Activity-Based Risk Assessment Besmar

Diunggah oleh

dwi_6188Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Activity-Based Risk Assessment Besmar

Diunggah oleh

dwi_6188Hak Cipta:

Format Tersedia

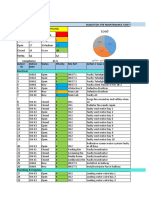

RISK ASSESSMENT FORM

ACTIVITY-BASED RISK ASSESSMENT INVENTORY OF WORK ACTIVITIES Company: Besmar Corporation Pte Ltd No. Process/Location 1. 2. 3. 4. 5. 6. 7. 7. Unloading of slave tiles and high pressure laminated panels Transfer of materials to working levels Preparation work Installation of Pedestals Laying of Slave Tiles Replace with High Pressure Laminated Panels Installation of Demountable Partition Installation of Sandwich Partition Work Activities Unloading of materials by Tower Crane/ Mobile Crane Unloading of materials by Fork Lift Transfer by Fork Lift Transfer by Pallet Jack Marking of position Using of Laser Guider for alignment Standby of materials Apply Glue on the floor Placing of Pedestals Cutting of Slave Tiles Placing of Slave Tiles Screw Slave Tiles at cut joints Remove of Slave Tiles Replace with High Pressure Laminated Panels Cutting of Steel Runner Installation of steel runner Installation of partition Installation of partition runner Installation of sandwich partition

ACTIVITY-BASED RISK ASSESSMENT FORM Low risk Medium risk High risk

INVENTORY OF WORK ACTIVITIES FORM

Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Construction Pte ltd Unloading of slave tiles and high pressure laminatdtiles Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard Collapse of tower crane Falling of materials Brake failure 1.2 Unloading By Mobile Crane Topple of crane Falling object while hoisting materials

Collision with cranes

Next Review Date: 2. Risk Evaluation 2b. Severity Major Major Major Major Major Major Major Major Major 3. Risk Control 2c. 2d. Risk Level Medium risk High risk High risk High risk High risk Medium risk Medium risk High risk Medium risk 3a. Additional Risk Control SWP for crane SWP for lifting SWP for lifting Equipment SWP for lifting SWP for lifting Permit to hoist Nil Engineering control Administrative control 3b. Action Officer, Designation (Follow-up date)

1a. No. 1.1

1b. Work Activity Unloading By Tower Crane

1d. Possible Accident / Ill Health & Persons-at-Risk Serious injury or death to workers Serious injury or death to workers Serious injury or death to workers Serious injury or death to workers and properties Serious injury or death to workers Serious injury or death to workers Serious injury or death to workers Serious injury or death to workers Asphyxiation, affects Central Nervous System, blood, and lungs

2a. Existing Risk Control (if any) LM certified Lifting team carrying out lifting activities 3 monthly maintenance LM certify Approve crane operator Lifting team Certify forklift operator Certify forklift operator Personal protective equipment (e.g. respirator etc. )

Likelihood Remote Occasional Remote Occasional Occasional Remote Remote Occasional Remote

1.3

Unloading By Forklift

Toppling of materials

Crush onto worker Inhalation of smoke ( CO2)

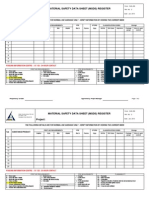

INVENTORY OF WORK ACTIVITIES FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Construction Pte ltd Transfer materials to working levels Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard High Noise Level Inhalation of carbon dioxide Toppling of materials

Crush onto worker

Next Review Date: 2. Risk Evaluation 2b. Severity Major Major Major Major Moderate Moderate Moderate 3. Risk Control 2c. 2d. Risk Level Medium risk Medium risk Medium risk High risk Medium risk Medium risk Medium risk 3a. Additional Risk Control Engineering Control using machineries Administrative control Nil Engineering control Engineering Control using machineries Administrative control Ensure proper housekeeping by respective trade supervisor Supervisor to keep an eye 3b. Action Officer, Designation (Follow-up date)

1a. No. 2.1

1b. Work Activity Transfer by forklift

1d. Possible Accident / Ill Health & Persons-at-Risk Noise induced deafness Asphyxiation, affects Central Nervous System, blood, and lungs Serious injury or death to workers Serious injury or death to workers Ergonomic Fracture of foot / toes crush Musculoskeletal and shock

2a. Existing Risk Control (if any) Personal protective equipment (e.g. ear plugs) Personal protective equipment (e.g. respirator etc. ) Certify forklift operator Certify forklift operator Nil Personal protective equipment (e.g. safety boots etc. ) Nil

Likelihood Remote Remote Remote Occasional Occasional Occasional Occasional

2.2

Transfer by Pallet Jack

Pull and Push heavy materials Roll over foot Slip and Fall

Crush onto worker

Serious injury

Nil

Major

Remote

Medium risk

RISK ASSESSMENT FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Corporation Pte Ltd Preparation Work Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard Frequent standing and squatting position Trip and fall 2. Risk Evaluation 2b. Severity Minor Moderate Next Review Date: 3. Risk Control 2c. 2d. Risk Level Low Medium risk Ensure proper housekeeping by respective trade supervisor Warning signs to be displayed Two to 1 piece Ensure proper housekeeping by respective trade supervisor 3a. Additional Risk Control 3b. Action Officer, Designation (Follow-up date)

1a. No. 3.1

1b. Work Activity Marking of position

1d. Possible Accident / Ill Health & Persons-at-Risk Ergonomic Musculoskeletal and shock Nil Nil

2a. Existing Risk Control (if any)

Likelihood Occasional Occasional

3.2 3.3

Using laser guider adjusting of level Standby of Slave tiles

for

Laser shoots at eyes Manual handling of slave tiles <15kg Trip and fall

Eyes irritation Ergonomic Musculoskeletal and shock

Personal protective equipment (e.g. eye wear) Nil Nil

Moderate Moderate Moderate

Remote Occasional Occasional

Low Medium risk Medium risk

Low risk

Medium risk

High risk

RISK ASSESSMENT FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Corporation Pte Ltd Installation of Pedestor Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard Contact with glue

Glue sniffing due to long hours handling glue

Next Review Date: 2. Risk Evaluation 2b. Severity Minor Moderate Major Moderate 3. Risk Control 2c. 2d. Risk Level Low Medium risk Medium risk Medium risk Do not expose to glue for long hours Barricade work area Ensure proper housekeeping by respective trade supervisor 3a. Additional Risk Control 3b. Action Officer, Designation (Follow-up date)

1a. No. 4.1

1b. Work Activity Apply glue to floor

1d. Possible Accident / Ill Health & Persons-at-Risk Irritation Inflammation to eyes and lung Blind the eyes Musculoskeletal and shock

2a. Existing Risk Control (if any)

Likelihood Occasional Occasional Remote Occasional

Personal protective equipment (e.g. hand gloves) Personal protective equipment (e.g. mask) Nil Nil

4.2

Placing of pedestor

Trip and fall onto pedestor Trip and fall

Low risk

Medium risk

High risk

RISK ASSESSMENT FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Corporation Pte Ltd Laying of Slave tiles Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard electrocution

Inhalation of cement dust

Next Review Date: 2. Risk Evaluation 2b. Severity Major Moderate Moderate Moderate Moderate Minor Moderate Major 3. Risk Control 2c. 2d. Risk Level Medium risk Medium risk Medium risk Medium risk Medium risk Low risk Medium risk Medium risk Rotating shift of workers SWP for Power Tools 3a. Additional Risk Control SWP for lifting equipment and operation Administrative control SWP for Power tools SWP for Power Tools Two to 1 piece 3b. Action Officer, Designation (Follow-up date)

1a. No. 5.1

1b. Work Activity Cutting of slave by electrical cutter

1d. Possible Accident / Ill Health & Persons-at-Risk Serious injury or death to workers Lung irritation Amputation Body injuries Ergonomic Injury to foot Noise induce hearing lost(NIHL), NID Electrocution

2a. Existing Risk Control (if any) Site supervisor and lifting supervisor supervision

Likelihood Remote Occasional Occasional Occasional Occasional Occasional Occasional Remote

Cutting of finger Breaking of cutting blade 5.2 Placing of slave tiles Manual handling of slave tiles <15kg Dropping of slave tiles Continuous noise generated Electrical hazard

Personal protective equipment (e.g. safety mask) Personal protective equipment (e.g. safety gloves etc. ) Personal protective equipment (e.g. safety helmet, gloves, etc.) Nil Nil Personal protective equipment (e.g. ear plug) Nil

5.3

Screw in slave tiles using electrical hand drill

Low risk

Medium risk

High risk

RISK ASSESSMENT FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Corporation Pte Ltd Replace with high pressure laminated tiles Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard Manual handling of slave tiles <15kg Dropping of slave tiles Manual handling of slave tiles <15kg Trip and fall 2. Risk Evaluation 2b. Severity Moderate Minor Moderate Moderate Next Review Date: 3. Risk Control 2c. 2d. Risk Level Medium risk Low risk Medium risk Medium risk 3a. Additional Risk Control Two to 1 piece Two to 1 piece Ensure proper housekeeping by respective trade supervisor 3b. Action Officer, Designation (Follow-up date)

1a. No. 6.1 6.2

1b. Work Activity Remove of slave tiles Replace with high pressure laminated tiles

1d. Possible Accident / Ill Health & Persons-at-Risk Ergonomic Injury to foot Ergonomic Musculoskeletal and shock Nil Nil Nil Nil

2a. Existing Risk Control (if any)

Likelihood Occasional Occasional Occasional Occasional

Dropping of slave tiles

Injury to foot

Nil

Minor

Occasional

Low risk

Low risk

Medium risk

High risk

INVENTORY OF WORK ACTIVITIES FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Corporation Pte Ltd Installation of Demountable partition Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard Using of electrical cutting machine Cutting of steel runner Fire sparks during cutting Flying particles during cutting 7.2 Installation of steel runner Using of electrical hand drill Cut by sharp edges of runner Trip and fall 2. Risk Evaluation 2b. Severity Major Moderate Major Moderate Moderate Moderate Moderate Next Review Date: 3. Risk Control 2c. 2d. Risk Level Medium risk Medium risk Medium risk Medium risk Low Medium risk Medium risk Blunt all sharp edges Ensure proper housekeeping by respective trade supervisor 3a. Additional Risk Control SWP for Power Tools SWP for Power Tools Emergency response procedure Administrative control 3b. Action Officer, Designation (Follow-up date)

1a. No. 7.1

1b. Work Activity Cutting of steel runner to length

1d. Possible Accident / Ill Health & Persons-at-Risk Electrocution Cut on finger Fire hazard Injury to eyes Twist of hand Cuts on body parts Musculoskeletal and shock Nil

2a. Existing Risk Control (if any)

Likelihood Remote Occasional Remote Occasional Remote Occasional Occasional

Protective guard Hot Work Permit Personal protective equipment (e.g. safety goggle etc. ) Nil Personal protective equipment (e.g. safety gloves etc. ) Nil Personal protective equipment (e.g. safety gloves etc. ) Nil

7.3

Installation of Partition

Using of electrical hand drill Collapse of partition Manual handling of heavy Partition

Twist of hand Injuries to body Ergonomic

Nil Personal protective equipment (e.g. safety gloves etc. ) Nil Nil

Moderate Moderate Moderate

Remote Occasional Occasional

Low Medium risk Medium risk Supervisor to supervise the work Two to 1 piece

INVENTORY OF WORK ACTIVITIES FORM

ACTIVITY-BASED RISK ASSESSMENT FORM Company: Process/ Location: Approved by: (Name, designation) (Date) Besmar Corporation Pte Ltd Installation of Demountable partition Conducted by: (Names, designations) (Date) Last Review Date: 1. Hazard Identification 1c. Hazard Cut by sharp edges of runner Trip and fall 2. Risk Evaluation 2b. Severity Moderate Moderate Next Review Date: 3. Risk Control 2c. 2d. Risk Level Medium risk Medium risk 3a. Additional Risk Control Blunt all sharp edges Ensure proper housekeeping by respective trade supervisor 3b. Action Officer, Designation (Follow-up date)

1a. No. 8.1

1b. Work Activity Installation of partition runner sandwich

1d. Possible Accident / Ill Health & Persons-at-Risk Cuts on body parts Musculoskeletal and shock

2a. Existing Risk Control (if any)

Likelihood Occasional Occasional

Nil Personal protective equipment (e.g. safety gloves etc. ) Nil

Using of electrical hand drill 8.2 Installation partition of sandwich Using of electrical hand drill Collapse of partition Workers falling from height Manual handling of heavy Partition

Twist of hand Twist of hand Injuries to body Serious injuries Ergonomic

Personal protective equipment (e.g. safety gloves etc. ) Personal protective equipment (e.g. safety gloves etc. ) Nil Personal protective equipment (e.g. safety gloves etc. ) Nil

Moderate Moderate Moderate Moderate Moderate

Remote Remote Occasional Occasional Occasional

Low Low Medium risk Medium risk Medium risk Supervisor to supervise the work SWP for working at height Two to 1 piece

Anda mungkin juga menyukai

- 10-TEC-BFM-F24 - Access Permit - R7 Dec 5 2020Dokumen1 halaman10-TEC-BFM-F24 - Access Permit - R7 Dec 5 2020Design Xess EventsBelum ada peringkat

- SOP 4 - Coal Bed Leveling in PGPDokumen18 halamanSOP 4 - Coal Bed Leveling in PGPfaraz ahmedBelum ada peringkat

- PPE Request Form (New)Dokumen1 halamanPPE Request Form (New)Syafrial AnasBelum ada peringkat

- Ho 89Dokumen1 halamanHo 89Shanmugam AnnamalaiBelum ada peringkat

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokumen3 halamanKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelBelum ada peringkat

- Stringing, Welding and Coating Process.Dokumen3 halamanStringing, Welding and Coating Process.Beyar. ShBelum ada peringkat

- HSE-RA-030 Bulk Excavation With Excavator - Rev 0Dokumen9 halamanHSE-RA-030 Bulk Excavation With Excavator - Rev 0عمروBelum ada peringkat

- 2.2 C New Safety Dashboard Nov2022Dokumen1 halaman2.2 C New Safety Dashboard Nov2022subodh kumarBelum ada peringkat

- PPE MatrixDokumen50 halamanPPE MatrixdigiarkanandBelum ada peringkat

- Comparison Auditor OHSAS 18001 IRCA SMK3Dokumen5 halamanComparison Auditor OHSAS 18001 IRCA SMK3Ricky ARIEF100% (1)

- Dr. Concrete Building Material: Safety Objectives and Targets ProcedureDokumen5 halamanDr. Concrete Building Material: Safety Objectives and Targets Proceduresudeesh kumarBelum ada peringkat

- Project EHS KPI - 24 Agustus 2013Dokumen1 halamanProject EHS KPI - 24 Agustus 2013Crystin Rotua Hasmi PanjaitanBelum ada peringkat

- Movile Plataform IncidentDokumen34 halamanMovile Plataform IncidentAnonymous GfPSYi4nBelum ada peringkat

- SOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Dokumen1 halamanSOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Amit BhadauriaBelum ada peringkat

- Permit To Work FormDokumen4 halamanPermit To Work FormMohammed Shams TabrezBelum ada peringkat

- HSE Engineer ProfileDokumen2 halamanHSE Engineer ProfileAbdellatef HossamBelum ada peringkat

- Monsoon Extreme Weather Plan p-06,07Dokumen6 halamanMonsoon Extreme Weather Plan p-06,07khurram shahzadBelum ada peringkat

- Packing ProcedureDokumen24 halamanPacking ProcedureAditya NugrahaBelum ada peringkat

- Updated 25-Apr-2023 HSE Observation Sheet and Action Tracker 9:39 AMDokumen3 halamanUpdated 25-Apr-2023 HSE Observation Sheet and Action Tracker 9:39 AMAnna EmelineBelum ada peringkat

- FILE-3.1.3-SCT-BAR-C2170-VOL-ID-SCC-HSEP14 - HSE Plan For Subcontractor - ERDokumen170 halamanFILE-3.1.3-SCT-BAR-C2170-VOL-ID-SCC-HSEP14 - HSE Plan For Subcontractor - ERHitesh KoolwalBelum ada peringkat

- DUDUTECH SITE MAINTENANCE TASKSDokumen4 halamanDUDUTECH SITE MAINTENANCE TASKSEmmanuelBelum ada peringkat

- SH-F43 - PTW Format - R02Dokumen2 halamanSH-F43 - PTW Format - R02vini100% (1)

- Hazard analysis and risk assessment for material handling and loading/unloadingDokumen2 halamanHazard analysis and risk assessment for material handling and loading/unloadingRais ZaynBelum ada peringkat

- Human Machine InterfaceDokumen10 halamanHuman Machine Interfacesushma29nBelum ada peringkat

- Contractor Work Permit: 1 ObjectiveDokumen11 halamanContractor Work Permit: 1 ObjectiveZeremia SamosirBelum ada peringkat

- (598295696) 08.0 Article 3.0 Section D - HSE (27012015)Dokumen17 halaman(598295696) 08.0 Article 3.0 Section D - HSE (27012015)NabilahBelum ada peringkat

- Material Safety Data Sheet (MSDS) Register ProjectDokumen2 halamanMaterial Safety Data Sheet (MSDS) Register ProjectTina CoBelum ada peringkat

- Templates Package 1 ContentDokumen1 halamanTemplates Package 1 ContentM IqbalBelum ada peringkat

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDokumen6 halamanHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineBelum ada peringkat

- RAMS Review for Telehandler WorksDokumen30 halamanRAMS Review for Telehandler WorksArturBelum ada peringkat

- Dust and EmissionsDokumen112 halamanDust and Emissions0808276kBelum ada peringkat

- Effective Safety Management Systems: by George RobothamDokumen33 halamanEffective Safety Management Systems: by George RobothamLoganathan DharmarBelum ada peringkat

- CC 27 EhspDokumen88 halamanCC 27 EhspABHISHEK BHARTIBelum ada peringkat

- JSa For Glass FixingDokumen17 halamanJSa For Glass FixingShekh BabulBelum ada peringkat

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDokumen168 halamanAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathBelum ada peringkat

- Swms Pile Test RKDokumen13 halamanSwms Pile Test RKrakeshkhanna78Belum ada peringkat

- TFU-Risk Assessment RA-04 - Noise PollutionDokumen1 halamanTFU-Risk Assessment RA-04 - Noise Pollutionarshin wildanBelum ada peringkat

- Warehouse Risk Assessment Aldir II IWPPDokumen25 halamanWarehouse Risk Assessment Aldir II IWPPMadhu MohanBelum ada peringkat

- Cover Page - Q09 NEWDokumen1 halamanCover Page - Q09 NEWpundir_vineetBelum ada peringkat

- Health and Safety Induction ChecklistDokumen2 halamanHealth and Safety Induction ChecklistYathawan Nair ThamutharamBelum ada peringkat

- JSA Installation of Platform and Guard Rails On Crawler CraneDokumen5 halamanJSA Installation of Platform and Guard Rails On Crawler CraneDann TanBelum ada peringkat

- COSHH Assessment TemplateDokumen2 halamanCOSHH Assessment TemplaterichardBelum ada peringkat

- EHS 2-F8 PTW LiftingDokumen2 halamanEHS 2-F8 PTW LiftingLee Xiao YuBelum ada peringkat

- Water blasting SWMSDokumen5 halamanWater blasting SWMSjohney2Belum ada peringkat

- Basic Elements of A Successful Safety and Health Program: Frank Dobson, CHSTDokumen46 halamanBasic Elements of A Successful Safety and Health Program: Frank Dobson, CHSTRoslanBelum ada peringkat

- Basra Multipurpose Terminal Construction Method StatementDokumen26 halamanBasra Multipurpose Terminal Construction Method StatementMahmoud FakhereddinBelum ada peringkat

- SWP Working Safely at Height Version 2.01Dokumen7 halamanSWP Working Safely at Height Version 2.01marvinBelum ada peringkat

- RA Excavation For Trial TrenchDokumen9 halamanRA Excavation For Trial TrenchSasi KumarBelum ada peringkat

- Ind Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)Dokumen14 halamanInd Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)tarique1189040Belum ada peringkat

- NEW CL - JLA Steel Hand Tool - SWPDokumen3 halamanNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Safety Program Audit 1684314377Dokumen24 halamanSafety Program Audit 1684314377Annisa AgustinaBelum ada peringkat

- 3.3.7 Hazdarous Waste LogDokumen2 halaman3.3.7 Hazdarous Waste LogSubzone ThreeBelum ada peringkat

- Safety and Health PolicyDokumen10 halamanSafety and Health Policynurul lovelymineBelum ada peringkat

- WEEKLY EHS REPORTDokumen15 halamanWEEKLY EHS REPORTBryt PaintsilBelum ada peringkat

- Elephant Project - Sayakha GujaratDokumen8 halamanElephant Project - Sayakha Gujaratalla malikBelum ada peringkat

- Contractor's Work Permit Latest 2020Dokumen2 halamanContractor's Work Permit Latest 2020Zoey ChongBelum ada peringkat

- 09-2020 Health Performance IndexDokumen4 halaman09-2020 Health Performance IndexBabay JamBelum ada peringkat

- Acf-Mra-067 - UcDokumen1 halamanAcf-Mra-067 - UcFateh AliyaBelum ada peringkat

- Ineco Hse Manual-SignedDokumen27 halamanIneco Hse Manual-SignedTantely RazafimahatratraBelum ada peringkat

- Educ 61 Module 5 ActivityDokumen4 halamanEduc 61 Module 5 ActivityMitchille GetizoBelum ada peringkat

- George B Dantzig PDFDokumen19 halamanGeorge B Dantzig PDFKeith BoltonBelum ada peringkat

- Unit 1 Question AnswerDokumen5 halamanUnit 1 Question AnswerSubhankar BiswalBelum ada peringkat

- Biocompatibility and HabitabilityDokumen143 halamanBiocompatibility and HabitabilitySvetozarKatuscakBelum ada peringkat

- Jurnal Metode Pelaksanaan Top Down B.ing PDFDokumen7 halamanJurnal Metode Pelaksanaan Top Down B.ing PDFBayu SamiajiBelum ada peringkat

- Corporate Presentation Codex International Fev 2022Dokumen9 halamanCorporate Presentation Codex International Fev 2022Stephane SeguierBelum ada peringkat

- Trip WireDokumen19 halamanTrip Wirepinky065558100% (2)

- Universal Chargers and GaugesDokumen2 halamanUniversal Chargers and GaugesFaizal JamalBelum ada peringkat

- Coal Gasification, Liquid Fuel Conversion (CTL), and CogenerationDokumen66 halamanCoal Gasification, Liquid Fuel Conversion (CTL), and CogenerationVăn Đại - BKHNBelum ada peringkat

- Laboratory Activity No. 01 - Properties of LiquidDokumen2 halamanLaboratory Activity No. 01 - Properties of LiquidCzarina Relleve0% (1)

- Paper 2Dokumen17 halamanPaper 2Khushil100% (1)

- Fc6a Plus (MQTT)Dokumen44 halamanFc6a Plus (MQTT)black boxBelum ada peringkat

- Alpha 10 Mini Manual Rev1Dokumen2 halamanAlpha 10 Mini Manual Rev1k4gw100% (1)

- The Importance of Understanding A CommunityDokumen23 halamanThe Importance of Understanding A Communityra sBelum ada peringkat

- WINTER 2021 SYLLABUS All Lab Classes - Docx-2Dokumen7 halamanWINTER 2021 SYLLABUS All Lab Classes - Docx-2Sushi M.SBelum ada peringkat

- #C C C$ C%C& C' C (CDokumen4 halaman#C C C$ C%C& C' C (CThong Chee WheiBelum ada peringkat

- Organizational Change & Development - VIL2021 - 22Dokumen3 halamanOrganizational Change & Development - VIL2021 - 22Rahul TRIPATHIBelum ada peringkat

- Install Steinitz Fractal Breakout Indicator MT4 (39Dokumen10 halamanInstall Steinitz Fractal Breakout Indicator MT4 (39florin_denys-1Belum ada peringkat

- 3.dummy VariablesDokumen25 halaman3.dummy VariablesUnushka ShresthaBelum ada peringkat

- Fire Risk Assessment FormDokumen16 halamanFire Risk Assessment Formmukamat safiiBelum ada peringkat

- BMED148 Assessment 1Dokumen5 halamanBMED148 Assessment 1ROMEL ALJUN TARROBALBelum ada peringkat

- Nordson EFD Ultimus I II Operating ManualDokumen32 halamanNordson EFD Ultimus I II Operating ManualFernando KrauchukBelum ada peringkat

- NFA To DFA Conversion: Rabin and Scott (1959)Dokumen14 halamanNFA To DFA Conversion: Rabin and Scott (1959)Rahul SinghBelum ada peringkat

- Big Data Analytics and Artificial Intelligence inDokumen10 halamanBig Data Analytics and Artificial Intelligence inMbaye Babacar MBODJBelum ada peringkat

- Calicut University: B. A PhilosophyDokumen6 halamanCalicut University: B. A PhilosophyEjaz KazmiBelum ada peringkat

- CH 07Dokumen40 halamanCH 07Ambreen31Belum ada peringkat

- Discrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebraDokumen6 halamanDiscrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebralakkajaoBelum ada peringkat

- Examining Oral Communication FunctionsDokumen5 halamanExamining Oral Communication FunctionsJoshua Lander Soquita CadayonaBelum ada peringkat

- Myers Et Al - Clear and Present ThinkingDokumen214 halamanMyers Et Al - Clear and Present ThinkingAEBelum ada peringkat

- Mohit Chakrabarti - Value Education - Changing PerspectivesDokumen79 halamanMohit Chakrabarti - Value Education - Changing PerspectivesDsakthyvikky100% (1)