0

qV - Volume Flow, m /s

dB(A) @ 3m: Inlet Side =

2000

92 87

4 Pole 24 rev/sec

1000 600

Sy Lin stem es

83 69 73 68 64 56 52 75 65 63 68 71 69

pSF - Fan Static Pressure, Pa

85 78

90

400

200

0504

0564

0634

0714

0804

1004

1254

1404

100 60 0.2

51

49 49

0404

55 64 67 71 73 73 78 88 93

0314

0.4

3

0.6

1.0

2.0

4.0

6.0

10.0

20.0

40.0

60.0

qV - Volume Flow, m /s

dB(A) @ 3m: Inlet Side =

B-32

DUCT MOUNTED FANS

FANTECH 2008

AXIAL FLOW FANS QUICK SELECTION GRAPHS

1000

86 96 82 78 90 95

6 Pole 16 rev/sec

600

Sy s Lin tem es

400

81 72 63 62 66 54 56 56 58 63 59 67 75 80

88

pSF - Fan Static Pressure, Pa

B

1606 1806 2006

200

59

100 60 40 0.2

0316 40

48

0566

51 57

0636

61

0716

0806

1006

1256

1406

0406

0506

45 67 65 70 76 81 83 88 92

0.4

0.6

3

1.0

2.0

4.0

6.0

10.0

20.0

40.0

60.0

100.0

qV - Volume Flow, m /s

dB(A) @ 3m: Inlet Side =

600

86

8 Pole 12 rev/sec

74 72 71 78 77 74 71 63 61 82

400

pSF - Fan Static Pressure, Pa

200

Sy s Lin tem es

100

58 56

57 51 58 0718 51 59

60

1258 1008

1408

1608

1808

2008

0808

60 40

0638

62

62

71

75

75

79

83

0.6

1.0

3

2.0

4.0

6.0

10.0

20.0

40.0

60.0

100.0

qV - Volume Flow, m /s

dB(A) @ 3m: Inlet Side =

400

81 78 72 70 75 78

10 Pole 10 rev/sec

pSF - Fan Static Pressure, Pa

200

100

em st s Sy ine L

1601

1801

2001

60 50 6.0

3

71

75

78

10.0

20.0

40.0

60.0

dB(A) @ 3m: Inlet Side =

80.0

qV - Volume Flow, m /s

FANTECH 2008

DUCT MOUNTED FANS

B-33

Anda mungkin juga menyukai

- Quat KrugerDokumen52 halamanQuat Krugerruby0808Belum ada peringkat

- Axial Flow Fans General Information: Elta Impeller RangeDokumen8 halamanAxial Flow Fans General Information: Elta Impeller Rangehardik033Belum ada peringkat

- Circular Duct Attenuators: Performance Data - Open TypeDokumen3 halamanCircular Duct Attenuators: Performance Data - Open TypePaul ShermanBelum ada peringkat

- Multi FlowDokumen5 halamanMulti FlowengineeringtambangBelum ada peringkat

- Technical Data - Fan Model APS1004BA7/19: Location: Designation: Performance - Required ActualDokumen6 halamanTechnical Data - Fan Model APS1004BA7/19: Location: Designation: Performance - Required Actualgaru2529Belum ada peringkat

- Technical Data - Fan Model AP0634AA530Dokumen5 halamanTechnical Data - Fan Model AP0634AA530garu2529Belum ada peringkat

- Ventilatoare Industriale AxialeDokumen27 halamanVentilatoare Industriale AxialeinicoleBelum ada peringkat

- Bifurcared Axial Flow Fans: High Performance, Low Maintenance, 'Motor Out of Airstream' For Complete Peace of MindDokumen11 halamanBifurcared Axial Flow Fans: High Performance, Low Maintenance, 'Motor Out of Airstream' For Complete Peace of MindKhalid SaqallahBelum ada peringkat

- CBMDokumen9 halamanCBMMuhidin KozicaBelum ada peringkat

- PL 008748Dokumen10 halamanPL 008748ronaldxmenBelum ada peringkat

- SafidDokumen36 halamanSafidFREDIELABRADOR100% (1)

- Compact Series Type HCFB / HCFT (Plastic Impellers) : Plate Mounted Axial Flow FansDokumen12 halamanCompact Series Type HCFB / HCFT (Plastic Impellers) : Plate Mounted Axial Flow FansPraise Sam AbrahamBelum ada peringkat

- BSB Series Single Inlet Centrifugal Fans with Backward WheelsDokumen52 halamanBSB Series Single Inlet Centrifugal Fans with Backward WheelsZwe1991Belum ada peringkat

- Ficha TecnicaDokumen27 halamanFicha TecnicaRaul Karniel Cruz LópezBelum ada peringkat

- TDA-F Series: Smokespill Axial FanDokumen4 halamanTDA-F Series: Smokespill Axial Fanjames_chan2178Belum ada peringkat

- Kruger Centrifugal Fan Sisw FC PDFDokumen43 halamanKruger Centrifugal Fan Sisw FC PDFcoolth2Belum ada peringkat

- Halton Single-Blade Damper Technical DocumentDokumen12 halamanHalton Single-Blade Damper Technical Documentalecs008Belum ada peringkat

- Single Inlet Centrifugal Fan: With Backward WheelsDokumen47 halamanSingle Inlet Centrifugal Fan: With Backward WheelsJay PresleyBelum ada peringkat

- SQ SeriesDokumen3 halamanSQ SeriesELWAN NAOVAL HAPID ALFANA -Belum ada peringkat

- EASA TCDS P.094 MT Propeller Entwicklung GMBH MTV 6 Series Propellers 02 29082008Dokumen7 halamanEASA TCDS P.094 MT Propeller Entwicklung GMBH MTV 6 Series Propellers 02 29082008최민수Belum ada peringkat

- Fda - Cat002.e3 - Fda 800 - 900Dokumen9 halamanFda - Cat002.e3 - Fda 800 - 900Akhileshkumar PandeyBelum ada peringkat

- FDA SeriesDokumen51 halamanFDA SeriesKedar ShethiaBelum ada peringkat

- Fans catalogue: Axial fans with EC motorsDokumen136 halamanFans catalogue: Axial fans with EC motorsMiodrag KesicBelum ada peringkat

- Pg.14 Compact Plate AxialsDokumen12 halamanPg.14 Compact Plate AxialsAntonis BafatakisBelum ada peringkat

- Kruger - BSB Series CatalogueDokumen6 halamanKruger - BSB Series Cataloguescribdbipin1100% (1)

- Summary Fan Data SheetDokumen3 halamanSummary Fan Data Sheetlijo johnBelum ada peringkat

- Technical Specifications For Centrifugal Pumps PDFDokumen12 halamanTechnical Specifications For Centrifugal Pumps PDFVicky GautamBelum ada peringkat

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDokumen24 halamanDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymBelum ada peringkat

- Ventilacion (Hannes-Indelva) - Submittal GreenheckDokumen8 halamanVentilacion (Hannes-Indelva) - Submittal GreenheckjoravicaBelum ada peringkat

- BPR SeriesDokumen6 halamanBPR SeriessapkoBelum ada peringkat

- Ventilating Fans & Air Moving PanasonicDokumen31 halamanVentilating Fans & Air Moving PanasonicBoy Alfredo PangaribuanBelum ada peringkat

- Dimensions - Inches Product Data: Split-System Evaporator Blowers 15 & 20 TONDokumen4 halamanDimensions - Inches Product Data: Split-System Evaporator Blowers 15 & 20 TONRafyss RodriguezBelum ada peringkat

- Ball Valves - Metal SeatedDokumen6 halamanBall Valves - Metal Seatedmetasoniko2014Belum ada peringkat

- Valvula Reductora de Presion Bermad Area 675 720-ULDokumen4 halamanValvula Reductora de Presion Bermad Area 675 720-ULChristian FherBelum ada peringkat

- Fisa Tehnica Pompe MultifreeDokumen10 halamanFisa Tehnica Pompe MultifreeOčtáv VátčoBelum ada peringkat

- Electrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Dokumen234 halamanElectrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Canea Mihai CaiusBelum ada peringkat

- LC SCDokumen28 halamanLC SChardik033Belum ada peringkat

- SN Series Screw PumpsDokumen12 halamanSN Series Screw PumpsAlexis Ernesto Cardenas BeltranBelum ada peringkat

- AXIAL FANS Complete Range of Axial FansDokumen40 halamanAXIAL FANS Complete Range of Axial FansDanilo Magallanes SampagaBelum ada peringkat

- TP SeriesDokumen3 halamanTP SeriesPrasad KadamBelum ada peringkat

- Axial Flow Fan - LeafletDokumen4 halamanAxial Flow Fan - LeafletZwe1991Belum ada peringkat

- TDA-L LEA001.E2 NewDokumen4 halamanTDA-L LEA001.E2 NewsugiantoBelum ada peringkat

- New Generation Series: FeaturesDokumen4 halamanNew Generation Series: FeaturesKhánh DươngBelum ada peringkat

- Vibratory Feeders and Conveyors PDFDokumen14 halamanVibratory Feeders and Conveyors PDFArnaldo BenitezBelum ada peringkat

- Amarex N: Submersible Motor Pumps DN 50 To 100Dokumen44 halamanAmarex N: Submersible Motor Pumps DN 50 To 100Ben RahierBelum ada peringkat

- 592 en 082 093 Compact HCFB HCBB Fid6087Dokumen12 halaman592 en 082 093 Compact HCFB HCBB Fid6087Boyko IzoffBelum ada peringkat

- BDB SeriesDokumen47 halamanBDB SeriesKedar Shethia100% (2)

- Vane Axial Flow Fans Performance CurvesDokumen40 halamanVane Axial Flow Fans Performance CurvesKim WongBelum ada peringkat

- Dasco 10-18Dokumen9 halamanDasco 10-18Ahmed Azad100% (1)

- F-550 Series Panel Mount Flowmeter: Pipe Size: 1/4", 3/8", 1/2" 3/4", 1"Dokumen1 halamanF-550 Series Panel Mount Flowmeter: Pipe Size: 1/4", 3/8", 1/2" 3/4", 1"Ahmed Said GhonimyBelum ada peringkat

- Axial Fans CostechDokumen14 halamanAxial Fans CostechEfra BlancoBelum ada peringkat

- Acf5 1103.01 GBDokumen16 halamanAcf5 1103.01 GBPedro Javier Medina CornejoBelum ada peringkat

- Data Sheet Tag 180-Pu-011eDokumen8 halamanData Sheet Tag 180-Pu-011eSarah PerezBelum ada peringkat

- Rectangular Ducts and FittingsDokumen31 halamanRectangular Ducts and FittingsSreejith MpBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- HKSAR@Guidance Notes For The Electrical Products (Safety) Regulation, 2007Dokumen104 halamanHKSAR@Guidance Notes For The Electrical Products (Safety) Regulation, 2007cyong7788Belum ada peringkat

- P-3C Aircraft Powerplant Electrical Systems ManualDokumen340 halamanP-3C Aircraft Powerplant Electrical Systems ManualEva LuhBelum ada peringkat

- Neca200 10 PDokumen30 halamanNeca200 10 Pcharlesc5746Belum ada peringkat

- Kpdisp KeypadDokumen2 halamanKpdisp KeypadInstalaciones y Servicios 2906, C.A. Amado IbarraBelum ada peringkat

- Installation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersDokumen2 halamanInstallation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersJed DavidBelum ada peringkat

- 8FG D CE049!21!0608 Electrical Wiring DiagramDokumen158 halaman8FG D CE049!21!0608 Electrical Wiring DiagramDuong Van HoanBelum ada peringkat

- KUJARIBUDokumen1.098 halamanKUJARIBUMike LitoriesBelum ada peringkat

- Asco Series 44 Pressure Sensor CatalogDokumen2 halamanAsco Series 44 Pressure Sensor CatalogAnonymous uXxyCieO3100% (1)

- In CabinetDokumen140 halamanIn Cabinetali_1976sweet7448Belum ada peringkat

- How To Make A Rifled Barrel in Europe FGC9 FGC-9 9x19mm 9mmDokumen88 halamanHow To Make A Rifled Barrel in Europe FGC9 FGC-9 9x19mm 9mmLaurent GranierBelum ada peringkat

- HFCC D Iom 03Dokumen16 halamanHFCC D Iom 03geovany_villagraBelum ada peringkat

- UntitledDokumen91 halamanUntitledLiza Mae BalboaBelum ada peringkat

- List of International StandardsDokumen6 halamanList of International StandardsAnonymous m65TTcfOT100% (3)

- Magna 3Dokumen36 halamanMagna 3mercruiserBelum ada peringkat

- How 3-Way Switches WorkDokumen5 halamanHow 3-Way Switches WorkAmr Ahmed ZeyadaBelum ada peringkat

- Lighting Stryker Bacnet™ Clb6438S Configurable Lighting ControllerDokumen24 halamanLighting Stryker Bacnet™ Clb6438S Configurable Lighting ControllerErmiasBelum ada peringkat

- Fire Resistant LSOH® Power Cables For Fi Xed WiringDokumen25 halamanFire Resistant LSOH® Power Cables For Fi Xed WiringCalvert WongBelum ada peringkat

- Panasonic MINAS A3 SeriesDokumen320 halamanPanasonic MINAS A3 SeriesNhật TrầnBelum ada peringkat

- CR750 CR751 CR760 Setup Operation Maintenance ENGDokumen130 halamanCR750 CR751 CR760 Setup Operation Maintenance ENGManu TejadoBelum ada peringkat

- Sporlan IB-G Interface Board: Installation and Operation InstructionsDokumen8 halamanSporlan IB-G Interface Board: Installation and Operation InstructionsCarlos ReisBelum ada peringkat

- 2 - MS-Wires and Cables Installation WorksDokumen6 halaman2 - MS-Wires and Cables Installation WorksAraf KalamBelum ada peringkat

- 415V LVAC Switchborad Ver1Dokumen7 halaman415V LVAC Switchborad Ver1g.HtrughtreBelum ada peringkat

- Optra - NubiraDokumen37 halamanOptra - NubiraDaniel Castillo PeñaBelum ada peringkat

- Universal Cutter Grinder SafetyDokumen8 halamanUniversal Cutter Grinder SafetysifuszBelum ada peringkat

- Inovance Md290 VFD Quick Guide English 20-4-20Dokumen103 halamanInovance Md290 VFD Quick Guide English 20-4-20DEE - 5 BKUBelum ada peringkat

- Heat Trace InstallationDokumen140 halamanHeat Trace Installationthanna9783Belum ada peringkat

- NEWAGE N10 N15 N20 Owners Manual A065B317 - I3 - 202105 - ENDokumen20 halamanNEWAGE N10 N15 N20 Owners Manual A065B317 - I3 - 202105 - ENElvis VincentBelum ada peringkat

- In Salah Gas: Supplier Document - Job No 6683Dokumen88 halamanIn Salah Gas: Supplier Document - Job No 6683Azzo ZizoBelum ada peringkat

- User's Manual: EJA Series Differential Pressure and Pressure Transmitters Installation ManualDokumen42 halamanUser's Manual: EJA Series Differential Pressure and Pressure Transmitters Installation Manualjulio javier gonzales gonzalesBelum ada peringkat

- Manual Reparatii Audi A2 1.6 FSI PDFDokumen104 halamanManual Reparatii Audi A2 1.6 FSI PDFferentz u100% (1)