PPM Dough DR

Diunggah oleh

Nike NurjannahDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PPM Dough DR

Diunggah oleh

Nike NurjannahHak Cipta:

Format Tersedia

Dr. Lin Carson http://www.bakerpedia.com/topic/title/straight_dough.

html

STRAIGHT DOUGH

Definition

Straight dough is the simplest and most widely used method among all the breadmaking methods. Based on differences in fermentation time, the straightdough method can further be divided into two types: 1) straight dough and 2) no-time dough. Straight-dough method involves just one step mixing, all the dry ingredients such as flour, sugar, and yeast are first put into the mixing bowl and mixed at low speed, and then the wet ingredients such as water, ice and egg are added. After all the ingredients are evenly mixed, the mixing speed is changed to medium level until the dough reaches full development. The dough temperature after mixing is between 26 and 28 (79-82 F). Straight- dough method is primarily used in smaller retail-scale bakeries and sometimes in larger commercial bakeries for short production runs of specialty products. In large commercial settings, no-time dough requires high-speed mixers, and the mixing level of the dough can slightly exceed that of the completion stage in order to soften the gluten and shorten the fermentation time. The temperature of the no-time dough is between 28 and 29 (82-84F), higher than straight dough. Large scale commercial operations that use the no-time dough can sometimes use pre-ferment, liquid brew or flour brew, to jump start the fermentation and to temper the water (that helps reduce dough mixing temperatures).

Function :

1. Bread, bagel, pretzel,pita, flat bread, and all yeast leavened baked products 2. Danissh, croissants, puff and flaky pastry, choux, and anyi laminatd baked products 3. Donuts, Doughnuts, waffle, churros, funnel cakes, fritters, and any chemically leavened products that are not baked in the oven 4. Pizza, calzone, stuffed bread products, fress, frozen 5. Nutritional bars, granola bars, whole grains, high fiber, sugar free, and good for you baked products

sponge and dough

Definition

The sponge and dough process is the most commonly used method in US commercial manufacturing. The Sponge and dough method is a two-stage

procedure. In the first stage, a certain amount of flour (around 65%-70% of the total dough flour), water, and yeast are mixed and fermented for a period of time to produce a sponge. The sponge fermentation time may be varied depending on the sponge temperature, the ingredients used and the amount ofyeast. In smallscale sponge production, the mixer is used to form the sponge and also used to store the sponge. In the large-scale production of sponge, separate container is used to store the sponge under controlled conditions to ensure the uniformity of sponge development, and the fermentation time is around 3-4 hours. The temperature of sponge dough is usually kept around 21C (70F), which is similar to the final dough temperature. In the second stage, the sponge is added to the other remaining ingredients to form a final dough. The final dough can be processed by a rapid processing method, immediately sized and shaped, or sometimes is given a short period of bulkfermentation time.

Function :

Anda mungkin juga menyukai

- Taste of Home Breads: 100 Oven-Fresh Loaves, Rolls, Biscuits and MoreDari EverandTaste of Home Breads: 100 Oven-Fresh Loaves, Rolls, Biscuits and MoreBelum ada peringkat

- Bread QualityDokumen3 halamanBread QualityAsia AmirBelum ada peringkat

- Keto Bread Machine Cookbook: Homemade Easy and Delicious Keto Bread Recipes in The Bread MachineDari EverandKeto Bread Machine Cookbook: Homemade Easy and Delicious Keto Bread Recipes in The Bread MachineBelum ada peringkat

- 12 Steps of BakingDokumen7 halaman12 Steps of Bakingzoltan2010100% (1)

- Basic Foods 2-YEAST BREADSDokumen7 halamanBasic Foods 2-YEAST BREADSBernadette YurongBelum ada peringkat

- 05 Handout 1Dokumen6 halaman05 Handout 1Daisylyn ArellanoBelum ada peringkat

- Basic Steps in Yeast Dough ProductionDokumen26 halamanBasic Steps in Yeast Dough Productionraymond marcos100% (1)

- Factors That Contribute To Successful BakingDokumen8 halamanFactors That Contribute To Successful BakingErrol San Juan100% (1)

- Preparation and Mixing of Sponge Dough and Straight DoughDokumen34 halamanPreparation and Mixing of Sponge Dough and Straight DoughRENATO NATORBelum ada peringkat

- Sliced Bread: The Science ofDokumen4 halamanSliced Bread: The Science ofGayatri PrameswariBelum ada peringkat

- A. Lean Dough - Is Made Up of Basic Ingredients For Bread Flour, (YeastDokumen3 halamanA. Lean Dough - Is Made Up of Basic Ingredients For Bread Flour, (YeastJeremy BersanoBelum ada peringkat

- Bakery Products and Rice MillingDokumen19 halamanBakery Products and Rice Millingabhishek.ajmaniBelum ada peringkat

- Sample Chefs Handbook For The Artisanal Bread BakerDokumen11 halamanSample Chefs Handbook For The Artisanal Bread BakerNidhi BirlaBelum ada peringkat

- BreadDokumen5 halamanBreadAisha JananBelum ada peringkat

- FHGJDokumen16 halamanFHGJChienna Sabandon OmolonBelum ada peringkat

- Breadmaking Diseases FaultsDokumen14 halamanBreadmaking Diseases FaultsIhsan BadshaBelum ada peringkat

- Pastry, Cakes and CookiesDokumen9 halamanPastry, Cakes and CookiesMheg Sophia HockkinsBelum ada peringkat

- Presentation Bakery and ConfectioneryDokumen64 halamanPresentation Bakery and ConfectioneryJagan Babu67% (3)

- Day 3-Baking Methods and Appliances - Copy - Copy FixedDokumen95 halamanDay 3-Baking Methods and Appliances - Copy - Copy Fixeddexter.lychenBelum ada peringkat

- Thesis On Bread MakingDokumen7 halamanThesis On Bread MakingJill Brown100% (2)

- Maam NotesDokumen86 halamanMaam NotesPranay MeskarBelum ada peringkat

- Bread Machine Baking at High Altitude: Assistant Professor of Food and NutritionDokumen4 halamanBread Machine Baking at High Altitude: Assistant Professor of Food and NutritionSosoBelum ada peringkat

- Bread Processing TechnologyDokumen39 halamanBread Processing TechnologyTemesgen MuletaBelum ada peringkat

- Methods of Bread ProductionDokumen14 halamanMethods of Bread ProductionShruti TiwariBelum ada peringkat

- Bread MakingDokumen51 halamanBread Makingalvin manalaysayBelum ada peringkat

- Advance Baking ResearchDokumen26 halamanAdvance Baking ResearchEllysa Mae Pablo ManlupigBelum ada peringkat

- Biscuit Manufacturing: Different Types of BiscuitDokumen15 halamanBiscuit Manufacturing: Different Types of Biscuit9889187549Belum ada peringkat

- Baking IndustryDokumen26 halamanBaking IndustrysibaniBelum ada peringkat

- 2ssc Abb PubDokumen3 halaman2ssc Abb PubO.L.D.E.Belum ada peringkat

- Module 8 CAKESDokumen11 halamanModule 8 CAKESJocel Villanuz PadasasBelum ada peringkat

- Bakery Products ProcessDokumen13 halamanBakery Products ProcessrakhigoelBelum ada peringkat

- Raw Materials: Mixing and Kneading The DoughDokumen3 halamanRaw Materials: Mixing and Kneading The Doughelvina_andreaBelum ada peringkat

- Pasta ProductionDokumen18 halamanPasta ProductionAbdelrahman Rowezak50% (2)

- Artikel Frozen DoughDokumen2 halamanArtikel Frozen DoughisaacioBelum ada peringkat

- BPP Ncii Pointers To ReviewDokumen6 halamanBPP Ncii Pointers To ReviewkyrograpixBelum ada peringkat

- General Guidelies and Principles in BakingDokumen22 halamanGeneral Guidelies and Principles in BakingElaine Portia LagundinoBelum ada peringkat

- Week 5 Module Bread and PastryDokumen7 halamanWeek 5 Module Bread and PastryJoan Dela CruzBelum ada peringkat

- Note 2-FST 405Dokumen9 halamanNote 2-FST 405Paul FavourBelum ada peringkat

- Baking Quality of Bread Flour - Sponge-Dough, Pound-Loaf MethodDokumen3 halamanBaking Quality of Bread Flour - Sponge-Dough, Pound-Loaf MethodTheKasiopea24Belum ada peringkat

- Bread and Bakers YeastDokumen20 halamanBread and Bakers YeastSagarika Ghosh100% (1)

- Cookie FormulationDokumen11 halamanCookie Formulationnaspterboy100% (3)

- Assignment #3: Baseline Principles of Puffed and Baked SnacksDokumen9 halamanAssignment #3: Baseline Principles of Puffed and Baked SnacksAyesha KhanBelum ada peringkat

- Cakes Pies Pastries - LecDokumen48 halamanCakes Pies Pastries - LecGloria Le Thi Esquivel100% (1)

- Bread MakingDokumen6 halamanBread MakingKunwar Apoorv Singh PariharBelum ada peringkat

- Bread and Pastry Production NC 2: (A Self Learning Module)Dokumen36 halamanBread and Pastry Production NC 2: (A Self Learning Module)jaydaman08Belum ada peringkat

- Bake+Info Info Yeast+Raised+DoughnutsDokumen3 halamanBake+Info Info Yeast+Raised+DoughnutsTomBelum ada peringkat

- Chapter 03Dokumen23 halamanChapter 03Muhibullah MuhibBelum ada peringkat

- Manufacturing Process of Food Grade PastriesDokumen20 halamanManufacturing Process of Food Grade PastriesMuneeb0% (1)

- How Bread Is Made: Factsheet No. 7Dokumen5 halamanHow Bread Is Made: Factsheet No. 7Rahat Monga100% (1)

- Bakery Notes TheroyDokumen39 halamanBakery Notes TheroySunil Kumar100% (7)

- Food Plant Layout and Sanitation - PresentationDokumen32 halamanFood Plant Layout and Sanitation - PresentationMehwish ButtBelum ada peringkat

- TABLE OF CONTEN-WPS OfficeDokumen9 halamanTABLE OF CONTEN-WPS OfficeJiryl AlpuertoBelum ada peringkat

- Unit 6 & 7 Dimension of BakingDokumen9 halamanUnit 6 & 7 Dimension of Bakingkeyrie88100% (1)

- Bread and Pastry ProcedureDokumen25 halamanBread and Pastry ProceduregabyculinarBelum ada peringkat

- Methods of Bread MakingDokumen3 halamanMethods of Bread Makinggauravkrishana28Belum ada peringkat

- Week 6 BPP Tle 9Dokumen5 halamanWeek 6 BPP Tle 9Rochelle ValenciaBelum ada peringkat

- Puffy Snacks: Classification of The Puffed Snack Production LineDokumen3 halamanPuffy Snacks: Classification of The Puffed Snack Production LineTaiba HameedBelum ada peringkat

- Raw Materials: Mixing and Kneading The DoughDokumen8 halamanRaw Materials: Mixing and Kneading The DoughVeena PushparajBelum ada peringkat

- 8.ingredients Used in Cake, Principles Involved in Cake Preparation Different Types of Cake and DecorationDokumen52 halaman8.ingredients Used in Cake, Principles Involved in Cake Preparation Different Types of Cake and DecorationDivya DiyaBelum ada peringkat

- Dry Wall, Ceiling, and Painting WorksDokumen29 halamanDry Wall, Ceiling, and Painting WorksFrance Ivan Ais100% (1)

- OrderFlow Charts and Notes 19th Sept 17 - VtrenderDokumen9 halamanOrderFlow Charts and Notes 19th Sept 17 - VtrenderSinghRaviBelum ada peringkat

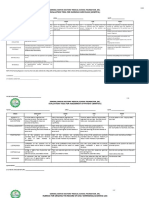

- PEDIA OPD RubricsDokumen11 halamanPEDIA OPD RubricsKylle AlimosaBelum ada peringkat

- Civil Engineering Interview QuestionsDokumen19 halamanCivil Engineering Interview QuestionsSrivardhanSrbBelum ada peringkat

- Design and Experimental Performance Assessment of An Outer Rotor PM Assisted SynRM For The Electric Bike PropulsionDokumen11 halamanDesign and Experimental Performance Assessment of An Outer Rotor PM Assisted SynRM For The Electric Bike PropulsionTejas PanchalBelum ada peringkat

- Green IguanaDokumen31 halamanGreen IguanaM 'Athieq Al-GhiffariBelum ada peringkat

- HelloDokumen31 halamanHelloShayne Dela DañosBelum ada peringkat

- Task Performance Valeros Roeul GDokumen6 halamanTask Performance Valeros Roeul GAnthony Gili100% (3)

- ZultaniteDokumen4 halamanZultaniteAcharya BalwantBelum ada peringkat

- T2T - One - U12 - Grammarworksheet - 1 Should For Advice PDFDokumen1 halamanT2T - One - U12 - Grammarworksheet - 1 Should For Advice PDFGrissellBelum ada peringkat

- Garden Club of Virginia RestorationsDokumen1 halamanGarden Club of Virginia RestorationsGarden Club of VirginiaBelum ada peringkat

- IsaiahDokumen7 halamanIsaiahJett Rovee Navarro100% (1)

- Why Nations Fail - SummaryDokumen3 halamanWhy Nations Fail - SummarysaraBelum ada peringkat

- The Structure of The Nazi Economy - Maxine Yaple SweezyDokumen273 halamanThe Structure of The Nazi Economy - Maxine Yaple Sweezygrljadus100% (2)

- 5.4 Marketing Arithmetic For Business AnalysisDokumen12 halaman5.4 Marketing Arithmetic For Business AnalysisashBelum ada peringkat

- United States Court of Appeals, Third CircuitDokumen8 halamanUnited States Court of Appeals, Third CircuitScribd Government DocsBelum ada peringkat

- 2-Emotional Abuse, Bullying and Forgiveness Among AdolescentsDokumen17 halaman2-Emotional Abuse, Bullying and Forgiveness Among AdolescentsClinical and Counselling Psychology ReviewBelum ada peringkat

- Determination of Physicochemical Pollutants in Wastewater and Some Food Crops Grown Along Kakuri Brewery Wastewater Channels, Kaduna State, NigeriaDokumen5 halamanDetermination of Physicochemical Pollutants in Wastewater and Some Food Crops Grown Along Kakuri Brewery Wastewater Channels, Kaduna State, NigeriamiguelBelum ada peringkat

- Referensi PUR - Urethane Surface coating-BlockedISO (Baxenden) - 20160802 PDFDokumen6 halamanReferensi PUR - Urethane Surface coating-BlockedISO (Baxenden) - 20160802 PDFFahmi Januar AnugrahBelum ada peringkat

- Alankit Assignments LTD.: Project Report ONDokumen84 halamanAlankit Assignments LTD.: Project Report ONmannuBelum ada peringkat

- James Ellroy PerfidiaDokumen4 halamanJames Ellroy PerfidiaMichelly Cristina SilvaBelum ada peringkat

- CA39BDokumen2 halamanCA39BWaheed Uddin Mohammed100% (2)

- How To Use The ActionDokumen3 halamanHow To Use The Actioncizgiaz cizgiBelum ada peringkat

- AFI 90-901 Operational Risk ManagementDokumen7 halamanAFI 90-901 Operational Risk ManagementJohan Lai100% (1)

- Kerjaya JuruterbangDokumen11 halamanKerjaya JuruterbangAqil NazriBelum ada peringkat

- Curriculum Vitae For Modern MutumwaDokumen4 halamanCurriculum Vitae For Modern MutumwaKudakwashe QuQu MaxineBelum ada peringkat

- Three Categories of AutismDokumen14 halamanThree Categories of Autismapi-327260204Belum ada peringkat

- University of Engineering & Management, Jaipur: (A) Production (B) Quality (C) Product Planning (D) All of The AboveDokumen4 halamanUniversity of Engineering & Management, Jaipur: (A) Production (B) Quality (C) Product Planning (D) All of The AboveSupriyo BiswasBelum ada peringkat

- Techniques of Demand ForecastingDokumen6 halamanTechniques of Demand Forecastingrealguy789Belum ada peringkat

- SPE-199498-MS Reuse of Produced Water in The Oil and Gas IndustryDokumen10 halamanSPE-199498-MS Reuse of Produced Water in The Oil and Gas Industry叶芊Belum ada peringkat

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterDari EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterPenilaian: 3.5 dari 5 bintang3.5/5 (487)

- Magnolia Table, Volume 3: A Collection of Recipes for GatheringDari EverandMagnolia Table, Volume 3: A Collection of Recipes for GatheringPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- The Obesity Code: Unlocking the Secrets of Weight LossDari EverandThe Obesity Code: Unlocking the Secrets of Weight LossPenilaian: 4 dari 5 bintang4/5 (6)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideDari EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsidePenilaian: 4 dari 5 bintang4/5 (6)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDari EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldPenilaian: 3.5 dari 5 bintang3.5/5 (5)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingDari EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingPenilaian: 4 dari 5 bintang4/5 (9)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyDari EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyPenilaian: 4 dari 5 bintang4/5 (1)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyDari EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyPenilaian: 4 dari 5 bintang4/5 (11)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomDari EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomPenilaian: 4 dari 5 bintang4/5 (1)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingDari EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingBelum ada peringkat

- Mexican Today: New and Rediscovered Recipes for Contemporary KitchensDari EverandMexican Today: New and Rediscovered Recipes for Contemporary KitchensPenilaian: 4 dari 5 bintang4/5 (6)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookDari EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthDari EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthPenilaian: 2 dari 5 bintang2/5 (1)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingDari EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingPenilaian: 4 dari 5 bintang4/5 (3)

- Authentic Mexican: Regional Cooking from the Heart of MexicoDari EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoBelum ada peringkat

- Grape, Olive, Pig: Deep Travels Through Spain's Food CultureDari EverandGrape, Olive, Pig: Deep Travels Through Spain's Food CulturePenilaian: 4.5 dari 5 bintang4.5/5 (15)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayDari EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayPenilaian: 4 dari 5 bintang4/5 (4)

- Glucose Goddess Method: A 4-Week Guide to Cutting Cravings, Getting Your Energy Back, and Feeling AmazingDari EverandGlucose Goddess Method: A 4-Week Guide to Cutting Cravings, Getting Your Energy Back, and Feeling AmazingPenilaian: 5 dari 5 bintang5/5 (61)

- Waiting: The True Confessions of a WaitressDari EverandWaiting: The True Confessions of a WaitressPenilaian: 3 dari 5 bintang3/5 (7)

- Keto Friendly Recipes: Easy Keto For Busy PeopleDari EverandKeto Friendly Recipes: Easy Keto For Busy PeoplePenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Poilâne: The Secrets of the World-Famous Bread BakeryDari EverandPoilâne: The Secrets of the World-Famous Bread BakeryBelum ada peringkat

- Trisha's Kitchen: Easy Comfort Food for Friends & FamilyDari EverandTrisha's Kitchen: Easy Comfort Food for Friends & FamilyPenilaian: 4 dari 5 bintang4/5 (5)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoDari EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoBelum ada peringkat